Quick Summary:

For smooth, tear-free nylon machining, a TiAlN ball nose end mill with a 35-degree helix angle is your go-to tool. It’s designed to handle nylon’s unique properties, preventing melting and ensuring clean cuts for hobbyists and pros alike.

Mastering Nylon Machining: Why a 35-Degree TiAlN Ball Nose End Mill is Your Secret Weapon

Working with nylon on a milling machine can sometimes feel like wrestling a sticky, melting blob. It’s a fantastic material for many projects, from DIY prototypes to detailed engineering parts, but its low melting point and toughness present a real challenge for standard cutting tools. You might find yourself fighting chips that weld to the cutter, experiencing excessive heat, and getting rough, unsatisfactory surface finishes. It’s a common frustration for beginners and experienced machinists alike. But don’t worry! The right tool can make all the difference. In this guide, I’ll walk you through why a specific type of end mill – the 35-degree TiAlN coated ball nose end mill – is absolutely essential for successful nylon machining. Get ready to transform your nylon projects from frustrating exercises into smooth, satisfying successes. We’ll cover everything from why this tool works so well to how to use it effectively for stunning results.

Understanding Nylon’s Machining Quirks

Before we dive into the tool itself, let’s chat about why nylon is a bit of a… diva to machine. Compared to metals like aluminum or plastics like ABS, nylon has a lower melting point and tends to gum up tools. It can also be quite tough, especially certain grades.

When a standard end mill bites into nylon, the friction generates considerable heat. Because nylon has a low thermal conductivity, this heat doesn’t have anywhere to escape quickly. The result? The nylon starts to soften and melt. This melted plastic then adheres to the cutting edges of the end mill, a phenomenon known as ‘built-up edge’ (BUE). BUE is a machinist’s nightmare. It essentially ruins the cutting edge, increases friction, and leads to poor surface finish, tool breakage, and dimensional inaccuracies. It’s like trying to cut butter with a dull knife that’s coated in more butter – messy and ineffective!

Furthermore, nylon can exhibit a degree of flexibility and stringiness. This means that under the force of a less-than-ideal cutting tool, it can deflect or deform, leading to inaccurate cuts. The chipping performance can also be problematic, with long, gummy chips being produced that can snag on the tool and further exacerbate the melting issue. For intricate contours, fillets, and 3D profiling, where the tool needs to engage the material in complex ways, these issues are amplified.

The Magic of the 35-Degree TiAlN Ball Nose End Mill

So, given these challenges, what makes a 35-degree TiAlN ball nose end mill the standout performer for nylon? It boils down to a clever combination of coating, geometry, and flute design, all working together to combat nylon’s natural tendencies.

TiAlN Coating: The Heat Shield

Let’s start with the coating: TiAlN stands for Titanium Aluminum Nitride. This is a hard, dark-colored coating applied to the surface of the end mill. Its primary function is to dramatically increase the tool’s hardness and wear resistance, especially at elevated temperatures. Think of it as a super-tough armor for your cutting tool. When machining, friction is inevitable. Standard uncoated end mills can quickly lose their sharpness and structural integrity when exposed to the heat generated by cutting. TiAlN resists this thermal degradation.

Specifically for plastics like nylon, this coating helps in a couple of key ways:

- Reduced Friction: The smooth, hard surface of TiAlN creates less friction between the tool and the workpiece. Less friction means less heat directly generated by the cut.

- Heat Dissipation: While it doesn’t cool the material, the coating’s properties help manage the heat that is generated. It prevents the heat from transferring as readily from the chip to the tool’s cutting edge, which is crucial for preventing melting.

- Anti-Welding Properties: The TiAlN coating also has inherent properties that make it more resistant to the workpiece material ‘sticking’ or welding onto the cutting edge. This significantly reduces the formation of Built-Up Edge (BUE) on nylon.

For a material like nylon that’s prone to melting, a robust coating that minimizes heat buildup and prevents material adhesion is absolutely critical. You can learn more about advanced tool coatings and their applications on resources like the National Institute of Standards and Technology (NIST), which often delves into material science and manufacturing technologies.

Ball Nose Geometry: For Smooth Contours

The “ball nose” part of the name refers to the shape of the end of the end mill. Instead of being flat or pointed, it has a hemispherical tip. This geometry is perfect for creating curved surfaces, fillets, and pockets with rounded bottoms. When machining nylon, this shape is advantageous because:

- Reduced Chipload per Tooth: The rounded profile naturally leads to a smaller chip thickness for a given depth of cut and feed rate, especially in trochoidal milling strategies. This helps manage heat generation and prevents excessive material deformation.

- Continuous Engagement: For 3D profiling and contouring, the ball nose allows for continuous engagement with the workpiece without creating sharp corners that can be stress points or lead to uneven material removal. This is vital for achieving smooth, flowing surfaces on nylon.

- Reduced Cutting Forces: Compared to a square end mill making a sharp corner, a ball nose can distribute cutting forces more evenly, leading to less strain on both the tool and the workpiece.

