Have you ever wondered how machines shape metal so precisely? One key player in this process is the precision metal lathe pulley. This small yet powerful component helps control the speed and movement of lathes. Imagine trying to carve a masterpiece from a block of metal without the right tools. It would be challenging, right?

The precision metal lathe pulley plays a vital role in making this easier. It allows craftsmen to cut, shape, and polish metal with great accuracy. Did you know that even slight changes in this pulley can affect the final product? It’s fascinating how something so small can make such a big difference.

As you read on, you’ll discover more about how precision metal lathe pulleys work. You’ll also learn why they are essential for anyone working with metal. Whether you’re a hobbyist or a professional, understanding this component can greatly enhance your skills. Let’s dive deeper into the world of precision engineering!

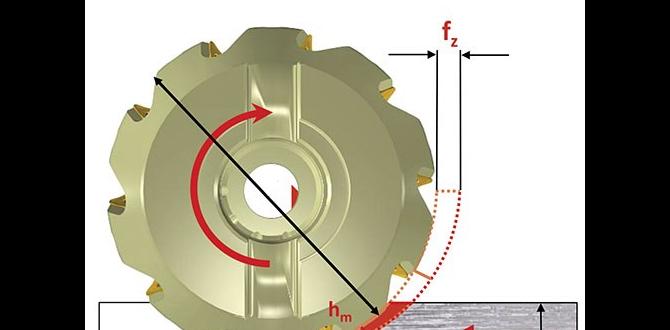

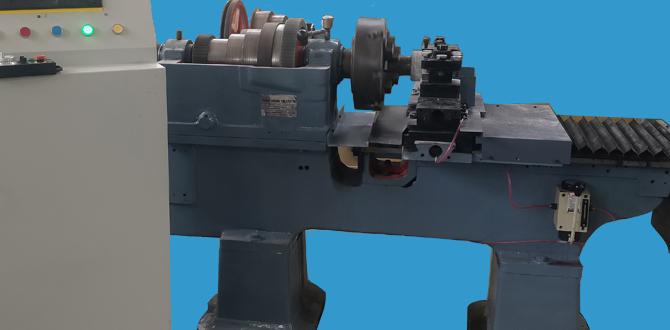

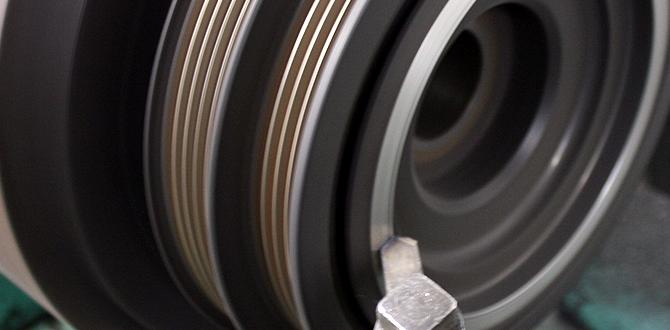

Precision Metal Lathe Pulley: Essential For Your Projects — When It Comes To Metalworking, The Precision Metal Lathe Pulley Plays A Crucial Role In The Efficiency And Accuracy Of Various Machining Tasks. This Component Is Integral To The Operation Of Lathes, Helping To Transfer Power And Manage Speed Effectively. Understanding Its Function And Features Can Significantly Enhance Your Machining Experience. What Is A Precision Metal Lathe Pulley? A Precision Metal Lathe Pulley Is A Circular Device Used On Lathes To Enable The Rotation Of The Workpiece. It Operates In Conjunction With A Belt Or Chain, Helping To Optimize The Lathe’S Performance By Transferring Rotational Energy From The Motor To The Spindle. The Precision And Accuracy Of These Pulleys Are Vital For Achieving The Desired Dimensions And Finishes On Machined Parts. Importance Of Precision Precision In Metalworking Cannot Be Overstated. A Quality Precision Metal Lathe Pulley Ensures That Your Lathe Operates Smoothly Without Slippage Or Loss Of Power. This Precision Is Crucial For Producing Parts With Tight Tolerances, Which Is Often Required In Industries Such As Aerospace, Automotive, And Manufacturing. Key Features To Consider When Selecting A Precision Metal Lathe Pulley, Consider The Following Features: – **Material**: Look For High-Quality Materials Such As Aluminum Or Steel, Which Provide Durability And Minimized Wear. – **Size And Compatibility**: Ensure That The Pulley Fits Your Specific Lathe Model And Matches The Required Specifications For Your Projects. – **Design**: A Well-Designed Pulley Reduces Vibration And Enhances Stability, Contributing To Smoother Operation. Maintenance Tips To Prolong The Life Of Your Precision Metal Lathe Pulley And Enhance Its Performance, Regular Maintenance Is Essential. Here Are A Few Tips: – **Regular Inspection**: Check For Signs Of Wear Or Damage Periodically. – **Proper Lubrication**: Apply Appropriate Lubricant To Reduce Friction. – **Belt Tension Adjustment**: Ensure That The Belt Connected To The Pulley Is Properly Tensioned To Prevent Slippage. Conclusion Choosing The Right Precision Metal Lathe Pulley Can Significantly Impact The Quality Of Your Metalworking Projects. By Understanding The Crucial Role It Plays And Considering The Important Features, You Can Optimize Your Lathe’S Performance And Achieve Better Results In Your Machining Tasks. Whether You’Re A Hobbyist Or A Professional, Investing In Quality Components Like Precision Pulleys Will Undoubtedly Pay Off In The Long Run.

