Have you ever wondered how machines can make things faster and better? Imagine a world where metal lathes could do their job with little help. That’s where automation comes in!

Many people love machines because they are cool and powerful. A metal lathe is one of those machines. It can shape metal into many useful parts. But what if we could make it even smarter? With reviews of metal lathe automation, we can discover how these tools are changing the game.

Did you know that metal lathes used to take a lot of time and effort to operate? With automation, we now see greater accuracy and speed. This means more fun for hobbyists and professionals alike. Imagine finishing a project faster than ever before!

So, are you ready to learn how automated metal lathes can change your work? Dive into the exciting world of machine reviews. You won’t want to miss the amazing possibilities that await!

Comprehensive Reviews Of Metal Lathe Automation Systems

Reviews of Metal Lathe Automation

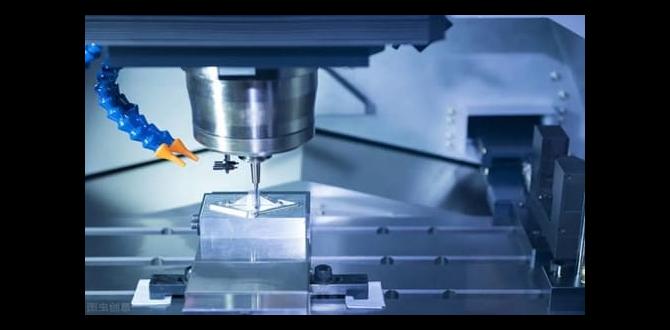

Metal lathe automation makes machining simpler and faster. Users love automated lathes for their efficiency and accuracy. They often share tips on what features are essential, like easy controls and safety options. Reviews highlight that automation can improve a workshop’s productivity. Imagine finishing tasks in half the time! Many users also enjoy the upgrade options available today. With a growing community, learning from others’ experiences can help you make the best choice.Understanding Metal Lathe Automation

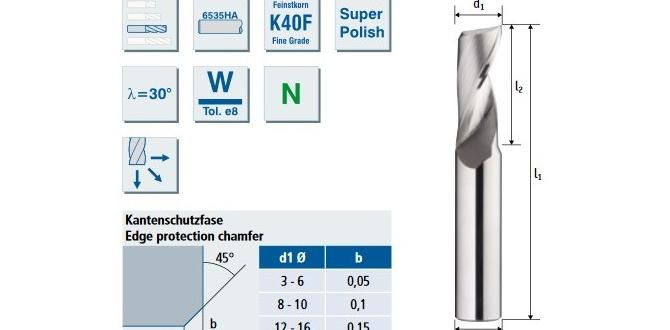

Definition of metal lathe automation and its significance in machining.. Key components and technologies involved in automation..Metal lathe automation helps machines work faster and more accurately. It uses robots and special tools to shape metal parts without much human help. This not only saves time but also reduces mistakes. Key components of automation include:

- CNC (Computer Numerical Control) systems that guide machines automatically.

- Sensors to monitor performance and ensure everything runs smoothly.

- Software to design and control the automation process.

This technology is important in machining because it boosts productivity and consistency, allowing businesses to produce high-quality parts efficiently.

What is the importance of metal lathe automation?

The importance of metal lathe automation lies in its ability to increase production speed, improve precision, and lower operational costs. More companies are using these systems to stay competitive in the industry.

Advantages of Metal Lathe Automation

Increased productivity and efficiency in manufacturing processes.. Enhanced precision and reduced human error..Automating metal lathes brings many benefits. It boosts productivity and makes work faster. With machines doing tasks, factories produce more items in less time. This saves money too. Machines are also very precise. They can create parts with exact shapes, cutting down on mistakes. With less human involvement, the chance of errors decreases. This means better quality products for everyone!

What are the main benefits of metal lathe automation?

The biggest advantages are:

- Higher productivity – Machines work faster than people.

- Greater precision – Automated machines make fewer mistakes.

- Cost savings – More products are made with less waste.

Top Metal Lathe Automation Brands and Models

Detailed review of leading brands in the market.. Comparison of popular models based on features and performance..Many brands make high-quality metal lathe automation tools. Each brand offers unique features and performance. For instance:

- Grizzly: Known for durable machines, ideal for hobbyists.

- Jet: Offers user-friendly controls, great for beginners.

- Smithy: Combines CNC technology with manual use.

- Taiwan: Known for high precision and robust construction.

By comparing these brands, users can find the right tool for their needs. Reviews often highlight the importance of choosing based on specific tasks.

What should I consider when choosing a metal lathe automation?

Consider features like speed, size, and ease of use before buying. Always check reviews to make the best choice!

