The Tialn Ball Nose End Mill 35 Degree is an excellent choice for machining plywood. Its specific rake angle and ball nose design allow for smooth cutting, reduced tear-out, and efficient material removal, especially when performing adaptive clearing operations.

Hey there, fellow makers and machinists! Daniel Bates here from Lathe Hub. Ever found yourself wrestling with plywood, wishing for cleaner cuts and smoother finishes? You’re not alone. Plywood can be tricky, with its layers and tendency to splinter. But what if I told you there’s a specific tool that can make a world of difference? We’re diving deep into the world of the Tialn ball nose end mill with a 35-degree angle, and why it’s your new best friend for tackling plywood projects, especially for adaptive clearing. Get ready to elevate your woodworking game!

Why the Tialn Ball Nose End Mill is a Plywood Powerhouse

When you’re working with CNC machines, choosing the right tool is half the battle. Plywood, with its cross-grained layers, can be notorious for producing fuzzy edges and tear-out. Standard end mills might struggle, chatter, or leave a rough surface. This is where specialized end mills shine. The Tialn ball nose end mill, particularly one with a 35-degree helix angle, offers a unique set of advantages perfectly suited for this material.

A ball nose end mill, as the name suggests, has a rounded tip. This allows it to create smooth, curved surfaces and cut in multiple directions without leaving sharp corners. The 35-degree helix angle on a Tialn coating typically indicates a design optimized for materials like aluminum and plastics, but its geometry also translates beautifully to softer woods and composites like plywood. It strikes a balance between aggressive material removal and a smooth finish, minimizing the chipping and splintering we dread.

This tool is especially beneficial for operations like adaptive clearing. Adaptive clearing is a sophisticated CAM strategy that dynamically adjusts the toolpath based on the material remaining, maintaining a consistent chip load. This minimizes tool wear and stress on the machine. A Tialn ball nose end mill, with its ability to cut efficiently and cleanly in sweeping motions, complements adaptive clearing perfectly, leading to faster machining times and superior surface finishes on plywood.

Understanding the Tialn Ball Nose End Mill (35 Degree Specifics)

Let’s break down what makes this particular end mill so effective for plywood.

Key Features and Their Benefits for Plywood

Ball Nose Geometry: The rounded tip is crucial. Unlike a square end mill, a ball nose leaves a smooth, radiused channel. This is fantastic for creating flowing contours, fillets, and pockets with rounded bottoms. For plywood, it helps reduce stress concentration at corners, minimizing the likelihood of delamination or chipping.

35-Degree Helix Angle: This angle refers to the spiral of the cutting flutes. A 35-degree helix is generally considered a good compromise for many materials. It provides a decent cutting geometry that can handle some of the aggressive nature of plywood’s layered structure. It’s aggressive enough to chip away material efficiently but not so steep that it causes excessive tear-out or chatter. This angle helps in shearing the material cleanly.

Tialn Coating: Tialn (Titanium Aluminum Nitride) is a hard, wear-resistant coating. While often associated with high-speed machining of metals, its ability to reduce friction and heat buildup is also beneficial in woodworking. For plywood, this means a sharper tool for longer and a cleaner cut, as it helps prevent the wood fibers from melting and gumming up the flutes. It also improves chip evacuation.

Number of Flutes: Most ball nose end mills come with 2 or 4 flutes. For soft materials like plywood, 2-flute end mills are often preferred. They offer more chip room, which is essential for preventing clogging and heat buildup. This leads to a cleaner cut and longer tool life.

How These Features Combat Plywood’s Challenges

Plywood is made by gluing thin sheets of wood veneer together, with the grain of each layer oriented at right angles to the adjacent layers. This cross-graining makes it strongbut also susceptible to tear-out and splintering, especially on the exit of the cut.

Reduced Tear-Out: The ball nose geometry, combined with an appropriate helix angle, allows the cutting edges to engage the material more gradually than a flat end mill. This leads to a cleaner shearing action rather than a tearing one.

