Comparing Mini Mill Vs Knee Mill: Key Differences Unveiled

Mini Mill vs Knee Mill

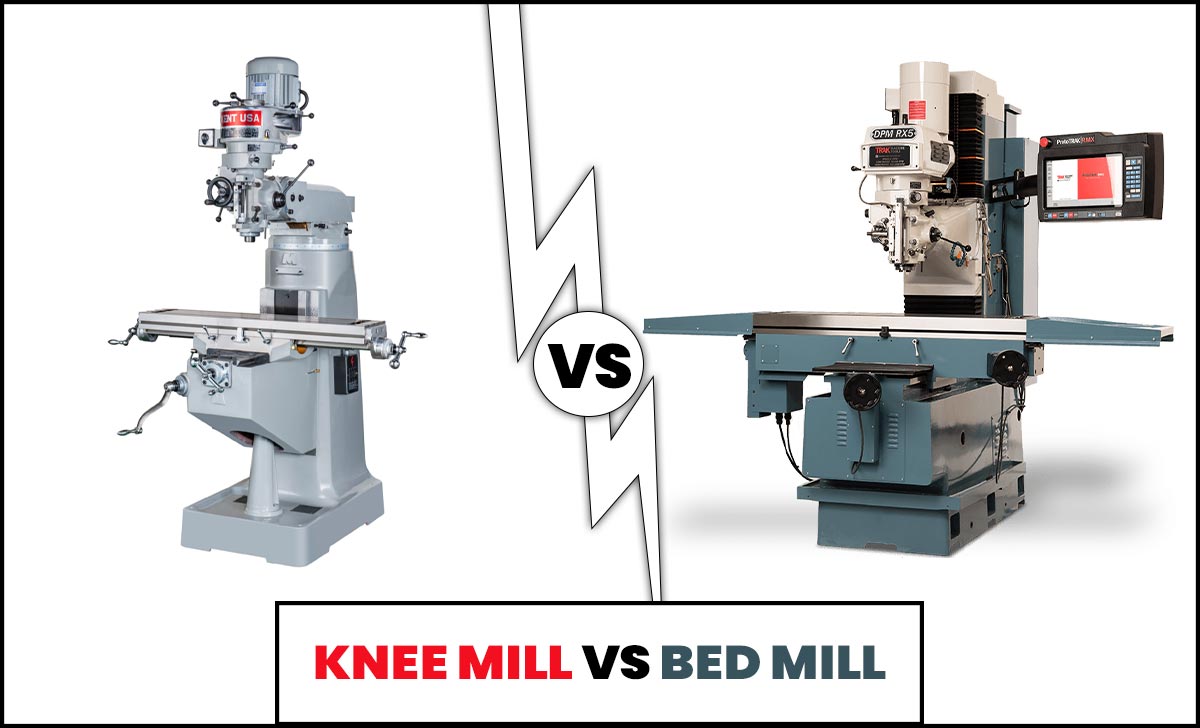

Have you ever wondered what makes mini mills and knee mills different? Picture a mini mill as the perfect tool for small projects. It fits easily in tiny spaces and handles light metalwork. Now, imagine a knee mill. It’s a hefty machine, ideal for big jobs and heavy materials. Curious about how they work? Mini mills are great for beginners, while knee mills suit skilled craftsmen. Which one fits your needs?Design and Construction

Structural differences. Material quality and durability.Mini mills are compact and lightweight. They take up less space, which is excellent for small workshops. Knee mills are larger and sturdier. They have a vertical movement that mini mills don’t. This makes them suitable for heavy tasks and bigger projects.

- Mini Mills: Handy and space-saving.

- Knee Mills: Perfect for heavy-duty work.

Material quality plays a role too. Mini mills have simpler constructions. This can make them less strong. Knee mills use stronger materials. They last longer and can handle more wear and tear.

What are the main differences?

