Have you ever wondered how a simple piece of metal can transform into something incredible? The tool post on a metal lathe is part of that magic. It connects the cutting tool to the machine, helping shape metal accurately.

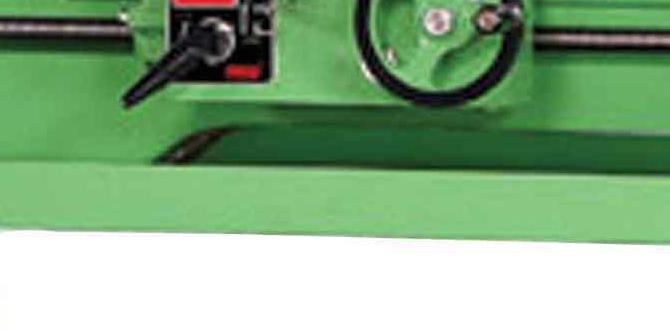

The control panel on a metal lathe plays a key role too. It’s where you adjust settings and control speeds. Imagine turning a dial and watching a rough block of steel become a shiny, smooth part. Isn’t that cool?

In this article, we will dive into the world of metal lathes. You’ll learn about the important features of the tool post and the control panel. You might even find out how easy you could start using a lathe yourself!

Tool Post Metal Lathe Control Panel: Essential Features & Functions

Tool Post Metal Lathe Control Panel

The tool post metal lathe control panel is essential for precision in machining. It allows users to adjust speed and tools easily, making metal shaping more efficient. Imagine working on a project where every second counts! This control panel simplifies the process, ensuring accuracy and quality in every cut. Understanding its features can improve your results. Did you know that proper control can reduce errors significantly? Explore the benefits of mastering this incredible tool!Understanding the Tool Post Metal Lathe

Definition and function of a metal lathe. Importance of the tool post in lathe operations.A metal lathe is a machine that shapes metal by spinning it against a cutting tool. Think of it as a giant pencil sharpener, but for metal! The tool post holds the cutting tool steady, allowing for precise movements. Without it, the lathe would be like a cat trying to catch a laser pointer—it wouldn’t be very effective! This part of the machine is crucial for making accurate cuts, ensuring your metal projects turn out just right.

| Function | Description |

|---|---|

| Shaping Metal | Rotates metal to achieve desired shape |

| Tool Stability | Holds cutting tool in place for accuracy |

| Detailed Work | Allows for intricate designs and features |

Components of the Control Panel

Detailed breakdown of control panel elements. Explanation of each component and its function.Every control panel has important parts that help it work smoothly. The main components include the power switch, speed dial, and emergency stop button. The power switch turns everything on—like flipping a light switch! The speed dial lets you choose how fast the lathe spins, which is super helpful. The emergency stop button? It’s like hitting the brakes on a car—press it when you need to suddenly stop. Check out the table below for more components:

| Component | Function |

|---|---|

| Power Switch | Turns the system on and off. |

| Speed Dial | Controls the spinning speed. |

| Emergency Stop | Immediately stops the machine. |

These parts work together like a team to make your metal lathe fun and safe to use. Remember, a happy lathe leads to happy projects!

Setting Up Your Metal Lathe Control Panel

Stepbystep guide to initial setup. Common mistakes to avoid during setup.To start setting up your metal lathe control panel, follow these quick steps. First, check the power supply; it should match your lathe’s needs. Next, connect the control panel wires to the lathe. Don’t mix them up! That could lead to some unexpected (and funny) results, like a lathe that won’t stop spinning!

Make sure to calibrate the settings, so your lathe runs smoothly. It’s like tuning a guitar; out of tune, it’s just noise. Common mistakes to avoid? Forgetting to tighten connections can lead to bumps and jitters—like a little dance party at your workstation. Use the table below as a checklist!

| Step | Tip |

|---|---|

| 1 | Check power supply |

| 2 | Connect wires carefully |

| 3 | Calibrate settings |

Remember to take your time. A little patience goes a long way, like waiting for cookies to bake! Happy latheing!

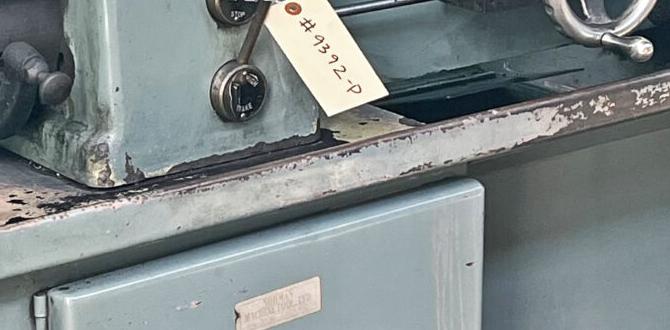

Maintenance Tips for Longevity

Regular maintenance practices for the control panel. Troubleshooting common issues with the panel.To keep the control panel running well, regular maintenance is key. Clean the panel often to remove dust and dirt. Check for loose wires, as they can cause problems. If you see any flashing lights or hear unusual sounds, troubleshoot quickly. This can save time and money!

