Transform scraps into stunning writing instruments with mini wood lathe pen projects! Discover clever designs, essential tools, and simple techniques to create beautiful, functional pens, even if you’re brand new to the lathe. Amaze yourself and others with your woodworking skills.

Turning a beautiful pen on a mini wood lathe might seem a bit daunting at first, especially if you’re just getting started with this fantastic hobby. You see those smooth, polished pens and wonder, “Can I really make one of those?” The good news is, absolutely! Mini wood lathe pen projects are one of the most rewarding ways to get into woodturning. They let you work with small pieces of wood, learn fundamental techniques, and create something you can use every day or give as a cherished gift. We’ll walk you through everything you need to know to get your pen-making journey started, making it simple and fun.

Why Mini Wood Lathe Pen Projects are Perfect for Beginners

Getting started with woodworking can sometimes feel overwhelming. There are so many tools and techniques! But here’s why starting with a mini wood lathe and pen projects is such a smart choice:

Small Scale, Big Learning: You’re working with small pieces of wood and relatively simple components. This means less material to worry about and fewer complicated steps. It’s a perfect way to get a feel for the lathe.

Affordable Entry Point: Mini lathes are generally less expensive than their larger counterparts, making them an accessible option for hobbyists. Pen turning kits are also budget-friendly.

Quick Wins: You can often complete a pen in a single session. This means you get that satisfying feeling of accomplishment quickly, which is great for staying motivated.

Creative Outlet: From choosing exotic woods to mixing materials, there’s a lot of room for creativity. You can make truly unique pens.

Useful Results: You end up with a functional, beautiful object that you or someone you know can use and appreciate daily.

Essential Tools and Materials for Pen Turning

Before you can turn that first pen, you’ll need a few key things. Don’t worry, you don’t need a workshop full of specialized gear to start.

The Lathe and Its Accessories

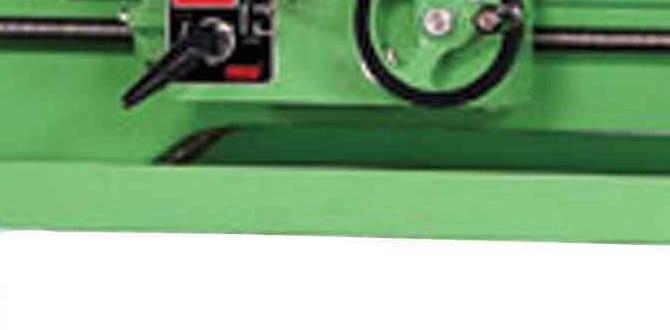

1. Mini Wood Lathe: Look for a sturdy, reliable mini lathe. Brands like Nova, Jet, and Grizzly offer great entry-level options. Ensure it has variable speed control, as this is very helpful for pen turning.

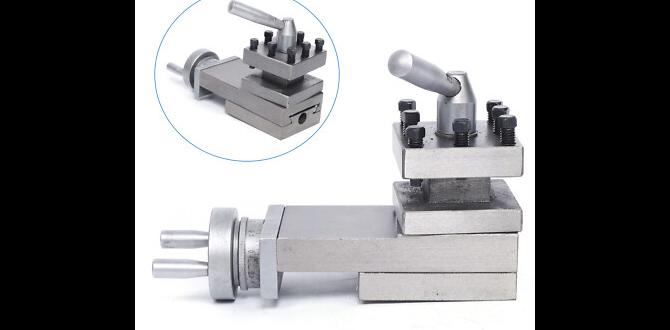

2. Pen Mandrel: This is a specialized bit that holds your pen parts and wood securely on the lathe. It usually has a tapered rod with threads.

3. Pen Maker’s Vise (Optional but helpful): If your lathe doesn’t have a robust tailstock for drilling, this can be useful for precisely drilling out your pen tubes.

Woodturning Tools

Gouge: A small spindle gouge (often 1/4″ or 3/8″) is your main workhorse for shaping the wood.

