Tool Holder Metal Lathe Torque: Essential For Precision Machining

Understanding Tool Holder Metal Lathe Torque

Tool holder metal lathe torque is essential for precise machining. Why is it important? Proper torque keeps the workpiece secure. This helps prevent mistakes during cutting. A loose holder can lead to poor results. Did you know that too much torque can damage tools? Remember to check settings often. Using the right tool holder also improves efficiency. With the correct torque, you create smoother finishes. Curious about how to achieve this balance? It’s key to successful metalworking!Understanding Tool Holders in Metal Lathes

Definition and function of tool holders. Types of tool holders used in metal lathes.Tool holders are special parts that keep cutting tools in place on a metal lathe. Think of them as the best friends of the tools! They help the lathe do its job by holding tools tightly so they can cut and shape metal smoothly. There are different types of tool holders to fit various tasks. Some common types include quick-change holders and fixed holders. Each has its strengths, making it easier for the lathe to create amazing shapes. It’s like having the right shoes for the right dance!

| Type of Tool Holder | Description |

|---|---|

| Fixed Tool Holders | Hold tools securely and do not change easily. |

| Quick-Change Tool Holders | Allow for easy swapping of tools to save time. |

| Collet Holders | Great for smaller tools and provide a tight grip. |

In summary, tool holders are vital for metal lathes, helping to ensure they work effectively and efficiently. Plus, they add a touch of style like a good hat on a sunny day!

The Importance of Torque in Metal Lathe Operations

Definition of torque and its significance in machining. How torque affects cutting performance and tool wear.Torque is a measure of how much force is needed to turn an object. In metal lathe operations, torque is very important. It helps determine how well a tool cuts. If the torque is too low, the tool can slip and not cut properly. If it is too high, the tool can wear out faster. Proper torque ensures better cutting performance and longer tool life. This balance keeps projects running smoothly and efficiently.

Why is torque crucial in metal lathe work?

Torque is vital because it affects the cutting speed and impact on tools. More torque helps the tool cut through hard materials, while lower torque can cause dull edges.

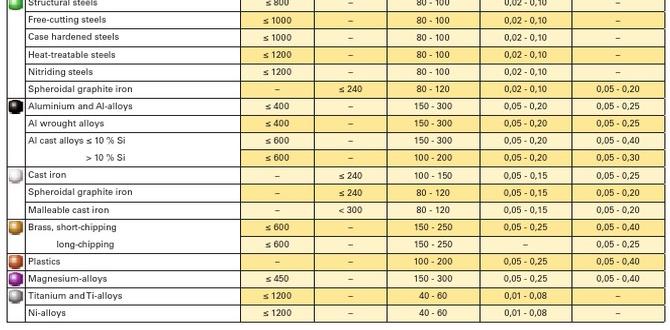

Factors Influencing Tool Holder Torque

Material properties of the tool holder. Design and geometry of the tool holder.Many details affect the torque of a tool holder. First, the material properties play a big role. Strong metals like steel can hold torque better than softer materials. Next, the design and geometry matter too. A well-shaped tool holder distributes force evenly. This helps prevent slipping and improves performance. Choosing the right material and design is key for the best results.

What are the main factors that affect tool holder torque?

The main factors affecting tool holder torque are the material properties and the design geometry. Strong materials and effective designs help maintain better torque performance.Key Factors:

- Material strength

- Shape and size

- Weight distribution

Selecting the Right Tool Holder for Optimal Torque

Key specifications to consider. Comparing different brands and models for torque performance.Selecting a tool holder is like finding the perfect pair of shoes for your lathe; it needs to fit snugly and work well. Focus on key specs like torque capacity and material quality. Different brands have unique designs that can affect performance. It’s like comparing apples and oranges, but we want the juiciest one! Here’s a smart little table to guide you through choices:

| Brand | Model | Torque Performance |

|---|---|---|

| Brand A | Model X | High Torque |

| Brand B | Model Y | Medium Torque |

| Brand C | Model Z | Low Torque |

Choose wisely and your lathe will thank you. After all, a happy lathe makes for happy projects!

Adjusting Torque Settings for Efficiency

Techniques for measuring and adjusting torque. Common mistakes to avoid when setting torque.Getting the torque settings right can make your lathe work like a charm. First, try using a torque wrench. It’s as crucial as a baker needs their oven! Measure carefully and adjust the torque to match what’s best for your project. Beware of common mistakes, like guessing or using the wrong settings; they can lead to sad, wobbly work. Remember, it’s all about precision. If you mess up, blame the cat – they always knock things over!

| Common Mistakes | Tips to Adjust Torque |

|---|---|

| Not using a torque wrench | Always measure! It’s like checking the wind before flying a kite. |

| Guessing the settings | Follow the tool’s manual for best results. |

| Ignoring manufacturer guidelines | Stick to the specs, or things might get out of hand! |

By focusing on these techniques for measuring and adjusting torque, you’ll ensure your project runs smoothly. And remember, practice makes perfect. Or, at least, less wobbly!

