The Tialn Ball Nose End Mill 35 Degree is an excellent choice for effectively machining Inconel 718, especially for thin-wall applications. Its specific coating and geometry minimize heat and chatter, leading to cleaner cuts and longer tool life. Learn how to use it successfully with this beginner’s guide.

Machining Inconel 718 can feel like a wrestling match. This superalloy is tough, sticky, and loves to generate heat. For beginners, working with it can be particularly daunting, especially when you need to create intricate shapes or work with thinner materials where chatter can quickly ruin your part. You might have heard about specialized tools that make this job easier, but where do you start? We’ve all been there, staring at a new project, wondering if your existing tools are up to the task. The good news is, the right tooling makes all the difference. Today, we’re going to demystify one of these game-changers: the Tialn ball nose end mill with a 35-degree helix angle, specifically for Inconel 718.

This isn’t just any end mill. Its unique design and specialized coating are engineered to tackle the challenges of Inconel 718, delivering smooth finishes and preventing those frustrating workpiece failures. We’ll walk you through exactly why this tool is so effective and how you can use it with confidence, even if you’re just starting out in milling. Get ready to turn those Inconel 718 challenges into successful machining victories!

Why Inconel 718 is a Machining Challenge

Before we dive into the specifics of the Tialn ball nose end mill, let’s quickly understand why Inconel 718 demands special attention. It’s a nickel-chromium superalloy known for its incredible strength, hardness, and resistance to high temperatures and corrosion. These same properties that make it fantastic for aerospace and demanding industrial applications also make it notoriously difficult to machine.

- High Strength and Hardness: Inconel 718 is very strong, meaning it requires higher cutting forces. This can lead to tool wear and vibrations.

- Low Thermal Conductivity: It doesn’t dissipate heat well. Most of the heat generated during machining stays in the cutting zone, which can quickly damage the cutting edge of your tool and the workpiece.

- Tendency to Work Harden: As you cut into it, Inconel 718 can become even harder, making subsequent cuts more difficult and increasing wear on your tools.

- Galling and Stickiness: The material can “stick” to the cutting tool, leading to poor surface finish and even tool breakage. This is particularly problematic in thin-wall machining where the workpiece is less rigid.

Introducing the Tialn Ball Nose End Mill 35 Degree

So, how do we combat these challenges? That’s where specialized tooling comes in. The Tialn ball nose end mill with a 35-degree helix angle is designed precisely for materials like Inconel 718. Let’s break down what makes it so effective:

What is a Ball Nose End Mill?

Unlike flat-bottomed end mills, a ball nose end mill has a fully rounded cutting tip. This shape is crucial for creating contoured surfaces, fillets, and pockets with rounded corners. The rounded tip allows for 3D machining and provides a smooth, continuous cutting action, which is especially beneficial for reducing stress concentrations in thin-wall parts.

What is the Tialn Coating?

Tialn stands for Titanium Aluminum Nitride. It’s a PVD (Physical Vapor Deposition) coating applied to the surface of the end mill. This coating offers:

- Extreme Hardness: It further increases the tool’s resistance to wear and abrasion, allowing it to cut through tough materials like Inconel 718 for longer.

- High Temperature Resistance: The coating can withstand higher temperatures than uncoated carbide, which is vital for materials that generate a lot of heat during machining.

- Reduced Friction: Tialn coating creates a smoother surface, reducing friction between the tool and the workpiece. This helps prevent material from sticking (galling) and lowers the heat generated.

- Oxidation Resistance: It helps protect the cutting edge from oxidizing at high temperatures, maintaining sharpness.

The Significance of the 35-Degree Helix Angle

The helix angle of an end mill refers to the angle of the flutes (the cutting edges that spiral around the tool). For machining tough alloys like Inconel 718, especially in thin-wall applications, a moderate helix angle like 35 degrees offers several advantages over steeper angles (like 45 degrees or more) or zero helix (straight flutes):

- Reduced Cutting Forces: A 35-degree helix angle generally results in lower axial and radial cutting forces compared to steeper helix angles. This is critical for thin-wall machining because it minimizes the tendency for the workpiece to flex or vibrate, which can lead to inaccuracy and poor surface finish.

- Improved Chip Evacuation: The angle helps to curl and break chips effectively, moving them away from the cutting zone. Good chip evacuation is essential to prevent chip recutting and to keep cutting temperatures from escalating.

- Smooth Cutting Action: The moderate angle provides a smoother, more continuous engagement with the material. This reduces chipping and chatter, leading to a better surface finish.

- Cutting Edge Strength: A 35-degree helix angle often allows for a stronger cutting edge geometry, which is better suited to handling the abrasive nature of Inconel 718.

