Have you ever wondered how metal parts are made? Imagine a machine that spins metal really fast, cutting it into shapes. This machine is called a metal lathe. But how do you set one up? That’s where a good setup guide comes in.

In this article, we will explore the exciting journey of metal lathe CAD design. CAD stands for Computer-Aided Design. It helps you create precise drawings and plans. With the right setup, you can bring your designs to life!

Many people think setting up a metal lathe is hard. But it can be simple if you follow the right steps. You’ll learn tips and tricks that make the process smoother. Are you ready to discover how to turn your ideas into real metal pieces?

Let’s dive into the world of metal lathe setup and find out how to use CAD design like a pro!

Setup Guide: Metal Lathe Cad Design For Beginners

Understanding Metal Lathe CAD Design Setup Guide

Setting up a metal lathe with CAD design can be exciting and challenging. This guide covers essential steps to help you create your designs effectively. Learn about choosing the right software and tools to make your lathe work smoothly. Discover how plans can improve your projects, from simple shapes to complex designs. Did you know that precise CAD drawings can save time and material? Start designing with confidence and let your creativity flow!Understanding Metal Lathes

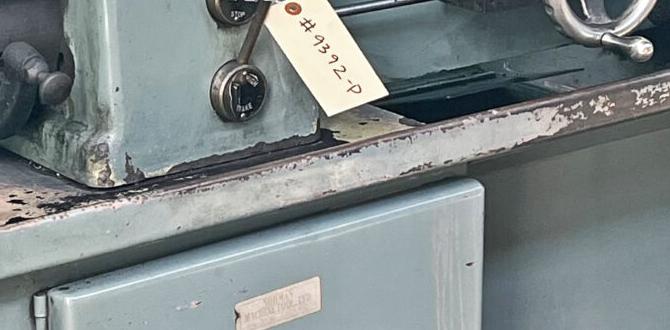

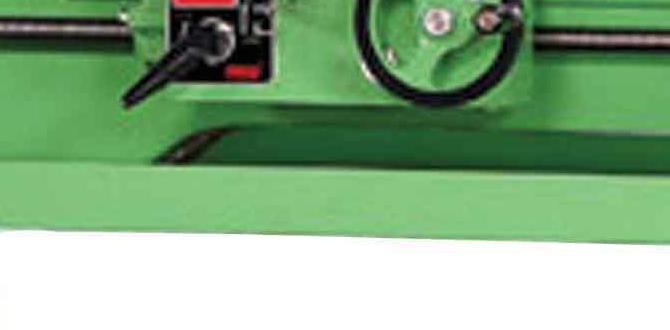

Definition and importance of metal lathes in manufacturing.. Different types of metal lathes and their functionalities..Metal lathes are machines that shape metal into different forms. They are crucial in manufacturing because they help create precise parts for cars, airplanes, and even robots! Think of them as magic wands for metal. There are different types, each with its own tricks to play. Some are big and can handle heavy jobs, while others are compact and perfect for detail work. Here’s a quick look at some common types:

| Type of Lathe | Functionality |

|---|---|

| Engine Lathe | Versatile and great for various tasks |

| CNC Lathe | Uses computer controls for precision |

| Turret Lathe | Good for producing many identical pieces |

Understanding how these machines work can make you the “lathe whisperer” of your workshop! So, grab a wrench and let’s dive in!

Preparing the Workspace

Key considerations for an effective metal lathe workspace.. Safety measures and equipment needed..Creating a great workspace for your metal lathe is like baking a cake—get the ingredients right! First, you need enough room to move around and make cuts without bumping into things. Safety is key. Always have protective gear like goggles and gloves. This will help you dodge mishaps, like that one time Bob almost turned into a metal pancake. So, grab your tools and set up a tidy table. Here’s a quick checklist to get you started:

| Essential Item | Purpose |

|---|---|

| Protective goggles | Protect your eyes from flying debris. |

| Gloves | Keep your hands safe from sharp edges and hot surfaces. |

| Good Lighting | See what you’re doing and avoid slip-ups. |

| Flat surface | Ensure stable, accurate work. |

Remember, a little planning goes a long way, just like adding frosting on that cake!