Mini mills fit smaller spaces. They are ideal for tiny workshops or garages. Knee mills are better for durable setups. They don’t wear out quickly.Size and Portability

Compactness of mini mills. Space requirements for knee mills.Imagine a little buddy and a burly giant. Mini mills are like hobbits—small but mighty. They fit in tight spots and still churn out great work! A mini mill can be tucked away in a corner, saving space for dance parties or pet parades. But the knee mill? It’s like a sumo wrestler in the room. They need more elbow room to stretch out and work properly. If space is a big deal, your choice might clear up as fast as a sneeze in a dust storm!

| Type | Space Needed |

|---|---|

| Mini Mill | Compact |

| Knee Mill | Spacious |

Precision and Accuracy

Comparing tolerances. Suitability for different applications.When it comes to making precise and accurate cuts, both a mini mill and a knee mill have their strengths. A mini mill is often preferred for smaller, intricate jobs, given its tighter tolerances. In contrast, a knee mill shines in heavy-duty applications, where strength and durability are paramount. Many experts say, “the right machine saves both time and headaches!” Here’s a quick comparison:

| Feature | Mini Mill | Knee Mill |

|---|---|---|

| Tolerances | Very tight | Moderate |

| Best For | Small, precise jobs | Heavy-duty tasks |

In essence, choosing between them depends on the task at hand. Want to make a detailed toy car? Mini mill. Need to carve a metal statue? Knee mill. Remember, choose wisely, or you’ll end up with more than just wood shavings in your hair!

Power and Performance

Spindle speed and horsepower. Capability for handling various materials.Ever wondered how a mini mill and a knee mill power up? Well, it’s a bit like comparing a scooter to a monster truck for their engines. The mini mill can fly with high spindle speeds, great for delicate tasks. However, don’t expect it to beat a knee mill’s horsepower strength. Knee mills handle heavy work with robust grace, like a knight in shining armor. These mighty machines march through various materials without fear. Check out how they stack up in this quick glance table:

| Feature | Mini Mill | Knee Mill |

|---|---|---|

| Spindle Speed | High | Moderate |

| Horsepower | Lower | Higher |

| Material Handling | Limited | Versatile |

Mini mills are ninjas with finesse, while knee mills are muscle-bound heroes, each unique in their craft.

Ease of Use and Setup

Setup complexity for mini mills and knee mills. Userfriendly features.Setting up a mill can feel like putting together a giant robot, but don’t worry! Mini mills are like toaster ovens; they’re easy to use. Just plug them in and you’re good to go! They have simple controls that make you feel like a machining wizard. Knee mills, however, are a bit more like setting up a washing machine. They need a bit more muscle and patience. But both get the job done beautifully.

Here’s a quick look:

| Mill Type | Setup Complexity |

|---|---|

| Mini Mill | Easy |

| Knee Mill | Moderate |

Features make the difference too. Mini mills often come with digital readouts, so you can pretend you’re playing a video game. Knee mills have knobs and levers, which makes you feel like an inventor. Out of the box, mini mills are user-friendly, while knee mills might need a little extra elbow grease, but they’re both perfect teammates once set up!

Cost Considerations

Price range comparison. Longterm investment value.Cost Considerations

When comparing a mini mill to a knee mill, prices vary. Mini mills range from $500 to $3,000. Knee mills often cost $5,000 to $20,000. A mini mill is cheaper but may have limits in its size and power. In long-term investments, a knee mill might be better for bigger projects due to its strength and features. A mini mill is a good starter choice. Remember, the right machine depends on what you need.

Which one offers better value for the future?

Knee mills offer better value for long-term projects. They are robust and can handle larger tasks. Mini mills are more suited for small, simpler tasks. If planning varied work, a knee mill is smart. They’ll do more and last longer. Choose well to match your needs and budget.

Maintenance and Upkeep

Routine maintenance requirements. Longevity and reliability.Maintaining both mini mills and knee mills keeps them in top shape. Mini mills are like low-maintenance pets—they need regular oiling and cleaning but won’t harp your time. On the other hand, knee mills, much like grumpy old cats, demand more attention. Their many moving parts require regular care to ensure longevity and reliability.

Here’s a handy comparison of care chores:

| Mini Mill | Knee Mill |

|---|---|

| Monthly lubrication | Weekly lubrication |

| Occasional cleaning | Frequent cleaning |

If Cinderella had two machines, the mini mill would let her head to the ball sooner. A common question is which lasts longer? Well, if nurtured like the prime of a fairy tale, both can be your best friends for years!

Applications and Suitability

Ideal projects for mini mills. Best uses for knee mills.Applications and Suitability

Choosing between a mini mill and a knee mill? Here’s how to decide. Mini mills work best for small projects. They are great for hobbies and model-making. Knee mills suit larger, precise tasks. They are the go-to for professionals who need high quality. Understanding these roles helps make smart choices.

What are the ideal projects for mini mills?

