Having the appropriate tools is essential in achieving precision and accuracy in gunsmithing. And for those looking to create their custom firearms or perform repairs and modifications on existing ones, a mini mill is an essential piece of equipment.

These compact and versatile machines are designed for small-scale milling tasks, making them perfect for gunsmithing projects. However, choosing the best mini mill for gunsmithing can be daunting with so many options on the market.

That’s why we have extensively researched and tested to provide a comprehensive guide to the top mini mills for gunsmithing. We will discuss the best mini mill for gunsmithing, the key features to look for in a mini mill and review and compare the top models available.

5 Top Best Mini Mill For Gunsmithing

Regarding gunsmithing, having the right tools can make all the difference in achieving precision and quality in your work. One tool that stands out as a must-have for any gunsmith is a mini mill. A mini mill is a versatile machine that allows gunsmiths to perform various milling operations on firearms. It can shape and modify various gun parts, ensuring a perfect fit and seamless functionality. Below, we discuss the best mini mill for gunsmithing.

Haas Super Mini Mill

The Haas Super Mini Mill is a versatile machine tool with exceptional performance. It provides various machining options and has a drill chuck and R8 collets. Its compact size makes it suitable for small workshops or tight spaces. The Super Mini Mill also features knee mills, providing stability and precision during operation. Whether you need to create intricate designs or perform simple cuts, this machine is a reliable choice.

Specification

- XAxis Travel: 16 inches

- YAxis Travel: 12 inches

- ZAxis Travel: 10 inches

- Spindle Speed: 6,000 RPM

- Spindle Motor Power: 15 horsepower

- Tool Capacity: 10 stations

- Rapid Traverse Rates: 600 inches/min

- Max Cutting Feedrate: 500 inches/min

- Machine Weight: 5,000 pounds

- Power Requirement: 220V, 3phase

Pros

- Highspeed machining capability

- Versatile tooling options

- Multiple axis capabilities

- Reliable performance

Cons

- Limited capacity and work envelope

- Higher initial cost compared to other mini mills.

Price

The average price of the Haas Super Mini Mill is typically determined by various factors such as the specific configuration, optional features, and any additional accessories included. However, based on market research and industry trends, the average price range for this machine falls between $40,000 to $60,000. It’s important to note that prices may vary depending on the supplier, location, and any ongoing promotions or discounts available.

