Have you ever wondered how metal parts are shaped so precisely? A tool post metal lathe drive system makes this possible. This amazing machine uses a special setup to rotate metal pieces while tools cut them into desired shapes.

Imagine crafting everything from tiny screws to big engine parts. Each piece starts as a block of metal. The tool post holds cutting tools. The drive system spins the metal. Together, they create beautiful and useful objects.

Did you know that the lathe is one of the oldest machines? It dates back thousands of years! Early craftsmen used hand-powered lathes to make furniture and tools. Today, modern tool post metal lathe drive systems are fast and accurate.

Why is this so exciting? Because it shows how far we’ve come in technology. Each time you see metal parts, remember the great journey they took. Let’s dive deeper into this fascinating world and learn how it all works!

Tool Post Metal Lathe Drive System: A Comprehensive Guide

Understanding Tool Post Metal Lathe Drive Systems

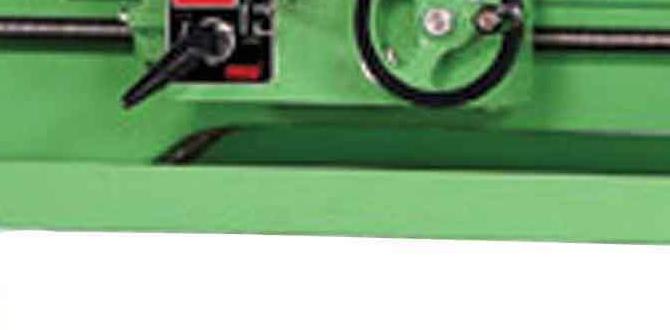

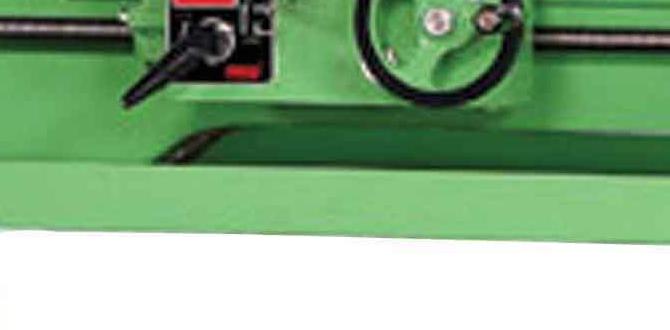

Tool post metal lathe drive systems are essential for precision machining. These systems provide the power necessary to rotate the workpiece, allowing for smooth cutting and shaping. Did you know that the right drive system can enhance your lathe’s performance? It influences speed and efficiency, making a significant difference in the quality of your projects. Choosing the proper drive system can save time and improve your work output. Understanding these elements can lead to better craftsmanship and improved results.What is a Tool Post Metal Lathe Drive System?

Definition and primary function of a drive system in metal lathes. Key components that make up the drive system.A drive system in a metal lathe is crucial for smooth operation. It powers the lathe and helps shape materials like metal and wood. In simple terms, it turns the workpiece so that tools can cut or shape it. Key parts include:

- Motor: Provides the energy.

- Gears: Change speed and torque.

- Belts: Transfer power between parts.

- Spindle: Holds and rotates the material.

What does the drive system do for a metal lathe?

The drive system ensures accurate and efficient machining. It allows the lathe to achieve the desired precision and control during cutting tasks.

Advantages of Modern Tool Post Drive Systems

Increased precision and accuracy in machining. Enhanced user control and safety features.Modern tool post drive systems bring many great benefits. They help machines work with increased precision and accuracy. This means less waste and better results. Users enjoy more control over their projects too. Safety features are improved, making it safer to use. Using these systems, even a beginner can make high-quality parts. Isn’t that exciting?

What are the main advantages of modern tool post drive systems?

The main advantages include:

- Greater accuracy: Machines produce parts that fit perfectly.

- Better control: Users can adjust settings easily.

- Safety features: Protect the user from accidents.

How to Choose the Right Drive System for Your Metal Lathe

Factors to consider: size, material, and intended use. Compatible accessories and upgrades for improved functionality.Choosing the right drive system for your metal lathe is important. Start by thinking about size and material. A larger lathe may need a more powerful drive system. Consider what you’ll use it for, too. Will you make big pieces or small details? Look for accessories that fit your needs. Upgrades can boost performance. Options like variable speed drives help you work better. Always check for compatibility before buying.

What should I consider when selecting a drive system?

Think about size, material, and how you plan to use it. These factors will help you pick the best drive system for your metal lathe.

