Unlock Smooth Aluminum Ramping: The TiAlN Ball Nose End Mill 35 Degree is your secret weapon for effortless, chatter-free cuts, preventing costly mistakes and surface damage.

Working with aluminum can be a dream or a nightmare depending on your tooling. If you’ve ever struggled with your end mill digging in, vibrating, or leaving a rough finish when cutting deep into aluminum, you’re not alone. The right tool makes all the difference, especially when creating complex shapes or pockets. We’re going to dive into why a 35-degree helix angle TiAlN ball nose end mill is so brilliant for ramping in aluminum, and how you can get amazing results every time. Get ready to make your aluminum machining easier and more effective!

What is a TiAlN Ball Nose End Mill and Why 35 Degrees for Aluminum?

Let’s break down this tool name: “TiAlN Ball Nose End Mill 35 Degree.”

End Mill: This is the cutting tool we’re talking about. It looks a bit like a drill bit but has cutting edges along its sides and on its tip. They’re used in milling machines to cut slots, pockets, profiles, and 3D shapes.

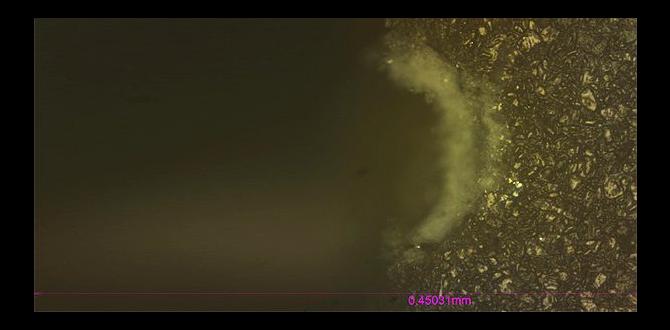

Ball Nose: This describes the shape of the cutting tip. A ball nose end mill has a rounded, hemispherical tip. This makes them perfect for cutting curved surfaces, finishing contours, and, importantly for us, making smooth ramps.

TiAlN (Titanium Aluminum Nitride) Coating: This is a super thin, hard coating applied to the surface of the end mill. Think of it like a suit of armor for the tool. TiAlN is excellent for high-temperature applications and is known for its toughness, wear resistance, and ability to reduce friction. This is a big deal when cutting sticky materials like aluminum.

35 Degree Helix Angle: This is the “sweet spot” for many aluminum applications, especially for ramping. The helix angle is the angle of the flutes (the spiral grooves) around the cutting tool. A 35-degree angle provides a good balance:

Good Chip Evacuation: It helps to efficiently clear out the aluminum chips, preventing them from clogging the flutes and causing issues.

Smooth Cutting Action: This angle is known for reducing vibration and chatter, leading to a much smoother cut.

Reduced Cutting Forces: It allows the tool to engage the material more gradually, reducing the force needed to cut.

Why is Ramping Important?

Ramping is a cutting strategy where the tool moves down into the material in a gentle, sloped path, like a ramp, instead of plunging straight down. This is crucial for several reasons:

Tool Life: Plunging straight down with an end mill puts a lot of stress on the tip. Ramping distributes this stress along the side of the tool, dramatically increasing its lifespan.

Surface Finish: Ramping creates a much smoother entry into the material, significantly improving the surface finish of your pockets and contours.

Machine Stress: It’s less demanding on your milling machine’s spindle and drive system.

Chip Control: As mentioned, it helps in managing aluminum chips, which can be gummy and problematic.

When you combine the efficient cutting action of a 35-degree helix angle with the smooth engagement of a ball nose tip, and the wear resistance of TiAlN coating, you have a tool specifically designed to excel at ramping in aluminum.

The Genius of 35 Degrees for Aluminum Ramping

So, why is 35 degrees often considered the “genius” angle for ramping aluminum with a ball nose end mill? It’s all about the physics of cutting and the properties of aluminum.