Skew Chisel: Useful for getting a clean finish and detail work.

Scraper (Optional): Some turners use scrapers for a smooth finish, though often gouges are sufficient for beginners.

Chuck with Pen Jaws (or similar): For holding the pen kit components securely.

Pen-Specific Supplies

Pen Kits: These are pre-made kits that include all the metal hardware for your pen (tip, clip, ink mechanism, etc.) and a tube to turn the wood around. They come in a huge variety of styles and finishes.

Adhesive: A strong wood glue or CA (super) glue is needed to secure the wood to the pen tubes.

Drill Bits: You’ll need a drill bit sized precisely for the pen tubes in your kit.

Sandpaper: A range of grits from around 100-120 up to 400-600 for sanding. Micro-mesh pads are excellent for a super-smooth, glossy finish.

Finishing Products: This could be a wood sealant, polyurethane, CA glue finish, or a simple wax.

Safety Gear – Don’t Skip This!

Safety Glasses/Face Shield: Non-negotiable. Wood chips and dust will fly.

Dust Mask/Respirator: Essential for protecting your lungs from wood dust.

Hearing Protection (Optional but recommended): Lathes can be noisy.

Step-by-Step: Your First Mini Wood Lathe Pen Project

Let’s get down to business! We’ll walk through turning a simple, classic pen.

Step 1: Prepare the Wood and Tubes

1. Select Your Wood: Choose a nice piece of hardwood. Something stable and enjoyable to look at. Oak, maple, walnut, cherry are all great beginner woods. Make sure it’s slightly longer and wider than your pen tube.

2. Cut the Blanks: Cut your wood into two rectangular blanks, one for the outside of the tip section and one for the outside of the barrel section. They should be at least 1/4 inch wider than the raw tubes.

3. Drill the Blanks: This is crucial. You need to drill a hole perfectly centered through each blank. The hole size should match your pen kit’s tubes. You can use a drill press for accuracy or a hand drill if you’re careful. The hole should be straight and go all the way through.

4. Glue the Tubes: Apply a generous amount of wood glue or CA glue inside the drilled holes of your wood blanks. Insert the pen tubes with a slight twist. Ensure the tubes are seated fully and are centered. Wipe away any excess glue immediately.

5. Let it Cure: Allow the glue to cure completely according to the adhesive manufacturer’s instructions. This is vital for ensuring the wood doesn’t spin on the tube later.

Step 2: Mount and Shape on the Lathe

1. Mount the Pen Mandrel: Insert the pen mandrel into your lathe’s tailstock and spindle.

2. Secure the First Blank: Place the blank with the tube for the barrel onto the mandrel. Mount the tailstock end of the mandrel in your tailstock. Use a live center on the headstock end if your lathe has one, or use a chuck to hold the mandrel’s threaded end carefully.

3. Set Your Speed: Start with a low to medium speed, around 1000-1500 RPM. You can increase it slightly as you become more comfortable, but never spin too fast, especially with small pieces.

4. Rough Turning: Using your gouge, begin to shape the wood. Gradually bring the wood down to the diameter of the tube. Be careful not to cut into the brass tube! Gradually shape the outside of the wood to match the shape of the pen kit – usually a gentle curve.

5. Repeat for the Other Blank: Remove the barrel blank and mount the tip blank onto the mandrel in the same way. Repeat the rough turning and shaping process.

A great resource for understanding woodworking tools like gouges and chisels is Wood Magazine’s guide to turning tools. They offer clear explanations and visual aids.

Step 3: Sanding and Finishing

1. Start Sanding: Once both pieces are shaped, begin sanding. Start with a coarser grit (around 100-120) to remove any tool marks. Gradually move through finer grits (180, 220, 320, 400).

2. Achieve a Smooth Surface: Ensure you sand all the way around each piece. You want the wood to feel perfectly smooth to the touch at 400 grit.

