Have you ever struggled to get your tool holder on a metal lathe just right? It’s frustrating, isn’t it? If the tailstock is misaligned, your projects can go awry. This alignment is key for crafting smooth, precise shapes.

Imagine trying to draw a straight line but your pencil is too wobbly. That’s similar to what happens without proper alignment. Your lathe needs everything in sync to work well. But don’t worry! Aligning the tailstock is simpler than you might think.

In this article, we will explore easy steps to check and adjust your tool holder and tailstock. You’ll discover tips that even beginners can follow. Soon, you’ll be creating tools that are not only functional but also beautifully crafted.

Get ready to dive into the world of metal lathes and learn how precision makes all the difference!

Tool Holder Metal Lathe Tailstock Alignment Techniques

Tool Holder Metal Lathe Tailstock Alignment

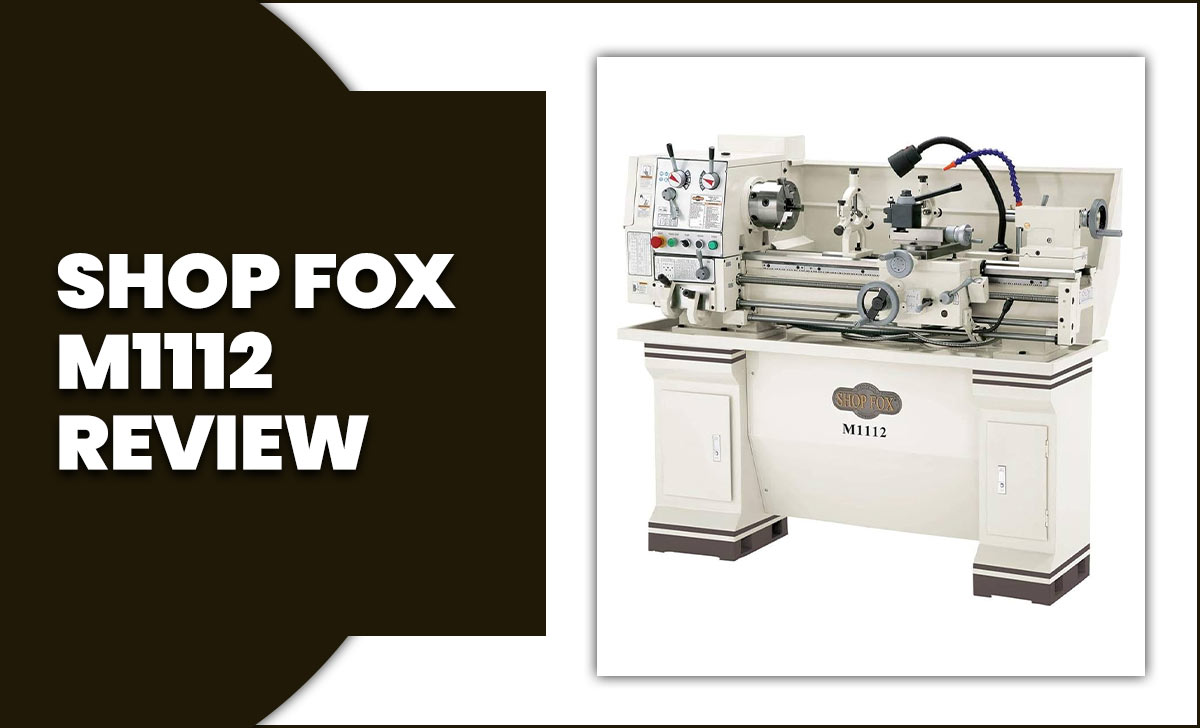

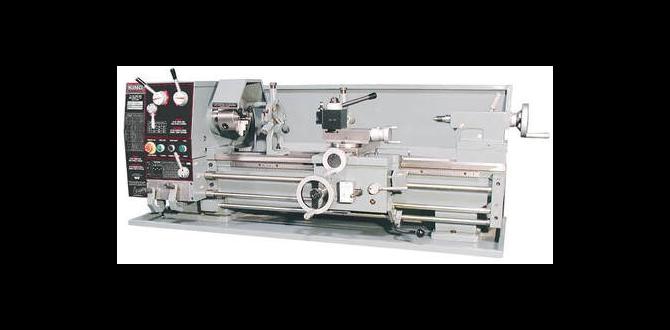

Proper alignment of the tailstock on a metal lathe is crucial for accurate machining. When the tailstock is misaligned, it can cause poor finishes or even damage your workpiece. Using a tool holder helps keep everything steady. Did you know that a simple adjustment can make a big difference? Check your alignment regularly to ensure the best performance. Taking time for this adjustment can save you from frustration and wasted materials later.Understanding Lathe Tailstock Alignment

Definition and purpose of tailstock alignment in metal lathes. Importance of precision in machining processes.Tailstock alignment is an important part of using metal lathes. It helps ensure the tailstock is lined up perfectly with the spindle. This alignment is crucial for precision machining. When everything is aligned well, it means better cuts and fewer mistakes. Without it, you might end up with wonky shapes that look like they were made by a toddler in art class! Remember, a good lathe must be as straight as a ruler.

Here’s a quick look at why tailstock alignment matters:

| Benefit | Importance |

|---|---|

| Improves Accuracy | Better results in machining. |

| Reduces Errors | Fewer mistakes in your projects. |

| Saves Time | Less time fixing problems. |

Common Issues with Tailstock Alignment