Aluminum, especially alloys like 6061, is known for being soft and gummy. This means chips can easily stick to the cutting tool, leading to:

Built-up Edge (BUE): Aluminum welding onto the cutting edge.

Poor Surface Finish: Rough, torn surfaces.

Increased Cutting Forces: Making the machine work harder.

Tool Breakage: When chips pack too tightly.

Traditional end mills with steeper helix angles (like 45 or 60 degrees) can sometimes be too aggressive for ramping gummy materials. They can grab, vibrate, and create a lot of heat. Conversely, very shallow helix angles might not clear chips well enough.

A 35-degree helix angle hits a sweet spot:

Gentle Engagement: The angle allows the tool to cut with less aggressive chip formation, reducing chatter and vibration. This is crucial for a smooth ramping motion.

Effective Chip Evacuation: While not as steep as a 45-degree angle, the 35-degree flute is still steep enough to help push those aluminum chips away from the cutting zone. This keeps the flutes clear and prevents BUE.

Good Balance of Strength and Sharpness: The cutting edges on a 35-degree helix are often more robust than those on a steeper angle, yet still sharp enough for efficient cutting.

TiAlN’s Helping Hand: The TiAlN coating adds another layer of magic. It’s incredibly hard, which means it resists wear. It also has low friction, which is a huge benefit when cutting aluminum because it helps prevent that gummy material from sticking to the mill. This means the tool stays sharper for longer, and you get a cleaner cut.

In essence, the 35-degree helix angle on a TiAlN coated ball nose end mill is a perfect storm for smooth, efficient, and precise aluminum ramping. It’s designed to make this often tricky operation feel effortless.

When to Use a TiAlN Ball Nose End Mill with a 35 Degree Helix

This specific type of end mill isn’t just for one scenario. It shines in these situations, especially when working with aluminum:

1. Ramp Milling Pockets and Cavities

This is its primary strength. When you need to create a deep pocket or a cavity in your aluminum part, ramping is the way to go. A 35-degree helix ball nose end mill will smoothly enter the material, spiral down, and create a clean surface as it descends. This is far superior to just plunging a standard end mill.

2. Creating Contours and 3D Surfaces

Because it’s a ball nose end mill, it’s ideal for finishing complex curved surfaces. When combined with its ramping ability, you can create flowing, organic shapes with excellent surface finish. The 35-degree helix ensures smooth transitions as the tool carves out the geometry.

3. High-Speed Machining (HSM) Strategies

For hobbyists and professionals alike, High-Speed Machining techniques often involve taking smaller, faster cuts. A 35-degree helix angle helps to manage the chip load and heat generated during these faster operations, making it a good companion for HSM in aluminum.

4. Machining Gummy Alloys

If you’re working with aluminum alloys known for being particularly sticky or gummy, like 7075 or even some batches of 6061, the improved chip evacuation and reduced friction provided by the 35-degree helix and TiAlN coating are invaluable.

5. Improving Tool Life and Reducing Breakage

For beginners, tools breaking can be frustrating and costly. Using the right tool for the job, like a 35-degree ball nose for ramping aluminum, dramatically reduces the risk of premature tool failure due to chip-packing or excessive forces. It’s a confidence builder!

6. When a Smooth Finish is Paramount

If the surface finish of your part is critical, especially in visual applications or areas that require precise fits, the clean cutting action promotes a much better finish than aggressive plunging.

External Link: Understanding Aluminum Alloys

To better understand why certain tools perform better with specific aluminum alloys, it’s helpful to learn about their properties. The MakeIt-3DP Guide to Aluminum Alloys provides a good overview of different types and their machining characteristics.

Best Practices for Ramping Aluminum with Your 35 Degree TiAlN Ball Nose End Mill

Achieving perfect results isn’t just about having the right tool; it’s also about how you use it. Here are some essential best practices:

1. Set Your Ramping Angle Correctly

The end mill has a 35-degree helix, but your actual ramp angle in the CAM software or manual control might need to be different. A common maximum ramping angle for aluminum is often around 5-10 degrees. The tool’s helix angle helps it to cut while it’s ramping. Don’t try to ramp at 35 degrees unless your CAM strategy specifically calls for it in a very unique way. The tool’s helix is about its internal flute geometry, not necessarily the path it takes into the material.

