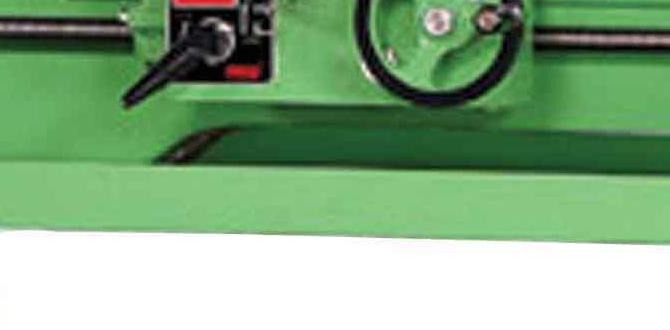

Have you ever watched a metal lathe in action? It’s like magic. The way it shapes metal can seem so complex, but with the right tools, anyone can learn.

One important tool to understand is the tool holder metal lathe threading dial. This small part plays a big role. It helps you set the right depth and position while threading.

Imagine you’re in a workshop, surrounded by machines. You’re focusing on your project. Suddenly, you need to change the settings. The threading dial on your tool holder guides you exactly where to go.

Did you know that using a good tool holder can make your work easier and faster? It can also improve the quality of your threads. Having the right equipment is key to success.

This article will explore how the tool holder metal lathe threading dial works. You’ll discover tips to make your projects easier. So, get ready to dive into the world of metal turning!

Tool Holder Metal Lathe Threading Dial: Essential Benefits

Tool Holder Metal Lathe Threading Dial

Tool holder metal lathe threading dials play a vital role in precision machining. These dials help users accurately adjust the cutting tool’s position. Have you ever wondered how professionals create perfect threads? The threading dial simplifies complex measurements in metal work. It ensures consistent results, making projects smooth and efficient. Working with a lathe becomes easier with this handy tool. Start mastering your lathe today and achieve impressive results!What is a Tool Holder Metal Lathe Threading Dial?

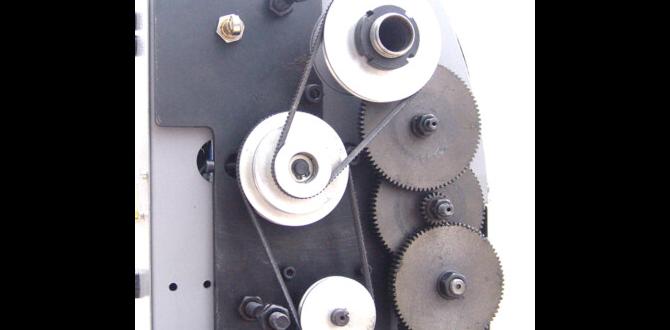

Definition and purpose of threading dials in metal lathes. Importance of tool holders in the lathe operation.A threading dial is a handy tool attached to the metal lathe. Its main job is to help you make precise threads on metal pieces, kind of like giving them a nice twist! Imagine trying to play twister but with gears and metal instead of colors. The threading dial makes sure your threads are evenly spaced and correct. Tool holders are also super important. They secure your cutting tools, helping the lathe operate smoothly and safely, like a seatbelt for tools!

| Tool Component | Purpose |

|---|---|

| Threading Dial | Ensures accurate thread spacing. |

| Tool Holder | Secures tools for safe operation. |

Benefits of Using a Threading Dial in Metal Lathes

Enhanced precision and accuracy in threading operations. Efficiency in production and timesaving features.Using a threading dial in metal lathes makes threading easier and smarter. It boosts precision and accuracy, which means your threads fit just right, like a perfectly made sandwich! Imagine saving time while getting fantastic results—it’s like having your cake and eating it too! The threading dial helps you work faster, trimming down production time. Here’s a quick look at how it improves your work:

| Benefit | Description |

|---|---|

| Enhanced Precision | Threads fit perfectly every time. |

| Efficiency | Work faster and save time! |

So, investing in a threading dial is not only smart but might also bring you some extra fun while working!

How to Choose the Right Tool Holder for Your Lathe

Factors to consider when selecting a tool holder. Compatibility with various lathe models and threading requirements.Choosing the right tool holder for your lathe is important. First, check if the holder is compatible with your lathe model. Different lathes need different sizes and shapes. Next, think about your threading needs. Some projects need precise threads, while others are simpler. Consider the material of the holder, too. A strong metal will last longer. Here are some key factors:

- Size and shape for your lathe model

- Type of threading required

- Material strength and durability

What should I look for in a tool holder?

Look for compatibility, size, and threading requirements. Make sure it fits your lathe and meets your project’s needs. Each detail matters for better performance!