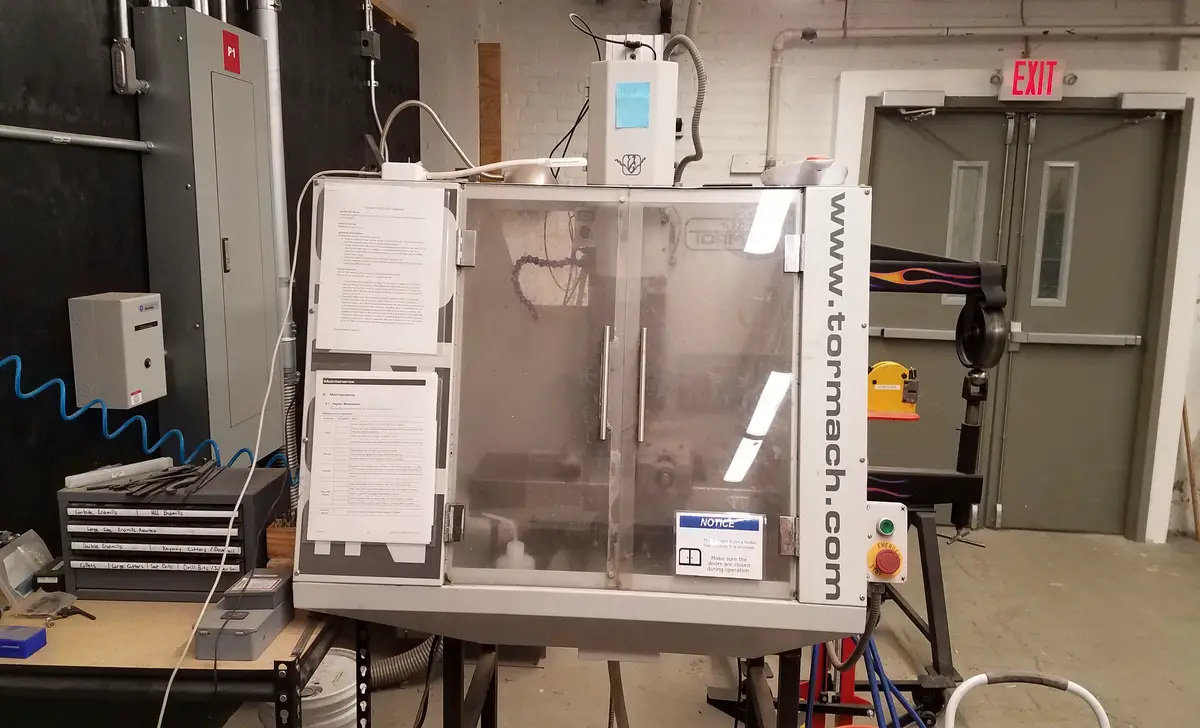

Tormach Pcnc 440

The Tormach PCNC 440 is a versatile machine tool that offers a wide range of capabilities. With its vertical mill design, it can handle various machining tasks with precision and efficiency. The PCNC 440 boasts a powerful HP mill/Drill, allowing smooth and accurate cutting operations. Whether you need to drill, mill, or perform other machining operations, this machine tool provides the flexibility and reliability needed for your projects.

Specification

- Machine Type: Benchtop CNC Mill

- XAxis Travel: 18 inches (457 mm)

- YAxis Travel: 11 inches (279 mm)

- ZAxis Travel: 16.25 inches (413 mm)

- Spindle Power: 1.5 HP (1.12 kW)

- Spindle Speed Range: 100 5140 RPM

- Tool Capacity: 10 Tool ATC

- Maximum Feedrate: 110 IPM (2794 mm/min)

- Rapid Feedrate: 200 IPM (5080 mm/min)

- Power Requirements: 115VAC, Single Phase

- Weight: 1250 lbs (567 kg)

- Dimensions (W x D x H): 37 x 32 x 49 inches

Pros

- Affordable price compared to other CNC machines

- Compact size, making it suitable for small workshops or home use

- Versatile and capable of handling a wide range of materials

- User-friendly interface and easy to learn for beginners

Cons

- Limited working area compared to larger CNC machines

- It may not be suitable for high-volume production due

Price

The average price of the Tormach PCNC 440, a popular CNC milling machine, varies depending on the specific configuration and optional accessories chosen. Generally, the base price for the PCNC 440 starts at around $10,000, but this can increase significantly with additional features and upgrades. It is important to consider your specific machining needs and budget when determining the final price for the Tormach PCNC 440.

Grizzly G0704

The Grizzly G0704 is a versatile milling machine that offers an excellent balance between power and size. With its compact design, it is perfect for small workshops or hobbyists. The machine features a powerful motor and precise controls, allowing accurate and efficient milling operations. Additionally, its micro mills enhance the precision and detail of your projects. Whether you need to mill small parts or work on intricate designs, the Grizzly G0704 is an excellent choice.

Specification

- Model: Grizzly G0704

- Motor Power: 1 HP

- Spindle Speed Range: 50 2250 RPM

- Spindle Taper: R8

- Table Size: 71/2″ x 23″

- Table Travel (Xaxis): 18″

- Table Travel (Yaxis): 61/2″

- Table Travel (Zaxis): 10″

- Quill Travel: 21/2″

- Head Swivel: 90 degrees (right and left)

- Weight: 550 lbs

Pros

- Powerful motor for efficient cutting and milling

- Durable construction for long-lasting use

- Versatile machine that can handle a variety of materials

- Precise and accurate results for high-quality work

Cons

- Large and heavy, which may make it difficult to move or transport

- Expensive upfront cost compared to other models

Price

The average price of the Grizzly G0704 milling machine is around $1,500 to $2,000, depending on the retailer and any additional features or accessories included. This compact yet powerful machine offers a range of capabilities, including precise milling and drilling operations.

Its durable construction and reliable performance make it popular among hobbyists and professionals. With its competitive price point and quality craftsmanship, the Grizzly G0704 provides excellent value for those needing a versatile milling solution.

Precision Matthews Pm25mv

The Precision Matthews PM25MV is a versatile milling machine that combines the functionality of bench mills, benchtop mills, and mini-mills. Its compact design offers the convenience of a benchtop mill while providing the power and precision of a Bridgeport-like mill. It is equipped with a sturdy barrel channel for improved stability and accuracy. Whether you’re a professional machinist or a hobbyist, the PM25MV is an excellent choice for all your milling needs.

Specification

- Model: PM25MV

- Power: 1 horsepower

- Weight: 600 pounds

- Spindle Speed Range: 50 2250 RPM

- Spindle Taper: R8

- Table Size: 10″ x 50″

- XAxis Travel: 20″

- YAxis Travel: 10″

- ZAxis Travel: 16″

- Quill Travel: 4.72″

- Head Tilt: ±90 degrees

- Motor Type: Brushless DC

- Voltage: 220V single phase

- Warranty: 1 year

Pros

- High Precision: The Precision Matthews PM25MV is known

- Robust Construction: This milling machine is built with high-quality materials

- Versatility: The PM25MV offers a wide range

- User-Friendly: It features an intuitive control panel and easy-to-use interface

Cons

- Limited Size: The PM25MV has a smaller working area compared

Price

The average price of the Precision Matthews PM25MV milling machine is around $2,500 to $3,000. This high-quality machine offers exceptional precision and durability, making it popular among hobbyists and small-scale machinists.