- Clean dust regularly.

- Inspect wires for looseness.

- Address flashing lights promptly.

What are common issues with the panel?

Common issues include malfunctioning buttons, error messages, and unresponsive screens. Regular checks help catch these problems early.

Safety Guidelines When Operating a Metal Lathe

Essential safety measures to follow. Importance of personal protective equipment (PPE).Using a metal lathe can be fun but requires care. Follow these safety measures for a safe experience:

- Always wear personal protective equipment (PPE), like goggles and gloves.

- Keep fingers and hair away from moving parts.

- Check the machine for loose tools and parts before starting.

- Use the proper settings for different materials.

Your protection is important. According to experts, wearing PPE reduces injury risk by up to 70%. Always stay aware to work safely.

What is the importance of personal protective equipment (PPE)?

PPE helps keep you safe. It protects your eyes, hands, and body while using machines. Using PPE can prevent accidents and serious injuries.

Enhancing Performance with Upgrades

Suggested upgrades for better control and efficiency. Impact of technological advancements on metal lathe control panels.Upgrading your metal lathe control panel can greatly improve how it works. With better tools and technology, you can control the machine more efficiently. Here are a few suggested upgrades:

- **Digital Readouts**: They show precise measurements, making your work easier.

- **Improved Software**: New programs can help automate tasks, saving time.

- **User-Friendly Interfaces**: These make it easier to operate the lathe, even for beginners.

New technology makes these panels more accurate and responsive. These upgrades can boost your metal lathe’s performance. Small changes can make a big difference!

What are some upgrades for metal lathe control panels?

Suggested upgrades include digital readouts, improved software, and user-friendly interfaces. These help with better control and efficiency.

Comparing Popular Tool Post Metal Lathe Control Panels

Review of leading brands and models. Analysis of features, pricing, and user feedback.Different brands and models of tool post metal lathe control panels offer unique features. Popular options include:

- Brand A: Known for durability and user-friendly design.

- Brand B: Offers advanced features at a competitive price.

- Brand C: Praised for excellent customer support.

Pricing varies. Users often share feedback highlighting ease of use and reliability. Always check reviews before buying.

What should I look for in a lathe control panel?

Look for features like user-friendliness, price, and durability. Good reviews from others can guide you too!

Conclusion

In summary, the tool post metal lathe control panel is essential for guiding your machining work. It helps you adjust settings easily and ensures precision. Understanding this tool can boost your skills and confidence. If you want to learn more, consider exploring tutorials or guides. Practice using the control panel to enhance your projects and improve your techniques!FAQs

What Are The Essential Components Of A Metal Lathe Control Panel, And How Do They Function Together To Control The Lathe Operations?A metal lathe control panel has a few important parts. First, there’s the power switch, which starts and stops the machine. Then, we have knobs and buttons to change the speed. You can also find a feed control to set how fast the tool moves. All these parts work together to help you shape metal safely and easily.

How Do You Troubleshoot Common Issues With The Control Panel Of A Tool Post Metal Lathe?To troubleshoot the control panel on a tool post metal lathe, you can start by checking the power. Make sure the lathe is plugged in and turned on. If the lights on the panel are off, check the circuit breaker. Next, look for any loose wires or connections. If something still isn’t working, consult the manual or ask for help.

What Safety Features Should Be Included In The Control Panel Of A Metal Lathe To Ensure Operator Safety?To keep you safe when using a metal lathe, the control panel should have a big emergency stop button. This button quickly stops the machine if there’s a problem. There should also be clear labels for all controls so you can see what each button does. A safety guard around the moving parts helps protect your hands. Finally, a light indicator can show when the machine is running, so you know when to stay away.

How Can Automation And Digital Interfaces Improve The Functionality Of A Metal Lathe Control Panel?Automation can make a metal lathe control panel easier to use. You can set it to run on its own, which saves time. Digital screens show clear information, so you can see what’s happening right away. You can also save your favorite settings, making it quicker to start projects. Overall, these changes help you work better and faster!

What Maintenance Practices Are Recommended For The Control Panel Of A Tool Post Metal Lathe To Ensure Reliable Performance?To keep the control panel of a metal lathe working well, you should clean it regularly. Use a soft cloth to wipe off dust and dirt. Check for any loose wires or connections and fix them. Make sure no liquids spill on the panel, as they can cause damage. Lastly, test the buttons and switches to ensure they work properly.