Have you ever wondered how to turn metal into amazing shapes? A metal lathe makes this possible. But to use it properly, understanding the wiring is key. That’s where a reviews metal lathe wiring diagram comes in handy. Imagine trying to create something fantastic, but your machine won’t work. Frustrating, right?

People love sharing their experiences with metal lathes. They describe how a good wiring diagram can save you time and trouble. Some even say it transforms the process from confusing to fun! If you’re eager to learn how to wire your lathe safely, you’re in the right place.

Did you know that many beginners feel lost when they face wires and connectors? Don’t worry! You’re not alone. Understanding how everything connects will make your projects smoother and more enjoyable. Let’s dive into the world of metal lathe wiring diagrams and uncover the secrets together!

Reviews Metal Lathe Wiring Diagram: Essential Insights For Diyers

Understanding Reviews Metal Lathe Wiring Diagram

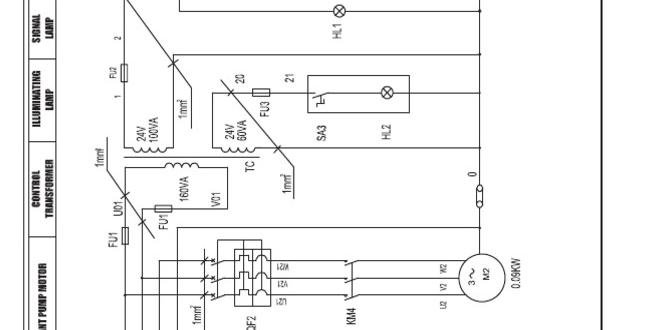

A reviews metal lathe wiring diagram is essential for safe and efficient operation. These diagrams help you understand the connections and configuration needed for various metal lathes. Readers discover the importance of proper wiring to prevent accidents and ensure smooth performance. Did you know that even a small wiring mistake can lead to major problems? With proper guidance from reliable reviews, lathes can operate as intended, helping you create perfect projects every time.Understanding Metal Lathe Wiring Components

Explanation of key components found in metal lathe wiring diagrams.. Importance of each component in the operation of a metal lathe..Metal lathes need many parts to work well. Each part plays a special role. Here are some key components:

- Power Supply: This gives energy to the lathe.

- Motor: It makes the lathe spin fast.

- Switch: This turns the machine on or off.

- Wires: They connect everything and allow energy to flow.

Understanding these parts helps you use a metal lathe safely. Each bit works together, so you can make your projects smoothly.

What are the key components in a metal lathe wiring diagram?

The main components are the power supply, motor, switch, and wiring. Each part ensures that the lathe operates correctly.

Benefits of Using a Wiring Diagram for Your Metal Lathe

How wiring diagrams enhance safety and efficiency during operation.. Common issues that can be resolved with proper wiring diagrams..Using a wiring diagram for your metal lathe has many benefits. It improves safety by showing clear connections, reducing risks. This means fewer accidents and a more secure workspace. It also boosts efficiency, helping machines run smoothly. Common problems like wiring errors can be easily spotted. With a diagram, you can:

- Identify faulty connections.

- Ensure proper power supply.

- Fix issues quickly.

Overall, a wiring diagram is a handy tool for every metal lathe user.

What are common issues that wiring diagrams help fix?

Wiring diagrams help fix problems like short circuits, incorrect voltage, and loose connections. They guide you in troubleshooting and making fixes quickly and safely.

Step-by-Step Guide to Reading Metal Lathe Wiring Diagrams

Tips for interpreting symbols and connections in diagrams.. Common pitfalls to avoid when reading wiring diagrams..Reading metal lathe wiring diagrams can be tricky, but some tips can help. Look for symbols like dots and lines. They show connections and parts. Always confirm colors of wires match what’s shown. Avoid mistakes by not skipping steps. Often, simple errors lead to big problems.

- Check for missing labels.

- Don’t rush through the diagram.

- Double-check your connections.

What are common symbols in wiring diagrams?

Common symbols include power sources, switches, and ground connections. These symbols help you understand how everything connects. Familiarize yourself with these to read diagrams better.

Where to Find Quality Metal Lathe Wiring Diagrams

Recommended resources for obtaining reliable wiring diagrams.. Online platforms and forums for metal lathe enthusiasts..Finding good metal lathe wiring diagrams is essential for safe and effective projects. Many resources are available to help you. Here are some recommended sources:

- Online forums: Websites like Reddit and Practical Machinist have groups where people share tips and diagrams.

- YouTube: Many creators make videos explaining wiring diagrams step by step.

- Manufacturer websites: Check the official sites of your metal lathe for manuals and diagrams.

- Books: Look for books about metalworking that include wiring information.

Using these resources can help you find the plans you need to get the job done right.

Where can you find metal lathe wiring diagrams?

You can find wiring diagrams on many sites. Check online forums, video tutorials on YouTube, and even books on metalworking. These places offer a wealth of information and tips to help you succeed!

DIY Wiring Tips for Your Metal Lathe

Essential tools and materials needed for wiring a metal lathe.. Safety precautions and best practices for DIY wiring projects..Wiring a metal lathe can be fun and rewarding. You need some essential tools and materials to get started:

- Wire cutters

- Wire strippers

- Electrical tape

- Connectors

- Multimeter

Safety comes first! Here are some tips:

- Always wear safety goggles.

- Work in a dry area.

- Disconnect power before starting.

- Read manuals for instructions.

Remember, a little safety goes a long way!

What are common tools for wiring a metal lathe?

