Have you ever wondered how metal parts become so precise? Imagine a machine that can cut metal with extreme accuracy. That’s where the precision metal lathe quill comes into play.

The quill is a part of the lathe that helps make those fine adjustments. It moves in and out to control the depth of cut. This tool allows craftsmen to create beautiful and exact shapes.

Did you know that precision lathes have been around since the 1700s? Back then, they were made by hand and required great skill. Today, they are more advanced and user-friendly.

Think about all the gadgets and machines we use today. They all rely on exact parts made by tools like the precision metal lathe quill. Isn’t it amazing how technology helps us create things we use every day?

In this article, we will explore how the quill works and why it is so important. Let’s dive into the fascinating world of metalworking together!

Precision Metal Lathe Quill: Understanding Its Importance

Understanding the Precision Metal Lathe Quill

The precision metal lathe quill is essential for your machining tasks. It holds tools securely in place, ensuring accuracy while working. Have you ever wondered how tools can spin so finely? The quill allows for precise adjustments, allowing for better control during projects. By using a quill, you can achieve smoother finishes and tighter tolerances. This part might seem small, but its role is crucial for quality machining. Now, who wouldn’t want those perfect cuts?What is a Precision Metal Lathe Quill?

Definition and function of a quill. Importance in metalworking and precision machining.A precision metal lathe quill is an important tool in metalworking. It holds the cutting tool and helps with precise movements. This part moves up and down, allowing for exact cuts on metal pieces. Without a quill, it would be hard to shape metals accurately. Its role is crucial in making sure that each piece is made with care and precision, leading to better quality work.

What does a precision metal lathe quill do?

The quill allows for:

- Controlled movement: It guides the tool smoothly while cutting.

- Precision: It ensures cuts are accurate and evenly spaced.

- Efficiency: It helps speed up projects by making work easier.

Key Features of Precision Metal Lathe Quills

Essential specifications to look for (e.g., size, material). Impact of quality features on performance and accuracy.Choosing the right precision metal lathe quill is exciting! Look for these key features:

- Size: Make sure it fits your lathe machine.

- Material: High-quality materials like steel mean more strength.

- Accuracy: A good quill helps make precise cuts.

Quality features boost your machine’s performance. With a top-notch quill, you can work faster and with less effort. This means your projects turn out better!

What should I check when buying a precision metal lathe quill?

Before you buy, check the size and material. These help your lathe work well. Strong materials also ensure long-lasting use.

How to Choose the Right Quill for Your Metal Lathe

Considerations based on application and projects. Recommendations for various skill levels (beginner to expert).Choosing a quill for your metal lathe is important. It can affect your work. Here are some points to think about:

- Consider your projects. Will you work on small or big parts?

- Think about your skill level. Beginners might choose simpler models, while experts may want advanced features.

- Check the material types you will use. Different materials may need different quills.

Each choice can help you make better projects. So pick wisely!

What should beginners look for in a quill?

Beginners should choose a simple quill with easy controls. This makes learning easier and helps build confidence.

Tips for different skill levels:

- Beginner: Basic quill with fewer options.

- Intermediate: Quill with adjustable settings.

- Expert: Advanced quill with high precision.

Installation and Setup of a Metal Lathe Quill

Stepbystep installation process. Common mistakes to avoid during setup.To set up your metal lathe quill, follow these steps carefully: 1. Gather your tools. 2. Secure the lathe. 3. Install the quill into the spindle. 4. Tighten all screws. Make sure everything is level and straight.

Be careful! Common mistakes include:

- Not checking for looseness.

- Failing to align the quill properly.

- Skipping safety measures.

What is the best way to install a metal lathe quill?

The best way to install a metal lathe quill is to follow step-by-step instructions carefully and check for proper alignment. This ensures safe and effective use.

Maintenance Tips for Longevity and Performance

Best practices for cleaning and care. Troubleshooting common issues related to quills.Proper care keeps your precision metal lathe quill working well. Here are some best practices to follow:

- Clean the quill with a soft cloth regularly.

- Check for rust and remove it promptly.

- Keep bearings lubricated for smooth operation.

- Store it in a dry place to prevent damage.

If you face issues, try these troubleshooting tips:

- Check for misalignment if it doesn’t move smoothly.

- Inspect the motor for any unusual noises.