Proven Inconel 718 Success: How it Works in Practice

Combining the rounded tip of a ball nose end mill with the Tialn coating and a 35-degree helix angle creates a tool that’s exceptionally well-suited for Inconel 718. Here’s why it’s proven to be successful:

For thin-wall machining, rigidity is king. Inconel 718’s tendency to deform under cutting pressure means that a tool that requires excessive force can cause the thin walls to flex, vibrate, or even collapse. The 35-degree helix angle on the Tialn ball nose end mill helps to mitigate this by:

- Minimizing Chatter: Chatter is the enemy of precision and surface finish. It’s caused by vibrations between the tool, workpiece, and machine. The smooth, sweeping cut that a 35-degree helix provides, especially when combined with the lubricity of the Tialn coating, significantly reduces the likelihood of chatter. This results in a much cleaner cut on delicate parts.

- Reducing Radial Plunge: When plunging an end mill into material, a steeper helix can cause a “camming” action that pushes the tool sideways. A 35-degree helix is gentler, allowing for more controlled entry into the material, which is crucial when you don’t want to disturb a thin-walled structure.

- Maintaining Tool Integrity: The Tialn coating’s hardness and heat resistance mean that the cutting edge stays sharper for longer, even when pushed through tough Inconel 718. This consistent sharpness is vital for achieving predictable and repeatable results.

When you consider that Inconel 718 is often used in aerospace components where precise, complex geometries and exceptional surface finish are non-negotiable, it’s easy to see why this specific tool combination becomes indispensable. For instance, in creating impellers or turbine blades, where thin walls and intricate contours are common, the ability of this end mill to provide these complex shapes without inducing damaging vibrations or heat is paramount. You can find more information on aerospace material machining challenges at sites like the NASA website, which often details the material science and engineering behind their projects.

Key Features for Beginners When Selecting Your Tool

When you’re starting out, navigating the world of end mills can be confusing. Here are the key features of your Tialn ball nose end mill that you should be aware of, even before you buy:

- Diameter: Choose a diameter suitable for the features you need to machine. Smaller diameters are good for intricate details, while larger ones are for broader areas.

- Number of Flutes: For Inconel 718 and similar tough materials, a 2-flute or 3-flute end mill is often recommended. Fewer flutes provide better chip clearance and are less prone to clogging in gummy materials.

- Coating: Ensure it’s Tialn (or a similar high-performance coating like AlTiN). This is your primary defense against the heat and abrasion of Inconel 718.

- Helix Angle: As we’ve discussed, 35 degrees is a sweet spot for Inconel 718, especially for thin-wall work.

- Carbide Grade: Most high-performance end mills for superalloys are made from solid carbide. Look for a reputable manufacturer that specifies their carbide grade, though for beginners, relying on brand reputation is a good start.

- Ball Radius: This refers to the radius of the rounded tip. A common size is 1mm or 0.060 inches, but this depends on the detail required for your specific part.

Essential Machining Parameters for Inconel 718

Using the right tool is only half the battle. Proper machining parameters are crucial for success with Inconel 718. These guidelines are general, and you may need to adjust them based on your specific machine, setup, and the exact grade of Inconel 718.

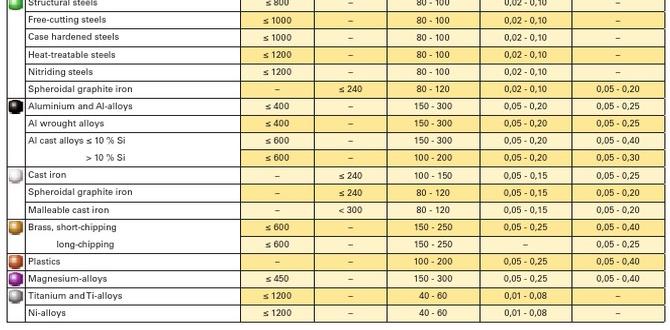

Surface Speed and Feed Rate Considerations

These are perhaps the most critical parameters. They dictate how fast the tool spins (surface speed) and how much material it removes with each pass (feed rate).

- Surface Speed (SFM or m/min): For Inconel 718 with a Tialn coated carbide end mill, you’re typically looking at lower surface speeds compared to machining softer metals like aluminum. A good starting point might be between 10-30 SFM (3-10 m/min). Too high, and you’ll burn up the tool; too low, and you won’t be cutting efficiently.

- Feed Rate (IPM or mm/min): This is often expressed as chip load (e.g., inches per tooth or mm per tooth). For Inconel 718, you want a robust chip load to ensure you’re actually shearing the material, not rubbing. For a 1/4″ (6mm) end mill, you might start with a chip load of 0.002 – 0.005 inches per tooth (0.05 – 0.12 mm/tooth). This means for a 2-flute end mill, the feed rate would be 2 x (chip load) x (RPM).