The 35-Degree Helix Angle: The Sweet Spot for Plastics

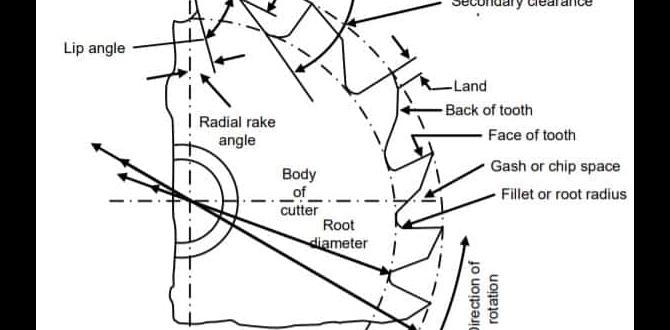

Now for the specific angle: 35 degrees. This refers to the helix angle of the flutes. The helix angle is the angle formed by the cutting edge and the axis of the tool. It affects chip evacuation, cutting forces, and chatter resistance.

Why 35 degrees for nylon?

- Good Chip Evacuation: A moderate helix angle like 35 degrees strikes a good balance. It’s steep enough to help pull chips up and away from the cutting zone effectively, preventing them from building up and causing melting. This is crucial for nylon.

- Reduced Axial Rake: A steeper helix angle generally leads to a more negative axial rake angle. For plastics, a significantly negative rake angle isn’t ideal as it can increase cutting forces and heat. A 35-degree helix provides a generally favorable rake angle for softer materials like nylon, preventing excessive gouging or tearing.

- Balance of Strength and Sharpness: Flutes with very steep helix angles can sometimes be less structurally strong. Conversely, very shallow angles might not evacuate chips as well. The 35-degree angle offers a good compromise, providing sufficient sharpness and chip control without compromising tool rigidity, which is important when dealing with nylon’s toughness.

- Reduced Chatter: The progressive engagement of the cutting edge due to the helix angle can also help dampen vibrations, leading to a smoother cut and reducing the likelihood of chatter, which can be a problem when machining flexible materials.

While higher helix angles (like 45 or 55 degrees) are often used for softer metals and plastics to improve chip evacuation, 35 degrees is often considered the “sweet spot” for nylon. It provides aggressive enough chip removal without inducing excessive cutting forces or heat that can overwhelm the material’s low melting point. It’s a carefully engineered balance for this specific material.

Trochoidal Milling: The Advanced Technique it Enables

The combination of a TiAlN coating, ball nose shape, and 35-degree helix angle is particularly well-suited for a machining strategy called trochoidal milling. This is a high-feed, low-depth-of-cut method that uses a circular path to create a scalloped groove. It’s incredibly effective for slotting and pocketing.

Here’s why it works so well with our end mill:

- Constant Chip Load Management: In trochoidal milling, the tool moves in a circular path while advancing linearly. This ensures that the chip load (the amount of material removed by each cutting edge per revolution) remains consistent and relatively small. Each tooth engages and disengages the material in a controlled manner.

- Superior Heat Control: Because the depth of cut in trochoidal milling is small and the chip load per tooth is managed, the heat generated is significantly less than with conventional slotting. The helical flutes of the 35-degree end mill help evacuate the thin chips efficiently, further minimizing heat buildup.

- Maximizing Tool Life: By consistently removing small chips and keeping the tool from being overloaded or overheating, trochoidal milling dramatically extends the life of your end mill, especially when working with tricky materials like nylon.

- Achieving Fine Surface Finishes: The smooth, consistent engagement and evacuation prevent material tearing and melting, leading to remarkably clean surfaces on nylon.

To implement trochoidal milling effectively, accurate CAM programming is essential. Software like Fusion 360 or Mastercam offer dedicated strategies for this. A good understanding of machining parameters is key. For more on this machining strategy, you can explore resources on advanced CAM techniques.

Key Features of a 35-Degree TiAlN Ball Nose End Mill

When you’re looking to purchase one of these specialized end mills, keep an eye out for these critical features:

- Material: Typically made from high-quality solid carbide for durability and heat resistance.

- Coating: TiAlN (Titanium Aluminum Nitride) is a must-have for its thermal stability and anti-stick properties.

- Geometry: Ball Nose – ensure the radius matches your desired fillet size or profile.

- Helix Angle: 35 degrees is the key number for effective nylon machining.

- Number of Flutes: For plastics, 2-flute or 3-flute end mills are common. 2-flute generally offers better chip clearance and is less prone to clogging in gummy materials, while 3-flute can offer a smoother finish and better rigidity for harder plastics or certain machining paths. For nylon, 2-flute is often preferred to maximize chip evacuation.

- Shank: Standard Weldon shank for secure clamping in your tool holder. Some may have coolant-through capabilities, which is an added bonus.

When to Use Your 35-Degree TiAlN Ball Nose End Mill on Nylon

This specialized end mill isn’t just for any job. It truly shines in these scenarios:

- 3D Contouring and Sculpting: Creating organic shapes, curved surfaces, or detailed models.

