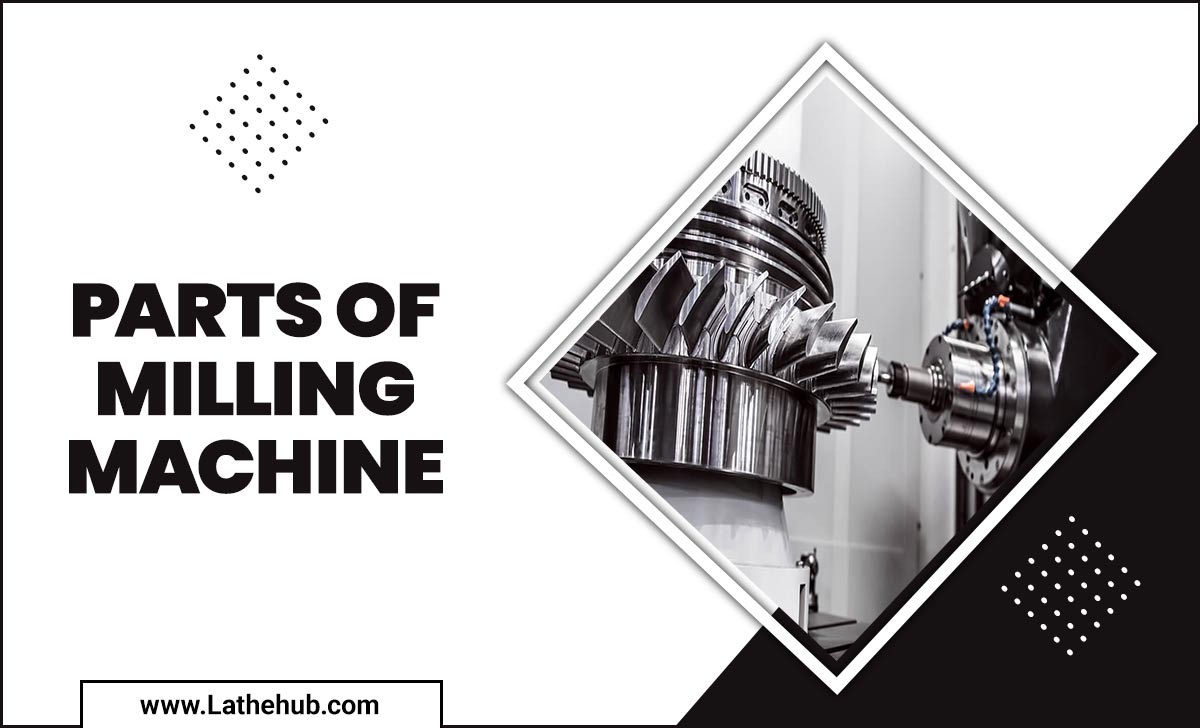

Milling machines have been a vital tool in the manufacturing industry for decades and are a cornerstone of production processes today. These versatile machines are handy to shape and create a wide range of precision parts for various industries, from automotive to aerospace.

While they may seem complex and intimidating at first glance, understanding the basic components and functions of a cam milling machine is crucial for any professional in the field of machining time.

Here, we will take an in-depth look at the various parts of a milling machine, including their roles and how they work together to achieve precise results. Whether you are a seasoned machinist or a novice in the industry, this comprehensive guide will provide a clear understanding of milling machine parts and their importance in manufacturing.

