Have you ever wondered how to save money on tools? Tool reconditioning for end mills is a smart way to do just that. Instead of buying new end mills, you can bring your old ones back to life. It’s like giving your favorite toy a new battery instead of buying a new one.

Most people don’t know that end mills can be sharpened and repaired. Did you know that reconditioning can make your tools last longer? It can even improve their performance! Imagine cutting through metal like butter. That’s the magic of tool reconditioning.

Every machinist knows that sharp tools work better. But what happens to those tools over time? They get dull, just like a pencil. Instead of tossing them out, think about how you can restore them. Tool reconditioning for end mills not only helps you save money but also keeps your workshop running smoothly.

Tool Reconditioning For End Mills: Enhance Performance Today

Tool Reconditioning for End Mills

Tool reconditioning for end mills extends their life and boosts performance. Instead of buying new tools, this process brings the used ones back to life. Imagine saving money while improving precision! Reconditioning remove wear and tear, restoring sharpness. It can also enhance dimensional accuracy. You might be surprised to know that regular maintenance can save up to 50% of your tool costs. Embracing reconditioning is a smart choice for any workshop!Understanding End Mills

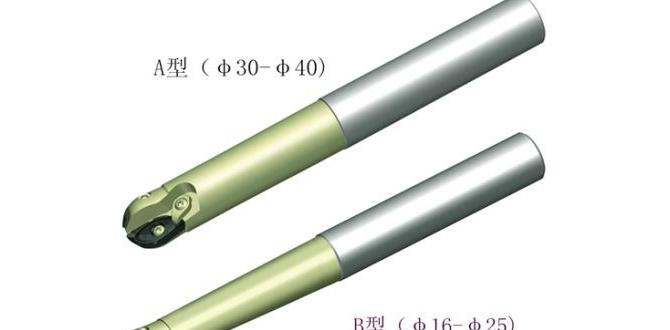

Definition and function of end mills in machining. Types and geometries of end mills and their applications.End mills are vital tools in machining. They are used to cut and shape materials like metal and wood. Think of them as the superheroes of the workshop! Different end mills come in various shapes, like flat, ball, or corner radius, each with special jobs. Some are perfect for detailed work, while others tackle tough tasks. Here’s a table to illustrate some types:

| End Mill Type | Geometry | Application |

|---|---|---|

| Flat End Mill | Flat Bottom | Face Milling |

| Ball End Mill | Rounded Tip | Curved Surfaces |

| Cylindrical End Mill | Cylindrical Shape | Slot Cutting |

Using the right end mill is like choosing the right ice cream flavor; it can make or break your project! Each type helps create smooth finishes and precise cuts, making machining more enjoyable. So, next time you grab an end mill, just remember: it’s not just a tool; it’s your trusty sidekick in the machining world!

Importance of Tool Reconditioning

Costeffectiveness of reconditioning versus new tool purchase. Impact on machining efficiency and quality.Keeping tools sharp is like keeping your favorite pencil pointy. Tool reconditioning is a smart way to save money. Instead of buying new end mills, you can make old ones shine again. This saves cash for snacks! Plus, sharp tools cut better, which means you get cleaner pieces and faster work. Everyone loves seeing smooth surfaces. So, why buy new when you can make old tools work like superheroes?

| Action | Cost | Efficiency |

|---|---|---|

| Tool Reconditioning | Less money spent | Higher quality cuts |

| Buying New Tools | More money spent | Possible waste of resources |

Signs That End Mills Need Reconditioning

Common indicators of wear and damage. Performance drop metrics to watch for.Spotting worn-out end mills isn’t rocket science. Look for common signs of wear and tear, like chipped edges or a dull finish. If your tool starts chattering or makes weird noises, it might be crying for help! Performance drops are another clue. A sudden increase in cutting time or poor surface finish means it’s time for a spa day—also known as reconditioning. Here’s a quick cheatsheet:

| Signs | Performance Drop Indicators |

|---|---|

| Chips or Cracks | Longer Cutting Time |

| Dull Cutting Edge | Poor Surface Quality |

| Unusual Noises | Frequent Tool Breakage |

Being aware of these signs helps keep your tools in tip-top shape, making you the hero of the workshop!

Reconditioning Processes for End Mills

Steps involved in the reconditioning process. Types of reconditioning (sharpening, coating, etc.).Reconditioning tools helps them last longer. There are a few main steps in the process. First, the end mill is cleaned to remove dirt. Next, it gets inspected for damage. Then, it may be sharpened to restore its cutting edge. Finally, coatings can be applied to improve performance. Common types of reconditioning include:

- Sharpening: Making the cutting edge sharper.

- Coating: Adding a special layer to reduce wear.