2. Proper Speeds and Feeds

This is crucial for any machining operation. For aluminum, you generally want to run your spindle faster and feed faster than you would for steel.

Spindle Speed (RPM): Look up recommended surface speeds for aluminum machining with TiAlN coated carbide end mills. These can range from 300 to 800 surface feet per minute (SFM), depending on the specific alloy and tool diameter. Convert this to RPM using the formula: RPM = (SFM 3.82) / Diameter (inches).

Feed Rate (IPM): Chip load is key here. Aim for a chip load that helps the tool “shave” rather than “scrape.” Start with manufacturer recommendations and adjust based on sound and surface finish. A good starting point for a 1/4″ end mill might be 0.002″ – 0.004″ per tooth.

Consulting the end mill manufacturer’s data sheet for specific speeds and feeds is always recommended.

3. Use a Quality Coolant or Lubricant

Aluminum can get sticky. Using a coolant or lubricant is highly recommended.

Flood Coolant: The best option if your machine allows. It keeps the tool cool, lubricates the cut, and flushes chips away.

Mist Coolant: A good alternative for hobby machines.

Lubricant Stick/Paste: For manual machining, a good aluminum-specific cutting lubricant applied directly to the cutting zone can make a world of difference.

4. Ensure Good Chip Evacuation

Even with a 35-degree helix, efficient chip evacuation is key.

Don’t Over-Depth: Avoid taking cuts that are too deep in one pass.

Control Your Path: Ensure your CAM software is programmed to clear chips effectively.

Air Blast: If using coolant, an air blast can help force chips out of deep pockets.

5. Material Holding is Paramount

Make sure your aluminum workpiece is securely clamped. Any vibration from a loose part will negatively impact your finish and tool life. Use vises, clamps, or jigs as appropriate for your project.

6. Program Your Ramps Carefully

In your CAM software (like Fusion 360, Mastercam, etc.), when setting up the toolpath:

Select “Ramp” or “Helical Interpolation” operation.

Set the maximum ramp step-down distance. This is how much the tool moves down per revolution when ramping. A smaller step-down is generally better for smoother cuts.

Set the ramp clearance. This is the vertical distance the tool will clear while moving between ramp paths.

7. Check and Re-check Your Tool Length:

Ensure your tool length offset is accurately set. A slight error here can cause issues with the ramp depth, leading to poor finish or even tool collision.

Table: TiAlN Ball Nose End Mill vs. Other Options for Aluminum Ramping

Here’s a quick comparison to highlight why the 35-degree TiAlN ball nose end mill is so effective for aluminum ramping.

Feature

TiAlN Ball Nose 35° Helix

Uncoated Ball Nose 35° Helix

TiAlN Ball Nose 45° Helix

Standard End Mill (Square)

Best For Ramping Aluminum

Excellent

Good

Very Good (can be more aggressive)

Poor (especially for deep pockets)

Surface Finish

Very Smooth

Smooth

Smooth to Good

Variable, often rougher

Chip Evacuation

Very Good

Very Good

Excellent

Moderate

Tool Life (in Aluminum)

Excellent (due to coating)

Good

Good (coating helps)

Limited (prone to BUE)

Vibration/Chatter Resistance

Excellent

Excellent

Good

Moderate

Heat Resistance

Excellent

Good

Excellent

Good

Cost

Medium-High

Medium

Medium-High

Low-Medium

As you can see, the combination of the TiAlN coating and the 35-degree helix provides a fantastic balance for aluminum. The coating fights stickiness and wear, while the helix angle promotes smooth cutting and good chip flow.

Choosing the Right Diameter and Flutes

While we’ve focused on the helix angle and coating, two other factors are important: diameter and flute count.

