Looking for a portable midi wood lathe that fits your workshop? This guide breaks down what to consider, from power and features to portability and budget. We’ll help you choose the right one for your woodworking projects, ensuring you get the best value and a reliable tool for years of creative turning.

Hey there, woodworking friends! Daniel Bates here from Lathe Hub. If you’ve ever dreamed of shaping beautiful bowls, intricate spindles, or unique craft items on your own, a wood lathe is your ticket. But maybe your workshop space is a bit cozy, or you just want the flexibility to move your tools around. That’s where a portable midi wood lathe shines! These compact powerhouses offer a fantastic balance of functionality and ease of use, perfect for beginners and seasoned woodworkers alike. Don’t let limited space hold back your creativity. This guide is designed to make choosing your first midi lathe a breeze, so you can start turning with confidence and safety.

Why Choose a Portable Midi Wood Lathe?

Portable midi wood lathes are a brilliant choice for many reasons, especially if you’re new to the craft or have space limitations. They offer a sweet spot between tiny hobby lathes and larger floor-standing models. Think of them as the versatile workhorses of the smaller lathe world.

- Space-Saving: Their smaller footprint means they can fit comfortably on a workbench or in a corner, making them ideal for garages, apartments, or smaller dedicated workshops.

- Portability: As the name suggests, many are designed to be moved. This is great if you need to clear space for other projects or even take your turning hobby to a friend’s place or a workshop class.

- Beginner-Friendly: Midi lathes often have simpler controls and are less intimidating than their larger counterparts. This allows you to focus on learning the fundamental techniques of woodturning safely.

- Affordability: Generally, midi lathes are more budget-friendly than full-size lathes, making them an accessible entry point into the hobby.

- Versatility: Despite their size, they can handle a surprising range of projects, from small bowls and delicate spindles to pen turning and cutting small craft items.

Key Features to Look For in a Portable Midi Wood Lathe

When you’re shopping for a portable midi wood lathe, there are several crucial features that will impact its performance, your safety, and your overall satisfaction. Let’s break down what really matters.

1. Motor Power and Speed Control

The motor is the heart of your lathe. For a midi lathe, look for a motor with enough power to handle the types of wood and project sizes you envision. A good starting point is usually between 1/2 HP to 1 HP.

Horsepower (HP):

- Low HP (e.g., 1/4 HP to 1/2 HP): Best for very small projects like pens, dowels, and softwoods. May struggle with larger pieces or dense hardwoods.

- Mid HP (e.g., 1/2 HP to 1 HP): This is the sweet spot for most midi lathes and beginners. It’s capable of handling a good range of projects, including smaller bowls and spindles made from various woods.

- Higher HP (e.g., 1 HP and up): While less common in true “midi” portable units, some offer this. It provides more torque for larger or denser materials but often comes at a higher price and weight.

Speed Control: This is arguably one of the most important features for a beginner. Variable speed control lets you adjust how fast the wood spins, which is crucial for safety and achieving different results. You’ll want a lathe with electronic variable speed (EVS) that allows you to change speeds on the fly. Lower speeds are safer when starting a piece or working with unbalanced stock. Higher speeds are good for finishing.

Speed Ranges: A wider speed range is better. Look for a minimum speed of around 250-500 RPM and a maximum speed of 3000-4000 RPM. This wide range gives you flexibility for different turning tasks.

2. Swing and Distance Between Centers

These two specifications tell you the maximum size of the workpiece your lathe can handle.

- Swing: This is the diameter of the largest workpiece the lathe can turn. It’s measured by the radius from the bed to the headstock center, then doubled. For example, a 10-inch swing means the lathe can turn a piece up to 10 inches in diameter without the wood hitting the lathe bed or tool rest assembly. For midi lathes, swings typically range from 8 to 14 inches.

- Distance Between Centers (or Bed Length): This determines the longest piece of wood you can turn. It’s the maximum length between the headstock center and the tailstock center. Midi lathes commonly offer between 16 and 24 inches of distance between centers.

Think about your projects: If you plan on turning mostly pens and small decorative items, an 8-inch swing and 16-inch distance might be fine. If you envision turning smaller bowls or longer spindles, aim for a 10-inch or 12-inch swing and 18-inch or 20-inch distance between centers.

3. Bed Construction and Stability

The bed of the lathe is its foundation. A sturdy bed is essential for minimizing vibration and ensuring accuracy and safety. While portable midi lathes are lighter than their larger counterparts, the material and design of the bed still matter.

- Cast Iron: Beds made from cast iron are heavier and offer excellent vibration damping. This is the gold standard for stability.

- Steel Tubing: Some lighter, more portable models use steel tubing for the bed. While this reduces weight significantly, it can lead to more vibration, especially when turning larger or unbalanced pieces.