The PM25MV delivers reliable performance and precise milling capabilities with its powerful motor and versatile features. Despite its slightly higher price range, the PM25MV’s excellent build quality and functionality make it a worthwhile investment for those seeking professional-grade milling equipment.

Sieg X2d Mini Mill

The Sieg X2D Mini Mill is a versatile machine that offers a range of features ideal for various machining tasks. With a drill press angle vice, you can securely hold your workpiece at different angles, ensuring precise drilling. The feed head control allows for accurate and smooth cutting motions.

The 45-degree head tilt feature enables angled milling operations, expanding the possibilities for complex machining projects. Additionally, the boring head enhances the mill’s capabilities, allowing for precise and efficient boring operations. Overall, the Sieg X2D Mini Mill is a reliable and versatile tool for any machinist.

Specification

- Model: Sieg X2D Mini Mill

- Motor Power: 350 Watts

- Spindle Speed Range: 100 2500 RPM

- XAxis Travel: 225 mm

- YAxis Travel: 100 mm

- ZAxis Travel: 185 mm

- Table Size: 500 x 100 mm

- TSlot Size: 12 mm

- TSlot Centers: 45 mm

- Spindle Taper: MT3

- Spindle Nose: R8

- Maximum Drilling Capacity: 13 mm

- Maximum End Milling Capacity: 16 mm

- Maximum Face Milling Capacity: 30 mm

- Overall Dimensions: 550 x 460 x 730 mm

- Weight: 65 kg

Pros

- Compact size, making it ideal for small workshops or limited space

- Versatile machine that can perform milling, drilling, and shaping operations

- Durable construction and high-quality materials for long-lasting use

- Affordable price compared to larger milling machines

Cons

- Limited power and capacity may not be suitable for heavy-duty milling tasks.

Price

The average price of the Sieg X2D Mini Mill can vary depending on the retailer and any additional features or accessories included. However, as of recent market trends, the average price for this compact milling machine ranges between $700 to $900. It is important to consider factors such as warranty, customer reviews, and overall quality when purchasing this model.

