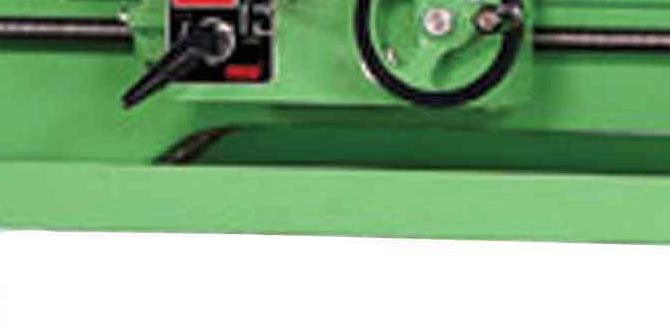

Have you ever seen a metal lathe in action? It’s a fascinating machine that shapes metal parts. Imagine a tool that spins fast and carves metal like a chef slicing vegetables. That’s a precision metal lathe!

But what makes a lathe even more exciting? The power feed. This feature lets the lathe move automatically. You can create perfect shapes without using much effort. Wouldn’t it be amazing to just press a button and watch as the lathe works?

Many hobbyists and professionals love using a precision metal lathe with a power feed. It saves time and makes work easier. Did you know that these lathes can help you build everything from model airplane parts to engine blocks?

Join us as we dive into how a precision metal lathe power feed works, why it’s important, and how it can change your metalworking experience forever!

Precision Metal Lathe Power Feed: Enhance Your Machining Skills

Precision Metal Lathe Power Feed

Precision metal lathes with power feed make machining easier and more efficient. They allow for smoother, controlled movement of the cutting tool, which means better accuracy. Imagine making perfect parts without constantly adjusting your machinery! Did you know that using power feed can reduce fatigue during long projects? This feature helps keep your work steady and consistent. So, if you’re serious about metalworking, a precision metal lathe with power feed might be your new best friend!Understanding Power Feed Systems

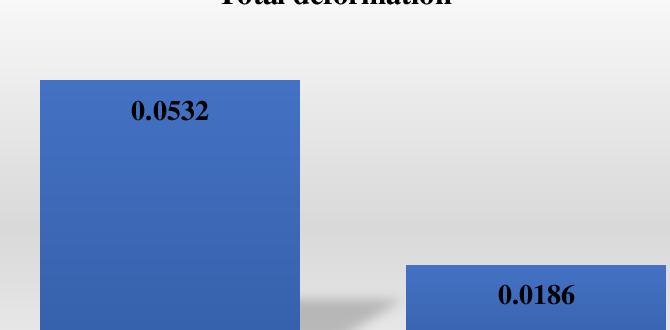

Explanation of power feed and its importance. Comparison of manual vs. power feed systems in machining.Power feed systems make machining smoother and quicker. They help move the workpiece or tool automatically instead of needing a human hand. This means less fatigue and more time for snacks! The difference between manual and power feed systems can be shocking. Manual feeds need constant attention, while power feeds do the work for you—like having a robot buddy in the shop.

| Feature | Manual Feed | Power Feed |

|---|---|---|

| Ease of Use | Requires constant effort | Automatic movement |

| Speed | Slower | Faster production |

| Fatigue Level | High fatigue | Low fatigue |

In short, power feed systems are like upgrading from a bicycle to a motorcycle. You’ll get there faster and have more energy for the fun stuff!

Advantages of Power Feed in Precision Metal Lathes

Improved accuracy and surface finish. Enhanced productivity and efficiency.Using a power feed in precision metal lathes brings many advantages. First, it improves accuracy and surface finish. This means your projects will look smoother and better! Second, it boosts productivity. You can finish your work faster and with less effort, like a superhero but with a lathe instead of a cape. Additionally, it helps reduce fatigue since you don’t have to crank the handle all day. More time for snacks!

| Advantages | Benefits |

|---|---|

| Improved Accuracy | Smoother Surface Finish |

| Enhanced Productivity | Less Physical Strain |

Key Features of Precision Metal Lathe Power Feed

Types of power feeds (automatic, variable speed). Control mechanisms and their significance.Power feeds are like the magic wands of precision metal lathes! They make cutting metal a breeze. There are two main types: automatic and variable speed. Automatic feeds do the work for you, so you can sip your coffee and relax. Variable speed lets you adjust the feed rate, giving you more control, like a DJ mixing tunes. Good control mechanisms are key. They help you get the perfect finish every time. Who knew metal work could be this fun?

| Type | Description |

|---|---|

| Automatic | Feeds automatically for smooth operation. |

| Variable Speed | Allows speed adjustments for precision cutting. |

Installation and Setup of Power Feed on Metal Lathes

Stepbystep guide to installing power feed systems. Common challenges encountered during installation.Installing a power feed on your metal lathe can be exciting. Follow this simple guide for a smooth setup:

- Gather your tools and power feed unit.

- Disconnect the lathe from power to ensure safety.

- Mount the power feed according to the instructions provided.

- Connect the wiring and ensure all parts fit securely.

- Test the system for smooth operation.

Common challenges include alignment issues and electrical connections. Ensure everything lines up perfectly. If parts don’t fit, check the manual. Remember, having patience helps you successfully complete the installation!

What are common challenges when installing a power feed system?

