Have you ever wanted to take your metal lathe to the next level? Imagine being able to grind, sharpen, or shape metal with precision. That’s where a tool post grinder for metal lathe comes in handy. This tool can turn your lathe into a powerful grinding machine.

Let’s think about it. You have a project in mind, but your tools just aren’t cutting it. Wouldn’t it be nice to have a way to polish or reshape metal easily? With a tool post grinder, you can. This small attachment makes a big difference.

Many hobbyists and professionals love using tool post grinders. They can create smooth finishes on parts that would take hours otherwise. Surprisingly, these grinders are not just for professionals. They can help anyone who enjoys working with metal.

In this article, we will explore the world of tool post grinders for metal lathes. You’ll learn how they work and why they are essential for any metalworking shop. So, are you ready to discover the magic of grinding?

Tool Post Grinder For Metal Lathe: Enhance Your Machining Efficiency

Understanding Tool Post Grinders for Metal Lathes

A tool post grinder for metal lathes is a game changer. It helps you turn a regular lathe into a powerful grinding machine. Imagine needing to sharpen parts or create precise finishes on metal pieces. This tool allows you to do just that without extra setups. It’s like having a mini workshop attached to your lathe. Curious about the versatility? You’ll find it can handle many different materials, making it essential for various projects.Understanding Tool Post Grinders

Definition and purpose of a tool post grinder. How it enhances metal lathe operations.A tool post grinder is a handy device for metal lathes. Think of it as a magic wand that turns your lathe into a grinding powerhouse! It helps sharpen and refine metal pieces, making your work smoother and more precise. With a tool post grinder, you gain control over your projects, enhancing accuracy and saving time. It’s like having your cake and eating it, too! Plus, it can handle stubborn imperfections that would rather hide in plain sight.

| Benefits of a Tool Post Grinder |

|---|

| Improves Surface Finish: Makes your metal look as shiny as a new penny! |

| Increases Accuracy: It’s like having a ruler that always plays by the rules. |

| Saves Time: Who doesn’t want more time for snacks? |

Benefits of Using a Tool Post Grinder

Improved precision and accuracy in machining. Versatility in grinding various materials.Using a tool post grinder can greatly enhance your metalworking projects. It helps you achieve better precision and accuracy in your machining tasks. This means you can create parts that fit together perfectly. Also, it is very versatile. You can grind different materials like steel, aluminum, and brass with ease. This makes it a great addition to any workshop!

What are the main benefits of using a tool post grinder?

Using a tool post grinder improves both precision and versatility in grinding tasks. You can create high-quality finishes and work with different materials for various projects.

- Enhances machining precision

- Grinds multiple materials

- Improves overall productivity

Components of a Tool Post Grinder

Main parts and their functions. Types of grinding wheels used.A tool post grinder has important parts that work together to shine metal. Key parts include:

- Motor: Powers the grinder and turns the grinding wheel.

- Spindle: Holds the grinding wheel in place.

- Base: Supports the entire tool post grinder.

- Tool Post: Attaches the grinder to the lathe.

Grinding wheels come in different types. Some are:

- Aluminum Oxide: Good for steel.

- Cubic Boron Nitride: Great for hard materials.

- Diamond: Best for super hard metals.

Each part works together to create smooth surfaces on metal. Knowing these parts can help you use a tool post grinder better.

What are the main components of a tool post grinder?

The main components are the motor, spindle, base, and tool post. These elements make the grinder function efficiently.

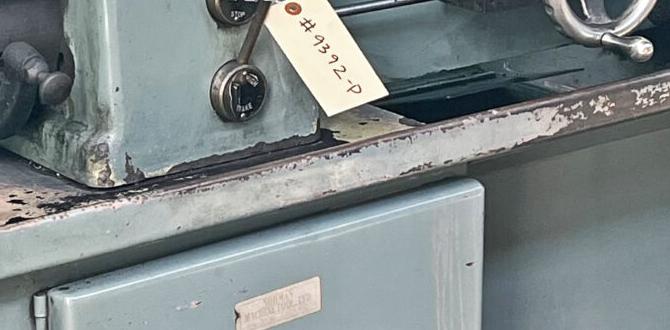

Choosing the Right Tool Post Grinder for Your Lathe

Key factors to consider (size, power, versatility). Recommended brands and models.Picking the best tool post grinder for your lathe is a bit like choosing the perfect pizza topping: it needs the right mix! First, consider the size—your grinder should fit snugly on your lathe, not like an oversized hat. Next up is power. A robust motor gets the job done quickly, saving you from waiting while your project takes a nap! Finally, think about versatility. You want a grinder that can adapt to different tasks, like a Swiss Army knife. Here are some brands to think about:

| Brand | Model | Power (HP) | Versatility |

|---|---|---|---|

| Grizzly | G9928 | 1 | Good |

| KBC Tools | KBC1812 | 1.5 | Excellent |

| Jet | JBG-8B | 1 | Fair |

Choose wisely, and your lathe will be grinding like a champ. After all, a happy lathe means happier projects!

