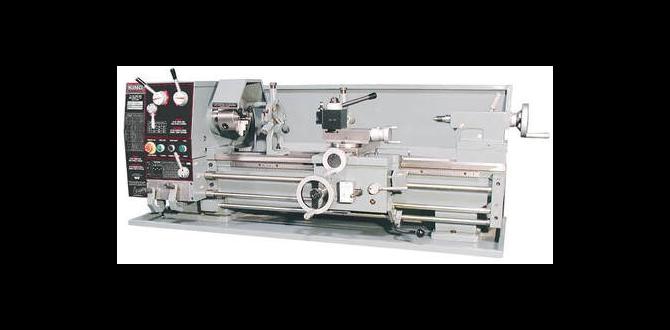

Have you ever watched a metal lathe at work? It’s fascinating how these machines shape metal into precise forms. One key factor in this process is spindle speed. Understanding spindle speed on a metal lathe is essential for anyone who wants to work with metal. But what exactly does it mean?

The spindle speed determines how fast the lathe spins the workpiece. A higher speed can help you cut metal quickly. But it also needs the right power feed to make smooth cuts. Imagine trying to slice through a firm vegetable with a dull knife. It just doesn’t work well!

Did you know that adjusting spindle speed can change the finish of the metal? If you’re not careful, using the wrong speed can cause mistakes. That can lead to frustration for beginners. But with the right knowledge, you can avoid these pitfalls. Learning how spindle speed and power feed work together is like unlocking a secret tool in your workshop.

Are you ready to explore the world of metal lathes? Understanding these concepts can open the door to many exciting projects. Let’s dive deeper into how spindle speed and power feed can make your metalworking experience incredible!

Understanding Spindle Speed And Power Feed In Metal Lathes

Understanding Spindle Speed on Metal Lathes

Spindle speed is crucial for using a metal lathe effectively. It refers to how fast the spindle spins. Selecting the right spindle speed can greatly affect the quality of your work. Did you know that different materials require different speeds? For instance, softer metals spin faster than harder ones. Power feed helps in making precise cuts at that speed. By learning to adjust these settings, you can improve your projects and master metalworking.Understanding Spindle Speed

Definition of spindle speed and its significance. Factors affecting spindle speed selection.Spindle speed is how fast the spindle of a lathe turns. It’s measured in revolutions per minute (RPM). Think of it as the speed limit for your lathe, ensuring you don’t take your project for a wild ride! Choosing the right spindle speed matters because it affects the quality of your work and tool wear. Factors like material type, tool size, and desired finish influence this choice. If you go too fast, it’s like trying to eat spaghetti with a fork – messy!

| Factors Affecting Spindle Speed | Impact |

|---|---|

| Material Type | Different materials require different speeds for optimal results. |

| Tool Size | Larger tools may need slower speeds to work effectively. |

| Desired Finish | A smooth finish might need slower speeds; a rough cut can handle more speed. |

Importance of Power Feed in Metal Lathes

Explanation of power feed and its role in machining. Comparison between manual feed and power feed.Power feed is like having a helpful robot assist you while working on a metal lathe. It automatically moves the tool against the material, saving you from arm cramps and probably saving your sanity too! In contrast, manual feed is all about you. It relies on your muscles, which can be tiring and a bit erratic. Power feed makes the work smoother, faster, and way more fun—like riding a bike instead of walking!

| Feature | Manual Feed | Power Feed |

|---|---|---|

| Control | Hands-on | Automated |

| Speed | Slower | Faster |

| Fatigue | Higher | Lower |

How to Calculate Optimal Spindle Speed

Formula for calculating spindle speed. Examples of spindle speed calculations for different materials.Calculating spindle speed can be a breeze! Use the formula: Spindle Speed (RPM) = (Cutting Speed x 12) / π x Diameter. It helps you find the perfect speed for different materials. For example, if you are working with aluminum, you might aim for around 1,000-2,000 RPM, while steel may require only 800-1,200 RPM. Check out this handy table for guidance:

| Material | Cutting Speed (ft/min) | Optimal Spindle Speed (RPM) |

|---|---|---|

| Aluminum | 300 | 1,066 |

| Steel | 100 | 318 |

| Brass | 250 | 1,047 |

By following this formula and checking the table, you can avoid spinning your wheels—literally! Happy machining!

Adjusting Power Feed Settings

Stepbystep guide for adjusting power feed. Common mistakes to avoid when setting power feed.Adjusting the power feed on a lathe can seem tricky. However, with the right steps, it becomes simple. Follow these to get started:

- Check your lathe’s manual for specific settings.

- Set the spindle speed appropriately.

- Change the feed rate slowly.

- Test the tool on scrap material first.

Common mistakes include:

- Setting too high of a speed.

- Ignoring noise from the machine.

- Forgetting to check feed rate after changing tools.

With careful adjustments, you can achieve great results. Always remember to take your time and make small changes. Happy machining!

What is a good feed rate for a metal lathe?

The best feed rate depends on the material being cut. For soft metals, try a higher feed rate. For harder materials, use a slower feed rate to reduce tool wear.

How do you know if the power feed is too fast?

You can tell if the feed is too fast by listening for rough sounds. If you see excessive tool wear, slow it down.

Choosing the Right Spindle Speed for Different Materials

Recommended spindle speeds for common metals. Impact of material hardness on spindle speed choices.Different metals need different spindle speeds for the best results. Here are some common spindle speeds for popular metals:

- Aluminum: 800-1,200 RPM

- Copper: 600-1,000 RPM

- Steel: 300-700 RPM

- Brass: 500-1,200 RPM

Harder materials require slower speeds. This helps to prevent damage. For instance, when working with hard steel, a lower speed gives better control. Always remember to adjust your speed based on the type of metal to get the best finish.

