Have you ever wondered how metal lathes can be made even better? Many people love working with CNC machines. One exciting way to boost their performance is through a tool holder metal lathe CNC retrofit.

This upgrade is like giving your old bike a new engine. With the right tools and some know-how, you can transform a standard metal lathe into a powerful CNC machine. Imagine the possibilities! Cutting and shaping metal with precision can lead to amazing projects.

Did you know that retrofitting is becoming more popular among hobbyists and professionals? It’s true! People enjoy making their machines work harder and smarter. So, what does it take to get started with a tool holder metal lathe CNC retrofit? Stick around to find out!

Tool Holder Metal Lathe Cnc Retrofit: Upgrade Your Machinery

Tool Holder Metal Lathe CNC Retrofit

Have you ever wondered how to upgrade your metal lathe for better performance? A tool holder CNC retrofit can transform your machine. It allows for more precise cuts and easier tool changes. This upgrade helps improve efficiency, saving time and reducing errors. Imagine consistently achieving perfect finishes! A well-designed tool holder makes operation smoother. Plus, DIY retrofitting can be a rewarding project. Enhance the capabilities of your lathe and enjoy greater creativity in your work!Understanding CNC Retrofits

Definition and purpose of CNC retrofits. Benefits of retrofitting a metal lathe with CNC technology.CNC retrofits change standard machines into more advanced ones. They add computer control to tools like lathes. This makes design and production easier. The benefits of retrofitting include:

- Improved precision: CNC machines work more accurately.

- Increased speed: They can produce parts faster.

- Lower costs: Retrofits save money on new machines.

By upgrading to CNC, users enjoy better results and efficiency. This means better products and more satisfied customers!

What is a CNC retrofit?

A CNC retrofit is adding computer controls to older machines. It helps them work better and faster.

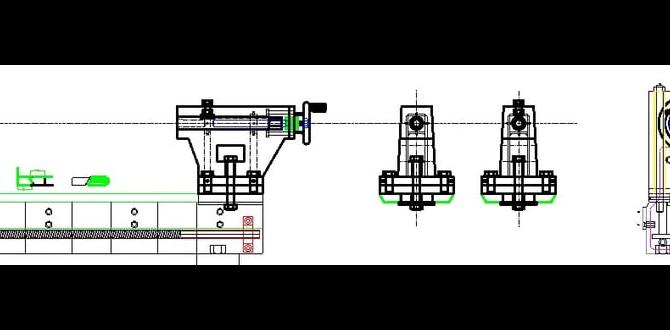

Types of Tool Holders for Metal Lathes

Common types of tool holders (e.g., collet chucks, turret tool holders). Pros and cons of each type for CNC applications.Tool holders are important for metal lathes. They help secure cutting tools firmly. Here are some common types:

- Collet Chucks: These hold tools tightly using a sleeve. This gives great accuracy.

- Turret Tool Holders: These allow quick tool changes. They save time during projects.

- Quick Change Tool Holders: These let users swap tools fast. They are user-friendly but may cost more.

Each type has pros and cons. Collet chucks offer precision but can be slow to change. Turret holders are quick, yet might need more setup time. Choosing the right one matters for CNC projects.

What are the benefits of each type of tool holder?

Collet chucks provide high accuracy. Turret tool holders allow fast tool changes, ideal for busy workshops.

Choosing the Right Tool Holder for Your CNC Retrofit

Factors to consider when selecting a tool holder. Compatibility with existing lathe models and CNC systems.Picking the right tool holder is important for your CNC retrofit project. Think about these key factors when choosing:

- Size: Ensure it fits your machine.

- Material: A strong material lasts longer.

- Design: Choose one that fits your tools well.

- Compatibility: Make sure it works with your existing lathe model and CNC system.

This way, you can improve your machining setup and get great results!

Why is compatibility important?

Compatibility ensures smooth operation. It allows the tool holder to fit into your CNC system without issues.