Smoother Surface Finish: The rounded profile of the ball nose end mill naturally produces a more blended surface, ideal for profiles and contours. For adaptive clearing, this means the sweeping toolpath will leave a consistent, smooth transition in the cleared areas.

Heat Dissipation: While plywood isn’t as prone to generating extreme heat as metals, friction is still a factor. The Tialn coating helps to manage this, keeping the cutting edge cooler and sharper. Good chip evacuation, facilitated by the flute design, also plays a role.

Setting Up for Success: Spindle Speed and Feed Rate

Getting the best results from your Tialn ball nose end mill on plywood isn’t just about the tool itself; it’s about how you use it. Proper spindle speed (RPM) and feed rate are critical.

Finding the Sweet Spot: RPM

Spindle speed dictates how fast the cutting edge rotates. Too slow, and you won’t get an efficient cut; too fast, and you risk burning the wood, excessive wear, and chatter. While exact RPMs depend on your CNC machine, the spindle motor’s power, and the plywood type, there are general guidelines.

For a typical 1/4-inch diameter ball nose end mill cutting plywood, a good starting point might be between 12,000 to 18,000 RPM.

Considerations for RPM:

Plywood Type: Hardwood plywoods might require slightly lower RPMs than softwoods, or conversely, faster speeds with more aggressive feed rates to maintain a shear.

Tool Diameter: Larger diameter end mills generally run at lower RPMs than smaller ones.

Machine Power: Underpowered spindles may struggle at higher RPMs, leading to bogging down.

Cooling/Dust Extraction: Good dust extraction can help manage heat.

Mastering the Feed Rate

Feed rate is how fast the material moves into the spinning cutting tool. It works hand-in-hand with RPM. A good rule of thumb is to maintain a consistent chip load. Chip load is the thickness of the material removed by each cutting edge.

For a 2-flute end mill in plywood, a chip load of 0.003 to 0.008 inches per flute is a reasonable range to start with. To calculate your feed rate:

`Feed Rate (inches per minute) = RPM × Number of Flutes × Chip Load per Flute`

Example Calculation:

Let’s say you are running at 18,000 RPM with a 2-flute end mill, aiming for a chip load of 0.005 inches per flute:

`Feed Rate = 18,000 RPM × 2 flutes × 0.005 in/flute = 180 inches per minute (IPM)`

Considerations for Feed Rate:

Listen to Your Machine: If you hear screaming or bogging, your feed rate is likely too high or your RPM too low. If you hear chattering, it might be too fast or your tool is too far out of balance.

Adaptive Clearing: In adaptive clearing, the feed rate is dynamic. Your CAM software will manage this, but starting with a conservative overall feed rate is wise.

Material Quality: If you notice tear-out, you might need to slow down your feed rate or adjust your spindle speed.

Step-by-Step Guide: Machining Plywood with Your Tialn Ball Nose End Mill

Let’s walk through the process of using your Tialn ball nose end mill for a typical plywood project, focusing on adaptive clearing.

Step 1: Prepare Your Design and CAM Setup

1. Design in CAD: Create or import your 3D model into your Computer-Aided Design (CAD) software. Ensure your design is clean and free of errors.

2. Import into CAM: Load your design into your Computer-Aided Manufacturing (CAM) software.

3. Select the Tool: Choose your Tialn 35-degree ball nose end mill from your tool library. If it’s not there, you’ll need to input its parameters:

Diameter

Number of Flutes

Flute length

Overall length

Shank diameter

4. Define Stock: Accurately define the dimensions and position of your plywood stock.

5. Set up Adaptive Clearing Toolpath:

Machining Area: Select the regions you want to clear out.

Stepover: This is a crucial parameter for adaptive clearing. It defines how much the tool “steps over” from one pass to the next. For a ball nose end mill, a stepover of 20-40% of the tool diameter is common. For a smoother finish, you might reduce this.