Precision Metal Lathe Pulley

A **precision metal lathe pulley** plays a vital role in metalworking. It helps control the machine’s speed and movement. Imagine shaping metal like clay! This pulley ensures that everything runs smoothly, making intricate designs possible. Did you know that a well-calibrated pulley can prevent costly mistakes? Understanding how pulleys work can help anyone interested in metal crafts. Whether you’re a beginner or a pro, this tool is essential for high-quality projects.Types of Precision Metal Lathe Pulleys

Description of different materials used (e.g., steel, aluminum). Comparison of fixed vs. adjustable pulleys.There are different types of pulleys used in precision metal lathes. They can be made from materials like steel and aluminum. Steel is strong, while aluminum is lightweight. Both have their own benefits. Pulleys can be fixed or adjustable. Fixed pulleys stay in one place, while adjustable ones can change position. This makes adjustable pulleys more flexible for different tasks. Knowing these differences helps you choose the right pulley for your project.

What materials are used for precision metal lathe pulleys?

Steel is strong and durable. Aluminum is light and resistant to rust. Choosing one depends on your needs.

Fixed vs. Adjustable Pulleys: Which is better?

- Fixed Pulleys: Stay in one spot; easy to use.

- Adjustable Pulleys: Can change position; more versatile.

Key Features to Consider

Importance of size and compatibility with lathe machines. Discussing load capacity and strength requirements.Choosing the right size and compatibility for a precision metal lathe pulley is very important. It must fit your lathe machine perfectly. If it’s too big or too small, it won’t work well. Pay attention to its load capacity. It should be strong enough to handle the work you do. Here are key points to remember:

- Check the pulley size for a snug fit.

- Ensure load capacity matches your lathe’s needs.

- Look for strong materials for durability.

What is the load capacity of a precision metal lathe pulley?

The load capacity of a precision metal lathe pulley varies, but many can handle weights between 200-500 pounds, depending on the size and material used. Always check the specifications to find the right fit for your projects.

Benefits of Using Precision Metal Lathe Pulleys

Enhancing machining efficiency and accuracy. Minimizing wear and tear on machinery.Using precision metal lathe pulleys offers many advantages. These pulleys help machines work better and faster by improving efficiency. They make sure each cut is precise, which increases accuracy. This means less time wasted on mistakes!

Also, these pulleys reduce wear and tear on your machinery. When parts fit perfectly, they last longer. This saves money on repairs and replacements.

- Boosts machining efficiency

- Enhances cutting accuracy

- Minimizes machinery wear

- Reduces repair costs

What makes precision metal lathe pulleys special?

They improve machine performance and extend machinery life. This saves time and money over time.

Installation Process for Precision Metal Lathe Pulleys

Stepbystep guide to installing pulleys on a lathe. Common mistakes to avoid during installation.Installing a precision metal lathe pulley can be simple if you follow each step. Start by turning off the lathe. Next, remove the old pulley gently. Then, clean the surface to ensure a snug fit. Place the new pulley on the shaft and secure it tightly. Finally, double-check alignment.

Here are some common mistakes to avoid:

- Not turning off the machine first.

- Failing to clean the surface.

- Over-tightening the screws.

- Ignoring alignment issues.

What is an important tip for installation?

Always consult the manual before starting installation. This helps you understand specific requirements for your lathe model. A little guidance goes a long way!

Maintenance Tips for Longevity

Regular inspection routines and what to look for. Lubrication and cleaning techniques to extend pulley life.Keeping your pulley in top shape is easy with some love and routine checks. First, look for any signs of wear or damage. Are there any unusual sounds? If your pulley sounds like a cat in a blender, it’s time to investigate! Regularly clean it with a soft cloth to remove dust and dirt. Remember to lubricate the moving parts with oil that won’t make it slippery, or you’ll be in a *sticky* situation! Want to keep track? Here’s a handy inspection table:

| Inspection Routine | What to Look For | How to Address |

|---|---|---|

| Visual Check | Signs of wear or cracks | Replace if needed |

| Noise Test | Unusual sounds | Investigate source |

| Cleaning | Dust and debris | Wipe down with a cloth |

| Lubrication | Dry parts | Apply suitable oil |

Stick to these tips, and your precision metal lathe pulley will thank you with a long, happy life!

