Have you ever wondered how a metal lathe works? Imagine turning a block of metal into a beautiful piece of art. It’s all possible with the right tools and setup. One key part of this process is the metal lathe controller board. This board is like the brain of the lathe. It helps control the movement of the machine.

Setting up a metal lathe controller board can seem tricky. But it doesn’t have to be! With the right setup guide, you can make it easy and fun. Do you enjoy working on projects? Then, this guide is perfect for you. It will walk you through the steps simply and clearly.

Here’s a fun fact: Did you know that lathes have been around for thousands of years? They have helped inventors and craftspeople create amazing things. Now, with modern technology, setting up a metal lathe is easier than ever before!

In this article, we’ll explore how to properly set up your metal lathe controller board. Getting started might be a little confusing, but soon you’ll be on your way to making fantastic projects. Ready to dive in?

Comprehensive Setup Guide For Metal Lathe Controller Board

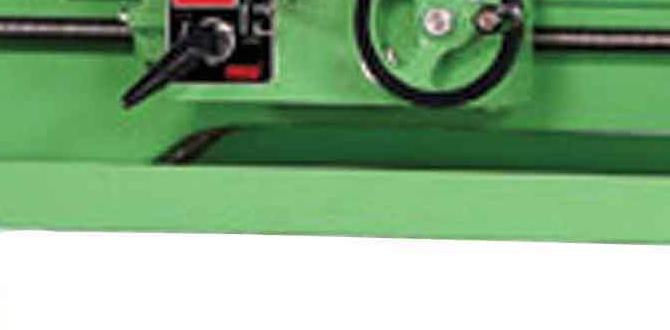

Setup Guide Metal Lathe Controller Board

Are you ready to dive into the exciting world of metal lathes? A setup guide for a metal lathe controller board can help you get started. This guide breaks down the steps required to connect your controller board accurately. You’ll learn how to configure the software, connect the wiring, and test your machine. Did you know that a well-set-up controller can enhance your lathe’s performance significantly? Follow the guide, and watch your projects come to life!Understanding Metal Lathe Controller Boards

Definition and purpose of a controller board in a metal lathe. Different types of controller boards available in the market.Controller boards are the brains behind metal lathes. They control motors and manage movements, turning raw metal into beautiful objects. Think of them as the orchestra conductors of your workshop! Various types of controller boards exist, each with its own strengths. Here’s a quick look:

| Type | Features |

|---|---|

| Basic | Good for beginners, easy to use. |

| Advanced | More features for experienced users. |

| Programmable | Allows custom settings and flexibility. |

Each board can help make your metal lathe journey smoother. Choose wisely, and your projects will shine like new pennies!

Essential Components Required for Setup

List of necessary hardware components for installation. Software requirements and compatible systems.To set up your lathe controller board, you need some essential parts. Here’s a quick list of hardware components:

- Power supply

- Stepper motors

- Cables

- Connectors

- Mounting brackets

You also need software to run it. Make sure your system is compatible. Popular options include:

- Mach3

- LinuxCNC

This setup helps your metal lathe run smoothly and efficiently.

What software do I need for my metal lathe controller?

You need specific software to control your metal lathe.Mach3 and LinuxCNC are popular options. Make sure these programs work with your system setup.

Step-by-Step Installation Process

Preparing your workspace and safety considerations. Detailed stepbystep instructions for wiring the controller board.Before diving into the installation, ensure your workspace is tidy and safe. A clean area helps avoid accidents, like tripping over that elusive coffee cup! Make sure you have all tools handy. Safety glasses? Check! Now, for wiring the controller board, follow these steps:

| Step | Action |

|---|---|

| 1 | Turn off all power to avoid shocking surprises. |

| 2 | Connect the wires to the board carefully. |

| 3 | Check your connections. A loose wire is worse than a misbehaving cat! |

| 4 | Power it on and test if everything runs smoothly. |

Follow these steps closely. Each connection matters for awesome performance!

Configuring the Metal Lathe Controller Board

Initial software installation and setup. Configuring settings for optimal performance.First, you need to install the software that comes with your metal lathe controller board. Follow the instructions carefully. After installation, launch the software and set up your preferences. This helps the lathe work better.

Next, configure the following settings for optimal performance:

- Motor speed

- Tool height

- Workpiece dimensions

Adjust each setting based on your project needs. This ensures smooth operation and accurate cuts. Remember, careful setup results in better work!

How do I install the software?

To install the software, download it from the provided link and follow the on-screen instructions.What settings should I configure for better performance?

Configure motor speed, tool height, and workpiece dimensions. These adjustments improve cutting accuracy.Troubleshooting Common Setup Issues

Identifying and resolving common wiring problems. Softwarerelated issues and their solutions.Wiring issues can be a headache. Check your connections first. Make sure everything is plugged in right. If the lights flash, the wiring may be loose. Sometimes, software settings cause problems too. Here are some common fixes:

- Ensure the drivers are installed correctly.

- Check for updates and install them.

- Restart your software if it stops responding.

With these simple steps, you can fix most common setup problems quickly. Remember, patience is key!

What are the main wiring problems?

Loose connections or wrong wiring can create issues. Always double-check that everything is in the right place.

Maintenance Tips for Longevity of the Controller Board

Routine maintenance practices to prolong the lifespan. Signs that indicate the need for repairs or upgrades.Taking care of your controller board helps it last longer. Here are some easy tips for maintenance:

- Keep it clean. Wipe off dust and dirt.