Mini mills excel at detailed work. They handle delicate tasks like making jewelry or custom parts. Their small size makes them portable. This is perfect for workspaces with limited space. They run quietly, so they won’t disturb surroundings.Top uses for mini mills:

- Jewelry making

- Prototyping small parts

- Model building

What are the best uses for knee mills?

Knee mills shine in versatility. Engineers and craftsmen favor them for heavy-duty work. They are ideal for intricate tasks requiring extreme precision. These machines are sturdy, offering dependable performance over time. Some experts say, “For accurate milling, knee mills never fail.”Notable tasks for knee mills:

- Milling large metal parts

- Complex shaping

- High-precision woodworking

In summary, mini mills and knee mills cater to specific needs. Knowing what each can do helps in choosing the right tool for your project. As they say, “Choose the right tool for the job, and half the work is done.” Great tools make great projects!

User Feedback and Reviews

Common user experiences. Advantages and disadvantages reported by users.Some users say picking between a mini mill and a knee mill is like choosing between a chihuahua and a great dane. Many people appreciate the mini mill’s compact size and affordability, noting how it’s perfect for small projects and tight spaces. However, they often mention it shakes like a leaf during heavy cutting.

Meanwhile, the knee mill is praised for its sturdiness and larger work capacity. It’s like the trusty workhorse you can count on for larger jobs. But users also notice it’s no compact cat; it demands more room and cash upfront. A user humorously mentioned, “If the tool were a car, the knee mill might need its own garage!”

| Feature | Mini Mill | Knee Mill |

|---|---|---|

| Size | Compact | Large |

| Portability | Easy to move | Stationary |

| Cost | Lower | Higher |

| Capacity | Limited | Extensive |

Both machines have their fans, and the choice often boils down to needs and budget. One thing is clear, both kinds bring something unique to the workshop!

Choosing the Right Mill for Your Needs

Factors to consider for different user profiles. Decisionmaking tips and guidelines.Finding the right mill can feel like picking ice cream flavors. Do you want a mini mill that’s small and sweet, or a knee mill that’s robust and reliable? Your choice depends on what you need. If you are a hobbyist, a mini mill might be your best friend. For larger projects, think about a knee mill. Consider these factors:

| User Profile | Best Mill Choice | Why? |

|---|---|---|

| Hobbyist | Mini Mill | Compact and versatile! |

| Professional | Knee Mill | Sturdier for heavy-duty work! |

Before making a decision, think about space, budget, and the projects you want to tackle. If your workspace resembles a tiny closet, the mini mill might fit better. Remember, the right choice makes your machining dreams a reality!

Conclusion

A mini mill is compact and great for simple projects. A knee mill is versatile and handles bigger tasks. Choose based on your project size and complexity. You can start small with a mini mill. If you’re curious, explore more online to decide what suits your needs best. Keep learning to make informed decisions.FAQs

What Are The Primary Differences In Design And Functionality Between Mini Mills And Knee Mills?Mini mills are smaller and lighter than knee mills. They are perfect for small projects and home use. Knee mills have a larger size and can handle bigger pieces of metal. You can adjust the knee on a knee mill for different heights, while mini mills don’t have this feature. This makes knee mills better for more complicated jobs.

In What Scenarios Would A Mini Mill Be More Beneficial Than A Knee Mill For Hobbyists Or Small-Scale Producers?A mini mill is better when you need to work in smaller spaces. It’s lighter and easier to move around. You can also use it for small projects or delicate parts. If you want something simple and cheap, a mini mill is a great choice. It helps you learn without spending too much money!

How Do The Cost And Maintenance Requirements Compare Between Mini Mills And Knee Mills?Mini mills are usually cheaper than knee mills. They cost less to buy and use less power. Knee mills can be more expensive and need more care. This means they might need more repairs over time. You can save money with mini mills if you don’t need the extra features of knee mills.

What Types Of Materials And Projects Are Best Suited For Each Type Of Mill?Different mills work best with certain materials. For example, a sawmill is great for cutting wood into boards. A flour mill is best for grinding grains into flour. A metal mill can shape metal for things like tools or parts. Each mill helps us create special projects more easily!

Can Both Mini Mills And Knee Mills Be Used For Cnc Conversions, And If So, What Are The Implications For User Experience And Capabilities?Yes, both mini mills and knee mills can be changed to work with CNC, which stands for Computer Numerical Control. This makes them easier to use because a computer can help control the machines. You can make more accurate cuts and repeat the same work many times. However, mini mills are smaller, so they may not handle big projects as well as knee mills. Each type has its own pros and cons, depending on what you need!