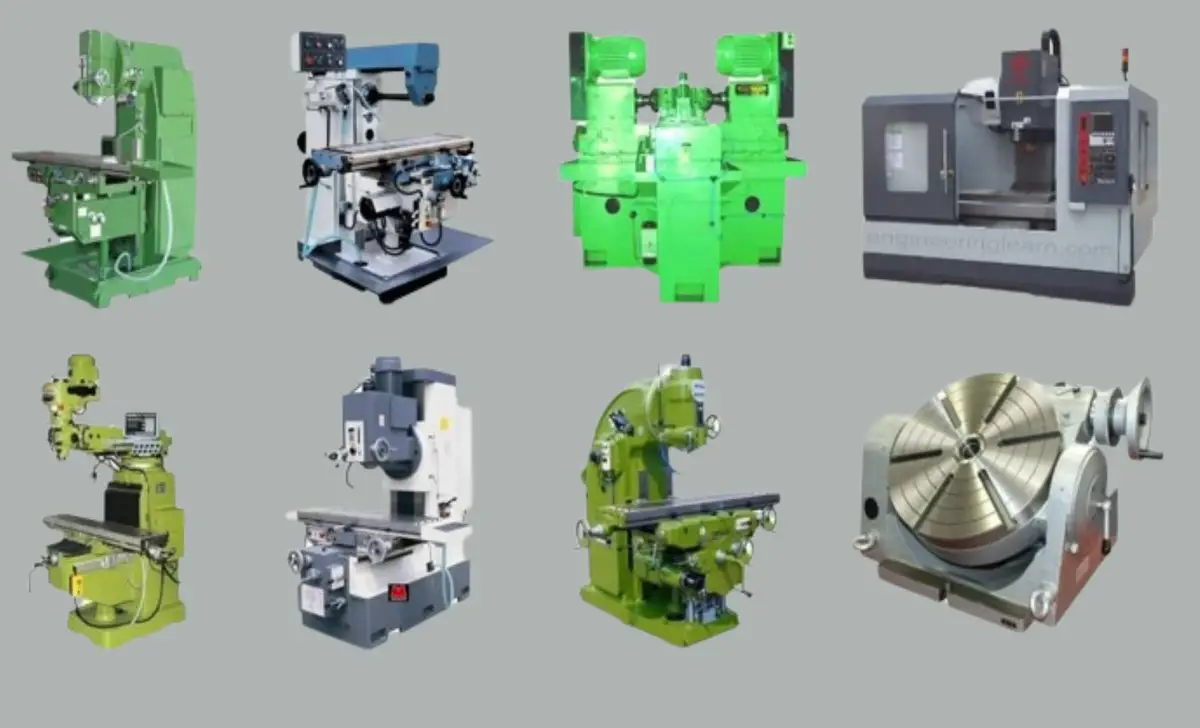

Types Of Milling Machines

There are several milling machines, each with specific features and applications. As the name suggests, a vertical component milling machine has a vertical feed spindle axis. This type of machine is suitable for operations that require the workpiece to be cut into the desired shape from top to bottom.

In contrast to vertical milling machines, horizontal mill milling machines have a horizontal spindle axis. CNC milling machines are computer-controlled milling machines. They offer precise control and automation, allowing complex shapes and designs to be easily machined. The most common types of gang milling machines include:

- Vertical Milling Machine

- Horizontal Milling Machine

- CNC Milling Machine

- Universal Milling Machine

Key Components Of A Milling Machine

A milling machine consists of various key components that perform milling operations. Understanding the different parts of a milling machine is essential for operating and maintaining the machine effectively. The milling head is responsible for the cutting action and comprises several elements. The base of the milling machine provides support and stability, while the column supports the spindle head.

The base and column are usually cast iron, ensuring rigidity and minimum vibration during machining work. The knee elevates the saddle, allowing vertical downward movement of the work table. The saddle, in turn, supports the work table and facilitates longitudinal variable speed power feed, which is crucial for precision machining work. The main components of a milling machine include:

- The Base and Column

- The Knee and Saddle

- The Work Table and Overarm

- The Spindle and Arbor Support

The Base And Column

The base and column of a milling machine are the foundational components that provide support and stability during milling operations. The base, usually made of cast iron, ensures the rigidity of the machine, minimizing vibration and enhancing the precision of the machining work. It supports the column, which houses the gearing mechanism for spindle speed control.

The base support houses the gearing mechanism, which allows for the control of the spindle speed. The cast iron column supports the milling machine parts, ensuring precise and accurate machining operations. The base and column form a strong and stable foundation for the milling machine.