Cost Analysis of Metal Lathe Automation

Breakdown of initial investment versus longterm savings.. Factors affecting the overall cost of automation in metal lathes..Investing in metal lathe automation can feel like buying a pet elephant—quite the outlay! But think about it: initial costs can be high, but long-term savings often steal the show. Automation boosts efficiency and reduces labor costs over time. Key factors influencing the overall price include the type of machinery, installation, and maintenance. Plus, don’t forget about energy efficiency; machines that sip juice like a goldfish can save big! Here’s a quick comparison:

| Cost Type | Initial Investment | Long-term Savings |

|---|---|---|

| Automation Equipment | $15,000 | Reduction in Labor Costs |

| Setup and Training | $5,000 | Fewer Errors, More Efficiency |

| Maintenance | Annual Costs | Lower Than Manual Machines |

In summary, while your wallet might feel a pinch now, the savings can fill it up later! Remember, good things come to those who wait (and automate)!

Case Studies: Success Stories in Metal Lathe Automation

Highlight of businesses that successfully implemented automation.. Analysis of improvements in productivity and efficiency postautomation..Many businesses have seen fantastic results after jumping on the metal lathe automation train! For example, a small machine shop boosted their production by over 50%. They found that less manual work meant fewer mistakes and more happy customers. Another company reported that their downtime dropped by 30% after implementing automation. Who knew machines could be such great workers? Here’s a peek at some success stories:

| Company | Productivity Increase | Efficiency Improvement |

|---|---|---|

| XYZ Machining | 50% | 30% |

| ABC Manufacturing | 40% | 25% |

| Quick Turn Ltd. | 70% | 35% |

These numbers clearly show that automation is not just a fancy gadget; it’s a game changer!

Future Trends in Metal Lathe Automation

Emerging technologies and innovations shaping the future.. Predictions for the evolution of automation in the metalworking industry..New technologies are changing how we use metal lathes. Automation is becoming smarter and faster. Robots and artificial intelligence help make work easier. They can perform tasks with great precision. Here are some trends to watch:

- Smart Manufacturing: Machines that can talk to each other and work better.

- 3D Printing: New ways to create parts quickly and cheaply.

- Data Analytics: Using data to find ways to improve processes.

Experts predict that in the future, automation will help the metalworking industry grow. This progress will lead to safer workplaces and better products.

What will automation look like in the future?

Automation will likely have machines that learn and adapt. They will understand what to do without much help. This change will make production faster and more efficient.

Conclusion

In conclusion, reviewing metal lathe automation shows it can save time and increase precision. You learn to work smarter, not harder. These tools make projects easier and more fun. We encourage you to explore different models and read user experiences. Start small, and see how automation can improve your metalworking skills today!FAQs

Certainly! Here Are Five Questions Related To The Topic Of Metal Lathe Automation:Sure! Metal lathe automation helps machines work better and faster. It can shape metal pieces without needing much help from people. This makes it easier for us to create things like tools and parts. When machines do more of the work, we can spend time on other fun projects!

Of course! Please provide the question you would like me to answer.

What Are The Primary Benefits Of Automating Metal Lathe Operations In A Manufacturing Setting?Automating metal lathe operations makes things faster and easier. You can produce more products in less time. Machines make fewer mistakes than people, so products are often better. This saves money and helps keep workers safer. Overall, automation helps us work smarter, not harder!

How Do Different Automation Technologies, Such As Cnc (Computer Numerical Control) Systems, Enhance The Precision And Efficiency Of Metal Lathes?Automation technologies like CNC (Computer Numerical Control) make metal lathes work better. They help machines cut metal exactly how we want. With CNC, you can create complex shapes quickly and accurately. This saves time and reduces mistakes. You get more pieces done in less time, which is really cool!

What Are The Common Challenges Faced By Manufacturers When Implementing Automation In Metal Lathe Processes?When we add machines to metal lathes, we can face some problems. First, it costs a lot of money to buy the new machines. Second, some workers might need new training to use the machines properly. Also, machines can break down, which can slow down work. Lastly, we need to make sure the machines work well with the older ones.

How Does The Integration Of Robotics With Metal Lathes Impact Production Speed And Labor Costs?Using robots with metal lathes helps make things faster. Robots can work all day without getting tired. This means we can produce more items in less time. Also, we need fewer people to do the same amount of work, which can lower costs. In short, robots help us make products quicker and save money on workers.

What Key Features Should Manufacturers Look For When Selecting Automated Metal Lathe Equipment To Meet Their Specific Production Needs?When choosing automated metal lathes, look for a few important features. First, check the machine’s speed and power. This helps it cut metal faster and easier. Next, see if it has good safety features to protect you. Finally, make sure it can work with the types of metal you need. These features will help us make better products!