Installation and Setup Guide

Stepbystep process for installation. Tips for proper alignment and calibration.To set up a tool post grinder for your metal lathe, follow these steps carefully. First, secure the grinder onto the lathe’s tool post. Then, check its alignment with the lathe’s spindle axis. Ensure it is straight and stable. Here are some tips for proper calibration:

- Use a dial indicator for accurate alignment.

- Adjust the height so the grinding wheel barely touches the workpiece.

- Tighten all screws firmly to prevent movement.

Take your time. A well-set grinder makes your work easier and more precise.

How do I calibrate my tool post grinder?

Calibrate your tool post grinder by checking the angle and height. Use a level to ensure everything is straight. Adjust until it is perfect for your projects.

Best Practices for Using a Tool Post Grinder

Safety precautions during operation. Techniques for achieving optimal results.Using a tool post grinder can be exciting, but safety is essential. Always wear goggles and protective gear. Keep your workspace tidy and organized. It helps prevent accidents. To get the best results, make sure to set the grinder correctly. Use a steady hand and check your speed. Consistency is key. Remember, practice makes perfect!

What are the key safety tips for using a tool post grinder?

Key safety tips include wearing safety goggles, keeping hands away from the grinder, and ensuring the workspace is clean.

Key techniques for better results:

- Set the grinder correctly.

- Keep a steady hand.

- Check speed regularly.

Common Issues and Troubleshooting

Typical problems encountered while using tool post grinders. Solutions and preventative measures.Using a tool post grinder can be quite the adventure, but trouble sometimes strikes. Common issues include overheating, poor finish, and strange noises that sound like a cat trying to sing! Fortunately, many problems have simple fixes. Regularly check the grinding wheel for wear, and keep everything clean—this helps prevent overheating. Always adjust the feed rate for a smoother finish. And remember, if it squeaks, it might need some grease, not a band-aid!

| Common Issues | Solutions | Preventative Measures |

|---|---|---|

| Overheating | Check wheel condition | Keep it clean |

| Poor finish | Adjust feed rate | Use the right speed |

| Strange noises | Lubricate moving parts | Regular maintenance |

Maintenance Tips for Longevity

Routine maintenance practices. How to extend the lifespan of your tool post grinder.Keeping your tool post grinder in top shape is easier than you think! Regular checks can make a big difference. Always clean off dust and debris after use. This simple act helps keep the motor happy. Also, lubricate the moving parts every now and then — it’s like giving a little oil to squeaky hinges! Remember, a well-lubricated grinder is a happy grinder! Check the belts for wear and tear, and replace them if they look like they’ve had more than a workout.

| Maintenance Task | Frequency |

|---|---|

| Clean Dust & Debris | After Each Use |

| Lubricate Moving Parts | Weekly |

| Inspect Belts | Monthly |

Following these tips can help your grinder last longer. Think of it as your tool’s way of thanking you with smoother, sharper results!