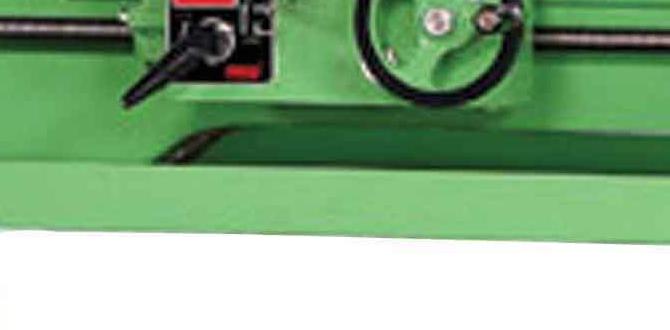

Step-by-Step Guide to Retrofitting Your Metal Lathe

Preparing your lathe for retrofit. Installing CNC components and tool holders.Before starting your retrofit, prepare your lathe. Clean it and check if all parts are working well. This makes installation easier. Next, gather all CNC components and tool holders. Attach them securely to ensure safety and performance.

- Disconnect power supply.

- Remove old parts carefully.

- Install new CNC components.

- Attach tool holders snugly.

Check that everything works before using the lathe again. This way, you can enjoy smooth operation.

What are the benefits of retrofitting a metal lathe?

Retrofitting saves money and time. It can make your lathe perform like new. This means better designs and higher accuracy. Many users report a 30% improvement in production speed.

Common Challenges in CNC Retrofits

Typical issues faced during retrofitting. Tips for troubleshooting and resolving common problems.CNC retrofits can feel like wrestling a greased pig. Common challenges pop up, like compatibility issues and wiring headaches. Your new tools might not match well with old machines. Plus, software glitches can turn a simple update into a full-blown drama. When you hit a snag, try checking connections or recalibrating your settings. Stick to these tips:

| Common Issues | Tips for Troubleshooting |

|---|---|

| Compatibility Problems | Research tools before buying. |

| Software Glitches | Update for the latest fixes. |

| Wiring Issues | Double-check connections. |

Remember, a little patience and planning go a long way! Keeping a sense of humor helps too. After all, who says you can’t have a laugh while fixing machinery?

Maintaining Your CNC Retrofitted Lathe

Best practices for maintenance of tool holder systems. Importance of regular checks and calibrations.Keeping your CNC retrofitted lathe in top shape is like giving it a daily spa treatment. Regular checks and calibrations can prevent big headaches. Just imagine if your lathe decides to play hide and seek with the right measurements! Always inspect tool holder systems to avoid unnecessary hiccups during machining. Think of it as tuning up your bicycle; a little maintenance goes a long way! Here’s a quick checklist to help you out:

| Task | Frequency |

|---|---|

| Inspect tool holders | Weekly |

| Check alignment | Monthly |

| Lubricate moving parts | Every 3 months |

| Calibrate settings | As needed |

By following these best practices, you’ll keep your lathe running smoothly and joyfully. Remember, a happy lathe makes for happy crafting!

Maximizing Efficiency with CNC Tool Holders

Techniques to optimize tool performance and lifespan. How to reduce downtime and increase production efficiency.Using CNC tool holders helps your machines work better. You can improve tool performance and lifespan with some tips. Keep tools clean and sharp to avoid mistakes. Use the right holder for each tool. This setup prevents downtime and keeps production high.

- Regularly check for wear and tear.

- Store tools safely to avoid damage.

- Adjust settings based on the material type.

These practices boost efficiency and give you more time to create quality products.

How can tool holders reduce downtime?

Strong tool holders reduce downtime by keeping the tools stable. They hold tools tightly and allow for quick changes. This speed helps keep the machines running smoothly.

Case Studies and Success Stories

Realworld examples of successful CNC retrofits. Lessons learned and insights from experienced machinists.Many machinists have successfully upgraded their CNC machines. These stories show how a simple tool holder metal lathe CNC retrofit can boost productivity. Experienced users share valuable lessons. For example, they recommend careful planning and choosing the right tools for the job. Here are some success tips:

- Test your setup before full production.

- Keep software updated for best results.

- Ask for help from expert machinists.

Learning from others helps everyone improve. Small changes can lead to big gains in efficiency.

What are some common benefits of CNC retrofitting?

CNC retrofitting often improves accuracy, reduces costs, and increases machine lifespan. Many users see a boost in production speed and flexibility as well.

Conclusion

In conclusion, a tool holder for a metal lathe CNC retrofit improves efficiency and precision. You can upgrade your machine for better results. Explore different types of tool holders to find the best fit. We encourage you to research further and consider investing in quality tools. This will make your projects easier and more enjoyable. Happy machining!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Tool Holder Metal Lathe Cnc Retrofit:Sure! A CNC retrofit is when we change a regular metal lathe to work with a computer. This helps us make pieces more easily and quickly. You can find new tool holders that fit on the lathe. These tool holders help hold the tools tight while they work. It’s a fun way to make things more precise!