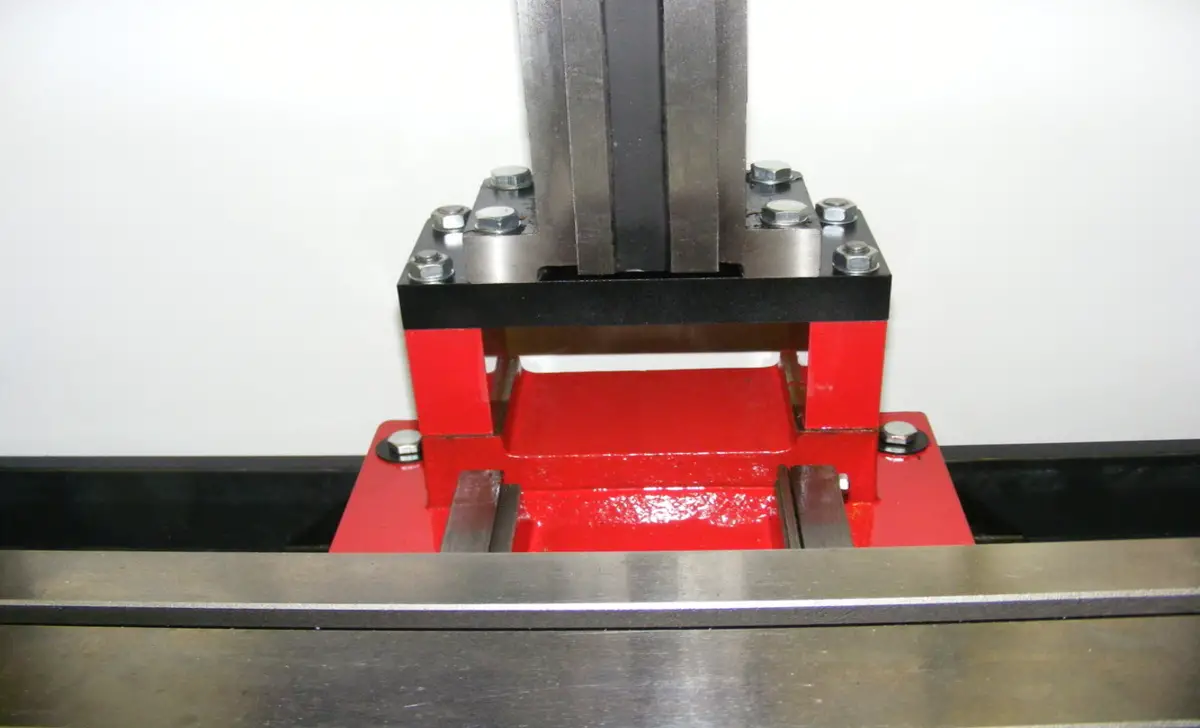

The Knee And Saddle

The knee and saddle of a milling machine play a crucial role in facilitating the movement of the work table. The knee elevates the saddle, allowing for vertical positioning of the workpiece, which is essential for precision machining work. The saddle, with the help of an elevating screw, supports the work table and enables longitudinal variable speed power feed. This variable speed power feed mechanism enhances the control and precision of the machining process.

The saddle supports the work table, ensuring minimum vibration during milling operations. Additionally, the saddle enables the movement of the work table in the horizontal direction, providing versatility and flexibility for machining operations. The dovetail cutters, often used in milling operations, rely on the vertical movement facilitated by the knee and saddle.

The Work Table And Overarm

The work table and overarm are important components of a milling machine that support the workpiece and provide stability during milling operations. The work table is a flat surface where the workpiece is secured and fed against the spinning tool. It is an integral part of milling, allowing for precise cutting operations.

Depending on the milling machine, the work table may be able to move in multiple directions, ensuring the desired shape is achieved. The overarm supports the arbour, allowing for the milling of cylindrical shapes. It is an optional component; its main function is supporting the horizontal milling attachment. The power feed mechanism, part of the saddle, manually controls the work table’s longitudinal variable speed power feed, enhancing the milling process’s precision and efficiency.

The Spindle And Arbor Support

The spindle and arbour support are integral components of a milling machine, responsible for rotating cutting tools and providing support during milling operations. The spindle, located in the spindle head, holds different milling cutters, such as end mills and face mills, allowing the machining of complex shapes. It plays a crucial role in the milling process, as the rotation of the spindle determines the speed at which material is removed from the workpiece.

The arbour support supports the arbour, enabling the vertical positioning of end mills for cutting operations. It ensures the precision and accuracy of the milling process, facilitating the creation of desired shapes and features. Together, the spindle and arbour support contribute to the functionality and versatility of the milling machine.

Exploring The Functionality Of Different Parts

The top of the column supports the ram and the spindle head. A machinist utilizes the axis for the rotation of a lathe. The workpiece spins on a rectangular piece of cast iron, part of the work table. The shaft, crank, and ram are vital for the functionality of different parts in a machine shop. The vice holds the workpiece in place during operations.