Signs of misalignment in lathe operations. Impact of misalignment on workpiece quality and tool wear.Misalignment in lathe operations often shows through several signs. You might notice irregular cuts or weird shapes in your workpiece. Tool wear can increase, leaving behind more chips than a potato factory! The quality of your work typically suffers, and you might need to scrap your project. This can lead to frustration, wasting both time and materials.

| Signs of Misalignment | Impact on Quality |

|---|---|

| Irregular Cuts | Lower Quality Work |

| Excessive Tool Wear | Increased Production Costs |

| Vibration and Noise | Unsafe Operations |

To avoid some extra headaches, keep an eye on these signs. Correcting misalignment early can save you from turning your lathe into a fancy paperweight!

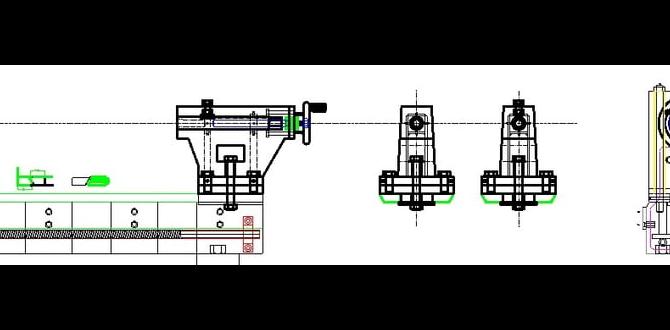

Tools and Equipment for Tailstock Alignment

Essential tools for achieving proper alignment. Advanced equipment for precision measurement.Getting your tailstock aligned properly is like trying to dance with two left feet—challenging but very important! Essential tools like a tailstock alignment bar can help you get everything lined up just right. For a bit more precision, think about using a dial indicator. It measures tiny differences, making sure your lathe is as straight as an arrow. Grab your toolbox and let’s make that tailstock alignment shine!

| Tool | Purpose |

|---|---|

| Tailstock Alignment Bar | Helps line up the tailstock accurately. |

| Dial Indicator | Measures precise adjustments in alignment. |

| Feeler Gauges | Checks gaps for perfection. |

Step-by-Step Guide to Aligning Tailstock

Detailed procedures for initial alignment. Techniques to verify alignment accuracy.To begin aligning the tailstock of your metal lathe, ensure it’s bolted down securely. Use a dial indicator to check its position. Place the indicator on the spindle and rotate it slowly. You want the reading to stay steady, like your best friend during a surprise party. If it wobbles, adjust the tailstock using its screws. Once you think you’ve made it perfect, check it again! Repeating this step ensures accuracy.

| Step | Action |

|---|---|

| 1 | Secure the tailstock. |

| 2 | Use a dial indicator on the spindle. |

| 3 | Rotate and check for steady readings. |

| 4 | Adjust if needed, then recheck. |

For accuracy, repeat the checks several times. Consistency is key! If the tailstock still isn’t aligned, you may need some help. Don’t hesitate to ask a fellow machinist; two heads are better than one, especially if one of them has snacks!

