Imagine building a robot with your friend, but you need two different screwdrivers. Each tool fits a special screw. Have you ever wondered why? Well, just like those screwdrivers, step drills and end mills have unique jobs too. Let’s dive into their world!

Step drills look like tiny, magical cones. They can make holes bigger without changing tools. End mills, on the other hand, are like pencils but they carve shapes. Isn’t that cool?

Here’s a fun fact: step drills are great at making holes in metal and wood. End mills love cutting through hard materials like cheese. Which tool would you choose? It’s like picking your favorite superhero!

So, why are step drills and end mills so different? And which one should you use for your project? Let’s explore and find out!

Step Drill Vs End Mill Drilling: A Comprehensive Comparison

Step Drill vs End Mill Drilling: Key Differences

Picture two tools: a step drill and an end mill. What’s their secret? The step drill makes holes bigger. Think of it like steps on a staircase. Each step drills a different size hole. Meanwhile, the end mill cuts in any direction, like a sculptor shaping clay. Want smoother edges? Go for the end mill. Need precise holes fast? The step drill is your friend. Who will you choose?What is Step Drill Drilling?

Explanation of step drill design and function. Typical applications and industries using step drill drilling.Imagine a little superhero for drilling! A step drill is a tool with a special design. It looks like a cone with steps. Each step is a different size, all on one tool, like a shrinking, metallic stairway. This makes it great for drilling holes of different sizes without needing to switch tools. You’ll see them working hard in the automobile and sheet metal industries, creating smooth holes efficiently. They’re popular in electronics too, helping make those neat little circuit boards.

| Industry | Use |

|---|---|

| Automobile | Creating holes for various parts |

| Sheet Metal | Drilling different-size holes easily |

| Electronics | Making precise circuit board holes |

Why is it such a hit? Well, one tool fits many jobs, saving time and effort. That’s a win for both workers and wallets! And remember, unlike some gym routines, this drill really helps build things!

What is End Mill Drilling?

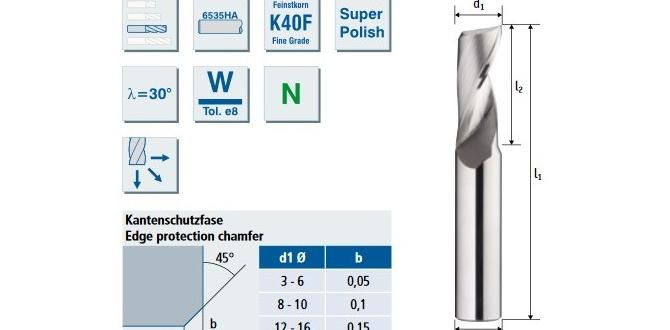

Explanation of end mill design and function. Typical applications and industries using end mill drilling.An end mill is a special type of drill bit. It has flutes or grooves that cut through materials. It spins very fast to make holes or shapes. People use end mills in many industries like car-making and furniture building.

- End mills make very smooth cuts.

- They can work on metals, wood, and plastics.

Why choose end mills?

End mills are great for shaping and cutting. They’re perfect if you want precise and neat results. Builders use them to make cool designs in materials.

End mills help make different objects. They can carve or cut clean edges. Think of it like a super sharp pencil that gives you perfect lines every time. Have you ever seen toy models or details on wooden furniture? That’s often done with end mills. Did you know? Many everyday items, like cars and furniture, are crafted using end mill drilling for precision!

Key Differences Between Step Drill and End Mill Drilling

Structural and functional differences. Performance variations in different materials.Comparing step drill bits and end mills is like deciding between dancing or diving—one moves through metal with grace, the other carves with precision. Step drill bits can handle thin sheets like pros, stepping down sizes swiftly, skipping the tool change mambo. But don’t ask them to tango with tough stuff; they might just sit it out. End mills, on the other hand, can chisel away at denser materials and make fancy shapes. Think of them as the sculptor’s chisels in the metalwork family.

| Feature | Step Drill | End Mill |

|---|---|---|

| Best for | Thin Materials | Dense Materials |

| Operation | Progressive Drilling | Cutting & Shaping |

| Efficiency | Quick Change between Sizes | Complex Cuts |

While step drill bits swiftly dance through thin materials, end mills offer power for a thick, challenging waltz of metalwork. Choose wisely, and remember: Every tool has its stage—and no one likes a party crasher!

