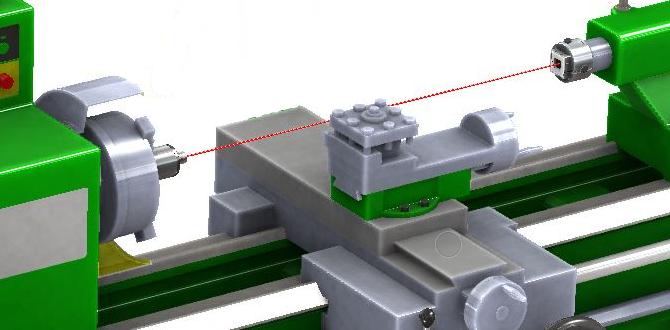

Have you ever wondered how metal parts are made? It’s fascinating! One crucial part of that process is using a metal lathe. This machine spins the metal, shaping it into usable items. The speed at which it spins is called the spindle speed.

Imagine designing a model car or a piece of furniture. To create perfect parts, you need precision. That’s where CAD design comes in. CAD stands for Computer-Aided Design. It helps people create detailed plans before cutting any metal. Spindle speed in a metal lathe plays a big role in this process.

Did you know that choosing the right spindle speed can make a huge difference? If it spins too fast or too slow, the metal can break or burn. But with the right speed, you create smooth and accurate shapes. Isn’t that amazing?

In this article, we will explore spindle speed, metal lathes, and the importance of CAD design. Let’s dive into the world of metalworking and discover how these elements work together!

Spindle Speed Metal Lathe Cad Design: A Comprehensive Guide

Understanding Spindle Speed in Metal Lathe CAD Design

Spindle speed is crucial for metal lathes working in CAD design. It affects how fast the lathe turns metal pieces. Choosing the right speed ensures smooth cutting, leading to better finishes. Did you know that a higher spindle speed can improve efficiency? However, too much speed might cause damage. Understanding this balance is key for any designer. Learn how spindle speed can impact your projects and make your designs come alive!What is Spindle Speed?

Definition and explanation of spindle speed in metal lathes. Importance of spindle speed in machining processes.Spindle speed is how fast the spindle turns in a metal lathe. It’s like the heartbeat of the machine. If it spins too slowly, the job takes forever. If it spins too fast, well, you might end up with shavings instead of a part! It’s vital for the machining process to find the right speed. Too slow could mean a dull tool, while too fast can damage both the tool and the material.

| Spindle Speed (RPM) | Effect |

|---|---|

| Low | Better control. Good for tough materials. |

| High | Fast work. Great for softer materials. |

Picking the right spindle speed can save time and money. So, think of it as not just spinning around but spinning smart!

Factors Influencing Spindle Speed

Material type and its impact on optimal spindle speed. Tool geometry and design considerations.Different factors affect spindle speed. The type of material you use is important. Harder materials need slower speeds. Softer materials can spin faster. This helps make cleaner cuts. Tool geometry also matters. Tools with sharper edges can work at higher speeds. The design of the tool impacts how well it cuts. Consider these points for the best spindle speed:

- Material hardness

- Surface finish desired

- Tool sharpness

- Tool shape

How does material type influence spindle speed?

Material type greatly impacts spindle speed. Softer materials allow for faster speeds, while harder materials require slower speeds for safety and quality.

What role does tool design play in optimum spindle speed?

Tool design is crucial for achieving the best results. Sharp tools can operate at higher speeds, ensuring efficient cutting and better finishes.

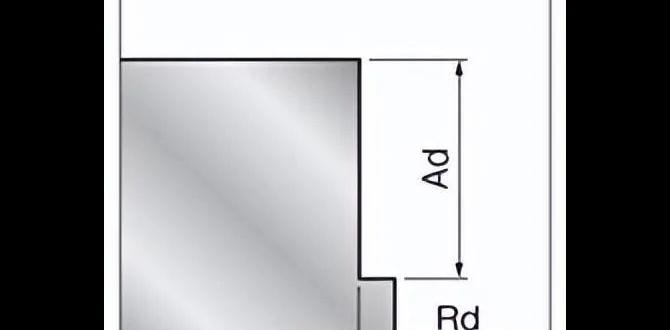

Calculating Optimal Spindle Speed

Formula for calculating spindle speed based on material and tooling. Examples and common practices in CAD design.To find the best spindle speed, you can use a simple formula: Spindle Speed = (Cutting Speed × 12) / π × Tool Diameter. This helps with different materials and tool types. For example:

- **Steel:** 100-150 RPM

- **Aluminum:** 300-400 RPM

- **Wood:** 600-800 RPM

Common CAD designs help users pick the right speed. They often have built-in calculators. These tools make working with lathes easier. Accurate speed can lead to better cuts and smoother surfaces.

