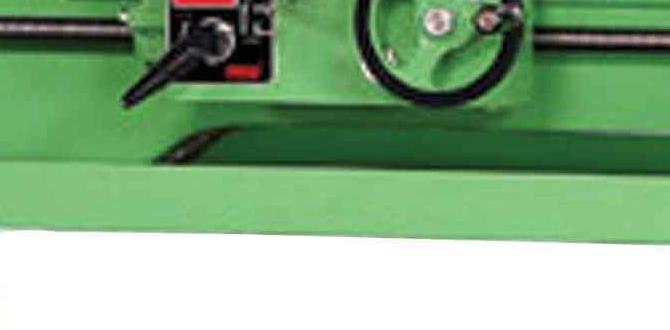

Have you ever dreamed of creating your own projects with a metal lathe? That smooth, powerful machine can help you turn metal into beautiful shapes. But before you start, you need the perfect setup. A good setup guide for your metal lathe bench can make all the difference.

Picture this: you’re in your garage, surrounded by tools and metal scraps. With a well-organized bench, everything you need is within reach. But where do you start? This article will walk you through it step by step.

Did you know that having a solid bench for your metal lathe can improve your work? It can help you avoid mistakes and make your projects easier. Setting it up right keeps your workspace safe and efficient. Let’s explore how to set up your metal lathe bench for the best results.

Essential Setup Guide For Your Metal Lathe Bench

Setup Guide for Metal Lathe Bench

Setting up a metal lathe bench can seem tricky at first. Start by ensuring it’s level for better performance. Did you know that a sturdy bench can make your lathe last longer? You’ll also want to organize your tools within easy reach. This not only saves time but also makes work more enjoyable. Remember, safety is key! Always wear protective gear while operating the lathe for a safer working environment.Choosing the Right Metal Lathe

Types of metal lathes: bench top vs. floor model. Key features to consider: size, horsepower, and precision.Picking the right metal lathe can feel like choosing between pizza or tacos—both are great, but it depends on your taste! You’ll find two main types: the bench top and the floor model. The bench top lathe is compact and perfect for small spaces, while the floor model is bigger and ideal for more heavy-duty tasks. Key features to think about include size, horsepower, and precision. These factors will help you spin like a pro!

| Feature | Bench Top Lathe | Floor Model |

|---|---|---|

| Size | Compact | Large |

| Horsepower | Less powerful | More powerful |

| Precision | Good for small projects | Great for precision work |

Necessary Tools and Equipment

Essential tools for setup: wrenches, levels, and measuring devices. Optional accessories for enhanced functionality: toolholders and chucks.Setting up your metal lathe bench requires some important tools. First, grab your trusty wrenches and levels. These help with making everything fit just right. You don’t want your lathe wobbling like a jelly on a plate! Next, have some measuring devices ready. They ensure your work is precise. For those who want to take it a notch higher, consider optional accessories like toolholders and chucks. They can really boost your lathe’s abilities and make you feel like a machining wizard!

| Essential Tools | Purpose |

|---|---|

| Wrenches | Tightening and adjusting parts |

| Levels | Ensuring stability and balance |

| Measuring Devices | Achieving precise measurements |

With these tools, you’re all set to tackle any project. Just remember, the right tools make all the difference—kind of like having your favorite snack nearby while working! 🍪

Preparing the Workspace

Ideal dimensions and layout for a metal lathe bench. Importance of ventilation and safety precautions in the workshop.Setting up a metal lathe bench is like building your dream workshop. First, grab your tape measure! The ideal size is about 5 to 6 feet long and 2 feet wide. This gives you space to work without bumping your elbows. Don’t forget ventilation; a fresh breeze can save you from strong smells that might make you feel dizzy. Safety is key—make sure to have goggles and gloves handy. A little prep can turn your workspace into a safe, fun zone! 😄

| Dimension | Recommendation |

|---|---|

| Length | 5-6 feet |

| Width | 2 feet |

Keep that workspace tidy! A clean spot helps everyone focus and stay safe. Happy lathe-ing!

Steps to Set Up Your Metal Lathe

Unpacking and inspecting components for damage. Leveling and securing the lathe to the bench.First, carefully unpack your metal lathe. Check each part for any damage. A dented component can be a real mood breaker! Next, find a sturdy bench. Set the lathe on it and make sure it’s level. Use a bubble level tool if you have one. Securing it tightly is key; you don’t want your lathe doing a dance party while you work!

| Step | Action |

|---|---|

| 1 | Unpack and inspect parts |

| 2 | Find a sturdy bench |

| 3 | Level the lathe |

| 4 | Secure the lathe |

Following these steps will help you set up your metal lathe like a pro. Remember, a stable setup leads to better projects!