Stepdown (or Maximum Roughing Stepdown): This is how deep the tool goes in each Z-axis pass. For plywood, a good starting point might be half the tool diameter, or even less for harder plywoods. For example, if you have a 1/4-inch end mill, a 0.125-inch stepdown is a good starting point.

mịn Stepdown (for finishing): After roughing, you may want to perform a finishing pass with a much smaller stepdown and a finer stepover (e.g., 10-20% of diameter) to achieve a super smooth surface.

Spindle Speed and Feed Rate: Input your calculated RPM and IPM. Your CAM software might allow you to set a “maximum” or “optimal” feed rate, and it will dynamically adjust this during the toolpath.

Ramp/Plunge Moves: Configure how the tool enters the material. For plywood, using a ramp move (like a shallow helix or a lead-in arc) is much better than a direct plunge, as it reduces stress and chatter.

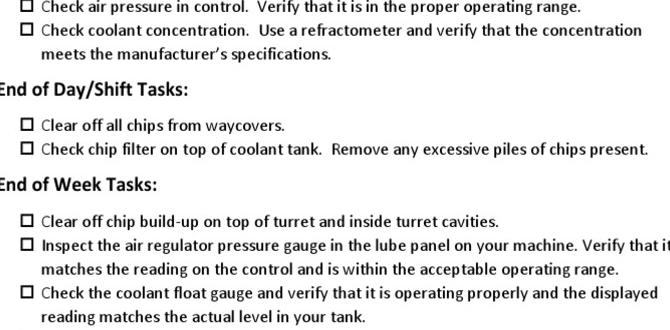

Step 2: Secure Your Plywood Material

1. Use a Reliable Method: Plywood must be clamped down securely to prevent any movement during machining. Use clamps, a vacuum table, or screws in non-critical areas. Ensure your clamps are positioned so they won’t interfere with the toolpath.

2. Check for Warping: Ensure your plywood sheet is flat against your machine bed. Warped material can lead to inconsistent cutting depths and potential tool breakage.

Step 3: Setup the Machine

1. Install the Tool: Carefully insert your Tialn ball nose end mill into the collet and tighten it securely in your CNC spindle.

2. Zero the Axes: Using your CNC controller, carefully jog the machine to set your X, Y, and Z zero points according to your CAM setup.

3. Set Z-Zero: This is often done by touching the end mill to the top surface of your stock. Some prefer to set Z-zero to the machine bed for certain operations.

4. Tool Height Offset: If your CNC has a tool sensor, use it to set the tool height offset accurately.

Step 4: Perform a Dry Run

Crucial Safety Step: Before cutting any material, run your program with the spindle OFF. Watch the toolpath carefully to ensure there are no collisions with clamps, the stock, or any other obstructions. This step can save you from costly mistakes.

Step 5: Execute the Machining Operation

1. Start the Program: Turn on your dust collection system, then start the CNC program.

2. Monitor the Cut: Stay near the machine and listen for any unusual sounds. Watch for excessive dust, smoke, or signs of the tool struggling.

3. Chip Evacuation: Ensure your dust collection is effectively removing chips. For plywood, good chip evacuation is key to preventing heat buildup and providing a cleaner cut. You might consider supplementary air blast.

Step 6: Inspect the Result

1. Clean the Part: Once the machining is complete and the machine has returned to a safe position, carefully remove your part.

2. Examine the Finish: Check the surface for tear-out, burning, or rough patches. Pay close attention to the edges and transitions.

3. Adjust and Repeat: If the results aren’t perfect, don’t be discouraged! Review your CAM settings, RPM, and feed rates based on what you observed. Make small adjustments and run the program again. For instance, if you see tear-out, try a slightly slower feed rate or a finer finishing pass.

Best Practices for Plywood Machining

To maximize the lifespan of your tool and achieve the best possible finish when machining plywood, keep these best practices in mind.

Material Selection Matters

Choose Quality Plywood: Higher quality plywoods (like Baltic Birch or high-grade hardwood plywoods) tend to have more uniform veneers and better glue adhesion, leading to cleaner cuts and less delamination. Avoid construction-grade plywood if a clean finish is paramount.