These steps keep end mills working well. Regular reconditioning saves money and time!

What is tool reconditioning for end mills?

Tool reconditioning for end mills is a process that restores their shape and sharpness. It increases their working life and efficiency, saving money on replacements.

Tools and Equipment Required for Reconditioning

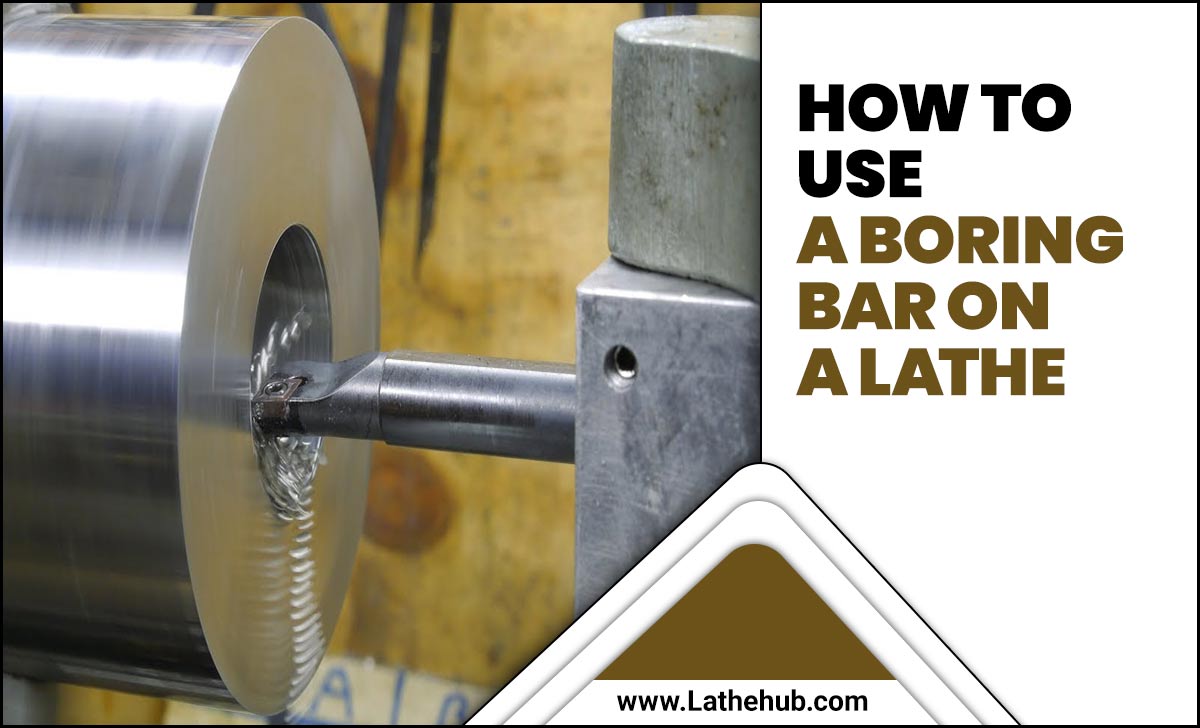

Essential machinery and tools for reconditioning end mills. Safety equipment and measures to consider.To recondition end mills, you need the right tools and equipment. Here are some essential items:

- Grinding Machine: This tool sharpens and shapes the end mills.

- Measuring Tools: Calipers and gauges help check sizes and angles.

- Workholding Fixtures: These hold the tools securely while you work.

- Cooling System: It keeps the tools cool during the grinding process.

Safety is key during reconditioning. Always wear protective gear like goggles and gloves. Make sure your workspace is clean and well-lit. Proper safety measures keep you safe while working with machinery.

What safety equipment should I use for reconditioning?

Use gloves, goggles, and ear protection when reconditioning tools to stay safe. These items protect you from flying debris and loud noises. Always work in a tidy, well-lit area for extra safety.

Choosing a Tool Reconditioning Service

Key factors to consider when selecting a service provider. Evaluating quality standards and guarantees offered.Finding the right reconditioning service is key for your tools. Consider several important factors to ensure quality. Start by checking the company’s experience and reputation. Ask about their quality standards, such as:

- Certification of their staff

- Types of tools they service

- Guarantees for the finished product

Quality assurance helps you trust their work. A solid guarantee can provide you peace of mind. Choose a service that values these things to get the best care for your end mills.

What should you look for in a service provider?

Look for a provider with good reviews, proper certifications, and a solid warranty on their services. This ensures you’re getting quality reconditioning for your tools.

