Tool Holder Metal Lathe Automation: Enhancing Efficiency

Tool Holder Metal Lathe Automation

Metal lathe automation with tool holders can change the way we work. It speeds up production and reduces mistakes. Imagine a machine that can switch tools automatically without any help. This means you can focus on other tasks. Automation not only saves time but also ensures consistent quality in your projects. Plus, you’ll find that using a tool holder makes everything easier and more efficient. Isn’t it fascinating how technology can make our work life so much better?Understanding Tool Holder Metal Lathe Automation

Definition of tool holder automation in metal lathes. Importance of automation in modern machining processes.Tool holder automation in metal lathes means using machines to change tools automatically. This helps make work easier and faster. Automation is important because it saves time and reduces mistakes. Machines can work without rest, completing tasks quickly. This leads to better quality products and more efficiency in factories.

- Improves productivity

- Reduces human error

- Increases safety

Why is tool holder automation important?

Tool holder automation improves efficiency and saves time in machining. It helps create high-quality items quickly and safely.

Benefits of Automation in Metal Lathe Operations

Increased productivity and efficiency. Reduction of human error and improved precision.Automation in metal lathe operations brings many benefits. First, it greatly increases productivity. Machines can work faster and longer than people. This means more items can be made in less time.

Second, automation reduces human error. Machines follow instructions perfectly. This leads to improved precision, meaning every piece is made the same way. Even tiny mistakes can cause big problems. With machines, those mistakes are less likely to happen.

How does automation increase productivity?

Automation allows machines to run continuously without breaks. This means they can create more products quickly, keeping up with business needs.

Benefits of Automation:

- More products made in less time

- Fewer mistakes in making items

- Consistent quality of each product

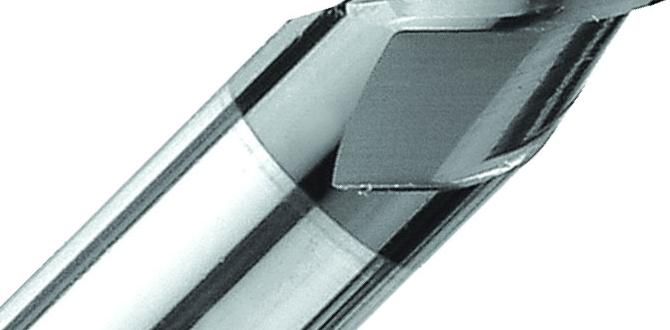

Key Features of Automated Tool Holders

Description of advanced features (tool change speed, precision adjustments). Importance of compatibility with existing machinery.Automated tool holders have several advanced features that improve how we work with machines. They can change tools quickly, making jobs faster and smoother. Precision adjustments help ensure that each cut is just right, reducing errors. It’s also important that these tool holders are compatible with existing machinery. This means they can easily fit into what you already have, saving time and money.

What are the benefits of automatic tool holders?

The main benefits include faster tool changes and greater accuracy in cutting. This helps improve overall efficiency and quality in manufacturing processes.

Key Features Include:

- Fast tool change speed

- Precise adjustments

- Compatibility with current machines

Integration of Automation Systems with Metal Lathes

Steps for successfully integrating automation systems. Challenges and solutions during integration.Automating metal lathes can change how we work. To begin, you should follow some simple steps for a smooth integration. Here are key points:

- Identify machine needs.

- Choose the right automation tools.

- Train staff to use new systems.

- Test the system before full use.

Challenges may arise, like software issues or delays. But solutions exist. You can update software or seek expert help. Always keep communication open with your team. This helps everyone stay informed and ready for any hurdles.

What are the steps for integrating automation with metal lathes?

The steps include identifying needs, selecting the right tools, providing training, and testing systems.

Case Studies: Successful Implementations of Tool Holder Automation

Realworld examples of businesses that benefited from automation. Analysis of outcomes and efficiency improvements.Many businesses have hit the jackpot with tool holder automation. For instance, a small machine shop in Ohio saw its production speed soar by 30% after automation. They traded in manual setups for smart tool holders, making their job as easy as pie—no more fumbling around! Another company, a metal lathe guru, cut down errors by 40% and made more products daily. Talk about hitting the sweet spot!

| Business | Improvement | Outcome |

|---|---|---|

| Machine Shop, Ohio | Speed Increased | +30% |

| Metal Lathe Company | Error Reduction | -40% |

These examples prove that switching to automation isn’t just a smart move; it’s also a game-changer that can boost profits while making workdays less stressful. Who wouldn’t want to nap without worrying about tool changes?

Future Trends in Tool Holder Automation

Anticipated advancements in technology and features. Impact of Industry 4.0 on tool holder automation.Exciting changes are on the horizon for tool holder automation! With technology leaping forward, we can expect smarter tool holders that adapt to various tasks. These innovations will improve precision and efficiency. Plus, thanks to Industry 4.0, everything is becoming connected. Imagine a tool holder that can communicate with your machine and optimize performance on its own! It’s like having a robot assistant who never complains about coffee breaks!

| Advancement | Feature |

|---|---|

| Smart Sensors | Real-time monitoring of tool performance |

| AI Integration | Predictive maintenance to prevent breakdowns |

| IoT Connectivity | Seamless communication with other machines |

These trends promise to make tool holders not only more efficient but also a little sassy! Who knew a tool holder could be so smart?

Choosing the Right Tool Holder Automation for Your Business

Factors to consider when selecting automation systems. Recommendations for specific industries or applications.Selecting an automation system for your business requires some careful thought. First, consider the type of tool holder metal lathe automation you need. Think about the following factors:

- Budget: How much can you spend?

- Space: Do you have enough room for new machines?

- Speed: How fast does your production need to be?