The common tools include a wire cutter, wire stripper, electrical tape, and connectors. A multimeter is also helpful to check your work.

Top Reviewed Metal Lathe Wiring Diagrams

Summary of the most popular and effective wiring diagrams available.. User experiences and testimonials regarding specific diagrams..Some popular wiring diagrams make it easy to set up your metal lathe. Users love their clarity and helpful instructions. Here are the top choices:

- Diagram A: Simple steps, user-friendly layout.

- Diagram B: Detailed labeling, great for beginners.

- Diagram C: Community favorite, lots of positive feedback.

People share their stories about how these diagrams made wiring fun and easier. Many said it saved them time and effort. A good wiring diagram can truly change your metal lathe experience!

Why are wiring diagrams important?

Wiring diagrams help you connect parts properly. They show which wire goes where, preventing mistakes. This way, you can work safely and effectively.

Troubleshooting Common Wiring Issues in Metal Lathes

Identification of common wiring problems and their symptoms.. Solutions and fixes for wiringrelated issues in metal lathes..Metal lathes can have wiring issues that may cause problems. Common signs include strange noises, sparks, or the machine not starting. These symptoms could mean loose wires, damaged connections, or a faulty power supply.

- Wires may be frayed or broken.

- Connections could be loose.

- The power supply might not be working.

To fix these issues:

- Check all connections and tighten them.

- Look for damaged wires and replace them.

- Test the power supply to make sure it works.

Addressing these problems will keep your metal lathe running smoothly.

What are the common wiring problems in metal lathes?

The common wiring problems in metal lathes are loose connections, frayed wires, and faulty power supplies. Recognizing these issues quickly can save time and repairs.

Conclusion

In conclusion, understanding a metal lathe wiring diagram is essential for safe operation. It shows how to connect wires correctly. Knowing this helps you avoid mistakes and keep your projects running smoothly. We encourage you to explore more guides and diagrams to enhance your skills. Take the next step and learn about your machine’s wiring today!FAQs

What Are The Key Components Involved In A Metal Lathe Wiring Diagram, And How Do They Interact With Each Other?A metal lathe wiring diagram shows how parts connect to make the machine work. The key components include the motor, power switch, and control box. The motor makes the lathe spin. The power switch turns the machine on and off. The control box helps control the speed and direction of the spinning. All these parts work together to help you shape metal.

How Do I Troubleshoot Common Wiring Issues In A Metal Lathe Using The Wiring Diagram?To troubleshoot wiring issues in a metal lathe, first, find the wiring diagram. This diagram shows how the wires connect. Check for loose or damaged wires by looking closely. If you find a problem, you can fix it or replace the wire. Finally, test the lathe again to see if it works properly.

What Safety Precautions Should Be Taken When Working With The Wiring Of A Metal Lathe?When working with the wiring of a metal lathe, you should always turn off the power first. Use rubber gloves to keep your hands safe from electric shocks. Make sure the area is dry and free of water. Don’t touch any exposed wires, and ask for help if you’re unsure. Always follow the safety rules to stay safe!

Are There Standard Color Codes For Wiring In Metal Lathes, And How Can I Use Them To Ensure Correct Connections?Yes, there are standard color codes for wiring in metal lathes. Usually, red is for power, black is for ground, and green is for safety. You can use these colors to connect wires correctly. Always make sure to match the colors when you connect the wires together. This way, your metal lathe will work safely and well.

What Should I Consider When Modifying Or Upgrading The Electrical System Of My Metal Lathe Based On Its Wiring Diagram?When changing your metal lathe’s electrical system, first check the wiring diagram. Make sure you know where each wire goes. You should use parts that fit your lathe well. Pay attention to safety so you don’t get shocked. Lastly, double-check everything before you plug it in.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Components Involved In A Metal Lathe Wiring Diagram, And How Do They Interact With Each Other? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe wiring diagram shows how parts connect to make the machine work. The key components include the motor, power switch, and control box. The motor makes the lathe spin. The power switch turns the machine on and off. The control box helps control the speed and direction of the spinning. All these parts work together to help you shape metal.”}},{“@type”: “Question”,”name”: “How Do I Troubleshoot Common Wiring Issues In A Metal Lathe Using The Wiring Diagram? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot wiring issues in a metal lathe, first, find the wiring diagram. This diagram shows how the wires connect. Check for loose or damaged wires by looking closely. If you find a problem, you can fix it or replace the wire. Finally, test the lathe again to see if it works properly.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Working With The Wiring Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When working with the wiring of a metal lathe, you should always turn off the power first. Use rubber gloves to keep your hands safe from electric shocks. Make sure the area is dry and free of water. Don’t touch any exposed wires, and ask for help if you’re unsure. Always follow the safety rules to stay safe!”}},{“@type”: “Question”,”name”: “Are There Standard Color Codes For Wiring In Metal Lathes, And How Can I Use Them To Ensure Correct Connections? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are standard color codes for wiring in metal lathes. Usually, red is for power, black is for ground, and green is for safety. You can use these colors to connect wires correctly. Always make sure to match the colors when you connect the wires together. This way, your metal lathe will work safely and well.”}},{“@type”: “Question”,”name”: “What Should I Consider When Modifying Or Upgrading The Electrical System Of My Metal Lathe Based On Its Wiring Diagram? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When changing your metal lathe’s electrical system, first check the wiring diagram. Make sure you know where each wire goes. You should use parts that fit your lathe well. Pay attention to safety so you don’t get shocked. Lastly, double-check everything before you plug it in.”}}]}