3. Apply Finish: This is where the wood really comes alive!

CA Glue Finish: Apply thin coats of CA glue, letting each layer set and then sanding with very fine grits (up to 1200 or higher) and then polishing. This gives a durable, glossy finish.

Wood Polish/Wax: Apply a good quality wood polish or finishing wax for a more satin or natural sheen.

Polyurethane/Lacquer: If you prefer a more traditional finish, a few thin coats of spray lacquer or polyurethane can work.

4. Polish: After your chosen finish has cured, you might want to buff it with a soft cloth or a buffing wheel for an extra shine.

Step 4: Assembly

1. Prepare for Assembly: Once the wood is shaped, sanded, and finished, you’ll need to carefully remove the blanks from the mandrel.

2. Assemble the Pen Kit: Follow the instructions that come with your pen kit. Usually, this involves:

Inserting the tip into one end of the barrel.

Inserting the ink cartridge.

Attaching the other half of the pen mechanism.

Pressing the end cap or tip section onto the barrel, often using a vise or a pen press. A common technique is described by Popular Mechanics for assembling a wooden pen.

3. Check Functionality: Ensure the pen mechanism twists open and closed smoothly and that the ink writes!

Congratulations, you’ve made your first pen!

Genius Mini Wood Lathe Pen Project Ideas to Inspire You

Beyond a basic pen, there are so many ways to get creative. Think about these ideas to elevate your pen-making game!

1. Mixed Media Pens

Combine wood with other interesting materials for a unique look and feel.

Wood and Resin: Pour colored or clear resin into channels carved into the wood, or use iridescent resin for swirling effects.

Wood and Metal: Inlay thin strips of brass, copper, or aluminum into the wood. You can also use metal blanks and add wood accents.

Wood and Acrylic: Acrylic blanks can offer vibrant colors and patterns that contrast beautifully with natural wood.

Wood and Horn/Bone: For a rustic or exotic touch, combine wood with ethically sourced horn or bone.

2. Natural Material Pens

Embrace the beauty of nature in its raw form.

Exotic Woods: Explore the rich colors and grain patterns of woods like Bocote, Purpleheart, Wenge, or Zebrawood.

Burls and Spalted Woods: These woods have unique, often dramatic, patterns caused by fungi. They are incredibly striking but can be more challenging to work with due to instability.

Found Objects: With care and stabilization, you might even be able to encase interesting found objects (like small pebbles or sea glass) within a clear resin blank that you then turn.

3. Themed Pens

Design pens with a specific theme in mind.

“Nature” Theme: Use woods with natural textures that evoke bark, or incorporate resin pours that look like water or sky.

“Industrial” Theme: Pair dark woods with metal accents, or use rougher finishes that mimic aged metal.

“Art Deco” or “Victorian” Style: Think intricate inlays, geometric patterns, or polished finishes with elegant wood choices.

4. Segmented Pens

This is an advanced technique but incredibly impressive. It involves gluing together many small rings of different woods (or other materials) to create a repeating pattern before drilling and turning. This allows for complex geometric designs.

For a glimpse into the world of segmented turning, check out resources from organizations like the American Association of Woodturners (AAW), which often feature examples and tutorials on advanced techniques:

American Association of Woodturners

5. Custom Engraved Pens

After turning and finishing, you can add custom engravings. This could be a name, a logo, a date, or a special message. This adds a deeply personal touch, perfect for gifts.

