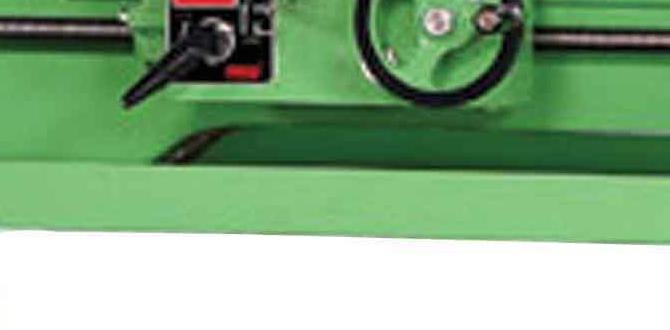

Have you ever wondered how important a tailstock is for your metal lathe? Every machinist knows that tailstock alignment can make or break a project. If it’s off, you risk mistakes that can ruin your hard work. It’s surprising how much difference a perfectly aligned tailstock can make!

Imagine spending hours crafting a part, only to find it doesn’t fit. Frustrating, right? That’s why understanding the nuances of tailstock alignment is crucial. It’s one of those details that can lead to top-rated metal lathe performance.

In this article, we will explore the best ways to align your tailstock. We’ll share tips and tricks that experts use to ensure precision. With the right knowledge, you can elevate your metalworking skills and achieve great results.

Top Rated Metal Lathe Tailstock Alignment Techniques

Top Rated Metal Lathe Tailstock Alignment

Proper alignment of a metal lathe tailstock is crucial for achieving precision in your projects. Misalignment can lead to poor-quality cuts. Did you know that even a small shift can spoil your workpiece? The top-rated methods ensure accuracy. Simple adjustments and tools can make a huge difference. Tip: Regular checks will save you time and frustration. Understanding tailstock alignment allows for better craftsmanship and smoother operations. Keep your lathe in top shape!Understanding Tailstock Alignment

Definition and importance of tailstock alignment in metal lathes. Common issues caused by improper tailstock alignment.Tailstock alignment is vital for metal lathes. It ensures that workpieces stay straight and secure while being shaped. Poor alignment can cause issues like chatter, reduced accuracy, and uneven wear. This can lead to damaged tools and bad results.

- Chatter: Makes a loud noise and creates rough surfaces.

- Poor Accuracy: Parts may not fit together correctly.

- Tool Damage: Tools wear out faster from bad alignment.

Why is tailstock alignment important?

Proper alignment helps create high-quality parts and extends tool life.

Benefits of Proper Tailstock Alignment

Improved accuracy in machining operations. Enhanced tool life and workpiece quality.Proper tailstock alignment on a metal lathe offers a bunch of benefits. First, it helps you create more accurate machined parts. When everything is lined up just right, your cuts are cleaner. Who doesn’t love a sharp-looking piece of work? Second, an aligned tailstock can boost tool life. This means your tools stay sharp longer and you spend less time replacing them. Plus, the quality of your workpiece improves too. It’s like giving your lathe a mini spa day!

| Benefit | Description |

|---|---|

| Accuracy | Improved precision in cuts. |

| Tool Life | Longer-lasting tools. |

| Workpiece Quality | Better finish and overall quality. |

Key Factors Affecting Tailstock Alignment

Role of bed distortion and machine wear. Influence of environmental factors on alignment.Tailstock alignment can be a bit finicky, like a cat trying to fit into a tiny box. One big factor is bed distortion, which happens when the lathe isn’t perfectly flat. Even a small bump can mess things up. Machine wear also plays a role as parts get older and lose their shape.

But wait, there’s more! Environmental factors, like temperature and humidity, can throw a wrench in the works. Just think of it as your lathe having a bad hair day. Keep a close eye on these things to ensure smooth sailing when working with your lathe.

| Factor | Impact on Alignment |

|---|---|

| Bed Distortion | Can cause misalignment |

| Machine Wear | Affects precision over time |

| Temperature Changes | Can expand or contract parts |

| Humidity Levels | Can lead to rust or corrosion |

Step-by-Step Process for Aligning the Tailstock

Detailed procedure for checking and adjusting the alignment. Common pitfalls and mistakes to avoid during the alignment process.Aligning the tailstock is key for smooth work. Here’s how you can check and adjust it:

- First, place a dial indicator on the tailstock.

- Next, slide it toward the spindle. Check for any movement.