CAD Software for Metal Lathe Design

Popular CAD software options available for metal lathe design.. Key features and advantages of each software type..Many people use CAD software for metal lathe design. Some popular options include:

- AutoCAD: Great for 2D and 3D designs. It has many tools for precision.

- Fusion 360: This software is cloud-based. It allows collaboration and has modeling features.

- SolidWorks: Known for its strong 3D modeling. It’s widely used in engineering.

Each of these programs has key features. They help create accurate metal lathe designs. Using the right software makes your work easier and faster!

What should I consider when choosing CAD software?

Consider factors like price, ease of use, and features. This helps you select the best software for your metal lathe projects.

Step-by-Step Setup Process

Detailed instructions for assembling and calibrating the lathe.. Tips for troubleshooting common setup issues..Assembling a metal lathe is like putting together a puzzle—exciting but tricky! Start by placing the base on a flat surface. Next, attach the bed securely. Remember to level it; a wobbly lathe is like a duck on roller skates! Calibrating the lathe helps it work perfectly. Check the alignment using a simple ruler. If it doesn’t seem right, don’t panic! Common issues include loose bolts or a misaligned tailstock. Tighten bolts, and adjust the tailstock as needed.

| Common Setup Issues | Quick Fixes |

|---|---|

| Loose bolts | Tighten them up! |

| Misaligned tailstock | Adjust until it’s straight! |

| Inaccurate measurements | Use a level for accuracy! |

Creating Your First CAD Design

Guidelines for initiating a CAD design project specifically for metal lathes.. Best practices for precision and accuracy in designs..Starting a CAD design project for metal lathes can be fun and rewarding. First, plan your design carefully. Think about what you want to create. Gather all your tools before you start. Use software that you find easy to learn. Precision is important, so keep these tips in mind:

- Measure everything twice.

- Use clear labels for parts.

- Double-check angles and dimensions.

- Save your work often.

What are the best practices for precision in CAD design?

Best practices include using the right measurements, checking designs regularly, and using grids to keep everything aligned. These steps help make sure your design works perfectly when you build it!

Maintaining Your Metal Lathe

Regular maintenance tasks to prolong the life of your lathe.. Signs that indicate maintenance is needed..To keep your metal lathe working well, you need to perform regular maintenance. This makes it last longer and work better. Simple tasks you can do include:

- Cleaning the lathe after each use.

- Checking oil levels and adding oil as needed.

- Inspecting parts for wear and tear.

- Adjusting belts and bearings if they seem loose.

Watch for signs that your lathe needs help:

- Unusual noises during operation.

- Inconsistent cutting or vibrations.

- Difficulty during startup.

By staying on top of these tasks, you’ll help your lathe stay in great shape!

What are the signs your metal lathe needs maintenance?

Signs of needed maintenance include unusual noises, vibrations, and difficulties in starting. These signs can indicate problems that may require immediate attention.

Resources and Support

Recommended online communities and forums for metal lathe users.. Educational resources for further learning on CAD design..Many metal lathe users find help in online communities and forums. These spaces allow you to ask questions and share tips. Here are some recommended places:

- Forums: The Metalworking Forum, CNC Zone, or Reddit’s r/Metalworking.

- Community Groups: Facebook groups focusing on metalworking.

- Educational Sites: Websites like Coursera or Udemy offer CAD design courses.

Engaging with these resources can boost your skills. Learning from others is always a good idea!

Where can I find CAD design courses?

You can explore websites like Coursera and Udemy for excellent CAD design courses. These platforms provide easy access to useful lessons that meet different skill levels.

Conclusion

In conclusion, a setup guide for metal lathe CAD design helps you understand your machine better. It shows you essential steps and tips. With this knowledge, you can create and modify designs easily. Now, try using a CAD program or read more guides to improve your skills. Happy designing, and remember, practice makes perfect!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Setting Up A Metal Lathe For Cad Design:To set up a metal lathe for computer-aided design (CAD), you need to do a few things. First, find a clean and safe place for the lathe. Next, make sure all the tools are ready and working well. Then, connect the lathe to a power source. Finally, follow your CAD program instructions to start designing and making parts!