Advantages and Disadvantages of Step Drill Drilling

Benefits of using step drill in manufacturing. Limitations of step drills in certain situations.Picture this: If you’re in a factory, step drills are like Swiss army knives. They’re amazing for drilling holes of different sizes without switching tools. They’re super fast and efficient. But, like swiss cheese, they have holes too. If you need to drill in hard materials or want a fancy precise hole, step drills might leave you hanging. Here’s a quick look:

| Benefits | Limitations |

|---|---|

| Fast and versatile drilling | Not great for hard materials |

| Cost-effective | Less precision |

So, while step drills can be as handy as a pocketknife in manufacturing, make sure they’re right for your task. Otherwise, you might need to call in their bigger sibling, the end mill, to finish the job!

Advantages and Disadvantages of End Mill Drilling

Advantages of using end mills in precision work. Potential drawbacks and challenge in specific cases.End mills are great for precision. They can make smooth and clean cuts. This is important for tiny or detailed work. They give more control compared to other tools. But, end mills may not work well in hard materials. They can break or wear out faster. It’s also tricky in deep hole drilling. Sometimes, you might need a special end mill, which can cost more.

Why choose an end mill for precision work?

End mills are best for precise, clean cuts, making them ideal for detailed tasks.

- They have a sharp edge for smooth finishes.

- Good for detailed designs.

- Works well in softer materials.

What are the challenges of using end mills?

End mills may struggle with hard or thick materials. They can wear out or break, needing replacements.

- Not ideal for tough materials.

- Costly if special ones are needed.

- Can wear out fast in certain tasks.

As the saying goes, “Use the right tools for the right job.” So, always think about the work you will do before picking an end mill.

Choosing the Right Tool: Factors to Consider

Material considerations and thickness implications. Speed, precision, and tool life comparisons.When picking the best drilling tool, it’s not a “one size fits all” kind of deal. The material’s nature and thickness do a lot of the talking. Is it a tough cookie like steel, or a softer bread-like wood?

Think about speed too! Step drills are fast but can struggle with very hard stuff. On the other hand, end mills offer precision but might take their sweet time.

Also, keep tool lifespan in mind. Using the wrong tool can be like expecting a cheese grater to give a haircut – messy and costly!

| Tool | Speed | Precision | Tool Life |

|---|---|---|---|

| Step Drill | High | Moderate | Variable |

| End Mill | Moderate | High | Consistent |

Remember, choosing wisely can save you time, money, and perhaps a lot of frustration! In the words of a wise craftsman, “The right tool makes all the difference.”

Cost Implications of Using Step Drill vs. End Mill

Initial investment and tool lifespan analysis. Longterm costefficiency in production.When deciding between step drills and end mills, your wallet might shout louder than your machine. A step drill usually needs a higher upfront investment compared to an end mill, but don’t let that scare you! Their long-lasting nature means fewer replacements over time. If you’re counting pennies in the long run, step drills might sneak a smile on your face as they promise better savings in continuous production.

Here’s a friendly cost breakdown:

| Tool Type | Initial Investment | Tool Lifespan |

|---|---|---|

| Step Drill | High | Long |

| End Mill | Lower | Shorter |

While end mills seem kinder to your budget at first, they may not outlast the grit of a step drill in a marathon of use. If your production line often says, “Let’s do this again,” choosing the right drill could be as important as choosing between waffles or pancakes for breakfast. Which one stays crispy longer?

Case Studies: Practical Applications and Results

Realworld examples of successful usage. Lessons learned from industryspecific case studies.There was a factory where workers were having trouble with drilling. They tried using both step drills and end mills to see which worked best. The sleepy robots preferred end mills for smoother drilling, whereas the team in charge of shiny metal parts loved step drills for quick hole-making.

