Have you ever wondered how precise parts are made in factories? Imagine a machine that can shape metal with incredible accuracy. This is where precision metal lathes come in. They are like magic tools that turn blocks of metal into beautiful, exact pieces.

But what if these machines could work all by themselves? That’s the exciting world of precision metal lathe automation. With automation, these lathes can run without a person watching over them. This means less waiting time and more perfect parts. Isn’t that cool?

One fun fact is that some of the fastest lathes can create a part in just a few minutes. That’s faster than making popcorn in the microwave! As technology advances, more companies explore how to use automation. This makes the process easier and more efficient.

In this article, we will dive into the world of precision metal lathe automation. We will explore how it works and why it’s so important. Ready to discover the future of metalworking? Let’s get started!

Precision Metal Lathe Automation: Enhancing Efficiency And Accuracy

Precision metal lathe automation transforms how machining works. Imagine machines that do the hard tasks for you! These lathes use advanced technology to cut metal parts with accuracy. They save time and reduce errors. This means fewer mistakes and better products. Did you know that automating lathes can also lower costs? With these machines, industries can get more done with less effort. Automation is the future!

The Importance of Automation in Metalworking

Benefits of automation in manufacturing processes. How automation improves precision and consistency.

Automation plays a big role in metalworking. It helps make parts faster and with more accuracy. Here are some benefits:

- Increased Speed: Machines can work faster than people.

- Higher Precision: Automation ensures parts fit perfectly every time.

- Consistency: Each piece looks and works the same way.

- Less Waste: Automated systems make fewer mistakes, saving materials.

Overall, automation in metalworking helps factories run smoother and better. This means happy workers and satisfied customers!

What are the benefits of automation in metalworking?

Automation improves speed, precision, and reduces waste in metalworking. This leads to better products and happier customers.

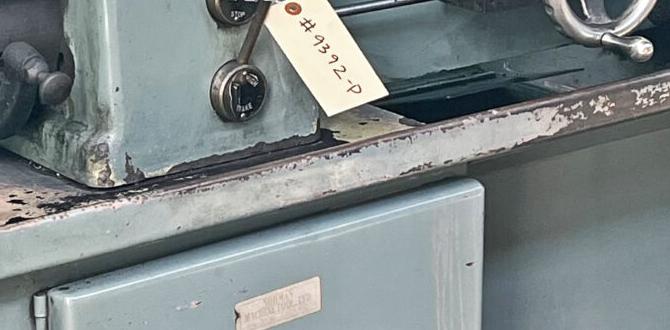

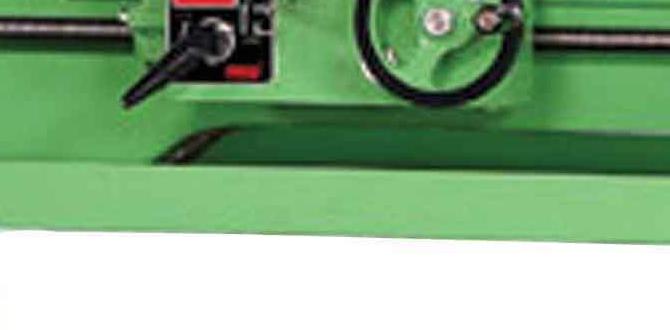

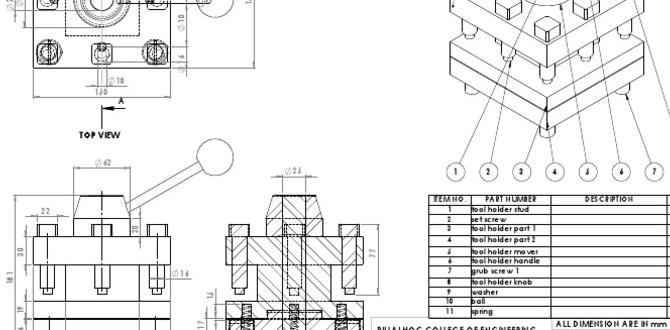

Key Features of Automated Precision Metal Lathes

Advanced control systems and software. Integration of robotics and CNC technology.

Automated precision metal lathes are like magic wands for manufacturers! They come with advanced control systems and smart software that make cutting metal easy. Imagine a computer that tells the lathe exactly how to spin and slice. Then, there’s the cool part: robotics and CNC tech! These machines can work together to create precise shapes without needing a coffee break. In fact, some studies show they boost productivity by up to 50%! Here’s a quick peek at their key features:

| Feature | Description |

|---|---|

| Control Systems | Smart software allows for precise adjustments and settings. |

| Robotics Integration | Robots work alongside lathes for faster, safer production. |

| CNC Technology | Computer-controlled for exact cuts and shapes, even in sleep mode! |

Applications of Precision Metal Lathe Automation

Industries benefiting from automated lathes (aerospace, automotive, etc.). Case studies of successful automation implementations.

Many industries are enjoying the benefits of precision metal lathe automation. Aerospace companies use these machines to create parts quickly and accurately. The same goes for the automotive industry, where speed and precision are vital for safety.

Case studies show impressive results from automation. For example, a well-known automotive factory saw a 30% increase in production after automating their lathe processes. This helps them meet customer demands better.

Here are some industries benefiting from automation:

- Aerospace

- Automotive

- Medical equipment

- Robotics

- Electronics

What are the benefits of precision metal lathe automation?

Automation offers better efficiency and consistent quality. It also reduces human error, making products safer. Plus, it helps save time! This is why so many industries are choosing automated lathes.

