Have you ever wondered how a metal lathe works? It’s more than just a machine; it’s a magical tool that shapes metal. One key part that makes it function is the gear train. The gear train connects to the tool post of the lathe and helps control movement.

Imagine turning a block of metal into a sleek gadget. The tool post metal lathe gear train makes this possible. It lets the lathe spin the metal while the cutting tool moves smoothly. Isn’t that fascinating? Each gear works together like a team to create perfect shapes.

Did you know that the right gear train can improve speed and precision? Many hobbyists and professionals rely on this clever mechanism. With the right setup, you can create amazing projects, from tiny bolts to large parts for machines.

So, let’s dive deeper into the world of tool post metal lathe gear trains. You’ll discover how they work, why they matter, and how you can use them to unlock your creative potential!

Tool Post Metal Lathe Gear Train: An Essential Guide

Explore the Tool Post Metal Lathe Gear Train

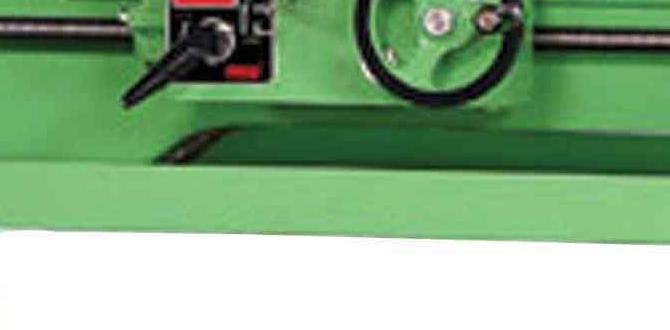

The tool post metal lathe gear train is essential for precision in machining. It helps control the movement of the cutting tool. Imagine creating beautifully shaped metal parts with ease! The gear train translates the motor’s rotation into usable speeds. Did you know that each gear influences the lathe’s efficiency? Understanding how it works can greatly enhance your crafting skills. Learn the parts and functions to become a pro at using a metal lathe!What is a Tool Post on a Metal Lathe?

Definition and function of the tool post. Different types of tool posts available in metalworking.A tool post is a vital part of a metal lathe. It holds the cutting tool in place, making sure it stays steady and precise. Think of it as the tool’s best buddy, keeping it from going on wild adventures during machining! There are a few types, including the **fixed tool post**, which holds the tool tightly, and the **quick-change tool post**, which allows for faster swaps. Metalworkers often pick the type based on their projects.

| Type of Tool Post | Function |

|---|---|

| Fixed Tool Post | Holds the cutting tool firmly in one place |

| Quick-Change Tool Post | Allows easy and fast changing of tools |

This makes the process smoother and speeds things up. So, having the right tool post is like having the right shoes for running. It makes all the difference!

Importance of the Gear Train in Metal Lathes

Explanation of the gear train and its role in lathe operations. How gear ratios affect machining processes.A gear train helps control the speed and power in a metal lathe. It consists of gears working together. These gears ensure smooth operations during machining. The gear ratios are crucial. They determine how fast the lathe spins and how much force it applies.

- The right gear ratio leads to precise cuts.

- Too high a ratio can cause errors or damage.

- Lower ratios allow for finer adjustments.

Understanding the gear train helps in making better parts.

How does a gear train affect lathe operations?

The gear train directly affects the speed and torque of the lathe. When the gears match well, they create smooth and fast machining. This results in better and cleaner finishes on materials. Good gear trains improve work quality and efficiency.

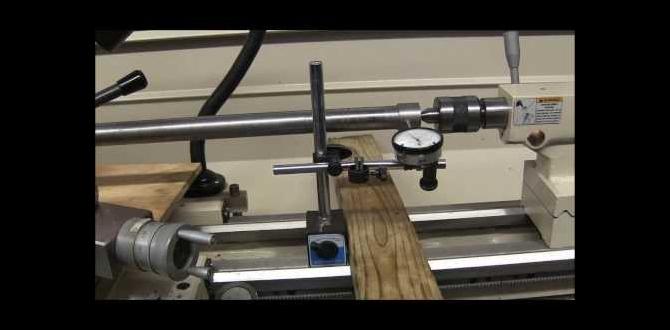

How to Set Up the Gear Train for Optimal Performance

Stepbystep guide to configuring the gear train. Tips for troubleshooting common setup issues.Configuring the gear train is key to smooth lathe operation. Start with these easy steps:

- Identify the correct gears for your setup.

- Align the gears properly to avoid skipping.

- Secure them tightly with the right tools.

- Test the setup to ensure everything runs smoothly.

If you face issues, try these tips:

- Check for misalignment.

- Look for worn gears that need replacement.

- Ensure all connections are tight.

Following these steps can help your machine run better.

What common mistakes should I avoid?

Common mistakes include misaligning gears and using the wrong size. Checking each gear before making adjustments can save time. Remember, patience brings better results!