What is the best spindle speed for aluminum?

The best spindle speed for aluminum is around 800 to 1,200 RPM. This speed helps cut smoothly and quickly.

Why does hardness affect spindle speed?

Harder materials require slower spindle speeds to avoid damage and ensure smooth cutting.

Benefits of Proper Spindle Speed and Power Feed Coordination

Enhanced machining efficiency and productivity. Quality of finished parts related to spindle speed and feed settings.Using the right spindle speed and power feed helps you work faster. This means you can finish more parts in less time. When everything works together, the quality of your parts improves too. Proper settings lead to smoother finishes and better shapes. You get less waste and fewer mistakes.

- Higher productivity

- Better part quality

- Less waste

Ultimately, understanding this coordination makes your projects easier and more successful.

Why is spindle speed important?

The right spindle speed gives smoother cuts. It helps avoid damage to the material, making finished parts look great. Correct settings lead to better quality and less time fixing mistakes.

Key points to remember:

- Increases efficiency

- Improves surface finish

- Reduces operational hiccups

Common Challenges and Troubleshooting

Identifying problems related to incorrect spindle speed. Solutions for power feed malfunctions.Issues with spindle speed can cause big problems. If the speed is too high or low, it can mess up your work. You might notice rough edges or uneven cuts. Always check the settings before starting. For power feed issues, follow these solutions:

- Clean the feed mechanism to remove dust.

- Check for loose wiring connections.

- Adjust the feed rate if it’s too slow or fast.

Being alert to these problems can save time and improve quality.

What are common spindle speed problems?

Common spindle speed problems include vibration, odd noises, and overheating. These can lead to damaged components or poor finishes.

What causes power feed malfunctions?

Power feed malfunctions may happen due to worn gears, electrical issues, or misalignment in the feed system. Regular check-ups can help prevent these issues.

Advanced Techniques for Optimizing Spindle Speed and Power Feed

Use of technology for monitoring and adjusting spindle speed. Techniques to achieve smoother cuts and reduce tool wear.Modern technology helps us monitor and adjust spindle speed easily. Using sensors, we can check the speed in real-time. This helps make smoother cuts and keeps tools sharp for longer. Here are some great techniques:

- Utilize speed sensors for accurate readings.

- Apply constant feed rates to minimize tool wear.

- Experiment with different materials to find the best settings.

These methods not only improve results but also keep your machine running great. It’s like having a smart assistant by your side!

How can technology improve spindle speed and power feed?

Technology enhances spindle speed and power feed by providing real-time data, allowing users to adjust settings for the best results. Proper monitoring reduces tool wear and leads to better cut quality.

Conclusion

In conclusion, understanding spindle speed and power feed on a metal lathe is vital for smooth operation. Higher spindle speeds can improve cutting efficiency. Knowing how to adjust power feed helps you achieve better results. We encourage you to experiment with different settings and practice regularly. For more tips, check out guides or tutorials on metal lathes. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Spindle Speed, Metal Lathe, And Power Feed:Sure! Spindle speed is how fast the machine’s spinning part turns. A metal lathe is a tool that shapes metal by spinning it. Power feed means the machine moves the metal automatically while you work. This makes it easier for you to create pieces and saves time. Just remember to adjust the speed and settings for the best results!

Sure! Please give me the question you want me to answer, and I’ll be happy to help!

How Does Spindle Speed Affect The Surface Finish And Tooling Life When Machining Different Materials On A Metal Lathe?Spindle speed is how fast the metal lathe’s part spins. A higher speed can give a smoother surface finish, but it can wear out the tools faster. If you use lower speeds with hard materials, your tools last longer. But for softer materials, you can go faster for a nice finish. It’s like riding a bike: go slow on rough paths and fast on smooth roads!

What Factors Should Be Considered When Selecting The Appropriate Spindle Speed For Specific Cutting Operations On A Metal Lathe?When picking a spindle speed for a metal lathe, you need to think about the material you’re cutting. Different metals, like steel or aluminum, need different speeds. You also need to consider the size of the tool you’re using. Larger tools often go slower, while smaller tools can spin faster. Finally, check the finish you want. A smooth finish might need a slower speed.

How Does The Power Feed Mechanism Enhance The Efficiency Of Material Removal Compared To Manual Feed Operations On A Lathe?The power feed mechanism on a lathe helps you remove material faster and easier. It moves the cutting tool automatically without your help. This means you can focus on other parts of the job. Your hands stay free, and you can be more precise. Overall, it saves time and makes your work smoother.

What Are The Potential Consequences Of Operating A Metal Lathe At Excessively High Or Low Spindle Speeds?If you run a metal lathe too fast, it can make the metal hot and can cause it to break. You might also hurt yourself if the metal flies off. If you go too slow, it can make a rough surface that’s not nice. It might take longer to finish your work, too. So, finding the right speed is really important!

How Can You Calculate The Optimal Spindle Speed And Feed Rate For Various Workpiece Diameters And Material Types On A Lathe?To find the best spindle speed for a lathe, you can use a simple formula. First, check the material you are using. Different materials need different speeds. You can find charts online that show the right speeds for each material type. For feed rate, start with a slower speed and increase it until you see the best results for your workpiece. Always remember to stay safe while working!