Choosing Wood Blanks: A Quick Guide

Understanding wood is part of the fun. Here’s a table to help beginners choose.

| Wood Type | Appearance | Workability | Notable Features |

|---|---|---|---|

| Maple | Light cream to pale brown, fine grain | Easy to work, sands well | Takes finishes very well, can show flame or bird’s eye patterns |

| Walnut | Rich dark brown, straight to wavy grain | Easy to work, glues and finishes well | Classic, elegant look, develops a nice patina |

| Cherry | Pinkish-brown, darkens with age to a reddish-brown | Moderately easy to work, smooth finish | Beautiful color change over time |

| Oak | Light brown with prominent grain patterns | Can be prone to splintering if not careful on the lathe | Strong, durable, distinctive grain |

| Purpleheart | Vibrant violet, darkens to a brownish-purple with age | Hard, can be brittle, requires sharp tools | Striking color, great contrast |

Types of Pen Kits

The pen kit you choose dictates the overall style and mechanism.

Twist Pens: The most common type. Twisting the top part extends or retracts the writing tip.

Click Pens: Often use a mechanism activated by clicking the top.

Executive Pens: Larger, more substantial pens often with a heavier feel.

Slimline Pens: Sleeker, thinner pens that are very popular.

Wall Street Pens: A larger, often more ornate style pen that feels substantial in the hand.

A great guide to understanding different pen kits and their assembly can often be found on sites that sell these kits, detailing their specific requirements. For example, Penn State Industries offers a wealth of information on pen kits.

Safety First! Always Prioritize Your Well-being

Working with power tools like a lathe comes with inherent risks. Making safety your top priority ensures you can enjoy this hobby for years to come.

Read Your Lathe Manual: Understand your specific machine’s controls and safety features.

Wear Appropriate Safety Gear: Always wear safety glasses or a full face shield. A dust mask or respirator is crucial for preventing respiratory issues from wood dust.

Secure Your Workpiece: Ensure your wood blanks are securely glued to the tubes and that the tubes are firmly mounted on the mandrel. A loose workpiece can be thrown from the lathe with dangerous force.

Start Slow: Begin turning at a low speed and gradually increase it as you gain confidence. Listen to your lathe and feel for vibrations.

Sharp Tools: Keep your turning tools sharp. Dull tools require more force, are harder to control, and can lead to gouges or catches.

Proper Stance and Grip: Stand comfortably and maintain a balanced stance. Hold your tools firmly with a confident grip, but don’t tense up. Follow the manufacturer’s recommendations for safe tool use, like those found on OSHA’s guidelines for woodworking machinery safety, which often overlap with general lathe safety.

Clear Your Workspace: Keep your area around the lathe clean and free of clutter. This prevents tripping hazards and ensures you have room to work.

Never Turn Off the Machine While Holding the Wood: Always let the lathe come to a complete stop before touching the wood or making adjustments.

Troubleshooting Common Pen Turning Issues

Even experienced turners run into small problems now and then. Here are a few common ones and how to solve them:

Wood Spins on Tube: This usually means the glue didn’t cure properly, or there wasn’t enough glue applied. When this happens, you often have to discard the blank and start over with new wood and a new tube. Ensure thorough curing next time.

Off-Center Hole: If your drilled hole isn’t centered, the finished pen will feel and look lopsided. Using a drill press is the best way to ensure accuracy. If it’s slightly off, you might be able to shave one side more than the other to compensate, but perfectly centered is always ideal.

Chipped Edges: This can happen when you reach the end of the tube during rough turning, or with certain aggressive woods. Use a very sharp tool and approach the end of the tube carefully. A sharp skew chisel can often clean up edges nicely.

* Sandpaper Glazing: If the wood is too soft or you’re using too much pressure, sandpaper can load up with dust and become ineffective. Ensure you’re using the right grits in order and change to a fresh piece of sandpaper frequently.

Frequently Asked Questions About Mini Wood Lathe Pens

Q1: What kind of wood is best for beginners to turn pens?

A1: For beginners, stable and easy-to-work woods like Maple, Walnut, Cherry, and Basswood are excellent choices. They are readily available and forgiving to turn.

Q2: How do I ensure the wood is centered on the pen tube?

A2: The most crucial step is drilling a perfectly centered hole through your wood blank before gluing. Using a drill press is highly recommended. When gluing, ensure the tube is also centered within the blank.