Electrical Requirements and Setup

Understanding voltage and power needs for different lathes. Safe electrical setups and wiring considerations.Setting up your metal lathe needs some zap from electricity! Most lathes run on 110V or 220V. Higher voltage can mean more power and less time waiting for the magic to happen. This is great if you want to turn raw metal into shiny parts, but make sure your outlet can handle it. Safety first! Always check wiring and use proper fuses. Nobody wants to feel like a light bulb on a bad day!

| Voltage | Power | Common Use |

|---|---|---|

| 110V | 1-2 HP | Small lathes |

| 220V | 3-5 HP | Professional lathes |

Ensure you use good wiring to avoid shocks. Never skimp on safety gear. The last thing you want is a surprise that ends with you needing a new hairstyle! Remember: a well-set electrical system keeps your metal lathe running smoothly and safely.

Maintenance and Care for Longevity

Routine checks and maintenance tasks to perform. Tips for cleaning and preventing rust on your lathe.Keeping your metal lathe happy is key to making it last. Regular checks are a must. Look for loose bolts and clean any chips left behind. If you see rust, it’s time to act! A simple wipe-down with oil can do wonders. Remember, happy lathe equals happy projects!

| Maintenance Task | Frequency |

|---|---|

| Check for tight bolts | Weekly |

| Clean chips and debris | After each use |

| Oil moving parts | Monthly |

| Inspect for rust | Every few months |

For cleaning, a soft cloth does wonders. To keep rust away, store your lathe in a dry spot. A dash of oil every now and then will keep it shiny and rust-free. Remember, a little care goes a long way!

Common Issues and Troubleshooting

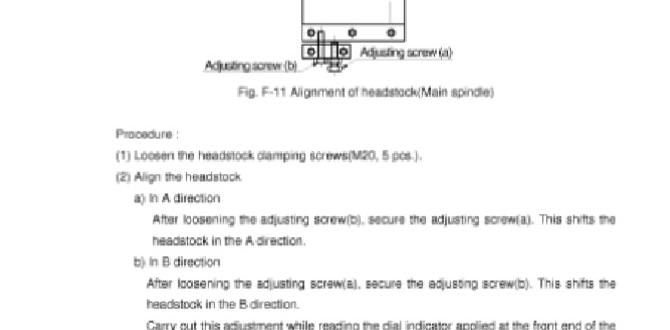

Identifying and resolving common setup problems. When to seek professional help or advice.Setting up a metal lathe bench can be tricky. You might face common problems like misalignment or shaking. These issues can affect your work. Here’s how to fix them:

- Check the Level: Ensure your bench is flat. Use a level tool to check.

- Secure All Parts: Tighten any loose screws or clamps.

- Read the Manual: Always refer to the setup guide for detailed steps.

If problems persist, consider seeking professional help. A skilled technician can save you time and effort. It’s always better to ask for advice when in doubt.

What should I do if I can’t fix the setup issues?

If you can’t solve the problems after trying, contact a pro. They can help you quickly and safely.

Resources for Continued Learning

Recommended books, courses, and online forums. Building a network with local machining clubs and workshops.There are many ways to keep learning about metal lathes. First, grab some recommended books, like “The Metal Lathe” that offer step-by-step instructions. You can also check out online courses that promise to make you a lathe master—who knows, you might even become the “lathe whisperer!”

Joining local machining clubs is a fantastic idea! You can share tips, tell stories, and maybe even swap funny lathe mishaps. Plus, connecting with others can lead to great workshops where you can learn hands-on. Remember, every expert was once a beginner with a “wow, I did that?” face.

| Resource Type | Examples |

|---|---|

| Books | The Metal Lathe, How to Run a Lathe |

| Online Courses | Udemy, Coursera |

| Forums | Practical Machinist, Reddit’s r/Machinists |

The right resources can turn you into a skilled lathe user faster than you can say “chip removal!” So, don’t hesitate to dive in and learn more!