Sure! Please ask your question, and I’ll be happy to help with a short and easy answer.

What Are The Essential Specifications To Consider When Selecting A Metal Lathe For Cad Design Projects?When you choose a metal lathe for your CAD design projects, think about a few key things. First, check the size. You need a lathe that fits your workspace and can handle the materials you use. Next, look at the speed. A lathe with different speeds helps you work on various projects better. Finally, consider the type of control. A simple control makes it easier for you to use the lathe.

How Can Cad Software Be Utilized To Create Detailed Schematics For Setting Up A Metal Lathe?You can use CAD software to make clear drawings of a metal lathe setup. First, you take measurements of the lathe and the space around it. Then, you can draw everything on the computer. This helps you see where parts will go, like the tools and materials. Finally, you can print the drawings or share them with others for help.

What Are The Most Common Mistakes To Avoid When Designing Parts For A Metal Lathe Using Cad?When designing parts for a metal lathe using CAD, you should avoid a few common mistakes. First, don’t forget to check your measurements. If they are wrong, your parts won’t fit together well. Also, make sure you consider the tools you will use. Finally, don’t skip the testing phase. Testing helps you find problems before you start cutting metal.

How Do You Ensure That The Cad Design Translates Accurately To Physical Machining On A Metal Lathe?To ensure that our Computer-Aided Design (CAD) is accurate for a metal lathe, we double-check our drawings. We measure the sizes carefully with tools. We also make a small model first to see if it works as planned. Finally, we adjust anything that doesn’t fit before starting the final piece. This way, we avoid mistakes and get the right shape!

What Tools And Accessories Are Recommended For Integrating Cad Designs With Metal Lathe Operations?To use CAD designs with a metal lathe, you need a few important tools. First, get a computer with CAD software to create your designs. Next, use a CNC machine, which helps control the lathe automatically. You’ll also want measuring tools, like calipers, to check your work. Finally, make sure you have safety gear, like goggles and gloves, to stay safe while working.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Setting Up A Metal Lathe For Cad Design:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe for computer-aided design (CAD), you need to do a few things. First, find a clean and safe place for the lathe. Next, make sure all the tools are ready and working well. Then, connect the lathe to a power source. Finally, follow your CAD program instructions to start designing and making parts!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help with a short and easy answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Specifications To Consider When Selecting A Metal Lathe For Cad Design Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you choose a metal lathe for your CAD design projects, think about a few key things. First, check the size. You need a lathe that fits your workspace and can handle the materials you use. Next, look at the speed. A lathe with different speeds helps you work on various projects better. Finally, consider the type of control. A simple control makes it easier for you to use the lathe.”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Utilized To Create Detailed Schematics For Setting Up A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use CAD software to make clear drawings of a metal lathe setup. First, you take measurements of the lathe and the space around it. Then, you can draw everything on the computer. This helps you see where parts will go, like the tools and materials. Finally, you can print the drawings or share them with others for help.”}},{“@type”: “Question”,”name”: “What Are The Most Common Mistakes To Avoid When Designing Parts For A Metal Lathe Using Cad?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing parts for a metal lathe using CAD, you should avoid a few common mistakes. First, don’t forget to check your measurements. If they are wrong, your parts won’t fit together well. Also, make sure you consider the tools you will use. Finally, don’t skip the testing phase. Testing helps you find problems before you start cutting metal.”}},{“@type”: “Question”,”name”: “How Do You Ensure That The Cad Design Translates Accurately To Physical Machining On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To ensure that our Computer-Aided Design (CAD) is accurate for a metal lathe, we double-check our drawings. We measure the sizes carefully with tools. We also make a small model first to see if it works as planned. Finally, we adjust anything that doesn’t fit before starting the final piece. This way, we avoid mistakes and get the right shape!”}},{“@type”: “Question”,”name”: “What Tools And Accessories Are Recommended For Integrating Cad Designs With Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To use CAD designs with a metal lathe, you need a few important tools. First, get a computer with CAD software to create your designs. Next, use a CNC machine, which helps control the lathe automatically. You’ll also want measuring tools, like calipers, to check your work. Finally, make sure you have safety gear, like goggles and gloves, to stay safe while working.”}}]}