Common Issues and Troubleshooting

Identifying signs of wear or malfunction. Solutions for common pulleyrelated problems.Watch out for signs that your precision metal lathe pulley is not working right. You may hear strange noises or see uneven movement. These signs mean it might be worn out or broken. Check for loose belts or damaged parts, as they are common issues. Here’s how to fix common problems:

- Tighten any loose parts to improve performance.

- Replace worn-out belts to ensure smooth operation.

- Lubricate the pulley regularly to keep it working well.

Taking these steps can make your work easier and your projects better!

What are signs of wear in a pulley?

Common signs include unusual noises, vibrations, and uneven speed. These can show your pulley needs attention.

How can I fix pulley issues?

Regular checks, replacing worn parts, and lubrication help resolve many problems.

Where to Buy Precision Metal Lathe Pulleys

Recommended suppliers and manufacturers. Factors to consider when purchasing (e.g., quality, warranty).Finding a good place to buy precision metal lathe pulleys is important. Check out these recommended suppliers for quality products:

- Local hardware stores

- Online marketplaces like Amazon

- Specialty machine parts suppliers

When buying, keep these factors in mind:

- Quality of material

- Warranty offers

- Customer reviews

Good quality means lasting parts. A strong warranty can save you money later. Researching sellers helps you find the best deals.

Where can I find precision metal lathe pulleys?

You can buy precision metal lathe pulleys at local hardware stores, online shops, or specialty retailers. Each option offers different prices and quality levels.

Case Studies: Precision Metal Lathe Pulley in Action

Realworld applications and user testimonials. Success stories highlighting efficiency gains with precision pulleys.Precision metal lathe pulleys are game-changers in many industries. They improve efficiency and save time. Let’s see how real users benefit:

- One company reported a 25% increase in production speed after switching to precision pulleys.

- A workshop shared that their machines ran quieter and smoother, leading to fewer breakdowns.

- Many users say they noticed less wear and tear on their tools, extending their lifespan.

These success stories prove how much impact precision metal lathe pulleys have in real-world applications.

What are the benefits of precision metal lathe pulleys?

Precision metal lathe pulleys provide efficiency, enhance machine performance, and reduce maintenance costs.

Conclusion

In summary, a precision metal lathe pulley is vital for smooth machine operation. It helps regulate speed and improve accuracy. You can use it for various projects, making your work easier. If you’re interested, consider trying one for your next project. Check out more resources to learn about its features and benefits. Explore and enjoy your metalworking journey!FAQs

What Are The Key Specifications To Consider When Selecting A Precision Metal Lathe Pulley For A Specific Machining Application?When choosing a pulley for a metal lathe, you need to think about size first. The diameter affects how fast your machine runs. Next, you should look at the weight, as heavier pulleys can be stronger. Also, check the material; good options are steel or aluminum for strength. Finally, make sure it fits your lathe perfectly so everything works smoothly.

How Does The Material Composition Of A Precision Metal Lathe Pulley Impact Its Durability And Performance?The material of a precision metal lathe pulley shapes how strong and effective it is. If a pulley is made from strong metal, it lasts longer and can handle heavy work. A weaker material might break or wear out quickly. So, choosing the right material helps the pulley to work well and stay safe.

What Are The Advantages Of Using A Precision Metal Lathe Pulley Compared To Other Types Of Drive Mechanisms In Machining?Using a precision metal lathe pulley is really helpful in machining. First, pulleys give you better speed control, so you can turn the metal just right. They are also strong and last a long time, which means you won’t have to replace them often. Plus, pulleys run smoother than other types, making less noise while you work. This helps us focus on creating awesome things!

How Can Proper Maintenance And Care Of Precision Metal Lathe Pulleys Extend Their Lifespan And Ensure Accuracy In Machining?Taking care of precision metal lathe pulleys helps them last longer and work better. You should clean them regularly to remove dust and dirt. Lubricating the pulleys keeps them moving smoothly without getting stuck. When they are well-maintained, they help make accurate cuts in metal. This means your projects will come out just right!

What Are Common Troubleshooting Techniques For Issues Related To Precision Metal Lathe Pulleys, Such As Slipping Or Misalignment?To fix slipping or misalignment in metal lathe pulleys, you can start by checking if they are tight. You should make sure all bolts and screws are secure. If they look off, adjust them until they line up correctly. Regularly clean the pulleys to remove dust or grease. This keeps everything running smoothly.