Maintenance Tips for Tool Holders and Lathe Torque

Best practices for tool holder care. Signs of wear and when to replace tool holders.Keeping your tool holders in tip-top shape helps your lathe run smoother than a buttered slide! First, regularly check for any signs of wear. If you see chips, cracks, or rust, it’s time to say goodbye to that tool holder and replace it. Not every hero wears a cape; some just hold tools really well!

To help you keep track of vital maintenance, here’s a handy table:

| Signs of Wear | Action |

|---|---|

| Chips or cracks | Replace immediately |

| Excessive rust | Consider replacement |

| Looseness when tightening | Inspect and replace if needed |

Regularly clean and lubricate your tool holders for optimum performance. Treat them like the precious gems they are!

Case Studies: Success Stories with Optimal Torque Settings

Example of improved efficiency in machining operations. Lessons learned from industry leaders.Many businesses have found success by using optimal torque settings in machining. For instance, a car parts manufacturer noticed a 20% increase in production speed. They learned that adjusting the torque on their tool holders made a big difference. Here are some key takeaways from industry leaders:

- Better torque settings lead to faster machining.

- Consistency in torque improves product quality.

- Monitoring torque helps to reduce tool wear.

These changes show how small adjustments can lead to big benefits in machining operations.

What are the benefits of optimal torque settings?

The benefits include faster production times, better quality products, and less tool wear.

Future Trends in Tool Holder Technology and Torque Management

Emerging innovations in tool holder design. The role of automation and smart technology in torque management.As we look ahead, tool holder designs are getting a tech makeover. Innovations like lightweight materials and quick-change systems are popping up everywhere. Imagine swapping tool holders faster than a pizza delivery! Automation and smart technology play a huge role in managing torque. They help maintain the perfect tightness, reducing mistakes and boosting safety. Plus, with smart sensors, we can monitor everything in real-time, making you feel like a torque wizard!

| Technology | Benefit |

|---|---|

| Lightweight Materials | Easy handling and quicker changes |

| Smart Sensors | Real-time torque monitoring |

| Quick-Change Systems | Simplifies tool holder swaps |

Conclusion

In summary, a tool holder for a metal lathe helps secure tools during cutting. Understanding torque is vital for effective machining. You want to choose a tool holder that matches your lathe and tools. Always prioritize safety and check your equipment regularly. To learn more, read about different types of tool holders and how they improve your work!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Tool Holder Metal Lathe Torque:Sure! Torque on a metal lathe is the twist force you need to turn the tool. It helps you cut metal shapes. If you have too little torque, the tool might not work well. Too much torque can break the tool or the machine. Always check the right level for what you’re making!

Sure! Please provide the question you would like me to answer.

What Is The Significance Of Torque Settings In Metal Lathe Tool Holders For Achieving Precision Machining?Torque settings tell you how tight to make the tool holder on a metal lathe. If it’s too loose, the tool can wobble and make mistakes. If it’s too tight, you might break the tool or the holder. Using the right torque helps us cut metal smoothly and accurately. This way, we can create the best parts for our projects.

How Does The Material Of A Tool Holder Affect Its Ability To Withstand Torque Loads During Metal Lathe Operations?The material of a tool holder is very important. Strong materials, like steel, can handle more twisting force. This means they won’t break as easily when we use them on a metal lathe. If the tool holder is weak, it might bend or break when we apply pressure. So, using the right material helps us work better and safer!

What Are The Common Torque Specifications Recommended For Different Types Of Tool Holders Used In Metal Lathes?Different tool holders for metal lathes have different torque needs. For example, you might use about 20 to 40 foot-pounds for a standard tool holder. For larger holders, like those for heavy tools, you may need 60 to 80 foot-pounds. Always check the instructions that came with your tool holder to be sure. Following these numbers helps keep everything safe and working well!

How Can Operators Ensure Proper Torque Application When Installing Tool Holders On A Metal Lathe To Prevent Slippage Or Damage?To make sure you apply the right torque when installing tool holders, you can use a torque wrench. This tool helps you measure how tight you’re making it. You should always follow the instructions that come with your lathe. Making sure things are tight prevents slippage and keeps everything safe. Always double-check your work!

What Are The Potential Consequences Of Using Incorrect Torque Levels On Tool Holders In A Metal Lathe Setup?Using the wrong torque levels on tool holders in a metal lathe can cause problems. If the tool is too loose, it might fall out and break. If it’s too tight, it can damage the tool or the holder. This can lead to bad cuts or even hurt you. So, it’s important to use the right amount of tightness!