- Adjust the tailstock if needed. Use screws or knobs to make small changes.

- Finally, test with a piece of material.

Avoid these common mistakes:

- Don’t rush through the setup.

- Make sure your workspace is clean.

- Double-check measurements before finalizing.

Taking your time will help ensure a perfect alignment!

Why is tailstock alignment important?

Proper alignment ensures your workpiece stays in place, preventing defects and inaccuracies. Good alignment improves the quality of your projects and keeps your metal lathe in good shape.

Quick Tips for Checking Alignment:

- Use a ruler for precise measurements.

- Check alignment often during your work.

- Keep tools within reach to make adjustments easier.

Maintenance Tips for Sustaining Tailstock Alignment

Regular maintenance practices to ensure longterm alignment. How to address wear and tear of components that affect alignment.Keeping your tailstock aligned is key to great results. Regular upkeep helps it stay in top form. Check the rails and screws often for wear. A small wobble can lead to big problems. You don’t want a tailstock that does the cha-cha on you!

Also, light lubrication can go a long way. It keeps everything smooth without turning into a slip-n-slide. If parts look tired, replace them before they cause a ruckus. Remember, an aligned tailstock is a happy tailstock!

| Maintenance Tips | Frequency |

|---|---|

| Inspect for wear | Every month |

| Lubricate moving parts | Weekly |

| Check screws | Before major projects |

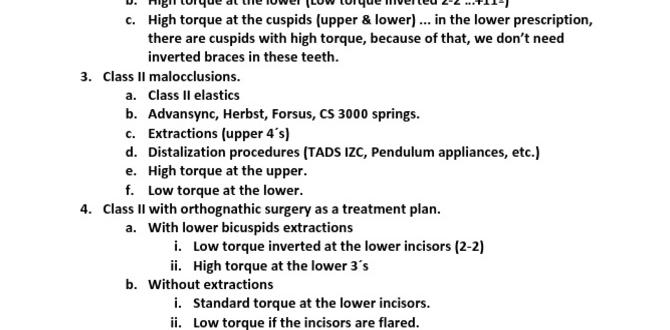

Comparing Top Rated Metal Lathes for Tailstock Alignment

Review of features in leading metal lathes relevant to tailstock alignment. User feedback and expert opinions on alignment capabilities.Finding the right metal lathe for tailstock alignment can be as tricky as teaching a cat to fetch. Some top-rated lathes stand out with features that make alignment easier. For instance, they have adjustable tailstocks and clear measurement markings, helping users get it just right. Expert reviews highlight that tailstock alignment is crucial for precise cuts. Users rave about models that promise spot-on alignment without the fuss. Check out some leading options:

| Model | Tailstock Adjustment | User Rating |

|---|---|---|

| Lathe A | Easy Adjustment | 4.8/5 |

| Lathe B | Precision Markings | 4.5/5 |

| Lathe C | Quick Release | 4.6/5 |

In conclusion, finding the right lathe can make your projects go from “meh” to “wow!” With the right alignment features, you’ll be ready to tackle any task with ease.

FAQs About Tailstock Alignment

Commonly asked questions regarding tailstock alignment. Expert answers and tips for specific alignment challenges.Many people have questions about tailstock alignment. Here are some common ones:

What is tailstock alignment?

Tailstock alignment keeps the tailstock in line with the lathe. Proper alignment improves accuracy and quality.

How do I know if my tailstock is aligned?

You can check by using a dial indicator or a test rod. Look for any gaps or unevenness in measurement.

What are signs of misalignment?

- Inconsistent cuts

- Damage to tools

- Poor surface finish

What should I do if it’s misaligned?

Adjust the tailstock until it aligns. Use shims or adjust the screws if needed. Testing after adjustments helps ensure accuracy.

How often should I check alignment?

It’s good to check tailstock alignment regularly, especially after moving or changing setups.

By keeping these tips in mind, you can maintain a well-aligned tailstock for better lathe performance!

Conclusion

In conclusion, top-rated metal lathe tailstock alignment is crucial for accurate machining. Proper alignment ensures better cuts and extends tool life. Always check your tailstock for precision. You can improve your projects by following simple alignment techniques. For more tips on metalworking, explore additional resources! You’ll enjoy the results and the satisfaction of better craftsmanship.FAQs

Here Are Five Related Questions On The Topic Of Top-Rated Metal Lathe Tailstock Alignment:Sure! To align a metal lathe tailstock, you need to make sure it’s straight with the spindle. You can do this by measuring from the tailstock to the spindle in a few spots. If it’s off, you can adjust it with screws on the tailstock. Always check again after you make changes! This helps you make better and smoother pieces when you work.