- Industry: What type of tools or materials are you working with?

For smaller shops, a simple automated system might work. Larger industries may need advanced options that handle more weight and speed. Always choose what fits your specific needs best!

What should I consider when choosing automation systems?

Focus on your business goals and production needs. Different industries have unique demands. For example, automotive parts require fast and precise automation, while woodworking may focus on flexibility and detail.

Conclusion

In summary, tool holder metal lathe automation improves your machining tasks by saving time and enhancing precision. You can boost your productivity with easy-to-use automated systems. Remember, investing in automation helps you stay ahead in your projects. For more insights, explore tutorials or guides on metal lathe automation to deepen your understanding and skills.FAQs

Sure! Here Are Five Related Questions On The Topic Of Tool Holder Metal Lathe Automation:Sure! Here are five questions about tool holder metal lathe automation: 1. What is a metal lathe? A metal lathe is a machine. It helps shape metal into different forms. 2. How does automation help with lathes? Automation makes lathes work automatically. This means they can cut metal without much help from people. 3. What is a tool holder? A tool holder is a part of the lathe. It holds the cutting tools in place. 4. Why is tool holder automation useful? Tool holder automation saves time. It allows for faster and more precise metal work. 5. Can I use a metal lathe at home? Yes, but you need to be careful. Metal lathes can be dangerous if not used properly.

Sure! Just let me know which question you want me to answer, and I’ll be happy to help!

What Are The Key Benefits Of Implementing Automation In Tool Holder Systems For Metal Lathes?Using automation in tool holder systems for metal lathes has many benefits. First, it saves time by changing tools quickly. This means you can finish projects faster. Second, automation reduces mistakes, so your work is more accurate. Finally, it makes the job easier for you because machines do the hard work. Overall, automation helps you be more efficient and successful!

How Do Automated Tool Holders Improve The Efficiency And Precision Of Machining Processes On A Metal Lathe?Automated tool holders make work on a metal lathe faster and more accurate. They can change tools quickly without you helping. This saves time and keeps everything lined up properly. With these tools, your projects look better and finish sooner.

What Types Of Sensors And Control Systems Are Commonly Used In Automated Tool Holder Solutions For Metal Lathes?In automated tool holder solutions for metal lathes, you can find sensors like position sensors and load sensors. Position sensors help know where the tool is. Load sensors check how much weight the tool is carrying. Control systems take this information and make decisions to move the tools better. We use these parts together to make the lathe work more smoothly and accurately.

How Can The Integration Of Robotics Enhance The Automation Of Tool Holders In A Metal Lathe Setup?Using robots in a metal lathe can make it easier to change tool holders automatically. Robots can grab and swap tools faster than people can. This makes the work quicker and reduces mistakes. With robots, you can also run the lathe for longer without needing breaks. Overall, it helps us make things better and faster!

What Challenges And Considerations Should Manufacturers Keep In Mind When Transitioning To Automated Tool Holder Systems In Metalworking?When moving to automated tool holders in metalworking, you need to think about a few important things. First, you have to train your staff to use new machines. This takes time and effort. Next, you must make sure your old machines can work with the new tool holders. Finally, you’ll want to keep an eye on costs to ensure you stay within your budget.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Tool Holder Metal Lathe Automation:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about tool holder metal lathe automation: 1. What is a metal lathe? A metal lathe is a machine. It helps shape metal into different forms. 2. How does automation help with lathes? Automation makes lathes work automatically. This means they can cut metal without much help from people. 3. What is a tool holder? A tool holder is a part of the lathe. It holds the cutting tools in place. 4. Why is tool holder automation useful? Tool holder automation saves time. It allows for faster and more precise metal work. 5. Can I use a metal lathe at home? Yes, but you need to be careful. Metal lathes can be dangerous if not used properly.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know which question you want me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Key Benefits Of Implementing Automation In Tool Holder Systems For Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using automation in tool holder systems for metal lathes has many benefits. First, it saves time by changing tools quickly. This means you can finish projects faster. Second, automation reduces mistakes, so your work is more accurate. Finally, it makes the job easier for you because machines do the hard work. Overall, automation helps you be more efficient and successful!”}},{“@type”: “Question”,”name”: “How Do Automated Tool Holders Improve The Efficiency And Precision Of Machining Processes On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automated tool holders make work on a metal lathe faster and more accurate. They can change tools quickly without you helping. This saves time and keeps everything lined up properly. With these tools, your projects look better and finish sooner.”}},{“@type”: “Question”,”name”: “What Types Of Sensors And Control Systems Are Commonly Used In Automated Tool Holder Solutions For Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In automated tool holder solutions for metal lathes, you can find sensors like position sensors and load sensors. Position sensors help know where the tool is. Load sensors check how much weight the tool is carrying. Control systems take this information and make decisions to move the tools better. We use these parts together to make the lathe work more smoothly and accurately.”}},{“@type”: “Question”,”name”: “How Can The Integration Of Robotics Enhance The Automation Of Tool Holders In A Metal Lathe Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using robots in a metal lathe can make it easier to change tool holders automatically. Robots can grab and swap tools faster than people can. This makes the work quicker and reduces mistakes. With robots, you can also run the lathe for longer without needing breaks. Overall, it helps us make things better and faster!”}},{“@type”: “Question”,”name”: “What Challenges And Considerations Should Manufacturers Keep In Mind When Transitioning To Automated Tool Holder Systems In Metalworking?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When moving to automated tool holders in metalworking, you need to think about a few important things. First, you have to train your staff to use new machines. This takes time and effort. Next, you must make sure your old machines can work with the new tool holders. Finally, you’ll want to keep an eye on costs to ensure you stay within your budget.”}}]}