Maintaining Your Metal Lathe Gear Train

Best practices for ensuring longevity and reliability of the gear train. Common maintenance pitfalls and how to avoid them.To keep your metal lathe gear train in great shape, regular maintenance is key. Here are some best practices:

- Check for oil regularly. Proper lubrication helps reduce friction.

- Clean dust and debris often. A clean gear train runs smoothly.

- Inspect for wear and tear. Look for cracks or rough spots.

- Align gears correctly. Misalignment can cause problems.

Many makers forget these steps. Skipping them can lead to costly repairs. Stay attentive and your gear train will last longer. Follow these tips for a reliable tool!

What are common mistakes in gear train maintenance?

Common mistakes include ignoring lubrication, neglecting cleaning, and failing to check for damage.

Upgrading Your Gear Train: When and Why?

Signs that indicate a need for upgrade. Benefits of modernizing the gear train, including technology advancements.Upgrading your gear train can greatly improve how your tool post metal lathe works. Watch for these signs that an upgrade might be needed:

- Your lathe struggles to make precise cuts.

- You notice unusual noises or vibrations.

- Parts wear out faster than before.

Modernizing your gear train offers many advantages:

- Improved accuracy and finish.

- Increased speed and efficiency.

- Access to advanced technology like digital controls.

Upgrades can make your lathe perform better, saving time and effort. Think about the benefits!

Why upgrade your gear train?

Upgrading can enhance performance, extend the machine’s life, and reduce repair costs. Think of it like getting a new engine for a car—it drives better!

Comparing Different Metal Lathe Models and Their Gear Train Designs

Review of popular metal lathe models and their gear configurations. Performance analysis of varying designs to cater to user needs.Many metal lathes have different gear train designs. Some popular models include the Jet JWL-1221VS, Grizzly G0766, and the Nova Comet II. Each model has unique features that cater to specific user needs. For example, some focus on speed and precision, while others prioritize power. Here’s a quick summary of key models and their gear configurations:

- Jet JWL-1221VS: Great for beginners, offers variable speed settings.

- Grizzly G0766: Known for its high torque and stability.

- Nova Comet II: Versatile design with multiple speed options.

Understanding these differences helps users choose the best metal lathe according to their needs. Performance can vary widely based on gear design, so explore each model carefully.

Which metal lathe has the best gear train design?

The Jet JWL-1221VS is often praised for its reliable gear train, providing smooth operation and a range of speeds.

Frequently Asked Questions About Tool Post and Gear Train

Addressing common queries related to setup, maintenance, and performance. Expert tips for beginners to navigate challenges related to gear trains.Many beginners have questions about setting up and caring for their gear trains. Here are some common concerns:

How do I set up a tool post?

For a good setup, ensure the tool post is tight and secure. Align the tool properly for accurate cutting. Regular checks help keep things running smoothly.

What is the best maintenance tip?

Keep gears clean. Lubricate them often. This simple step can prevent wear and tear.

Performance Tips:

- Start at low speeds.

- Adjust feed rates as needed.

- Check for vibrations during use.

These tips can help make your journey with the gear train easier and more enjoyable!

Conclusion

In conclusion, the tool post on a metal lathe helps position tools correctly, while the gear train controls the speed and power. Understanding these parts is key to mastering lathe operations. We can enhance our skills by practicing with real projects. So, dive deeper into this topic to boost your metalworking confidence and creativity!FAQs

What Is The Function Of A Gear Train In A Metal Lathe, And How Does It Affect The Lathe’S Performance?A gear train in a metal lathe helps change how fast the spindle turns. It helps us make cuts at different speeds. When we adjust the gears, we can do different jobs better. This makes the lathe work more smoothly and helps us create better parts.

How Do Different Gear Ratios In A Lathe’S Gear Train Influence The Speed And Torque Of The Spindle?Different gear ratios in a lathe change how fast the spindle turns. A high gear ratio makes the spindle turn faster but with less force. This is good for light tasks. A low gear ratio gives more force but makes the spindle turn slower. This helps when cutting hard materials.

What Are The Common Materials Used For Gears In A Metal Lathe Gear Train, And How Do They Impact Durability And Precision?Common materials used for gears in a metal lathe gear train are steel, brass, and plastic. Steel is strong and lasts a long time. Brass is good for reducing friction, which helps gears move smoothly. Plastic is lighter but may wear out quicker. These materials affect how long gears last and how accurate they are when making things.

How Can One Troubleshoot And Repair Issues With The Gear Train In A Metal Lathe?To troubleshoot the gear train in a metal lathe, first, you should unplug the machine for safety. Then, check for any broken or loose gears by looking closely at them. If you find something wrong, you can tighten screws or replace broken parts. Don’t forget to clean the gears to help them work better. Finally, test the lathe again to see if it runs smoothly!

What Are The Advantages Of Using An Electronic Variable-Speed Drive Compared To A Traditional Gear Train In A Metal Lathe?Using an electronic variable-speed drive makes machines like lathes easier to control. You can change the speed quickly with just a button. This means you can work faster or slower depending on what you’re making. It also makes less noise and uses less energy compared to old gear trains. Overall, it’s a simpler and smarter way to run the lathe.