Have you ever wondered how metal lathes create amazing projects? The secret often lies in their gear trains. A good gear train helps the lathe work smoothly and accurately. This makes it easier to shape metal just the way you want it.

Imagine building a model or fixing a part on your bike. Having a top rated metal lathe with a strong gear train can make all the difference. It can turn a simple task into something fun and exciting.

Did you know that the right gear train can extend the life of a lathe? It’s true! When parts work together well, they last longer. In this article, we will explore the top rated metal lathe gear trains. You’ll learn what to look for and why they matter. Get ready to discover how these clever designs can enhance your metalworking adventures!

Top Rated Metal Lathe Gear Train: Maximizing Precision And Efficiency

Top Rated Metal Lathe Gear Train

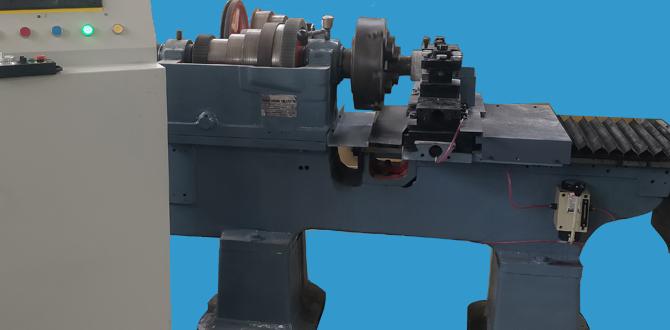

Discover the secrets of the top-rated metal lathe gear train! A well-designed gear train is crucial for smooth lathe operation. It ensures precision in crafting items, from intricate art pieces to sturdy parts. Did you know that even a small mistake in gear alignment can affect your work greatly? A reliable gear train not only boosts performance but also extends the lathe’s life. This knowledge can help both beginners and pros unlock their full lathe potential.Understanding Metal Lathe Gear Trains

Definition and significance in metalworking.. How gear trains affect lathe performance..Metal lathe gear trains are like the secret sauce in metalworking. They connect gears to control speed and torque, making lathes smoother and safer. Their main job is to let the machine spin materials quickly and efficiently. Think of it as a dance party, where each gear takes its turn to make the show better. Without a good gear train, lathes would move like a snail on vacation!

| Key Features | Importance |

|---|---|

| Speed Control | Even slow dancers need rhythm! |

| Torque Regulation | No one wants a dance-off gone wrong! |

| Precision | Helps create perfect shapes! |

In summary, gear trains are crucial for lathe performance. They ensure tools run smoothly, extending their life and improving outcomes in metal projects. Remember, a well-structured gear train is like the ultimate dance partner: it keeps everything in sync!

Key Features of Top Rated Metal Lathe Gear Trains

Material quality and durability considerations.. Gear ratios and their impact on machining capabilities..Metal lathe gear trains are all about quality and durability. A good gear train is like a superhero’s cape; it helps do the tough jobs! Quality materials ensure it lasts longer and handles tough tasks without falling apart. Then come the gear ratios. These little numbers can either make or break your machining capabilities. They control speed and torque, letting you smoothly shape metal like it’s butter or spin out of control like a wild roller coaster ride!

| Feature | Importance |

|---|---|

| Material Quality | Ensures durability and performance |

| Gear Ratios | Affects speed and torque for efficiency |

How to Choose the Right Gear Train for Your Metal Lathe

Factors to consider based on your projects and materials.. Understanding your lathe’s compatibility with gear trains..Choosing a gear train for your metal lathe is like picking a superhero sidekick—each one has special skills! First, think about the materials you’ll use. Softer materials need less power, while harder ones require more strength. Next, check if your lathe can work with the gear train you like. It’s a match made in machining heaven! Here’s a quick look:

| Material Type | Power Needed |

|---|---|

| Soft Metals | Low |

| Hard Metals | High |

Remember, a good gear train can help you create amazing projects without turning you into an angry machine monster!

Maintenance Tips for Longevity of Gear Trains

Best practices for cleaning and lubrication.. Common issues and troubleshooting methods..To keep your gear train running well, follow these simple steps. First, clean the gears regularly. Use a soft cloth to remove dust and grime. Next, always lubricate the gears with oil suitable for metal. This helps them move smoothly without wear.

If you notice issues, like strange noises or missed turns, act fast. A common problem is debris stuck in the gears. Clear it out to solve many troubles. Also, check if the oil needs replacing. Regular maintenance keeps your gear train in top shape!

What are the best practices for cleaning and lubrication?

Best practices include regular cleaning and proper lubrication every few months. Always check for debris and apply oil to keep it running well.

Common issues and troubleshooting methods:

- Strange noises: Check for debris.

- Gears slipping: Ensure proper lubrication.

- Rust formation: Wipe with oil to prevent corrosion.

Innovations in Metal Lathe Gear Train Technology

Recent advancements and their implications for users.. The future of gear train design in metalworking..Recent advancements in metal lathe gear train technology are exciting. New designs offer better accuracy and speed for users. This means smoother operations and less downtime. As gear train designs improve, they can handle bigger loads and last longer. This helps metalworkers produce high-quality parts quickly. The future looks bright for gear trains. Innovations may also lower costs and reduce noise, making work environments better for everyone.

What are the benefits of recent advancements in gear train technology?

Recent advancements improve efficiency, reduce costs, and enhance the durability of gear trains. Users can expect faster speeds and better product quality.