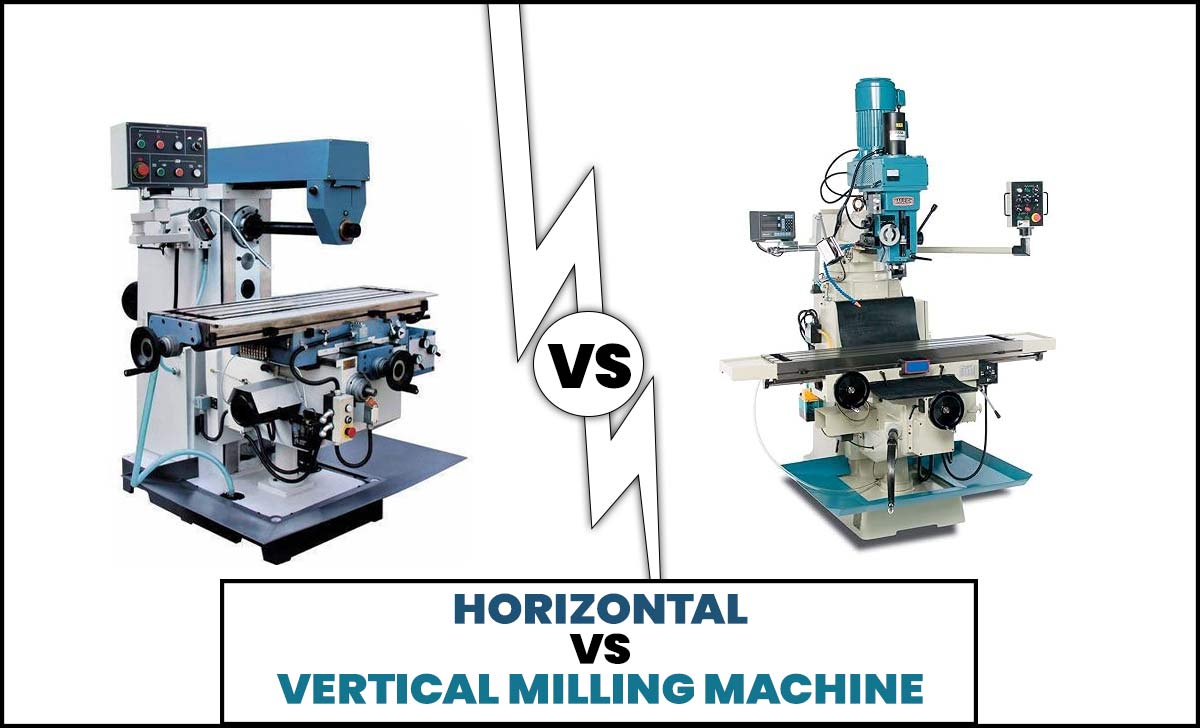

Comparing Tool Post Grinders with Other Grinding Methods

Advantages and disadvantages compared to standalone grinders. Situations where a tool post grinder excels.Tool post grinders have some great benefits but also some downsides compared to standalone grinders. They are compact and fit right on a lathe, saving space. This makes them perfect for jobs where you need both turning and grinding. However, they may not be as powerful as standalone grinders, which can handle larger tasks. You might choose a tool post grinder when you want to do quick touch-ups or small parts instead of heavy grinding. Here are some key points:

- Advantages: Space-saving design, good for small parts.

- Disadvantages: Less powerful than standalone grinders, limited to smaller jobs.

When should I choose a tool post grinder?

Use a tool post grinder for quick tasks or when working in small spaces. They work best for precise grinding on smaller pieces.

Case Studies and Real-World Applications

Examples of industries benefiting from tool post grinders. Success stories from users and their experiences.Many industries have discovered the magic of tool post grinders, and their success stories are fun to hear. For example, the automotive industry uses these grinders to fix engine parts with precision. A machinist once shared, “Once I used a tool post grinder, I felt like I had superpowers!” Even hobbyists find joy in crafting intricate designs at home. Here are a few key sectors that have benefited:

| Industry | Benefit |

|---|---|

| Manufacturing | Improved surface finish |

| Aerospace | Enhanced part accuracy |

| Construction | Efficient tool sharpening |

These are just a few examples, but they show the wide range of applications. Isn’t it great when a tool makes life easier? It’s like finding a slice of pizza when you’re only expecting salad!

Conclusion

In conclusion, a tool post grinder for your metal lathe can boost your projects. It helps you grind, shape, and finish metal easily. This tool saves time and improves accuracy. You can create better parts and projects. Explore more about tool post grinders and try one out. You’ll be pleased with the results!FAQs

What Is The Primary Function Of A Tool Post Grinder When Used With A Metal Lathe?A tool post grinder helps you make metal pieces smooth and shiny. You attach it to a metal lathe, which is a machine that rotates metal. As it spins, the grinder removes small bits of metal. This makes the surface nicer and more accurate for your projects. It’s like polishing a rough stone to make it smooth!

How Do You Properly Install A Tool Post Grinder Onto A Metal Lathe?To install a tool post grinder on a metal lathe, first, make sure the lathe is off and unplugged. Then, find the tool post area where you attach tools. Remove any old tool and clean the surface. Slide the grinder into the tool post and tighten it so it stays in place. Finally, check if everything is secure before you plug in the lathe.

What Types Of Grinding Wheels Are Most Commonly Used With Tool Post Grinders?The most common types of grinding wheels used with tool post grinders are made of aluminum oxide and silicon carbide. Aluminum oxide wheels are great for general use and work on many materials. Silicon carbide wheels are better for grinding hard materials like glass and ceramics. You can choose a wheel based on what you need to grind.

What Safety Precautions Should Be Taken When Operating A Tool Post Grinder On A Metal Lathe?When using a tool post grinder on a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear a snug-fitting shirt to prevent anything from getting caught. Stand clear of the moving parts while the tool is running. Make sure the tool is secure before you start and never reach into the machine while it’s on. Always follow the instructions to stay safe.

Can A Tool Post Grinder Be Used For Both External And Internal Grinding, And If So, How?Yes, a tool post grinder can be used for both external and internal grinding. For external grinding, you attach the grinder to the outside of the tool. To grind inside a hole, you fit it with a special attachment called a collet. This lets you reach inside and smooth the inner surfaces. It’s a handy tool for making things just right!