Maintenance Tips for Tailstock Alignment

Routine checks and adjustments for optimal performance. Best practices for longterm maintenance of lathe components.Keeping your tailstock aligned is like brushing your teeth: skip it, and you’ll regret it! Regular checks help catch issues early. Look for wobbling or slipping—these are signs it needs adjusting. Cleaning it will also keep it shiny and happy! For long-term care, store your lathe in a dry place to prevent rust, and check your components often. A clean lathe is a happy lathe!

| Maintenance Tip | Frequency |

|---|---|

| Check alignment | Weekly |

| Clean components | Every use |

| Lubricate parts | Monthly |

Case Studies: Real-World Examples of Tailstock Alignment

Analysis of successful alignment interventions in various machining scenarios. Lessons learned from misalignment issues in industry.In the world of machining, aligning the tailstock is crucial. One case involved a factory that faced many broken bits. After a careful alignment, they saved 30% on tool replacement costs. Another instance showed a misaligned tailstock causing wobbly parts. After adjustments, they boasted better precision and no more “wobbly noodles.”

| Scenario | Alignment Action | Results |

|---|---|---|

| Broken Tools | Re-alignment | Saved 30% on costs |

| Wobbly Parts | Tailstock Adjustment | Greater precision |

These examples teach us that even small adjustments can make a big difference. Keep that tailstock aligned, and your machining can run smoother than your favorite slide on a playground!

Advanced Tailstock Adjustment Techniques

Techniques for finetuning alignment in highprecision applications. Variations in alignment methods for different lathe models.Fine-tuning your lathe tailstock is like perfecting your dance moves—timing is everything! Small adjustments can make a big difference in precision. Different lathe models have unique alignment needs, so understanding each machine’s quirks is key. Check if your tailstock has screws or levers for easy tweaks. A quick test cut can help you see if you’re hitting the sweet spot. Remember, a well-aligned tailstock makes both your work and your day much smoother!

| Technique | Best For | Notes |

|---|---|---|

| Vertical Adjustment | Wood Lathes | Watch for wobble! |

| Horizontal Alignment | Metal Lathes | Aligns cutting tools accurately. |

| Incremental Tweaking | All Models | Small changes, big difference! |

Conclusion

In conclusion, aligning your tool holder metal lathe tailstock is vital for precision. Accurate alignment improves cutting and reduces errors. Check for tightness and level regularly. If you need more tips, you can explore guides and videos online. Remember, practicing these steps will enhance your skills and confidence in using a lathe. Let’s keep learning together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Tool Holder Metal Lathe Tailstock Alignment:Sure! Here are five questions about tool holder metal lathe tailstock alignment: 1. **Why is tailstock alignment important?** Tailstock alignment is important because it helps our tools cut smoothly. If it’s not aligned, the tool can wobble. 2. **How do you check if it’s aligned?** To check alignment, we can use a ruler or a special tool. We look at where the tailstock meets the tool holder. 3. **What happens if it’s not aligned?** If it’s not aligned, it can lead to bad cuts. It might even damage the tool or the material. 4. **How can we fix misalignment?** We can adjust the tailstock by loosening screws and moving it. Then, we tighten the screws back. 5. **How often should we check the alignment?** We should check the alignment regularly, especially before starting a new project. This helps ensure everything works well.

Sure! Please provide the question you’d like me to answer.