- Pocketing with Radiused Corners: Machining pockets where sharp internal corners would be problematic or impossible to achieve cleanly in nylon.

- Creating Fillets and Rounds: Adding smooth transitions between surfaces.

- Engraving Intricate Designs: Where precise, clean detail is required.

- Any application where preventing melting and achieving a smooth finish on nylon is paramount.

It’s a specialist tool, meaning it might not be the first end mill you grab for simple, straight slotting in softer materials, but when nylon’s specific challenges come into play, it becomes invaluable.

Setting Up for Success: Machining Parameters and Best Practices

Using the right tool is only half the battle. Proper setup and machining parameters are crucial for getting the best results from your 35-degree TiAlN ball nose end mill when working with nylon.

Feed Rate and Spindle Speed (The Dance Between Them)

Finding the right balance between feed rate (how fast the tool moves through the material) and spindle speed (how fast the tool rotates) is key. Here’s a general guideline for nylon:

- Spindle Speed (RPM): Nylon generally prefers slower to moderate spindle speeds. Running too fast increases heat generation exponentially. Start in the range of 6,000 to 15,000 RPM, depending on the diameter of your end mill and rigidity of your setup. Smaller end mills might need faster speeds, while larger ones need slower speeds.

- Feed Rate (IPM or mm/min): This is where you can afford to be a bit more aggressive, especially with trochoidal milling. A higher feed rate, coupled with a shallow

depth of cut, helps ensure that the chips are thin and are aggressively evacuated by the helix angle. Start in the range of 15-40 inches per minute (380-1000 mm/min) for a 1/4-inch (6mm) end mill, adjusting based on the chip load.

- Chip Load per Tooth: This is arguably the most important parameter for plastics. It’s the thickness of the material removed by each cutting edge per revolution. For nylon with a 2-flute end mill, aim for a chip load between 0.002″ to 0.005″ (0.05mm to 0.13mm) per tooth. A higher chip load with a shallow depth of cut is generally better for heat management.

A good starting point for a 1/4″ (6mm) diameter, 2-flute, 35-degree helix TiAlN ball nose end mill on nylon:

| Parameter | Typical Value (Imperial) | Typical Value (Metric) | Notes |

|---|---|---|---|

| Spindle Speed (RPM) | 10,000 – 15,000 | 10,000 – 15,000 | Adjust for tool diameter and rigidity. |

| Feed Rate (IPM) | 20 – 35 | 500 – 900 | For trochoidal milling. |

| Depth of Cut (Axial – DOC) | 0.010″ – 0.040″ | 0.25mm – 1.0mm | Shallow is good for heat control. |

| Width of Cut (Radial – Stepover) | 20-50% for contouring, up to 70%+ for trochoidal | Trochoidal uses a large stepover. | |

| Chip Load per Tooth | 0.002″ – 0.004″ | 0.05mm – 0.10mm | Crucial for preventing melting. |

Depth of Cut (DOC) and Stepover

For nylon, it’s usually best to take shallow axial depths of cut (DOC) – think typically no more than 1/16″ (1.5mm) for larger diameters, and even less for smaller ones. This helps keep the heat down.

The radial stepover (how much the tool moves sideways in each pass) will depend on your strategy. For general contouring, 30-50% is common. For trochoidal milling, you might use a much larger radial stepover (60-80% or more) because the tool is moving in a circular pattern, effectively engaging more of its cutting circumference with each pass.

Coolant and Lubrication

Using a coolant or lubricant is highly recommended, even with the TiAlN coating. It helps further reduce friction and heat, and it can also assist in clearing chips.

- Flood Coolant: If your machine has it, a good flood coolant system is excellent for removing heat and washing away chips.

- Mist Coolant: A mist coolant system provides a fine spray of coolant and air, which is very effective for plastics. The air blast also helps clear chips.

- Dry Machining (with caution): In some very light-duty applications or with extremely small tools on desktop CNCs, you might get away with dry machining if you are meticulously controlling your parameters. However, this is generally not recommended for reliable, repeatable results on nylon.

- Lubricants: Specific plastic-machining lubricants can also be beneficial. Things like compressed air aimed directly at the cut can help.

Avoid using excessive amounts of oil-based coolants, as they can sometimes react with certain plastics or create difficult-to-clean residues.

Tool Holder and Workholding

Ensure your tool holder is clean and provides a secure grip on the end mill. Runout (wobble) in the tool holder will lead to uneven cutting and poor surface finish, which is especially noticeable on plastics.

Workholding is also critical. Nylon can be a bit springy. Make sure your part is held firmly and won’t shift or vibrate during machining. Double-sided tape can work for very light cuts or prototypes, but for more robust parts, mechanical vices, clamps, or fixtures are necessary.

Air Blast

Even without coolant, a directed air blast at the cutting zone can be surprisingly effective. It helps cool the cut and, more importantly, blows away chips that would otherwise sit, reheat, and melt into the nylon.