Key Principle: Think of it as a delicate balance. You need enough speed to cut efficiently, but not so much that you generate excessive heat. You need enough feed to create a proper chip, but not so much that you overload the tool or the machine.

Depth of Cut (DOC) and Width of Cut (WOC)

These determine how much material you remove in each pass.

- Depth of Cut (DOC): For Inconel 718, especially with thin walls, it’s often best to take relatively shallow axial depths of cut. This reduces the load on the tool and minimizes deflection. You might be looking at DOCs as low as 0.010 – 0.050 inches (0.25 – 1.25 mm) for finishing passes, and perhaps up to 0.100 – 0.200 inches (2.5 – 5 mm) for roughing, depending on the tool diameter and machine rigidity.

- Width of Cut (WOC): For ball nose end mills, the radial engagement (WOC) significantly impacts cutting forces. For achieving smooth finishes in Inconel 718, especially in complex 3D contours, a common strategy is to use a small radial engagement, sometimes referred to as a “high-efficiency machining” (HEM) strategy or “adaptive clearing.” This can be as low as 10-30% of the tool diameter (.025″ – .075″ for a 1/4″ end mill). This strategy reduces cutting forces, controls heat, and maximizes tool life.

Coolant and Lubrication

Proper coolant and lubrication are non-negotiable when machining Inconel 718. The goal is to flood the cutting zone to:

- Cool the tool and workpiece.

- Flush chips away efficiently.

- Lubricate the cutting edge to reduce friction and prevent galling.

A high-pressure coolant system, often through-the-tool coolant (if your machine supports it), is highly recommended. A synthetic coolant or a specialized coolant for superalloys is ideal. For lighter operations, a good quality cutting fluid applied generously can also work.

Recommended Machining Procedures

Here’s a general approach to machining Inconel 718 with your Tialn ball nose end mill, focusing on beginner-friendly steps:

Step 1: Secure Your Workpiece Firmly

This is paramount for thin-wall machining. Ensure your Inconel 718 part is held robustly in a vise or fixture. Use soft jaws if necessary to avoid marring the part but ensure there’s no chance of movement during cutting. Any flex or movement here will translate into poor results. For thin-wall parts, consider using a backing material or internal support if possible.

Step 2: Set Up Your Machine and Tool

- Mount the Tialn ball nose end mill securely in your collet or tool holder. Ensure runout (the wobble of the tool) is minimized for the best results.

- If using through-the-tool coolant, connect it now.

- If your machine has tool length compensation (TLC), ensure you have accurately measured the tool length.

Step 3: Program Your Toolpaths (Or Manually Enter Parameters)

This is where you define how the end mill will cut the material. For beginners, starting with simpler toolpaths is wise.

- Facing: If you need a flat surface, use a generous WOC (maybe 50% of the tool diameter) for a flat end mill, but for a ball nose, you’d typically use a raster or contour path with a small WOC (10-30% is good for finishing passes).

- Profiling/Contouring: Use ball nose end mills for cutting complex 3D shapes or adding fillets. Keep the WOC small (10-20% of tool diameter) for a smooth finish.

- Pocketing: For pockets with rounded corners, the ball nose is ideal. Consider using adaptive or high-efficiency clearing strategies if your CAM software supports them, as they maintain a consistent chip load and WOC.

Step 4: Implement Conservative Cutting Parameters

Start with the lower end of the recommended speeds and feeds. It’s always better to be too slow and conservative initially than to break a tool or ruin a part.

| Diameter | Flutes | Surface Speed (SFM) | Chip Load per Tooth (in/tooth) | RPM (approx.) | Feed Rate (IPM, approx.) | Axial DOC (in) | Radial WOC (%) |

|---|---|---|---|---|---|---|---|

| 1/4″ (6.35mm) | 2 | 15-25 | 0.003 – 0.005 | 2000-3000 | 12 – 30 | 0.015 – 0.050 | 0.050 – 0.100 (20-40%) |

| 1/2″ (12.7mm) | 3 | 15-25 | 0.005 – 0.008 | 1000-1500 | 15 – 36 | 0.030 – 0.100 | 0.100 – 0.150 (20-30%) |

Note: These are starting points. Always consult your tool manufacturer’s recommendations and adjust based on your specific setup and sound/vibration. Higher rigidity allows for higher parameters.

Step 5: Ensure Adequate Coolant Flow

Flood the cutting zone with your chosen coolant. Listen to the sound of the cut – a good ringing sound is generally desirable, while a screeching or grinding noise indicates a problem (likely heat or chatter).

Step 6: Make Your Cut and Listen!

Start the spindle and