Grain Direction: While adaptive clearing minimizes the impact of grain direction to some extent, understanding how your end mill will traverse the grain can still be helpful.

Tooling and Maintenance

Sharpness is Key: A dull end mill is the enemy of clean plywood cuts. Tialn coatings help, but eventually, even the best tools wear out. Replace or resharpen your end mill if you notice a degradation in cut quality.

Proper Collet Usage: Use the correct size collet for your end mill shank. A loose end mill in a collet can cause runout, leading to poor finish and potential tool breakage.

Consider Dedicated Plywood Bits: While the Tialn ball nose is versatile, specialized bits like compression bits or single-flute up-cut/down-cut bits are designed specifically for plywood. However, the ball nose excels for contoured surfaces and adaptive clearing.

Machine and Environment

Dust Collection: This cannot be stressed enough. Plywood dust can be fine and irritating, and it will clog your tool and machine. An effective dust collection system is essential for both your health and the quality of your cuts.

Rigidity: Ensure your CNC machine is rigid and well-maintained. Flex in the gantry or spindle can translate to poor cut quality, especially with materials like plywood. Refer to your machine manual for maintenance schedules. For more on general CNC rigidity, resources like CNC Cookbook offer valuable insights.

Cooling (Optional for Plywood): While not always necessary for plywood, sometimes a light mist or air blast can help keep the cutting area cool and clear chips.

CAM Strategies for Plywood

Lead-in/Lead-out: Always use lead-in and lead-out moves. This allows the tool to enter and exit the material smoothly, reducing stress on the cutting edge and minimizing tear-out at the start and end of a pass. For plywood, a tangential lead-in (an arc that is tangent to the toolpath) is often superior to a direct plunge.

Ramping: When plunging into the material, always use a ramp move instead of a direct plunge. This is where the tool moves down at an angle into the material.

* Finishing Passes: For the best surface quality, always include a dedicated finishing pass with a small stepover and potentially a reduced stepdown.

Tialn Ball Nose End Mill: A Summary of Advantages for Plywood

Here’s a quick look at why this tool is a smart choice:

| Advantage | Benefit for Plywood |

| :—————————– | :————————————————————————————- |

| Ball Nose Geometry | Smooth contours, rounded internal corners, reduced stress at edges. |

| 35-Degree Helix Angle | Efficient cutting, good balance of material removal and clean shearing. |

| Tialn Coating | Reduced friction, heat, and tool wear; improved chip evacuation; longer tool life. |

| Adaptive Clearing Synergy | Works perfectly with dynamic toolpaths for efficient, consistent material removal. |

| Reduced Tear-Out | Less splintering and fuzzing, leading to cleaner edges. |

| Smoother Surface Finish | Transcends into higher quality parts, especially for curved surfaces. |

Frequently Asked Questions (FAQ)

Q1: Will a Tialn ball nose end mill work on all types of plywood?

A1: It works well on most common plywood types, including hardwood and softwood plywoods. High-quality plywoods will generally yield better results. Very soft, brittle, or layered composites might still present challenges requiring more fine-tuning of speeds and feeds.

Q2: Can I use this end mill for pocketing in plywood?

A2: Absolutely! The ball nose geometry is excellent for pocketing with rounded internal corners. For deep pockets, you’ll use adaptive clearing with appropriate stepdown settings, and the ball nose will smoothly clear out the material.

Q3: How do I know if my end mill is dull?

A3: Signs of a dull end mill include increased chatter, burning of the material, fuzzy edges even with good feeds/speeds, and a need to push the material harder (which you shouldn’t need to do on a CNC). You’ll also notice increased load on your spindle motor.

Q4: What’s the difference between a 35-degree and a 30-degree or 45-degree helix angle on an end mill for plywood?

A4: A lower helix angle (like 30 degrees) is generally more aggressive and better for softer woods, but can cause more tear-out. A higher angle (like 45 degrees) is better for harder materials and creates a smoother finish but removes material slower. The 35-degree angle