- Mounting Options: Consider how you’ll mount the lathe. Some come with rubber feet for benchtop use, while others might have optional stands or mounting plates. A stable mounting surface is key to minimizing wobble.

For portability, a slightly lighter bed might be a trade-off you’re willing to make. However, always prioritize a design that minimizes vibration as much as possible through features like a robust headstock and tailstock connection, and a solid tool rest system.

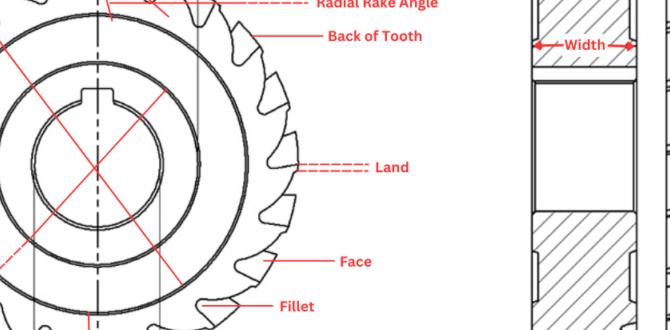

4. Tool Rest and Tool Post Design

The tool rest is where you support your chisels as you cut the wood. A stable and easily adjustable tool rest is critical for control and safety.

- Size and Shape: Look for a substantial tool rest that provides good support for your gouges and chisels. The length and angle of adjustment are important.

- Locking Mechanism: A secure locking mechanism ensures the tool rest doesn’t shift during operation.

- Tool Post: The part that holds the tool rest to the bed. Ensure it’s robust and allows for easy height and position adjustments.

Many midi lathes come with a standard tool rest. Some higher-end models might offer different sizes or quick-release mechanisms for faster changes.

5. Headstock and Tailstock Quality

These are the two main components that hold and spin your wood.

- Headstock: This houses the drive mechanism and the spindle that the drive center attaches to. It should be solid and well-aligned. Look for standard threading (e.g., 1″ x 8 TPI) so you can use readily available chucks and accessories. M33 x 3.5 is also common.

- Tailstock: This provides support for longer workpieces via a live center, and it holds drill bits for drilling into the end of a workpiece. It should align perfectly with the headstock. A Morse taper (usually #1 or #2) inside the tailstock bore is standard and allows for easy insertion and removal of accessories like live centers and drill chucks.

Models with easy-to-operate cam locks for the tailstock and tool rest are a plus for quick adjustments.

6. Included Accessories and Upgradability

What comes in the box? Most midi lathes come with a few essential accessories to get you started.

- Faceplate: For mounting larger, flat pieces of wood.

- Spur Drive Center: Attaches to the headstock to grip one end of the wood.

- Live Center: Attaches to the tailstock and spins freely with the wood, providing support at the tailstock end.

- Basic Chisel Set: Some lathes include a starter set of woodturning chisels (gouges). These are often basic quality, and most serious turners will upgrade them eventually.

Upgradability: Check if the lathe uses standard fittings (like the headstock thread size and Morse taper sizes) that will allow you to add accessories like a chuck, vacuum base, or extension bed later on. This can significantly extend the life and capability of your lathe.

Top Portable Midi Wood Lathes: A Quick Comparison

Choosing the “best” portable midi wood lathe depends entirely on your budget, space, and intended use. Here’s a look at some popular contenders that often appear on beginner lists. Keep in mind that models and specifications can change, so always check the latest details from the manufacturer.

This table provides general comparative information. Always verify exact specifications for the current model you are considering.

| Feature | Example Model A (e.g., Jet JWL-1440VS) | Example Model B (e.g., Powermatic 1790001, 14″ VS) | Example Model C (e.g., Rikon 70-180C) | Example Model D (e.g., Delta Industrial 46-460) |

|---|---|---|---|---|

| Motor Power | 1.5 HP (often with belt change for more power) | ~3 HP (larger benchtop/midi) | 3/4 HP EVS | 1 HP EVS |

| Swing | 14 inches | 17 inches (larger midi) | 12 inches | 12 inches |

| Distance Between Centers | 40 inches | 36 inches | 18 inches | 16 inches |

| Speed Control | Electronic Variable Speed (EVS) | Electronic Variable Speed (EVS) | Electronic Variable Speed (EVS) | Electronic Variable Speed (EVS) |

| Bed Material | Cast Iron | Cast Iron | Cast Iron | Cast Iron |

| Approx. Weight | ~250 lbs | ~350 lbs | ~100 lbs | ~95 lbs |

| Portability Factor | Heavy, but manageable with care | Much heavier, less portable | Very portable | Very portable |

| Target User | Intermediate to advanced, larger projects | Serious hobbyist, larger projects | Beginner to intermediate, smaller projects | Beginner to intermediate, pen/small project focus |

Note: Specific model numbers and features vary by manufacturer and production year. This table uses representative examples. Always check the manufacturer’s latest specifications.