- Look for loose screws or parts causing problems.

Your quill can last long with these simple steps!

What are common issues with precision metal lathe quills?

Common issues include misalignment, rust, and unusual noises from the motor.How can I fix misalignment?

Realign the quill carefully and check all screws for tightness.Enhancing Precision with Upgraded Quills

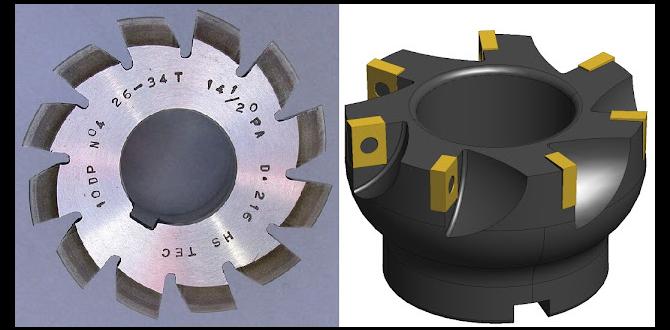

Discussion of aftermarket versus OEM quills. Performance benefits of highquality upgrades.Finding the right quill can feel like searching for a needle in a haystack. Aftermarket quills often offer better performance than OEM options; they’re like the superhero version of your standard equipment! Upgraded quills lead to smoother operations and enhanced accuracy. Imagine turning metal parts with precision as sharp as your wit! In fact, high-quality upgrades can make your lathe work so well that even the metal might start to giggle.

| Quill Type | Benefits |

|---|---|

| OEM Quills | Standard performance, familiar design |

| Aftermarket Quills | Improved precision, enhanced durability |

Real-World Applications of Precision Metal Lathe Quills

Examples of industries that rely on precision quills. Case studies demonstrating effectiveness in various projects.Many industries lean on precision metal lathe quills for their work. For example, automotive and aerospace companies use quills to make exact parts. In a case study, a car maker improved production by 30% after using advanced quills. They made parts faster and with fewer mistakes. Medical equipment manufacturers rely on these tools too, ensuring patient safety with reliable components. Precision is the name of the game, and quills help keep it on point!

| Industry | Use of Precision Quills | Effectiveness |

|---|---|---|

| Automotive | Producing precise engine components | 30% faster production |

| Aerospace | Creating lightweight parts | High safety standards |

| Medical | Making surgical tools | Enhanced reliability |

Conclusion

In summary, a precision metal lathe quill is vital for accurate machining. It helps you control depth and precision. Learning to use it correctly improves your projects significantly. Always choose quality tools for the best results. To enhance your skills, consider reading guides or watching videos on lathe techniques. Dive in and start creating amazing metalwork today!FAQs

What Are The Primary Functions Of A Quill In A Precision Metal Lathe?A quill in a precision metal lathe helps us move tools up and down. It makes it easier to cut and shape metal pieces. We can also adjust the depth of the cut by using the quill. This way, we get the right size and shape for our projects.

How Does The Design Of A Quill Affect The Accuracy And Finish Of Machined Parts?The design of a quill helps control how tools cut metal parts. If a quill is strong and steady, it makes more accurate shapes. This means the parts fit better together. A well-made quill also helps the finish look nice and smooth. So, a good quill is important for making good machines!

What Materials Are Commonly Used To Manufacture Quills For Precision Metal Lathes?Quills for precision metal lathes are usually made from strong metals like steel or aluminum. These materials are tough and help the quills last a long time. Sometimes, they use plastic for lighter quills. We want the quills to be strong and easy to use when working with metal.

How Can One Properly Maintain And Align The Quill On A Metal Lathe For Optimal Performance?To keep the quill on a metal lathe working well, you should first clean it regularly. Use a soft cloth to remove dust and dirt. Next, check if the quill moves smoothly; if not, you may need to lubricate it. Finally, make sure the quill is straight by using a level or ruler. Doing this will help the lathe work better!

What Are The Common Issues That Can Arise With The Quill In A Precision Metal Lathe, And How Can They Be Resolved?When using a quill in a precision metal lathe, you might see some problems. One issue is if the quill gets stuck. You can fix this by cleaning it and adding some oil. Another problem is if it’s not lined up right, which can cause uneven cuts. Make sure to adjust the quill so it’s straight before starting your work.