Here’s a fun table that shows what they found out:

| Tool | Performance | Result |

|---|---|---|

| Step Drill | Fast and efficient | Great for speed |

| End Mill | Precise and sharp | Best for fine work |

**Lesson learned**: Pick the tool based on your needs. One does not fit all, and both are useful, like peanut butter and jelly. A wise worker said, “Always let the task decide the tool, not the other way around.” That was the best advice. Now they drill like pros and everyone in town knows!

Trends and Innovations in Drill Technologies

Recent advancements in tool material and design. Future outlook for step drill and end mill drilling techniques.Today’s drills are smarter and faster. New tools use strong materials like carbide. This helps them last longer and cut better. Designs have also changed. Some drills now have special grooves. This makes them cut smoother. What does the future hold? Step drill and end mill drilling might use new tech like AI for better precision. Experts say we need these better tools. As factories grow, the demand for advanced techniques in drilling will also rise. This means more shiny inventions are on the way!

Why are new tool materials important?

New tool materials make drills more durable and efficient. Using stronger materials means tools won’t wear out quickly. This saves money over time. They also help in making smooth and precise cuts, which is very important in modern industries.

How do improved designs benefit drilling?

Improved designs help the drill cut better. Advanced designs like special grooves in drills make them cut smoother and faster. This reduces the effort needed and saves time.

Conclusion

When choosing between step drills and end mills, consider your needs. Step drills are great for making holes of different sizes. End mills are better for shaping and cutting. Think about your project and tools before deciding. Exploring both options can improve your skills. For more understanding, keep learning about different drilling methods and their uses.FAQs

What Are The Key Differences Between Step Drills And End Mills When It Comes To Drilling Operations In Metalworking?Step drills and end mills are different tools for working with metal. Step drills make holes of different sizes. They look like cones with steps. You can drill several hole sizes without changing the tool. End mills, however, cut side-to-side and shape metal. They are great at cutting curves and edges.

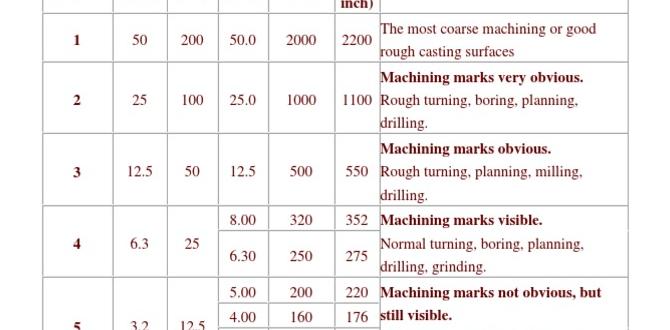

How Do The Cutting Mechanisms Of Step Drills And End Mills Differ In Terms Of Efficiency And Finish Quality?A step drill cuts metal by making holes bigger as it goes down. It can be fast but leaves rough edges. An end mill slices sideways to shape or carve out metal. It works a bit slower but gives a smoother finish. For shiny, neat edges, use an end mill.

In What Scenarios Would A Step Drill Be More Advantageous To Use Over An End Mill For Creating Holes In Metal Or Other Materials?A step drill is great for making holes of different sizes quickly. You can use it to make holes bigger without changing tools. It’s handy if you need a smooth hole in thin materials, like sheet metal. Step drills work fast and save time when you need holes of various sizes.

What Are The Limitations And Considerations To Keep In Mind When Using An End Mill For Drilling Operations Compared To Using A Step Drill?When you use an end mill to drill, it may not make very deep or smooth holes. The end mill can also wear out more quickly because it isn’t designed for drilling like a step drill is. Step drills make smoother holes because they are made especially for that. Consider using the right tool for the job to make everything easier and safer.

How Does The Choice Between A Step Drill And An End Mill Affect The Overall Cost And Speed Of A Drilling Project In Manufacturing?Choosing between a step drill and an end mill can change how much a project costs and how fast it gets done. A step drill cuts many holes quickly, which can save us time and money. An end mill is great for special shapes, but it can take longer and cost more. Picking the right tool helps make the job quicker and keeps it affordable.