- Check connections. Make sure all wires are tight.

- Watch for weird noises. They might mean something is wrong.

- Look for any damaged parts. Fix them before they break more.

- Upgrade if needed. New software can make it work better.

By following these simple steps, you can enjoy better performance and extend your device’s life.

What signs mean I need repairs or upgrades?

If you see any strange lights or get error messages on the screen, it’s time to check your controller board. Listening for odd sounds when it runs can also hint that something is off. Regular checks will save you trouble later!

Conclusion

In summary, a metal lathe controller board setup guide helps you understand wiring, programming, and calibration. Following clear steps makes the process easier. Remember to keep safety in mind while working. You can improve your skills by practicing what you’ve learned. We encourage you to explore more resources and tutorials to become a metal lathe expert!FAQs

Sure! Here Are Five Related Questions About Setting Up A Metal Lathe Controller Board:Sure! Here are five questions you might ask when setting up a metal lathe controller board: 1. How do I connect the wires? 2. What power supply do I need? 3. How do I program the controller? 4. What safety checks should I do? 5. How do I test if it works right? If you want help with any of these, just ask!

Sure! I can help you with that. Please ask your question!

What Are The Essential Components Needed For Connecting A Metal Lathe Controller Board To The Lathe Machine?To connect a metal lathe controller board to the lathe machine, you need a few things. First, you’ll need wires to connect everything. Next, you need a power supply to give energy to the lathe and the controller. You also need connectors to link the wires to the board and the machine. Finally, some basic tools, like a screwdriver, will help you make the connections.

How Do You Configure The Firmware Settings On The Controller Board For Optimal Performance With A Specific Metal Lathe Model?To set up the firmware on the controller board for your metal lathe, first, find the manual for your lathe model. It will give you the right settings to use. Next, you can connect the controller board to your computer. Then, you’ll enter those settings into the firmware software. Finally, save your changes and test the lathe to make sure it works well.

What Safety Precautions Should Be Taken When Setting Up And Testing A Metal Lathe Controller Board?When setting up a metal lathe controller board, make sure to wear safety glasses. This protects your eyes from tiny flying bits. Always unplug the machine before you start working on it. Keep your hands away from moving parts to avoid getting hurt. Finally, work in a clean area to avoid accidents.

How Do You Troubleshoot Common Issues That May Arise During The Setup Of A Metal Lathe Controller Board?To troubleshoot a metal lathe controller board, first, check all your wires. Make sure they are connected tightly. Then, look at the power supply to see if it’s working. If the board isn’t responding, reset it and try again. If there are still problems, consult the manual for help or ask someone with experience.

What Programming Languages Or Software Are Commonly Used To Operate And Customize The Functionality Of A Metal Lathe Controller Board?To control a metal lathe board, you can use programming languages like G-code and Python. G-code helps the machine understand what to do. Python is a language that’s easy to learn and can be used to customize settings. You might also use software like Mach3 or LinuxCNC, which help you run the lathe smoothly. These tools make it fun and simple to create things with a lathe!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions About Setting Up A Metal Lathe Controller Board:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions you might ask when setting up a metal lathe controller board: 1. How do I connect the wires? 2. What power supply do I need? 3. How do I program the controller? 4. What safety checks should I do? 5. How do I test if it works right? If you want help with any of these, just ask!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I can help you with that. Please ask your question!”}},{“@type”: “Question”,”name”: “What Are The Essential Components Needed For Connecting A Metal Lathe Controller Board To The Lathe Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To connect a metal lathe controller board to the lathe machine, you need a few things. First, you’ll need wires to connect everything. Next, you need a power supply to give energy to the lathe and the controller. You also need connectors to link the wires to the board and the machine. Finally, some basic tools, like a screwdriver, will help you make the connections.”}},{“@type”: “Question”,”name”: “How Do You Configure The Firmware Settings On The Controller Board For Optimal Performance With A Specific Metal Lathe Model?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up the firmware on the controller board for your metal lathe, first, find the manual for your lathe model. It will give you the right settings to use. Next, you can connect the controller board to your computer. Then, you’ll enter those settings into the firmware software. Finally, save your changes and test the lathe to make sure it works well.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Setting Up And Testing A Metal Lathe Controller Board?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When setting up a metal lathe controller board, make sure to wear safety glasses. This protects your eyes from tiny flying bits. Always unplug the machine before you start working on it. Keep your hands away from moving parts to avoid getting hurt. Finally, work in a clean area to avoid accidents.”}},{“@type”: “Question”,”name”: “How Do You Troubleshoot Common Issues That May Arise During The Setup Of A Metal Lathe Controller Board?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot a metal lathe controller board, first, check all your wires. Make sure they are connected tightly. Then, look at the power supply to see if it’s working. If the board isn’t responding, reset it and try again. If there are still problems, consult the manual for help or ask someone with experience.”}},{“@type”: “Question”,”name”: “What Programming Languages Or Software Are Commonly Used To Operate And Customize The Functionality Of A Metal Lathe Controller Board?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To control a metal lathe board, you can use programming languages like G-code and Python. G-code helps the machine understand what to do. Python is a language that’s easy to learn and can be used to customize settings. You might also use software like Mach3 or LinuxCNC, which help you run the lathe smoothly. These tools make it fun and simple to create things with a lathe!”}}]}