What Are The Key Steps For Accurately Aligning The Tailstock On A Metal Lathe?To align the tailstock on a metal lathe, start by loosening its bolts. Next, place a straight piece of metal, like a rod, in the spindle. Move the tailstock closer to the rod. Then, check if the tailstock is in line with the rod by looking carefully. Finally, tighten the bolts to hold the tailstock in place.

How Does Improper Tailstock Alignment Affect The Precision Of Machined Parts On A Lathe?Improper tailstock alignment on a lathe can make parts uneven and wobbly. When the tailstock isn’t lined up, the tool can cut at the wrong angle. This causes mistakes in the size and shape of the part. You might end up with pieces that don’t fit together properly. In short, it can ruin your work!

What Tools Or Gauges Are Typically Used For Checking Tailstock Alignment?To check tailstock alignment, you can use a few simple tools. A dial indicator is one option; it helps measure tiny changes. A center gauge can also help to see if everything lines up. You can even use a long ruler to check the distance. These tools make sure your machine works properly.

How Can You Adjust The Tailstock To Compensate For Any Misalignment Detected?To fix misalignment, you can adjust the tailstock on your machine. First, you check if the tailstock is lined up with the main part. If it’s not, you can carefully move it to one side or the other. Make small adjustments and test again until it lines up correctly. This way, your work will be smoother and more accurate.

What Common Issues Can Arise From Tailstock Misalignment During Machining Operations?When the tailstock is misaligned, problems can happen during machining. Your parts might not be the right size or shape. They could end up with rough edges or bad surfaces. This means you may need to fix them, which takes more time. You might also waste materials, which can be frustrating!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Tool Holder Metal Lathe Tailstock Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about tool holder metal lathe tailstock alignment: 1. **Why is tailstock alignment important?** Tailstock alignment is important because it helps our tools cut smoothly. If it’s not aligned, the tool can wobble. 2. **How do you check if it’s aligned?** To check alignment, we can use a ruler or a special tool. We look at where the tailstock meets the tool holder. 3. **What happens if it’s not aligned?** If it’s not aligned, it can lead to bad cuts. It might even damage the tool or the material. 4. **How can we fix misalignment?** We can adjust the tailstock by loosening screws and moving it. Then, we tighten the screws back. 5. **How often should we check the alignment?** We should check the alignment regularly, especially before starting a new project. This helps ensure everything works well.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Steps For Accurately Aligning The Tailstock On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock on a metal lathe, start by loosening its bolts. Next, place a straight piece of metal, like a rod, in the spindle. Move the tailstock closer to the rod. Then, check if the tailstock is in line with the rod by looking carefully. Finally, tighten the bolts to hold the tailstock in place.”}},{“@type”: “Question”,”name”: “How Does Improper Tailstock Alignment Affect The Precision Of Machined Parts On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Improper tailstock alignment on a lathe can make parts uneven and wobbly. When the tailstock isn’t lined up, the tool can cut at the wrong angle. This causes mistakes in the size and shape of the part. You might end up with pieces that don’t fit together properly. In short, it can ruin your work!”}},{“@type”: “Question”,”name”: “What Tools Or Gauges Are Typically Used For Checking Tailstock Alignment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check tailstock alignment, you can use a few simple tools. A dial indicator is one option; it helps measure tiny changes. A center gauge can also help to see if everything lines up. You can even use a long ruler to check the distance. These tools make sure your machine works properly.”}},{“@type”: “Question”,”name”: “How Can You Adjust The Tailstock To Compensate For Any Misalignment Detected?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix misalignment, you can adjust the tailstock on your machine. First, you check if the tailstock is lined up with the main part. If it’s not, you can carefully move it to one side or the other. Make small adjustments and test again until it lines up correctly. This way, your work will be smoother and more accurate.”}},{“@type”: “Question”,”name”: “What Common Issues Can Arise From Tailstock Misalignment During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the tailstock is misaligned, problems can happen during machining. Your parts might not be the right size or shape. They could end up with rough edges or bad surfaces. This means you may need to fix them, which takes more time. You might also waste materials, which can be frustrating!”}}]}