Role Of The Base And Column

The vertical movement of the spindle head is supported by the base and column, ensuring precise milling operations. Rigidity for machining work is provided by the base supporting the column. Control over spindle speed is facilitated by the gearing mechanism supported by the cast iron base and column.

These components ensure the necessary support for milling machine operations, vital for precision machining work. Additionally, they play an integral role in shaping the workpiece, which is essential for achieving precision in machining work.

Functionality Of The Knee And Saddle

Facilitating both longitudinal and crosswise movement of the work table, the knee and saddle are essential for precision machining work. The saddle’s ability to elevate the work table allows for vital vertical positioning of the workpiece while the knee supports the saddle, facilitating horizontal movement crucial for precision machining. Ensuring longitudinal variable speed power feed, these components play a crucial role in maintaining the rigidity of the milling machine, guaranteeing precise machining work.

Utility Of The Work Table And Overarm

Supporting the workpiece, the work table facilitates the precision milling of complex shapes, which is crucial for machining. Additionally, the overarm enables precision milling of cylindrical shapes by supporting the arbour, which is essential for precision machining. It also accommodates smaller parts, machined using the end mills, ensuring precision machining work. The work table’s longitudinal variable speed power feed control panel is another vital feature for precision machining.

Importance Of The Spindle And Arbor Support

The spindle of a milling machine plays a crucial role in supporting different milling cutters, facilitating the precision machining of complex shapes. This is essential for any machinist working in a machine shop. Additionally, the arbour support contributes to the vertical positioning of end mills during cutting operations, ensuring accurate and efficient machining work.

Furthermore, the spindle head’s control over spindle speed is vital for achieving precision in milling operations, making it an indispensable part of the machine. The inclusion of the vertical positioning screw as a key detail of the arbour support further enhances its importance in facilitating precise machining work.

Operations Conducted On Milling Machines

Milling operations cover face milling, end milling, slot milling, and precision machining. The work table backs the workpiece and advances it against the spinning tool. Horizontal, vertical, and CNC milling methods each have unique details. The spindle head swivels for cutting diverse angles, ensuring accurate machining work. Longitudinal variable speed power feed enables the work table to move at different speeds as the cutting tool removes unwanted material.

How To Maintain A Milling Machine?

A milling machine is a versatile piece of equipment widely used in various industries for shaping and cutting layer of material. Understanding the different parts of a milling machine is essential for operating it effectively and safely.

One of the key components is the base, which provides stability and support to the machine. It is usually made of cast iron to ensure durability and minimize vibrations during operation. The column, another crucial part, is mounted on the base and provides vertical movement to the workpiece. Here is how to Maintain a Milling Machine:

- Clean And Lubricate: Regularly clean the milling machine to remove any dirt, chips, or debris that may accumulate during operation. Use a brush or vacuum to clean the machine thoroughly. Additionally, lubricate the moving parts, such as the slides, gears, and bearings, with appropriate lubricants to ensure smooth operation.

- Check For Wear And Tear: Inspect the machine for any signs of wear and tear, such as loose or damaged components, worn-out belts, or broken tools. Replace or repair any damaged parts immediately to avoid further damage to the machine.

- Align And Adjust: Periodically check the alignment of the milling machine to ensure that the table, spindle, and other components are properly aligned. Adjust the machine to maintain proper alignment, which is crucial for accurate and precise machining.

- Monitor Coolant And Chips: If your milling machine uses coolant or cutting fluid, regularly check its level and condition. Maintain the recommended coolant concentration and clean or replace the coolant as needed.

- Keep A Maintenance Schedule: Create a maintenance schedule for your milling machine and follow it diligently. This schedule should include regular inspections, cleaning, lubrication, and any other specific maintenance tasks recommended by the machine manufacturer.