Key benefits:

- Improved accuracy

- Higher tolerance to loads

- Less noise

- Increased lifespan

Frequently Asked Questions About Metal Lathe Gear Trains

Common queries and expert answers.. Tips from experienced users regarding gear train performance..Many people wonder about gear trains in metal lathes. Here are some common questions and answers that can help you out. First, how does a gear train affect performance? Well, it changes the speed and torque, making your lathe more efficient. Next, what should I know about maintenance? Regular oiling and cleaning are key. Lastly, can I upgrade my gear train? Absolutely! An upgrade can boost performance. Remember, even a metal lathe can be a diva sometimes!

| Question | Answer |

|---|---|

| How does gear ratio affect cutting speed? | A higher ratio means faster speeds! |

| What tools do I need for maintenance? | A wrench and some oil will do the trick! |

| Can I use my lathe without a gear train? | Not unless you enjoy making paperweights! |

Conclusion

In summary, a top-rated metal lathe gear train improves your machining experience. It offers accuracy, speed, and durability. You should look for features like robust materials and smooth operation. Remember, a good gear train makes a big difference. If you’re interested, check out reviews or visit local shops to see them in action. Happy machining!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Top-Rated Metal Lathe Gear Trains:Sure! A top-rated metal lathe gear train helps machines turn metal into parts. It uses gears to change how fast the tool spins. This makes it easier to shape metal into different forms. Good gear trains make our work smoother and more accurate. You can find lathes with great gear trains to help you make cool projects!

Sure! Please provide me with the question you’d like me to answer.

What Are The Most Important Features To Consider When Selecting A Gear Train For A Metal Lathe?When picking a gear train for a metal lathe, we should think about a few key things. First, we want the gears to be strong enough to handle metal. Next, we need to make sure they can turn at different speeds. This helps us make different shapes. Lastly, it’s good to choose gears that fit well together so they don’t make too much noise or get stuck.

How Do Different Gear Train Configurations Impact The Performance And Precision Of A Metal Lathe?Different gear trains help a metal lathe work better in different ways. If you choose a gear train that is set up for speed, the lathe can spin fast. This is great for quick jobs but might not be super precise. On the other hand, a gear train for more precision makes the lathe slower but helps it cut very accurately. So, picking the right gear train helps you get the job done just the way you want!

What Are Some Highly-Rated Brands Or Models Of Metal Lathes Known For Their Superior Gear Train Design?Some great brands of metal lathes with good gear train designs are Taig, Jet, and Grizzly. These lathes are popular because they work really well. You can trust them to spin metal accurately. Many people like them for their strong parts and smooth operation. They make it easier to create cool projects!

How Can Maintenance Practices Improve The Longevity And Performance Of A Metal Lathe’S Gear Train?To keep a metal lathe’s gear train working well, you need to clean it regularly. Dirt and dust can make the gears wear out faster. You should also oil the gears to keep them moving smoothly. Checking for any loose or damaged parts helps prevent bigger problems later. By taking care of it, you make sure it lasts longer and works better.

What Are The Common Issues Faced With Gear Trains In Metal Lathes, And How Can They Be Resolved?Gear trains in metal lathes can have a few common problems. Sometimes gears can wear out, making them noisy or hard to turn. You might also find that they don’t line up right, which can make the machine less accurate. To fix these issues, you can check the gears and replace worn ones. Making sure everything is tight and well-lubricated can help too.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Top-Rated Metal Lathe Gear Trains:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A top-rated metal lathe gear train helps machines turn metal into parts. It uses gears to change how fast the tool spins. This makes it easier to shape metal into different forms. Good gear trains make our work smoother and more accurate. You can find lathes with great gear trains to help you make cool projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Most Important Features To Consider When Selecting A Gear Train For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a gear train for a metal lathe, we should think about a few key things. First, we want the gears to be strong enough to handle metal. Next, we need to make sure they can turn at different speeds. This helps us make different shapes. Lastly, it’s good to choose gears that fit well together so they don’t make too much noise or get stuck.”}},{“@type”: “Question”,”name”: “How Do Different Gear Train Configurations Impact The Performance And Precision Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different gear trains help a metal lathe work better in different ways. If you choose a gear train that is set up for speed, the lathe can spin fast. This is great for quick jobs but might not be super precise. On the other hand, a gear train for more precision makes the lathe slower but helps it cut very accurately. So, picking the right gear train helps you get the job done just the way you want!”}},{“@type”: “Question”,”name”: “What Are Some Highly-Rated Brands Or Models Of Metal Lathes Known For Their Superior Gear Train Design?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some great brands of metal lathes with good gear train designs are Taig, Jet, and Grizzly. These lathes are popular because they work really well. You can trust them to spin metal accurately. Many people like them for their strong parts and smooth operation. They make it easier to create cool projects!”}},{“@type”: “Question”,”name”: “How Can Maintenance Practices Improve The Longevity And Performance Of A Metal Lathe’S Gear Train?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe’s gear train working well, you need to clean it regularly. Dirt and dust can make the gears wear out faster. You should also oil the gears to keep them moving smoothly. Checking for any loose or damaged parts helps prevent bigger problems later. By taking care of it, you make sure it lasts longer and works better.”}},{“@type”: “Question”,”name”: “What Are The Common Issues Faced With Gear Trains In Metal Lathes, And How Can They Be Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Gear trains in metal lathes can have a few common problems. Sometimes gears can wear out, making them noisy or hard to turn. You might also find that they don’t line up right, which can make the machine less accurate. To fix these issues, you can check the gears and replace worn ones. Making sure everything is tight and well-lubricated can help too.”}}]}