Challenges in Implementing Automation

Common obstacles manufacturers face. Solutions to overcome integration and technical issues.

Implementing automation can feel like trying to do a cartwheel while juggling! Manufacturers often face hurdles like high costs and technical glitches. These can make the process slow and frustrating. But don’t sweat it! Solutions exist. Training staff and using user-friendly software can smooth out those bumps. Check out the table below for a quick recap!

| Challenges | Solutions |

|---|---|

| High initial costs | Invest gradually in affordable tech |

| Technical glitches | Regular maintenance and updates |

| Staff resistance | Provide hands-on training |

With teamwork and the right tools, you can turn those challenges into fun puzzles to solve!

Future Trends in Precision Metal Lathe Automation

Emerging technologies and innovations to watch. Predictions for the future of automated manufacturing processes.

New tools are changing the game for precision metal lathe automation. Technologies like artificial intelligence and robotics are making machines smarter. These machines are learning to work faster and more accurately. Here are some exciting trends to watch:

- AI in machine monitoring

- Smart sensors for real-time adjustments

- Collaboration between humans and robots

Future predictions show that automated processes will be quicker. They will also reduce waste and costs. As these technologies improve, manufacturing will become even better.

What are the future trends in automated manufacturing?

Future trends include greater use of AI, smart sensors, and collaborative robots. These innovations will make manufacturing faster and more efficient.

Choosing the Right Automated Lathe for Your Business

Factors to consider when selecting a precision lathe. Comparison of leading automated lathe models in the market.

Choosing the right automated lathe is key for your business success. First, think about your production needs. What materials will you work with? Next, consider the lathe’s speed and precision. Third, check its automation level. Some models work faster than others. Finally, look at customer support options. This can save you time and trouble later.

- Production volume required

- Material compatibility

- Speed and precision

- Automation features

- Customer support availability

Compare popular lathe models available now. Each offers unique features to suit different needs.

What are some main features to look for in a lathe?

Look for precision, speed, and automation levels. These features can make your work smoother and faster. Don’t forget about your budget too!

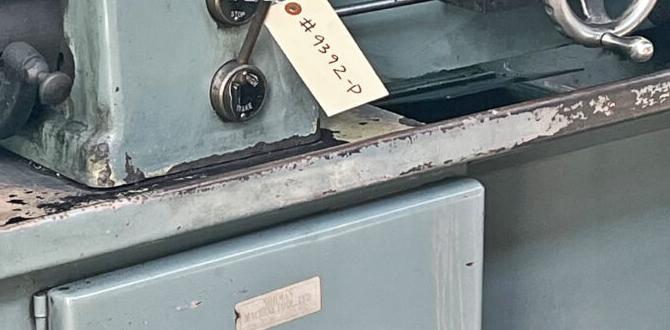

Maintenance and Upkeep of Automated Precision Lathes

Best practices for maintaining automation systems. Signs that indicate the need for repair or upgrade.

To keep automated precision lathes running well, follow some simple rules. Routine checks help find issues early. Here are some best practices:

- Clean machines regularly to avoid dirt buildup.

- Lubricate parts to reduce friction and wear.

- Calibrate settings for accurate performance.

Pay attention to signs that indicate repair or upgrade is needed. Look for:

- Unusual noises during operation.

- Inconsistent results in output.

- Frequent error messages on the display.

Taking care of your equipment leads to better safety and production quality.

What are the signs of needing repair or upgrade?

Look for changes in sound, output quality, or display errors. These are clear signs that your lathe needs attention. Regular check-ups can prevent major problems.

Conclusion

In summary, precision metal lathe automation improves efficiency and accuracy in manufacturing. With automated lathes, you can save time and reduce mistakes. This technology helps create high-quality products quickly. If you’re interested, explore more about how these machines work and consider how they can benefit your projects. Understanding this technology can give you a great advantage!

FAQs

What Are The Key Benefits Of Automating Precision Metal Lathes In Manufacturing Processes?

Automating precision metal lathes helps us make things faster and more accurately. Machines can work without stopping, which saves time. We also reduce mistakes, so our products are better. Plus, it can lower costs since we need fewer workers for simple tasks. Overall, automation makes our work easier and helps us create high-quality items.

How Does The Integration Of Cnc Technology Enhance The Capabilities Of Precision Metal Lathes?

CNC technology, which stands for Computer Numerical Control, helps metal lathes work better. With CNC, machines can make very precise cuts. This means we can create metal pieces that fit together perfectly. It also allows us to make complicated shapes easily. Overall, CNC makes metal lathes faster and more accurate.

What Types Of Materials Are Most Commonly Processed Using Automated Precision Metal Lathes, And How Does Automation Affect Their Machining?

Automated precision metal lathes often work with materials like steel, aluminum, and brass. These metals are strong and are used in many things, like cars and machines. Automation means the machines can work faster and make fewer mistakes. This helps us create more parts quickly and safely. Overall, automation makes metalworking easier and better!

What Are The Challenges And Considerations When Implementing Automation In Existing Precision Metal Lathe Setups?

When we add automation to metal lathes, we face some challenges. First, we need to make sure new machines fit with the old ones. Sometimes, they don’t work well together. Second, training workers to use automation is important. We want everyone to feel confident and safe. Finally, we must keep the machines maintained so they work properly all the time.

How Can Machine Learning And Ai Be Used To Optimize The Performance And Efficiency Of Automated Precision Metal Lathes?

Machine learning and AI can help metal lathes make better parts. They can learn from past work to find the best settings. This means less waste and faster production. We can also use them to predict problems before they happen. This helps keep everything running smoothly and saves time.