To get a sense of the latest offerings and genuine user experiences, I highly recommend checking out reviews on reputable woodworking sites and forums. You can also look for videos on platforms like YouTube where makers demonstrate the lathes in action. Sites like USA Welding Supplies often have detailed product pages with specifications and customer feedback that can be very informative.

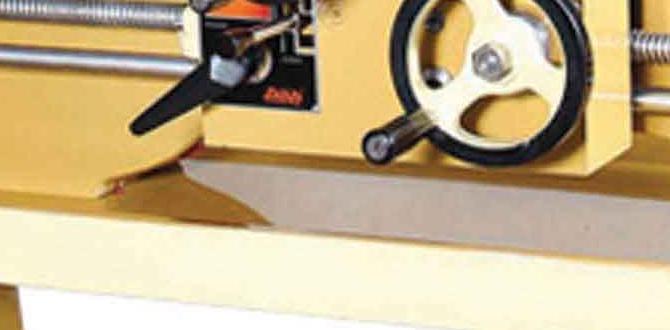

Setting Up Your Portable Midi Wood Lathe

Once your new lathe arrives, the excitement builds! Proper setup is crucial for safety and performance. Don’t skip these steps.

-

Unpacking and Inspection

Carefully unpack all components. Check for any shipping damage. Compare parts against the packing list in your manual.

-

Choose a Stable Location

Place your lathe on a sturdy, level workbench. If using a stand, ensure it’s on a solid floor. Heavy rubber mats can help absorb vibrations and prevent slipping.

-

Mounting (if applicable)

Some smaller lathes can simply rest on a bench. Others may benefit from being clamped down or bolted to a workbench for ultimate stability. Read your manual for recommendations.

-

Install the Headstock and Tailstock

Ensure the headstock is securely mounted to the bed. Place the tailstock on the bed ways and align it with the headstock. Lock both firmly in place.

-

Attach the Tool Rest Assembly

Slide the tool rest post onto the bed and position it close to where you’ll be working. Lock it down securely.

-

Install Drive and Live Centers

Thread the drive center (spur) into the headstock spindle. Insert the live center into the tailstock quill. Slightly advance the tailstock to put a slight pressure between the centers; this is where your wood will sit.

-

Check Belt Adjustment (if applicable)

Many midi lathes have belt-driven pulleys. Ensure the belt is properly tensioned – not too tight, not too loose. Consult your manual for the correct procedure. Some lathes use electronic speed control without belts.

-

Test Run (No Wood)

With the lathe unplugged, rotate the pulleys by hand to ensure free movement. Plug it in and run it at its lowest speed. Listen for any unusual noises or excessive vibration. Gradually increase speed and repeat. If anything seems wrong, unplug and re-check your setup.

Safe Operation of Your Portable Midi Wood Lathe

Safety is paramount when using any power tool, and a wood lathe is no exception. These machines can be dangerous if not used correctly. Always prioritize safety!

Here are essential safety practices:

- Read the Manual: Seriously. Every lathe is slightly different. Your manual is your best friend for understanding its specific features and safety requirements.

- Wear Safety Gear:

- Eye Protection: Always wear safety glasses or a full face shield. Wood chips can fly off at high speeds.

- Dust Mask/Respirator: Wood dust is harmful to your lungs. Wear a mask, especially for longer periods.

- Hearing Protection: Lathes can be noisy; earplugs or muffs are a good idea.

- No Loose Clothing/Jewelry: Avoid baggy sleeves, ties, necklaces, or anything that could get caught in the spinning wood or lathe parts. Tie back long hair.

- Secure Your Workpiece: Ensure your wood is properly mounted between centers or on a faceplate/chuck. It should run true with minimal wobble or runout.

- Use the Right Tools: Use proper woodturning chisels (gouges, scrapers, etc.) designed for lathes. Keep them sharp – dull tools are dangerous and produce poor results.

- Correct Tool Rest Placement: Position the tool rest as close to the wood as possible (about 1/8″ or 3mm gap) and slightly below the center line of the workpiece. This provides crucial support and prevents catches.

- Start Slow: Always start the lathe at its lowest speed, especially when beginning a new piece or rough turning. Gradually increase speed as the workpiece becomes rounder and smoother.

- Never Stop the Lathe with Your Hand: Do not try to slow down the spinning wood by touching it.

- Be Aware of Your Surroundings: Keep your workspace clean and free of clutter. Ensure good lighting.

- Never Leave a Running Lathe Unattended: Always stay within reach and attentive when the lathe is on.

- Unplug When Changing Accessories: Always turn off and unplug the lathe before making any adjustments, cleaning, or changing tools/accessories.

For more in-depth safety guidelines, check resources like the Occupational Safety and Health Administration (OSHA) regulations for woodworking machinery. While these are industrial standards, they contain excellent safety