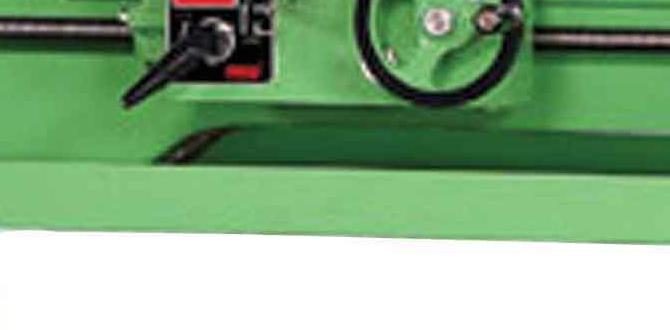

Installation and Setup of Metal Lathe Threading Dials

Stepbystep installation guide. Common mistakes to avoid during setup.Setting up a metal lathe threading dial can be like assembling a puzzle. Follow these simple steps to avoid frustration. Start by locating the dial’s mounting area on your lathe. Then, attach the threading dial securely using the provided screws. Remember, tight doesn’t mean over-tight! Common mistakes include misaligning the dial; a tilted dial can ruin your work. Finally, test it out before you start turning. It should spin smoothly and make you feel like a pro!

| Step | Tip |

|---|---|

| 1 | Find the right spot! |

| 2 | Secure it without Hulk strength. |

| 3 | Check alignment; slanted dials are no fun. |

Maintenance Tips for Tool Holder Metal Lathe Threading Dials

Routine maintenance practices for longevity. Signs that indicate the need for repair or replacement.Keeping your tool holder metal lathe threading dial in good shape is essential. Regular care helps it last longer. Check for wear and clean it often. Signs it may need repairs include:

- Unusual sounds during use

- Difficulty adjusting the dial

- Visible signs of rust or damage

Address these issues quickly to avoid bigger problems later. Remember, a little maintenance goes a long way!

What are common maintenance practices for threading dials?

Common practices include cleaning and oiling regularly. Keep the dial free of dust and debris. Regular checks help catch any early signs of wear or damage.

Common Problems and Troubleshooting Threading Dials

Frequent issues users face with threading dials. Solutions and preventive measures.Threading dials can be tricky. Users often face problems like misalignment or skipping numbers. This can make it hard to get accurate threads. Fortunately, there are easy solutions. Check the alignment and clean the parts. Regular maintenance helps prevent issues. Here are some common problems:

- Skipping numbers during use

- Difficulty in reading dial markings

- Parts getting stuck or jammed

By staying proactive, you can avoid these pitfalls and enjoy smoother use of the threading dial.

What should someone do if the threading dial skips numbers?

Ensure proper alignment and clean dirty parts regularly. This will help the dial function smoothly and accurately.

Innovations and Trends in Tool Holder Technologies

Latest advancements in threading dial technology. Future trends shaping the industry.New ideas are changing tool holder technologies. One exciting change is in threading dial technology. These dials now have better accuracy. They help workers make precise cuts. In the future, we might see even smarter dials. They could use sensors to provide instant feedback. This would make work easier and faster.

- Increased accuracy for better performance.

- Use of smart sensors for instant feedback.

- Focus on user-friendly designs.

What are the latest trends in threading dial technology?

Latest trends focus on improved accuracy, enhanced user interfaces, and better integration with digital tools.

Comparative Analysis of Popular Brands and Models

Review of top manufacturers of metal lathe threading dials. Features that set them apart in the market.Several companies make great metal lathe threading dials. Each brand has features that make it special. For instance, some dials are easier to read. Others might have fun colors that pop out! But who doesn’t love a fancy tool, right?

| Brand | Features |

|---|---|

| Brand A | Clear markings, easy to adjust |

| Brand B | Colorful design, sturdy build |

| Brand C | Budget-friendly, reliable performance |

Choosing the right dial can feel like picking a favorite ice cream flavor. Just remember, your choice will make a big difference in your lathe work!

Conclusion

In summary, a tool holder on a metal lathe with a threading dial is essential for precise work. It helps you control the cutting process and achieve accurate threads. Understanding how to use this tool can improve your projects significantly. We encourage you to practice with your lathe and explore more online tutorials to enhance your skills!FAQs

Sure! Here Are Five Questions Related To The Topic Of Tool Holder Metal Lathe Threading Dials:Sure! Here are five questions about tool holder metal lathe threading dials: 1. **What is a threading dial?** A threading dial helps you make precise threads on metal. It shows where to start cutting. 2. **How does it work?** You turn the lathe and watch the dial. When it lines up, you start threading. 3. **Why is it important?** It ensures your threads are even and correct. This makes your projects fit together nicely. 4. **Can I use it for all sizes?** Most threading dials work with many sizes. Just check if it fits your lathe. 5. **What happens if I don’t use it?** Without it, threads might be wrong. This can cause parts to not fit well.