Common challenges include: misalignment, improper wiring, and unclear instructions. Ensure you follow all steps precisely. Have a friend help you if certain tasks prove difficult.

Maintenance Tips for Power Feed Systems

Regular maintenance practices to ensure longevity. Troubleshooting common issues with power feed systems.Keeping your power feed system in top shape is like giving your pet goldfish a clean bowl. Regular checks make sure everything runs smoothly. Lubricate moving parts every few weeks; it’s the oil that keeps the fun going! If something goes wrong, check connections and belts first. A loose screw is often the culprit—like leaving your shoelaces untied. Here’s a quick guide:

| Maintenance Task | Frequency |

|---|---|

| Lubricate moving parts | Every 2 weeks |

| Check connections | Monthly |

| Tighten screws | Monthly |

With these easy steps, your power feed system will be as happy as a dog with two tails!

Choosing the Right Power Feed for Your Precision Metal Lathe

Factors to consider when selecting a power feed system. Recommendations for brands and models.Choosing the right power feed system for a precision metal lathe can feel like a tricky puzzle. First, you need to think about the size of your lathe and the type of projects you’re tackling. Some brands are known for being top-notch, like Grizzly and Sherline. They offer reliable systems that won’t let you down, kind of like your favorite superhero! Here’s a quick look at some popular options:

| Brand | Model | Features |

|---|---|---|

| Grizzly | G0781 | Heavy-duty, variable speed |

| Sherline | 4100 | Compact, easy to use |

| Harbor Freight | 60588 | Affordable, good for beginners |

Don’t forget to check reviews! The right power feed can turn a tough task into a smooth ride, much like riding a bike instead of running a marathon!

Real-World Applications of Precision Metal Lathe Power Feed

Industries that benefit from power feed lathes. Case studies highlighting successful applications.Many industries utilize precision metal lathe power feeds. These machines help create various parts with high accuracy. Here are some key fields that benefit:

- Aerospace: Produces engine parts that must fit perfectly.

- Automotive: Makes engine components and transmission parts.

- Manufacturing: Creates tools and gears for many products.

In certain cases, companies saved time and improved quality with power feeds. For example, one automotive company increased its production speed by 30%. This result helped them meet customer demand faster.

What industries use power feed lathes?

Power feed lathes are used in industries such as aerospace, automotive, and manufacturing for creating precise parts efficiently.Future Trends in Precision Metal Lathe Power Feed Technology

Innovations on the horizon in power feed systems. Predictions for the evolution of precision metal lathes.Exciting changes are coming for power feed systems in precision metal lathes! Imagine having machines that can think for themselves. New smart technologies will help these lathes work with less human help. This means quicker and smoother operations, like a dancer gliding across the floor. Experts predict that soon, machines will be able to learn and adapt to different jobs, just like a chameleon changes color!

| Future Innovations | Predicted Changes |

|---|---|

| Smart Automation | No human needed! |

| Faster Operations | Like zooming cars! |

| Adaptive Functions | Chameleon-like skills! |

With these upgrades, the future of precision metal lathes will be as exciting as a rollercoaster ride. Manufacturers will create more efficient systems, saving time and money. So, if you think metal lathes are cool now, just wait for what’s next!

Conclusion

In conclusion, a precision metal lathe power feed makes your machining tasks easier and more accurate. It automates movements, saving you time and effort. If you want to improve your projects, consider using a power feed system. You can read more about different models online or visit a local workshop to see one in action. Happy machining!FAQs

What Are The Main Components Of A Precision Metal Lathe Power Feed System And How Do They Function Together?A precision metal lathe power feed system has a few key parts. First, there’s the motor, which gives power to the system. Next, there are gears that help control how fast or slow the lathe moves. Lastly, there are levers that you can pull to switch the feed on or off. Together, these parts let the lathe cut metal smoothly and quickly while you work.

How Does The Power Feed Mechanism Enhance The Efficiency And Accuracy Of Cutting Operations On A Precision Metal Lathe?The power feed mechanism helps make cutting on a metal lathe easier and more precise. It moves the tool automatically, so you don’t have to do it by hand. This means the tool cuts evenly and smoothly each time. It saves time and energy, letting you make better parts faster. You get more accurate pieces without mistakes!

What Are The Differences Between Automatic And Manual Power Feed Controls In Precision Metal Lathes, And What Are The Advantages Of Each?Automatic power feed controls move the tool for you. This means you can work faster and make smoother cuts. Manual power feed lets you control everything by hand. This offers more precision and is good for small adjustments. Each type has its benefits depending on what you need to do.

How Do You Properly Maintain And Troubleshoot A Power Feed System On A Precision Metal Lathe To Prevent Downtime?To keep the power feed system on a metal lathe working well, check it often. Look for loose wires or parts that are dirty. You should clean any dirt or oil to stop problems. If something isn’t working right, turn off the machine and check the manual for help. It’s like taking care of a toy; you want it to last and work perfectly!

In What Applications Would A Precision Metal Lathe With Power Feed Be Preferred Over One With Only Manual Feed Capabilities?A precision metal lathe with power feed is great for making many similar parts quickly. It helps us do the same job over and over without getting tired. We can work faster and more accurately, especially for big projects. This type of lathe is helpful in factories or workshops where we need to make lots of pieces. Power feed lets us focus on other things while the machine does its job.