How can I calculate spindle speed for different materials?

Simply use the formula: Spindle Speed = (Cutting Speed × 12) / π × Tool Diameter. This lets you adjust for different materials like steel, aluminum, or wood easily.

Effects of Incorrect Spindle Speed

Common mistakes and their consequences on machining quality. Strategies for avoiding errors in spindle speed settings.Using the wrong spindle speed can harm quality in metal lathe work. Common mistakes include setting the speed too high or too low. This can lead to poor finishes, chipped tools, or wasted materials. To avoid these errors, check your machine’s settings before starting. Also, follow these tips:

- Always read the manual.

- Test speeds on scrap material.

- Keep calm and adjust slowly.

These steps can help you maintain good machining quality.

What happens with incorrect spindle speed?

Incorrect spindle speed can cause problems like rough cuts and tool damage. This means you might need to redo the work. In the long run, you can save time and resources by paying attention to the right speeds.

Case Studies: Spindle Speed in Action

Realworld examples of successful CAD designs utilizing optimal spindle speed. Analysis of failed projects due to improper spindle speed management.Many real-world projects show how spindle speed can make a design work well. For example, a car part made using CAD designs had success because the right spindle speed was used. On the other hand, some projects failed. They picked the wrong spindle speed, which harmed the product. This led to wasted materials and time.

- Success: CAD design for a bicycle frame with optimal spindle speed.

- Failure: Engine part that couldn’t meet safety standards due to incorrect spindle speed.

Why is spindle speed important?

Spindle speed controls how fast the machine works. It influences how smooth the cuts are and the quality of the parts made. Picking the right speed saves time and money.

Best Practices for Integrating Spindle Speed in CAD Design

Tips for engineers and designers to enhance spindle speed calculations. Importance of simulation tools in validating spindle speed settings.Combining spindle speed in CAD design can be very helpful. Here are some tips for engineers to improve their calculations:

- Measure materials accurately for better results.

- Use consistent units for calculations.

- Consider tool wear and life expectancy.

- Test different speeds for optimal performance.

Simulation tools are important, too. They help to check if spindle speed settings work well. This step can save time and reduce errors. It’s like using a practice run before the big game!

How can engineers validate spindle speed settings effectively?

Engineers can use simulation software to test spindle speed settings. This approach confirms that the design will perform as expected. Using these tools makes design safer and more efficient.

Conclusion

In conclusion, understanding spindle speed in metal lathe CAD design is crucial for quality work. It helps you choose the right speed for different materials. This improves your projects’ accuracy and finish. We encourage you to practice using these concepts in your designs. Explore more about spindle speeds online to boost your skills and confidence in metalworking!FAQs

Sure! Here Are Five Related Questions On The Topic Of Spindle Speed In Metal Lathe Cad Design:Sure! Spindle speed is how fast the metal lathe spins. It affects how smoothly we cut metal. Faster speeds can create smoother surfaces. We need to choose the right speed for different materials. This helps make better parts!

Sure! Please give me the question you want me to answer.

What Factors Should Be Considered When Determining The Optimal Spindle Speed For Different Materials In A Cad Design For A Metal Lathe?When choosing the best spindle speed for different materials, you should consider their hardness. Softer metals like aluminum can spin faster, while harder metals like steel need slower speeds. You also need to think about the type of tool you use and the shape you want to make. Lastly, keeping the design cool helps too, so some speeds work better than others for cooling.

How Can Cad Software Be Used To Simulate The Effects Of Varying Spindle Speeds On Machining Performance And Surface Finish?We can use CAD software to see how changing spindle speeds affects our machining projects. First, we set different speeds in the software. Then, we watch how these speeds change the way the machine cuts materials. This helps us understand which speed gives us the best surface finish. It’s like testing different bike speeds to see which one feels best!