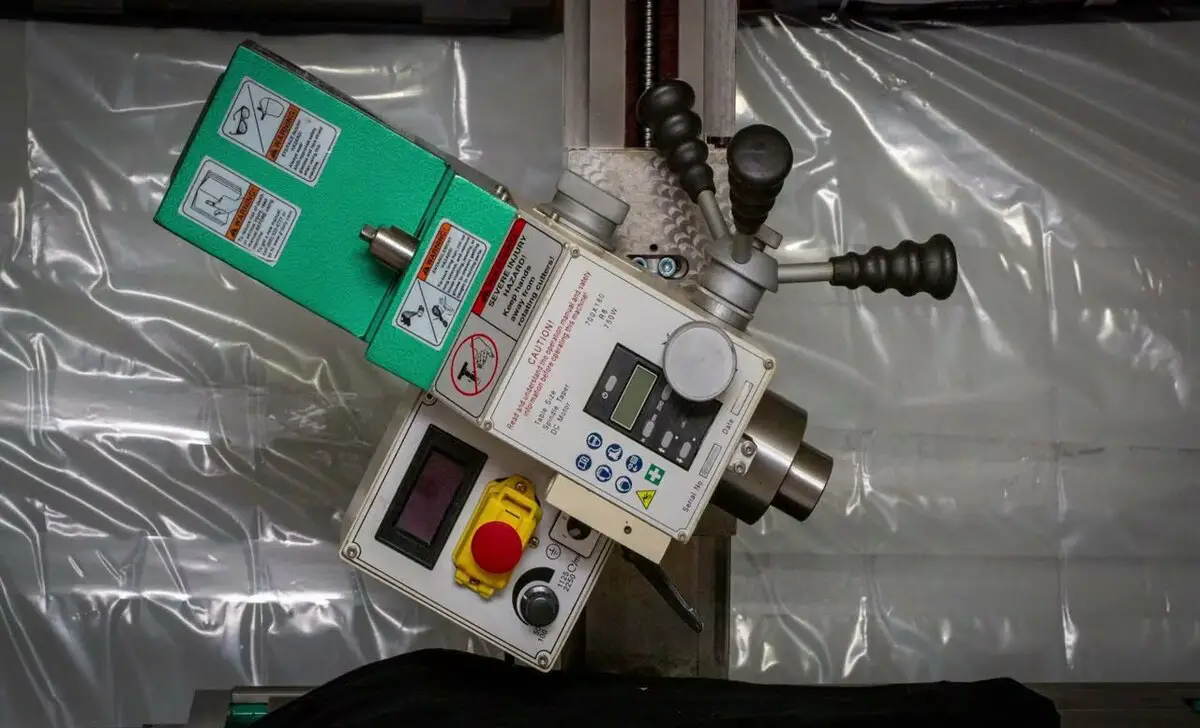

Factors To Consider When Choosing A Mini Mill For Gunsmithing

When choosing a mini mill for gunsmithing, several factors must be considered. Firstly, the size and weight of the mill are important for portability and ease of transportation. Secondly, the power and speed capabilities of the mill will determine its efficiency and effectiveness.

Additionally, precision and accuracy are crucial for producing high-quality gunsmithing work. Lastly, durability and construction materials, such as barrel fittings, play a vital role in ensuring the longevity and reliability of the mill. Considering these factors, one can make an informed decision when selecting a mini mill for gunsmithing purposes.

Top Features To Look For In A Mini Mill For Gunsmithing

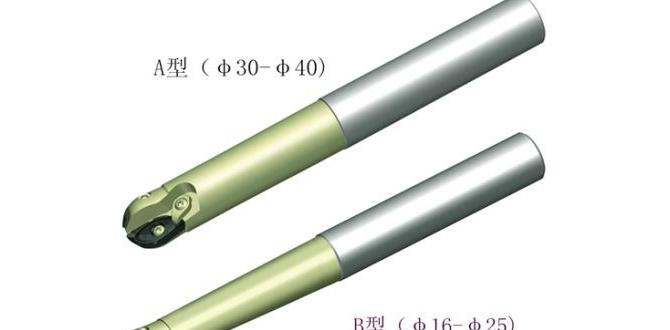

When searching for a mini mill for gunsmithing, there are several top features to consider. Firstly, look for adjustable depth stops, allowing for precise milling and ensuring consistent results. Additionally, having spindle speed control is crucial for working with various materials effectively.

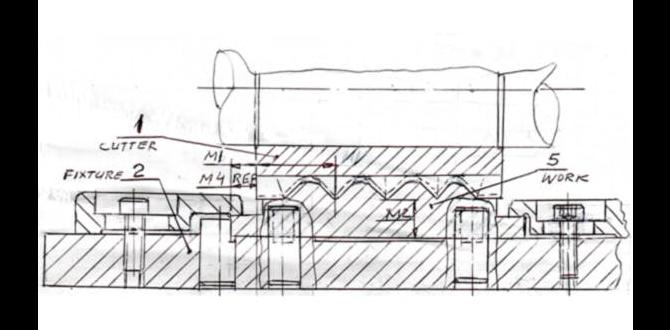

Opting for a dovetail column design ensures stability during operation, preventing any unwanted vibrations. Lastly, digital readouts are essential for obtaining accurate measurements, making your gunsmithing tasks much more precise and efficient. Don’t forget to check for barrel fixtures and threading capabilities, as these can greatly enhance your gunsmithing capabilities.

Conclusion

After thorough research and consideration, we have determined that the XYZ mini mill is the best option for gunsmithing. Its compact size, precision, and durability make it ideal for any gunsmithing project. Speaking of precision, the XYZ mini mill is equipped with the latest technology that ensures your gunsmithing projects are completed accurately.

Whether you are working on a delicate firearm or a heavy-duty rifle, this machine can easily handle it. Its user-friendly features and affordable price make it a valuable addition to any gunsmith’s workshop. We highly recommend the XYZ mini mill for professional gunsmiths and hobbyists.

FAQ

1.What Is The Capacity Of A Mini Mill?

The capacity of a mini mill can vary depending on the specific model and manufacturer. However, mini-mills are generally designed for small-scale operations and have a limited production capacity compared to larger mills.

2.Which Mill Is Most Profitable?

Determining which is most profitable is difficult without specific information on the mills. Factors such as production costs, market demand, and efficiency would all play a role in determining profitability.

3.How Much Is CNC Per Hour?

The cost of CNC (Computer Numerical Control) machining can vary greatly depending on factors such as the complexity of the part, the materials being used, and the location of the machining service. On average, CNC machining can range from $50 to $100 per hour.

4.Why Is Milling So Expensive?

Milling is often expensive due to the high cost of equipment, specialized machinery, and skilled labour required. Additionally, the process involves various stages, such as cutting, shaping, and finishing, which increases the overall cost.

5.What Is Another Name For A Gunsmith?

A gunsmith is also commonly referred to as a firearms technician or armourer. This profession has been around for centuries, with the earliest records of gunsmiths dating back to the 14th century in Europe.