DIY Reconditioning Techniques

Basic techniques for those who prefer a handson approach. Recommended tools for athome reconditioning.Ready to get your end mills back in shape? Start with some handy techniques! You can sharpen those dull edges right at home. Grab a sharpening stone and some lubricant for a smooth glide. Don’t forget safety goggles—nobody wants to catch a flying chip! You might also try a tool rest for better control. Check out the table below for recommended tools to help you ace your DIY projects!

| Tool | Purpose |

|---|---|

| Sharpening Stone | To refine the cutting edges |

| Lubricant | To reduce friction during sharpening |

| Tool Rest | For steady and accurate sharpening |

Case Studies and Success Stories

Realworld examples of successful end mill reconditioning. Analysis of cost savings and performance improvement.One company turned its tools into superheroes by reconditioning its end mills. They saved over 30% on costs while boosting performance. This magic trick didn’t just sharpen their tools; it made their entire operation smoother. By using reconditioned end mills, they noticed less downtime and happier employees. After all, fewer tool changes mean more time for coffee breaks! Here’s a quick look at the numbers:

| Measurement | Before Reconditioning | After Reconditioning |

|---|---|---|

| Cost Savings | $10,000 | $6,000 |

| Performance Improvement | 70% | 90% |

With smiles all around, it’s clear that reconditioning can lead to super savings and sharper tools!

Future Trends in Tool Reconditioning

Innovations and advances in reconditioning technologies. Predicted industry shifts concerning sustainability and recycling.Many new ideas are changing tool reconditioning. With machines getting smarter, we see faster ways to fix end mills. Innovations like laser sharpening and automated cleaning are making the process easier. Companies are also focusing on the environment. They aim to recycle more and waste less.

- Use of AI to detect tool wear

- More eco-friendly materials

- Increased recycling practices

- Focus on energy-efficient machines

Sustainability is key in the future. This shift reflects a growing concern for our planet. Reconditioning tools helps reduce waste and promotes a greener industry.

What are the upcoming trends in tool reconditioning?

Upcoming trends include AI advancements and energy-saving techniques. New recycling practices will also help the environment.

Conclusion

In conclusion, tool reconditioning for end mills helps save money and extend tool life. By sharpening and repairing worn tools, we keep them efficient and reliable. You can improve your machining projects with well-maintained end mills. Next, consider exploring reconditioning services or learning more about this process. It’s a smart way to boost your workshop skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Tool Reconditioning For End Mills:Sure! Here are five related questions on the topic of tool reconditioning for end mills: 1. **What is tool reconditioning?** Tool reconditioning means fixing old tools to make them sharp and good as new. 2. **Why do we recondition end mills?** We recondition end mills to save money and keep them working longer. 3. **How do we know when to recondition?** You can tell it’s time to recondition when the end mill isn’t cutting well anymore. 4. **Can anyone recondition end mills?** You need special tools and skills to recondition end mills properly, so it’s usually done by experts. 5. **What tools do we need for reconditioning?** You typically need a grinder and some measuring tools to check the end mill’s condition.

Sure! Just let me know what question you would like me to answer.

What Are The Most Common Signs That An End Mill Needs Reconditioning?You might know an end mill needs reconditioning if it gets dull and struggles to cut properly. If you see chips or rough edges on your materials, that’s a sign too. When you hear loud noises or feel a lot of vibration while using it, pay attention. Lastly, if the end mill is turning blue or looks damaged, it’s time to fix it.

What Processes Are Typically Involved In The Reconditioning Of End Mills?To recondition end mills, we start by cleaning them to remove dirt and old metal. Next, we check their edges. If they are dull, we sharpen them to make them pointy again. Then, we polish them to make sure they work smoothly. Finally, we inspect them again to make sure they are ready to use.

How Can Reconditioning Of End Mills Improve Their Performance And Lifespan?Reconditioning end mills is like giving them a makeover. It sharpens their cutting edges and makes them work better. When they’re sharp, they cut materials more easily. This can help them last longer, so you don’t have to buy new ones as often. Keeping tools in great shape means you can do your work faster and get better results!

What Equipment Or Tools Are Required For Effectively Reconditioning End Mills?To recondition end mills, you need a few tools. First, use a sharpening machine to make the edges sharp again. You also need a measuring tool to check the size and shape. A good cleaning brush helps keep things tidy. Finally, safety gear, like gloves and goggles, is important to protect yourself while working.

Are There Specific Materials Or Coatings That Are Better Suited For End Mills In Terms Of Reconditioning And Longevity?Yes, some materials and coatings help end mills last longer and be reconditioned easily. Carbide is a strong material that many end mills use. Coatings like titanium nitride or carbide help protect them from wear. These coatings can also make cutting smoother. Choosing these options can make your end mills last much longer!