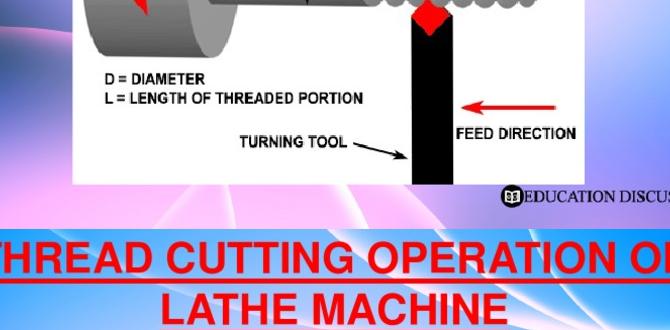

What Are The Typical Spindle Speed Ranges For Various Operations (E.G., Turning, Drilling, Threading) In A Metal Lathe, And How Can These Be Represented In Cad Design?In a metal lathe, spindle speeds can change depending on what you’re doing. For turning, speeds are usually between 200 to 3,000 revolutions per minute (RPM). When drilling, speeds are around 300 to 1,500 RPM. For threading, you might use speeds from 200 to 800 RPM. In CAD (Computer-Aided Design), you can show these speeds by adding notes or labels to your designs, so everyone knows what speeds to use.

How Does The Choice Of Tooling Impact The Spindle Speed Settings In A Metal Lathe, And How Can Cad Design Incorporate Tooling Specifications?The tools you choose for a metal lathe can change how fast the spindle turns. Some tools need high speeds, while others work better at lower speeds. We must pay attention to these speeds to avoid breaking the tool. In CAD (Computer-Aided Design), you can add details about your tools. This helps everyone know the best settings to use when working.

What Role Does Spindle Speed Play In The Overall Design And Efficiency Of A Cnc Lathe, And How Can This Be Integrated Into The Cad Design Process?Spindle speed is how fast the lathe spins the material. It affects how well and how quickly we can make parts. If we choose the right speed, we can make smoother and better parts. In CAD design, we can add the right spindle speed in our plans. This helps us create more efficient and effective designs.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Spindle Speed In Metal Lathe Cad Design:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Spindle speed is how fast the metal lathe spins. It affects how smoothly we cut metal. Faster speeds can create smoother surfaces. We need to choose the right speed for different materials. This helps make better parts!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Determining The Optimal Spindle Speed For Different Materials In A Cad Design For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing the best spindle speed for different materials, you should consider their hardness. Softer metals like aluminum can spin faster, while harder metals like steel need slower speeds. You also need to think about the type of tool you use and the shape you want to make. Lastly, keeping the design cool helps too, so some speeds work better than others for cooling.”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Used To Simulate The Effects Of Varying Spindle Speeds On Machining Performance And Surface Finish?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use CAD software to see how changing spindle speeds affects our machining projects. First, we set different speeds in the software. Then, we watch how these speeds change the way the machine cuts materials. This helps us understand which speed gives us the best surface finish. It’s like testing different bike speeds to see which one feels best!”}},{“@type”: “Question”,”name”: “What Are The Typical Spindle Speed Ranges For Various Operations (E.G., Turning, Drilling, Threading) In A Metal Lathe, And How Can These Be Represented In Cad Design?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a metal lathe, spindle speeds can change depending on what you’re doing. For turning, speeds are usually between 200 to 3,000 revolutions per minute (RPM). When drilling, speeds are around 300 to 1,500 RPM. For threading, you might use speeds from 200 to 800 RPM. In CAD (Computer-Aided Design), you can show these speeds by adding notes or labels to your designs, so everyone knows what speeds to use.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Tooling Impact The Spindle Speed Settings In A Metal Lathe, And How Can Cad Design Incorporate Tooling Specifications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The tools you choose for a metal lathe can change how fast the spindle turns. Some tools need high speeds, while others work better at lower speeds. We must pay attention to these speeds to avoid breaking the tool. In CAD (Computer-Aided Design), you can add details about your tools. This helps everyone know the best settings to use when working.”}},{“@type”: “Question”,”name”: “What Role Does Spindle Speed Play In The Overall Design And Efficiency Of A Cnc Lathe, And How Can This Be Integrated Into The Cad Design Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Spindle speed is how fast the lathe spins the material. It affects how well and how quickly we can make parts. If we choose the right speed, we can make smoother and better parts. In CAD design, we can add the right spindle speed in our plans. This helps us create more efficient and effective designs.”}}]}