Of course! Please provide the question you would like me to answer, and I will follow your guidelines.

What Is The Primary Function Of A Threading Dial On A Metal Lathe?The threading dial helps you cut threads on metal pieces using a lathe. It shows you the exact point to start and stop working. When you turn the dial, it lines up with the right spot. This way, you can make nice, even threads without mistakes. It makes your work easier and more accurate!

How Do You Properly Set Up And Calibrate A Threading Dial For Accurate Thread Cutting?To set up a threading dial, first, make sure your machine is turned off. Next, attach the threading dial to the lathe. You then need to find a thread start point on your workpiece. Once you have this, you turn the dial to zero. Lastly, check the dial’s alignment as you begin threading. This ensures your cuts are even and accurate.

What Are The Differences Between Using A Threading Dial And Using A Tailstock For Thread Cutting On A Lathe?Using a threading dial helps you line up your cuts when making threads on a lathe. It shows you the right time to move the tool. The tailstock, on the other hand, holds tools and helps you support the workpiece while cutting. With the tailstock, you have more stability, but it doesn’t help with lining up cuts like the threading dial does. So, one helps with measuring, and the other helps with support.

Can A Threading Dial Be Used For Both Internal And External Threading Operations, And If So, How?Yes, you can use a threading dial for both internal and external threads. The dial helps you line up the tool correctly. For internal threading, you place the tool inside a hole. For external threading, you use the dial while the tool is outside the material. This way, the threading dial helps you make threads safely and accurately.

What Common Issues Or Mistakes Should Operators Be Aware Of When Using A Threading Dial On A Metal Lathe?When using a threading dial on a metal lathe, be careful not to rush. First, make sure the machine is set correctly. Next, always line up the threading dial with the right marks. If you miss them, your thread won’t fit properly. Finally, keep an eye on the tool to avoid breaking it!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Topic Of Tool Holder Metal Lathe Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about tool holder metal lathe threading dials: 1. **What is a threading dial?** A threading dial helps you make precise threads on metal. It shows where to start cutting. 2. **How does it work?** You turn the lathe and watch the dial. When it lines up, you start threading. 3. **Why is it important?** It ensures your threads are even and correct. This makes your projects fit together nicely. 4. **Can I use it for all sizes?** Most threading dials work with many sizes. Just check if it fits your lathe. 5. **What happens if I don’t use it?** Without it, threads might be wrong. This can cause parts to not fit well.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide the question you would like me to answer, and I will follow your guidelines.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of A Threading Dial On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial helps you cut threads on metal pieces using a lathe. It shows you the exact point to start and stop working. When you turn the dial, it lines up with the right spot. This way, you can make nice, even threads without mistakes. It makes your work easier and more accurate!”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Calibrate A Threading Dial For Accurate Thread Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a threading dial, first, make sure your machine is turned off. Next, attach the threading dial to the lathe. You then need to find a thread start point on your workpiece. Once you have this, you turn the dial to zero. Lastly, check the dial’s alignment as you begin threading. This ensures your cuts are even and accurate.”}},{“@type”: “Question”,”name”: “What Are The Differences Between Using A Threading Dial And Using A Tailstock For Thread Cutting On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a threading dial helps you line up your cuts when making threads on a lathe. It shows you the right time to move the tool. The tailstock, on the other hand, holds tools and helps you support the workpiece while cutting. With the tailstock, you have more stability, but it doesn’t help with lining up cuts like the threading dial does. So, one helps with measuring, and the other helps with support.”}},{“@type”: “Question”,”name”: “Can A Threading Dial Be Used For Both Internal And External Threading Operations, And If So, How?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can use a threading dial for both internal and external threads. The dial helps you line up the tool correctly. For internal threading, you place the tool inside a hole. For external threading, you use the dial while the tool is outside the material. This way, the threading dial helps you make threads safely and accurately.”}},{“@type”: “Question”,”name”: “What Common Issues Or Mistakes Should Operators Be Aware Of When Using A Threading Dial On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a threading dial on a metal lathe, be careful not to rush. First, make sure the machine is set correctly. Next, always line up the threading dial with the right marks. If you miss them, your thread won’t fit properly. Finally, keep an eye on the tool to avoid breaking it!”}}]}