Sure! Please provide the question you would like me to answer.

What Are The Best Techniques For Ensuring Accurate Tailstock Alignment On A Metal Lathe?To align the tailstock on a metal lathe, you can use a few easy steps. First, check if the tailstock is straight by using a ruler or a straightedge. Next, adjust the tailstock until it lines up with the spindle, which is the part that holds the main workpiece. You can also use a test bar, which is a long, straight piece of metal, to see if everything is even. Finally, tighten all the screws and give it a last check to ensure everything is aligned properly.

How Can Misalignment Of The Tailstock Affect The Quality Of Turned Parts In Metalworking?If the tailstock isn’t lined up right, it can make your metal parts wobbly. This means the pieces won’t be smooth and could fit badly. You might end up with parts that are too big or too small. Keeping everything aligned helps us make better parts that work well together.

What Are The Top-Rated Tools Or Indicators Recommended For Checking Tailstock Alignment On A Lathe?To check tailstock alignment on a lathe, you can use a few good tools. A dial indicator is very useful because it shows small changes easily. A test bar is another tool that helps you see if everything is straight. You can also use a laser tool for precise measurements. These tools help us make sure our lathe works correctly!

How Often Should Tailstock Alignment Be Checked And Adjusted To Maintain Precision In Machining Projects?You should check the tailstock alignment often, especially before starting a new project. It’s good to do this whenever you notice problems in your work. If you use your machine a lot, check it every week. Remember, keeping it aligned helps your projects turn out better!

What Common Issues Can Arise From Improper Tailstock Alignment, And How Can They Be Resolved?When the tailstock isn’t lined up right, it can cause problems like wobbling or uneven cuts. This happens because the piece we’re working on isn’t held straight. To fix this, you can adjust the tailstock until it lines up correctly with the rest of the machine. Checking your work often helps to make sure everything stays in place.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Top-Rated Metal Lathe Tailstock Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! To align a metal lathe tailstock, you need to make sure it’s straight with the spindle. You can do this by measuring from the tailstock to the spindle in a few spots. If it’s off, you can adjust it with screws on the tailstock. Always check again after you make changes! This helps you make better and smoother pieces when you work.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Best Techniques For Ensuring Accurate Tailstock Alignment On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock on a metal lathe, you can use a few easy steps. First, check if the tailstock is straight by using a ruler or a straightedge. Next, adjust the tailstock until it lines up with the spindle, which is the part that holds the main workpiece. You can also use a test bar, which is a long, straight piece of metal, to see if everything is even. Finally, tighten all the screws and give it a last check to ensure everything is aligned properly.”}},{“@type”: “Question”,”name”: “How Can Misalignment Of The Tailstock Affect The Quality Of Turned Parts In Metalworking?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock isn’t lined up right, it can make your metal parts wobbly. This means the pieces won’t be smooth and could fit badly. You might end up with parts that are too big or too small. Keeping everything aligned helps us make better parts that work well together.”}},{“@type”: “Question”,”name”: “What Are The Top-Rated Tools Or Indicators Recommended For Checking Tailstock Alignment On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check tailstock alignment on a lathe, you can use a few good tools. A dial indicator is very useful because it shows small changes easily. A test bar is another tool that helps you see if everything is straight. You can also use a laser tool for precise measurements. These tools help us make sure our lathe works correctly!”}},{“@type”: “Question”,”name”: “How Often Should Tailstock Alignment Be Checked And Adjusted To Maintain Precision In Machining Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the tailstock alignment often, especially before starting a new project. It’s good to do this whenever you notice problems in your work. If you use your machine a lot, check it every week. Remember, keeping it aligned helps your projects turn out better!”}},{“@type”: “Question”,”name”: “What Common Issues Can Arise From Improper Tailstock Alignment, And How Can They Be Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the tailstock isn’t lined up right, it can cause problems like wobbling or uneven cuts. This happens because the piece we’re working on isn’t held straight. To fix this, you can adjust the tailstock until it lines up correctly with the rest of the machine. Checking your work often helps to make sure everything stays in place.”}}]}