Sure! Please tell me what question you want me to answer.

What Are The Key Benefits Of Retrofitting A Traditional Metal Lathe With Cnc Technology?Retrofitting a traditional metal lathe with CNC (Computer Numerical Control) technology makes it easier to use. You can create precise and complex shapes quickly. It also allows us to make the same part over and over with very little mistake. Plus, it can save time and help you do more work in less time!

Which Types Of Tool Holders Are Most Compatible With Cnc Retrofitted Lathes, And How Do They Differ From Traditional Holders?CNC retrofitted lathes work best with quick-change tool holders. These holders let you swap tools quickly and easily. Unlike traditional holders, which need more time to change tools, quick-change holders save time. This makes your work faster and helps you be more productive. You can do more with less hassle!

What Are The Essential Components Required For A Successful Cnc Retrofit On A Metal Lathe?To successfully upgrade a metal lathe to CNC, you need a few key parts. First, you need a controller to tell the machine what to do. Second, you need motors to move the parts of the lathe. Third, you need sensors to help the machine track its position. Lastly, you’ll need software to help you design and run your projects. With these parts, your lathe can become a smart machine!

How Can Existing Tooling And Fixtures Be Adapted For Use In A Cnc Retrofitted Metal Lathe?You can adapt existing tools and fixtures for a CNC (Computer Numerical Control) lathe by making a few changes. First, check if they fit the new machine and change them if needed. You might need to add special mounts or screw holes. Next, adjust any tools to work with the automatic movements of the CNC lathe. Finally, test everything to make sure it works well together.

What Challenges Might One Encounter During The Retrofit Process, And How Can They Be Effectively Addressed?During the retrofit process, you might face problems like finding the right parts or dealing with old building designs. These can make the project harder. To solve them, you can ask experts for help and plan carefully. Checking everything before starting can also make it easier to fix issues as they come up.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Tool Holder Metal Lathe Cnc Retrofit:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A CNC retrofit is when we change a regular metal lathe to work with a computer. This helps us make pieces more easily and quickly. You can find new tool holders that fit on the lathe. These tool holders help hold the tools tight while they work. It’s a fun way to make things more precise!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please tell me what question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Benefits Of Retrofitting A Traditional Metal Lathe With Cnc Technology?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Retrofitting a traditional metal lathe with CNC (Computer Numerical Control) technology makes it easier to use. You can create precise and complex shapes quickly. It also allows us to make the same part over and over with very little mistake. Plus, it can save time and help you do more work in less time!”}},{“@type”: “Question”,”name”: “Which Types Of Tool Holders Are Most Compatible With Cnc Retrofitted Lathes, And How Do They Differ From Traditional Holders?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC retrofitted lathes work best with quick-change tool holders. These holders let you swap tools quickly and easily. Unlike traditional holders, which need more time to change tools, quick-change holders save time. This makes your work faster and helps you be more productive. You can do more with less hassle!”}},{“@type”: “Question”,”name”: “What Are The Essential Components Required For A Successful Cnc Retrofit On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To successfully upgrade a metal lathe to CNC, you need a few key parts. First, you need a controller to tell the machine what to do. Second, you need motors to move the parts of the lathe. Third, you need sensors to help the machine track its position. Lastly, you’ll need software to help you design and run your projects. With these parts, your lathe can become a smart machine!”}},{“@type”: “Question”,”name”: “How Can Existing Tooling And Fixtures Be Adapted For Use In A Cnc Retrofitted Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can adapt existing tools and fixtures for a CNC (Computer Numerical Control) lathe by making a few changes. First, check if they fit the new machine and change them if needed. You might need to add special mounts or screw holes. Next, adjust any tools to work with the automatic movements of the CNC lathe. Finally, test everything to make sure it works well together.”}},{“@type”: “Question”,”name”: “What Challenges Might One Encounter During The Retrofit Process, And How Can They Be Effectively Addressed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “During the retrofit process, you might face problems like finding the right parts or dealing with old building designs. These can make the project harder. To solve them, you can ask experts for help and plan carefully. Checking everything before starting can also make it easier to fix issues as they come up.”}}]}