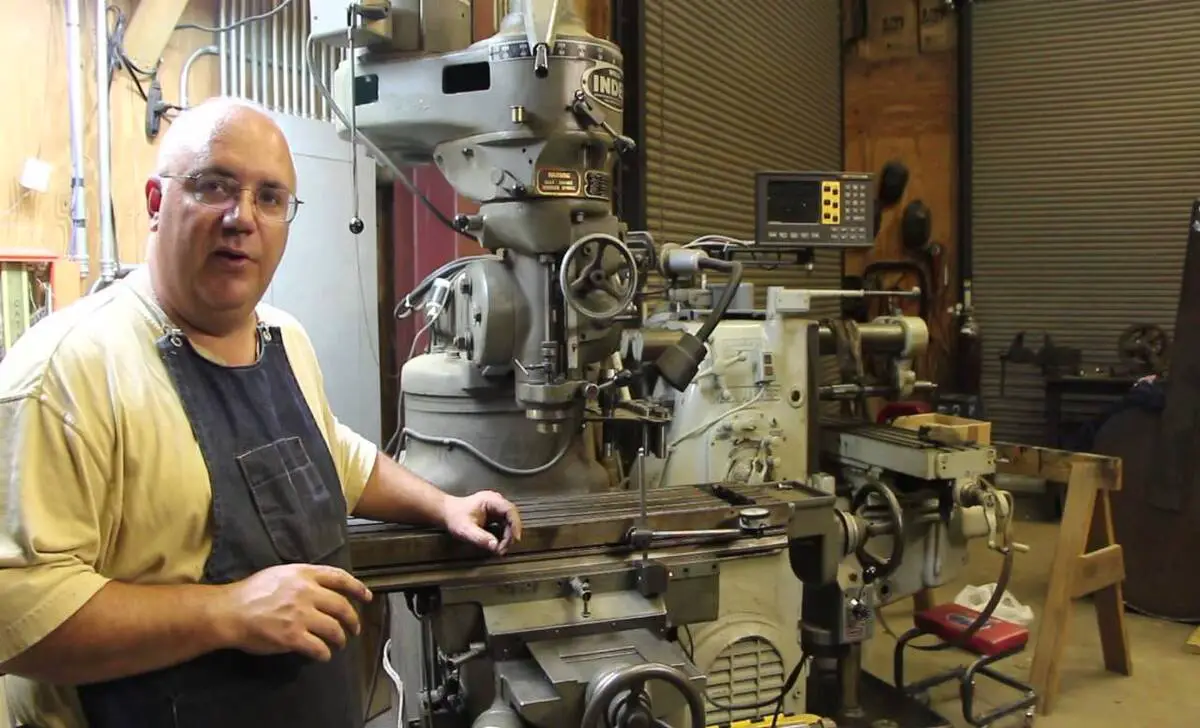

Choosing The Right Milling Machine For Your Needs

Choosing the right milling machine for your needs is crucial to ensure successful and efficient operations. When selecting a milling machine, consider the type of materials you will be working with, the size and complexity of the projects, and your budget. Various types of milling machines are available, including vertical, horizontal, and universal models, each with its advantages and applications.

Additionally, pay attention to the machine’s spindle speed, motor power, and available tooling options. By carefully evaluating these factors and understanding your specific requirements, you can make an informed decision and acquire a milling machine to meet your needs and deliver accurate and high-quality results.

Conclusion

To summarize, a milling machine is a versatile, powerful tool used in various industries for shaping and cutting materials. It consists of several key components: base and column, knee and saddle, work table and overarm, and spindle and arbour support. Each part plays a crucial role in the overall functionality and precision of the machine.

Understanding the different parts and their functions is essential for conducting operations on a groove milling machine effectively. Additionally, proper maintenance is vital to ensure optimal performance and longevity. With advanced gear milling techniques and applications, you can achieve complex shapes and designs accurately and efficiently. When selecting an angular milling machine, consider your specific needs and requirements.

Frequently Asked Questions

1.What Is A Milling Machine?

A milling machine is a versatile tool to shape solid materials like metal or wood. Remove material from the workpiece using a rotating cutting tool to create different shapes.

2.What Are The Main Parts Of The Milling Machine?

The milling machine consists of various key components: base, column, knee, saddle, table, spindle, and overarm. These parts work together to enable precise cutting operations.

3.What Are The Parts Of A Mill Called?

The main components of a milling machine are the base, column, knee, saddle, table, spindle, and overarm. These parts work together to facilitate various machining operations.

4.What Are The 6 Major Components Of A Vertical Milling Machine?

The major components of a vertical plane milling machine include the base, column, knee, worktable, spindle, and overarm/outrigger. The base provides stability, while the column houses the spindle.

5.What Is The Anatomy Of A Milling Machine?

A cam milling machine consists of various components: base, column, knee, saddle, table, spindle, and cutting tool. The base offers stability and support, while the column houses the spindle.