Key Factors to Consider:

- Size of the lathe

- Type of material

- Intended use

- Compatible accessories

- Desired upgrades

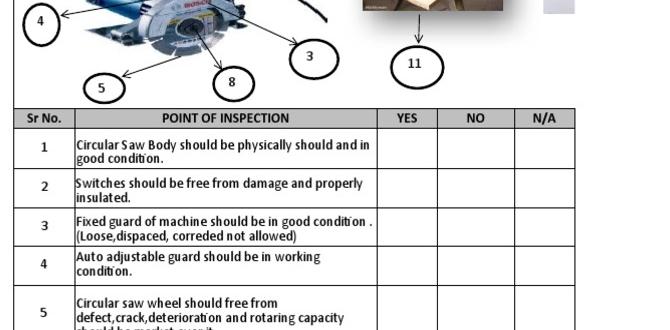

Common Issues with Tool Post Drive Systems and Solutions

Identifying and troubleshooting common mechanical problems. Maintenance tips to prolong the lifespan of the drive system.Tool post drive systems can face several tricky problems. You might notice strange noises or uneven cutting. These issues often come from worn parts or poor lubrication. Regular maintenance can help keep your machine running smoothly.

- Check for loose or damaged parts.

- Keep all moving parts well-lubricated.

- Clean the drive system to prevent dust buildup.

Overall, small fixes can make a big difference. Caring for your drive system means it will last longer and work better!

What are common issues with a tool post drive system?

Common issues include noisy operations and uneven cuts, which can result from worn-out components or insufficient lubrication.

How can you maintain your tool post drive system?

Regularly check for loose parts, lubricate moving sections, and keep the system clean.

Comparing Popular Brands and Models

Top brands in the market: features and benefits. Reviews and user testimonials for various drive systems.Different brands offer unique features for tool post metal lathe drive systems. Popular brands include Jet, Grizzly, and Shop Fox. Each brand has something special to share. Here are some highlights:

- Jet: Known for its durability and user-friendly design.

- Grizzly: Offers great value and robust features.

- Shop Fox: Praised for its high-quality build and accessories.

Many users share positive feedback. They love how easy these systems are to use. Testimonials often mention improved precision and smooth operation. Overall, these brands are trusted choices in the metalworking community.

What do users say about tool post metal lathe drive systems?

Users appreciate the smooth operation and precision offered by different brands. Many find it easy to make accurate cuts, which saves time and effort.

Future Trends in Tool Post Drive System Technology

Innovations on the horizon: automatic adjustments and smart systems. Impact of technology on machining efficiency and output quality.The future of tool post drive systems looks bright and exciting! Imagine machines that make automatic adjustments. That’s right! Smart systems will monitor and adapt to changes in real-time. This means better machining efficiency and higher output quality. According to recent studies, these innovations could boost production speed by up to 30%. Maybe soon, machines will work so well, we’ll have to ask them for advice. Who knows, they might even recommend us!

| Trend | Description |

|---|---|

| Automatic Adjustments | Machines adjust settings for optimal performance. |

| Smart Systems | Technology analyzes and improves efficiency. |

Conclusion

In summary, the tool post metal lathe drive system is essential for smooth machining. It helps shape materials accurately. Understanding how it works can improve your skills. We recommend exploring tutorials or hands-on practice to see these systems in action. By diving deeper, you can master metalworking and create amazing projects. Keep learning and experimenting!FAQs

What Are The Key Components Of A Drive System In A Metal Lathe, And How Do They Interact To Ensure Smooth Operation?A metal lathe has a few important parts that help it spin and cut metal smoothly. First, there’s the motor, which is like the engine that makes everything move. It turns a belt, which connects to the spindle. The spindle holds the metal piece and spins it very fast. Together, these parts work to make sure the lathe cuts evenly and safely.

Of course! Please provide the question you would like me to answer.

How Does The Choice Of Motor Type (Ac Vs. Dc) Influence The Performance And Versatility Of A Metal Lathe’S Drive System?The type of motor we choose for a metal lathe affects how it works. AC motors (Alternating Current) can run longer and are great for steady tasks. DC motors (Direct Current) are better for changing speeds quickly. So, if you want to do more different jobs, a DC motor might be best. But for long jobs, AC would be the better choice.

Sure! Please provide the question you’d like me to answer.

What Role Do Gears And Pulleys Play In The Torque And Speed Adjustments Of A Metal Lathe’S Drive System?Gears and pulleys help change how fast the metal lathe spins. Gears can increase torque, which means more turning power. When we use different pulley sizes, we can also speed things up or slow them down. This makes it easier to work with different materials. So, gears and pulleys help us control both speed and strength while using the lathe.

Sure! Just let me know what question you’d like me to answer.

How Can The Maintenance Of A Lathe’S Drive System Reduce Wear And Prolong The Lifespan Of The Machine?Taking care of a lathe’s drive system helps it run better. When we keep it clean and well-lubricated, parts do not rub as much. This stops them from wearing out quickly. Regular checks can catch problems early, so we can fix them before they get worse. By doing this, we help the lathe last a long time!

Of course! Please provide the question you’d like me to answer.

What Advancements In Drive System Technology Have Been Made For Modern Metal Lathes, And How Do They Improve Functionality Compared To Older Models?Modern metal lathes use better drive systems, like servo motors. These motors help the machines move smoothly and accurately. They let you change speeds quickly, which saves time. Also, new lathes are quieter and easier to control. Overall, these advancements make lathes faster and more efficient than older ones.