Conclusion

In conclusion, setting up a metal lathe bench is simple with the right steps. First, ensure a sturdy, level surface. Then, organize your tools for easy access. Always follow safety guidelines for a smooth experience. Now that you have these tips, you can start your projects confidently. Consider reading more on metal lathe techniques for even better results!FAQs

Sure! Here Are Five Related Questions On Setting Up A Metal Lathe Bench:To set up a metal lathe bench, first, pick a strong surface that won’t wobble. Next, make sure you have enough space around the lathe to work safely. Then, gather all your tools and keep them nearby. Check that the lathe is level so it works correctly. Lastly, always wear safety gear, like goggles and gloves, when using it.

Sure! Please provide the question you would like me to answer.

What Measurements Should I Take To Determine The Appropriate Size For My Metal Lathe Bench?To find the right size for your metal lathe bench, measure your lathe’s length and width. Add some extra space around it for tools and moving easily. Make sure the bench is strong enough to hold the lathe’s weight. Lastly, check how high the bench should be for you to work comfortably.

How Do I Ensure My Metal Lathe Is Level And Stable Once It Is Placed On The Bench?To make sure your metal lathe is level and stable, start by placing a level tool on top. Adjust the legs or supports until the bubble in the level is in the center. Next, check that the lathe is not wobbling by gently pushing it. If it moves, make more adjustments. Finally, tighten any screws or bolts to keep everything in place.

What Materials Are Recommended For Constructing A Durable And Effective Metal Lathe Bench?To build a strong metal lathe bench, you should use heavy wood or thick steel. These materials make the bench sturdy and prevent it from shaking. You can also add a layer of plywood on top for a flat work surface. Make sure to use strong screws to hold everything together. This way, your lathe will stay in place while you work!

How Should I Organize Tools And Accessories Around My Metal Lathe Bench For Efficiency And Safety?To organize tools around your metal lathe bench, start by keeping frequently used tools close. Use shelves or pegboards to hang them up. Store small accessories, like screws and bits, in labeled boxes. Make sure your workspace is clean and free of clutter. This will help you work safely and quickly!

What Are The Electrical And Power Requirements I Need To Consider When Setting Up My Metal Lathe Bench?When setting up your metal lathe bench, think about power needs first. Check if your lathe needs 110 volts or 220 volts. Make sure you have enough outlets nearby. You also want to use an extension cord that can handle the lathe’s power. Lastly, ensure your bench has good lighting to see what you’re doing!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On Setting Up A Metal Lathe Bench:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe bench, first, pick a strong surface that won’t wobble. Next, make sure you have enough space around the lathe to work safely. Then, gather all your tools and keep them nearby. Check that the lathe is level so it works correctly. Lastly, always wear safety gear, like goggles and gloves, when using it.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Measurements Should I Take To Determine The Appropriate Size For My Metal Lathe Bench?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right size for your metal lathe bench, measure your lathe’s length and width. Add some extra space around it for tools and moving easily. Make sure the bench is strong enough to hold the lathe’s weight. Lastly, check how high the bench should be for you to work comfortably.”}},{“@type”: “Question”,”name”: “How Do I Ensure My Metal Lathe Is Level And Stable Once It Is Placed On The Bench?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure your metal lathe is level and stable, start by placing a level tool on top. Adjust the legs or supports until the bubble in the level is in the center. Next, check that the lathe is not wobbling by gently pushing it. If it moves, make more adjustments. Finally, tighten any screws or bolts to keep everything in place.”}},{“@type”: “Question”,”name”: “What Materials Are Recommended For Constructing A Durable And Effective Metal Lathe Bench?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To build a strong metal lathe bench, you should use heavy wood or thick steel. These materials make the bench sturdy and prevent it from shaking. You can also add a layer of plywood on top for a flat work surface. Make sure to use strong screws to hold everything together. This way, your lathe will stay in place while you work!”}},{“@type”: “Question”,”name”: “How Should I Organize Tools And Accessories Around My Metal Lathe Bench For Efficiency And Safety?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To organize tools around your metal lathe bench, start by keeping frequently used tools close. Use shelves or pegboards to hang them up. Store small accessories, like screws and bits, in labeled boxes. Make sure your workspace is clean and free of clutter. This will help you work safely and quickly!”}},{“@type”: “Question”,”name”: “What Are The Electrical And Power Requirements I Need To Consider When Setting Up My Metal Lathe Bench?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When setting up your metal lathe bench, think about power needs first. Check if your lathe needs 110 volts or 220 volts. Make sure you have enough outlets nearby. You also want to use an extension cord that can handle the lathe’s power. Lastly, ensure your bench has good lighting to see what you’re doing!”}}]}