Diameter:

The diameter of your ball nose end mill will be determined by the size of your features.

Larger diameters are great for roughing and general contouring.

Smaller diameters are needed for detailed work, tight corners, and plunge cuts.

For ramping, the diameter matters for the step-over you can achieve. A larger diameter means you can ramp further across the surface in each pass, potentially speeding up machining. Always ensure your tool is smaller than the tightest radius you need to cut.

Flute Count

2-Flute End Mills: Often preferred for aluminum. They provide good chip clearance and are less prone to chip packing than multi-flute tools. The larger flute volume helps to carry chips away.

3-Flute End Mills: Can also work for aluminum, especially if you’re running at higher speeds and need more cutting edges for better surface finish. However, they can sometimes pack chips more easily than 2-flute tools.

4-Flute End Mills: Generally not recommended for aluminum, as they can lead to chip packing and reduced cutting action. They are better suited for harder materials like steel.

For ramping aluminum with a 35-degree helix, a

2-flute TiAlN coated ball nose end mill is usually the go-to choice.

Safety First!

Machining, no matter how simple it seems, always requires a focus on safety. When using your TiAlN ball nose end mill for ramping:

Wear Safety Glasses: Always, without exception. Aluminum chips can be sharp and unpredictable.

Secure Your Workpiece: A loose workpiece can cause the tool to grab violently, leading to tool breakage or part ejection.

Proper Machine Guarding: Ensure all guards are in place.

Listen to Your Machine: If you hear excessive chattering, grinding, or unusual noises, stop the machine immediately and investigate. It’s likely an issue with speeds/feeds, tool condition, or workpiece holding).

Understand Your CAM Software: If you’re using CAM, make sure you understand the toolpaths you’re generating. Simulation can help catch potential problems.

Tool Condition:** Regularly inspect your end mill for any signs of wear, chipping, or built-up edge. A dull or damaged tool is a safety hazard and produces poor results.

FAQ: Your TiAlN Ball Nose End Mill Questions Answered

Q1: What is the main advantage of a TiAlN coating on an end mill for aluminum?

A1: The TiAlN coating provides excellent hardness and reduces friction. This is great for aluminum because it helps prevent the gummy material from sticking to the cutting edge (built-up edge) and improves tool life and surface finish.

Q2: Can I use a 35-degree helix ball nose end mill for materials other than aluminum?

A2: Yes, but it’s optimized for aluminum. It can work well on other softer non-ferrous materials like plastics and brass. For steels and harder metals, you’d typically look for end mills with different coatings (like AlTiN or CrN) and helix angles.

Q3: How do I know if my CAM software is set up for proper ramping?

A3: When setting up a 2D pocket or 3D contour operation in your CAM software, look for options like “Ramp,” “Helical Interpolation,” or “3D Adaptive” passes. Choosing one of these and defining a ramp clearance and acceptable ramp step-down will engage the ramping feature.

Q4: My aluminum is still coming out rough. What else could be wrong?

A4:

Q1: What is the main advantage of a TiAlN coating on an end mill for aluminum?

A1: The TiAlN coating provides excellent hardness and reduces friction. This is great for aluminum because it helps prevent the gummy material from sticking to the cutting edge (built-up edge) and improves tool life and surface finish.

Q2: Can I use a 35-degree helix ball nose end mill for materials other than aluminum?

A2: Yes, but it’s optimized for aluminum. It can work well on other softer non-ferrous materials like plastics and brass. For steels and harder metals, you’d typically look for end mills with different coatings (like AlTiN or CrN) and helix angles.

Q3: How do I know if my CAM software is set up for proper ramping?

A3: When setting up a 2D pocket or 3D contour operation in your CAM software, look for options like “Ramp,” “Helical Interpolation,” or “3D Adaptive” passes. Choosing one of these and defining a ramp clearance and acceptable ramp step-down will engage the ramping feature.

Q4: My aluminum is still coming out rough. What else could be wrong?

A4: