Tool Post Metal Lathe Automation: Streamlining Precision Work

Tool Post Metal Lathe Automation

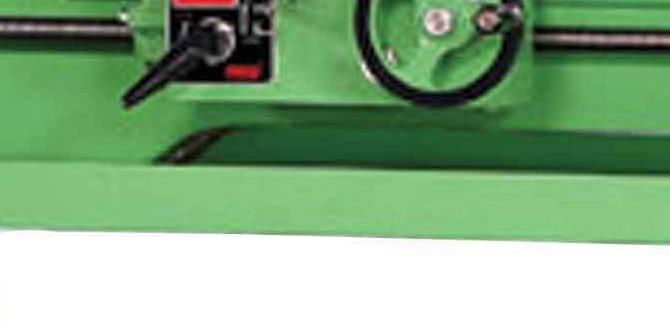

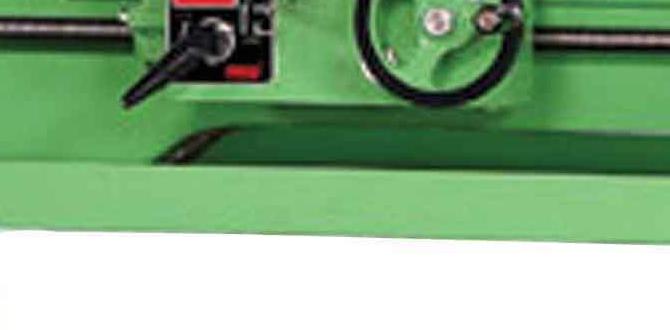

Tool post metal lathe automation makes metalworking easier and more efficient. What if turning a metal piece took a fraction of the time? With automation, tasks like cutting and shaping become precise and quick. Imagine a machine that adjusts itself and works without much human help! This technology reduces errors and boosts productivity. Plus, it saves time and money. As industries grow, automated lathes could be the key to future innovations in manufacturing.Benefits of Automation in Metal Lathes

Increased precision and repeatability in machining processes. Reduction in manual labor and operator fatigue.Automating metal lathes brings many advantages. First, it enhances precision and repeatability in machining. Machines follow precise instructions, making each part exactly the same. This prevents mistakes that can happen with manual work.

Second, automation reduces manual labor. Operators don’t need to stand for long hours. This helps them stay fresh and focused. Less fatigue means better performance at work. Overall, automation is smarter and safer!

What are the main benefits of automation in metal lathes?

Automation in metal lathes improves precision, reduces manual labor, and decreases operator fatigue.

Best Practices for Implementing Automation

Key considerations when choosing an automation system for lathes. Tips for integrating automation smoothly into existing workflow.Choosing the right automation system for lathes is like picking a favorite ice cream flavor—there are many options! Start by considering compatibility with your current machine. You don’t want a new gadget that doesn’t fit, like trying to squeeze a square peg into a round hole. Also, check for ease of use. A complex system might make you feel like you need a PhD to operate it!

Integrating automation can be smooth as butter. **First,** ensure all team members are trained. It’s important everyone knows how to use the new tool; no one wants a surprise “who forgot to turn it on?” moment! **Second,** keep communication open. Regular check-ins can prevent hiccups that feel like popping bubble wrap.

| Key Considerations | Tips for Integration |

|---|---|

| Compatibility with existing machines | Train team members thoroughly |

| User-friendly interface | Maintain open communication |

Common Mistakes to Avoid with Metal Lathe Automation

Identification of pitfalls in the automation setup process. Strategies for troubleshooting and maintaining automated systems.When using metal lathe automation, it’s easy to stumble into some common traps. First, be careful not to skip the setup checklist. Missing steps can lead to headaches later. Regular maintenance is also key. Dirty tools can become moody and refuse to work right, just like us before our morning coffee! To help, here’s a quick table of common mistakes and solutions:

| Mistake | Solution |

|---|---|

| Skipping setup steps | Follow the checklist carefully |

| Poor maintenance | Clean tools regularly |

| Ignoring errors | Check for alerts or issues |

By avoiding these pitfalls and keeping an eye on your machines, you’ll improve your automation process. Remember, a happy tool makes for a happy lathe!

Case Studies: Successful Automation Implementations

Examples of industries that have benefited from lathe automation. Key metrics and improvements observed postautomation.Many industries have seen great results with lathe automation. For example, automotive and aerospace sectors have improved production speed and accuracy. After automating, companies reported:

- 30% increase in production speed

- 40% reduction in errors

- 25% cost savings

These improvements helped them stay competitive. Automation not only makes work easier but also helps businesses grow.

What industries benefit from lathe automation?

Industries like automotive, aerospace, and manufacturing have greatly benefited from lathe automation. They enjoy higher quality and faster production times.

Future Trends in Tool Post Metal Lathe Automation

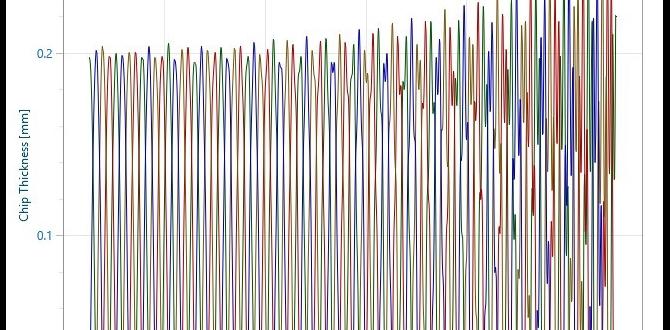

Exploration of emerging technologies in automation. Predictions for the future of metalworking automation and its impact on production efficiency.New technologies are changing how we do metalwork. Automation is becoming smarter every day. Robots and AI help metal lathes work better and faster. As we look ahead, we expect automation to save time and reduce errors. This means factories can make more parts quickly. Here are some key trends to watch:

- Advanced sensors for real-time monitoring.

- Robots that learn from their tasks.

- Increased use of machine learning.

These changes may lead to better quality products and fewer mistakes, driving down costs and boosting efficiency.

What is the future of tool post metal lathe automation?

The future looks bright! Automation will keep improving. This means machines will become faster and smarter, leading to more precise metalwork.

Resources for Further Learning

Recommended books, online courses, and tutorials on lathe automation. List of reputable suppliers and manufacturers of automated lathe tools.Ready to dive deeper into lathe automation? Check out these great resources! First, grab a couple of recommended books like “Lathe Automation Basics” or “Mastering Automation Systems.” They’re packed with useful info and fun illustrations. Next, online courses on platforms like Udemy or Coursera give you hands-on experience without the mess. Don’t forget awesome tutorials available on YouTube! Knowledge is power, and these tools will help you work smarter, not harder. Plus, if you need automated lathe tools, check out these suppliers:

| Supplier | Website |

|---|---|

| Machinery Solutions | www.machinerysolutions.com |

| Automation Direct | www.automationdirect.com |

| Industrial Tool Suppliers | www.industrytools.com |

These are just a few options to get you started on your lathe automation adventure!

Conclusion

In conclusion, tool post metal lathe automation simplifies machining tasks. It saves time and improves accuracy. You can produce better parts with less effort. If you’re curious, explore more about these tools. Consider trying automation in your projects. With practice, you’ll see great results. Keep learning and have fun with your metalworking journey!FAQs

Here Are Five Related Questions On The Topic Of Tool Post Metal Lathe Automation:Sure! Here are short answers to some related questions about tool post metal lathe automation: 1. **What is a tool post?** A tool post is a part of a lathe machine that holds the cutting tool. It helps us shape metal pieces into different forms. 2. **How does lathe automation help?** Lathe automation makes metal shaping faster and easier. Machines can run on their own, so we can do other tasks. 3. **What does a lathe do?** A lathe cuts and shapes metal into round pieces. It spins the metal while a cutting tool does the work. 4. **Can automation make mistakes?** Yes, machines can make mistakes if they are not set up right. That’s why we need to check them often. 5. **Is using a lathe fun?** Yes! Using a lathe allows you to create cool projects. It’s exciting to see your ideas become real things.

Sure! Please provide the question you’d like me to answer.

What Are The Key Advantages Of Automating The Tool Post Of A Metal Lathe In Terms Of Efficiency And Precision?Automating the tool post of a metal lathe makes things faster and easier. It helps you change tools without doing it by hand. This saves time, so you can finish work more quickly. Automation also makes cuts more exact, meaning your parts fit better. Overall, it helps you work more efficiently and with greater accuracy.

What Types Of Sensors And Control Systems Are Commonly Used In The Automation Of Tool Posts On Metal Lathes?In metal lathes, we often use sensors like limit switches and position sensors. Limit switches tell us when the tool post reaches the end of its movement. Position sensors help track where the tool post is, so we can adjust it correctly. The control systems then take this information to move the tool post automatically. This makes it easier and faster to shape metal parts accurately.

How Does The Integration Of Cnc Technology Enhance The Capabilities And Flexibility Of Automated Tool Posts In Metal Lathes?CNC stands for Computer Numerical Control. It helps machines, like metal lathes, work better. With CNC, we can change tools quickly and easily. This means we can make different shapes and sizes without stopping the machine. It allows us to create more things faster and with great accuracy.

What Are The Potential Challenges And Limitations Faced When Retrofitting Existing Manual Lathes With Automated Tool Posts?When you try to add automatic tool holders to old lathes, it can be tricky. First, the old machines might not fit the new parts well. Second, we might need to change some of the machine’s wires and controls, which can be hard. Also, there could be problems getting the right tools to work with the new setup. Lastly, it can cost a lot of money, and we need to make sure it’s worth it.

How Can Automation Of The Tool Post Contribute To Improving Safety Standards In Metalworking Environments?Automating the tool post means machines can do the work without people getting too close. This helps keep you safe because there is less chance of accidents. It also makes the work faster and more precise. By using machines, we can focus on more important tasks and stay away from dangers. Overall, this makes metalworking a safer place for everyone.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Tool Post Metal Lathe Automation:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are short answers to some related questions about tool post metal lathe automation: 1. **What is a tool post?** A tool post is a part of a lathe machine that holds the cutting tool. It helps us shape metal pieces into different forms. 2. **How does lathe automation help?** Lathe automation makes metal shaping faster and easier. Machines can run on their own, so we can do other tasks. 3. **What does a lathe do?** A lathe cuts and shapes metal into round pieces. It spins the metal while a cutting tool does the work. 4. **Can automation make mistakes?** Yes, machines can make mistakes if they are not set up right. That’s why we need to check them often. 5. **Is using a lathe fun?** Yes! Using a lathe allows you to create cool projects. It’s exciting to see your ideas become real things.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Advantages Of Automating The Tool Post Of A Metal Lathe In Terms Of Efficiency And Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automating the tool post of a metal lathe makes things faster and easier. It helps you change tools without doing it by hand. This saves time, so you can finish work more quickly. Automation also makes cuts more exact, meaning your parts fit better. Overall, it helps you work more efficiently and with greater accuracy.”}},{“@type”: “Question”,”name”: “What Types Of Sensors And Control Systems Are Commonly Used In The Automation Of Tool Posts On Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In metal lathes, we often use sensors like limit switches and position sensors. Limit switches tell us when the tool post reaches the end of its movement. Position sensors help track where the tool post is, so we can adjust it correctly. The control systems then take this information to move the tool post automatically. This makes it easier and faster to shape metal parts accurately.”}},{“@type”: “Question”,”name”: “How Does The Integration Of Cnc Technology Enhance The Capabilities And Flexibility Of Automated Tool Posts In Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC stands for Computer Numerical Control. It helps machines, like metal lathes, work better. With CNC, we can change tools quickly and easily. This means we can make different shapes and sizes without stopping the machine. It allows us to create more things faster and with great accuracy.”}},{“@type”: “Question”,”name”: “What Are The Potential Challenges And Limitations Faced When Retrofitting Existing Manual Lathes With Automated Tool Posts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you try to add automatic tool holders to old lathes, it can be tricky. First, the old machines might not fit the new parts well. Second, we might need to change some of the machine’s wires and controls, which can be hard. Also, there could be problems getting the right tools to work with the new setup. Lastly, it can cost a lot of money, and we need to make sure it’s worth it.”}},{“@type”: “Question”,”name”: “How Can Automation Of The Tool Post Contribute To Improving Safety Standards In Metalworking Environments?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automating the tool post means machines can do the work without people getting too close. This helps keep you safe because there is less chance of accidents. It also makes the work faster and more precise. By using machines, we can focus on more important tasks and stay away from dangers. Overall, this makes metalworking a safer place for everyone.”}}]}