Have you ever wondered what makes a metal lathe truly special? Many hobbyists and professionals seek out the best machines to enhance their projects. The top rated metal lathe torque is often a key feature to consider. Torque is a measure of how much power a lathe can produce. It can make a big difference in your work.

Imagine you’re crafting a beautiful wooden table leg. You need precision, strength, and control. A lathe with high torque can help you achieve that perfect finish. Without it, your project might not turn out as planned.

Did you know that even small lathes can offer great torque? This can surprise many new users. The right metal lathe can turn tough materials into smooth shapes. As we explore the options for the best lathes, we’ll uncover how torque plays a vital role.

Join us on this journey to discover the top rated metal lathe torque. You’ll learn how to choose the right lathe and why it matters for your projects. Let’s dive in!

Top Rated Metal Lathe Torque: Unleashing Precision Power

Top Rated Metal Lathe Torque

Discover the world of top-rated metal lathes designed for maximum torque. These amazing machines offer smooth and powerful performance for various projects. Did you know that the right torque can make all the difference in metalworking? A higher torque means you can cut tougher materials with ease. This summary explores key features like motor strength and durability. Thinking about turning your projects into a masterpiece? A solid metal lathe might be your best friend!Understanding Metal Lathe Torque

Definition and significance of torque in metal lathes. How torque affects machining performance.Torque is like the muscle power of a metal lathe. It tells the machine how hard it can turn the metal. This is super important because more torque means better cutting and shaping. Imagine trying to slice butter with a dull knife; it just doesn’t work well! Higher torque helps the lathe perform better, making smooth cuts and saving time. So, having the right torque can turn a clunky task into a smooth ride, just like riding a bike with training wheels!

| Torque | Effect |

|---|---|

| Low Torque | Poor cutting quality |

| High Torque | Better machining performance |

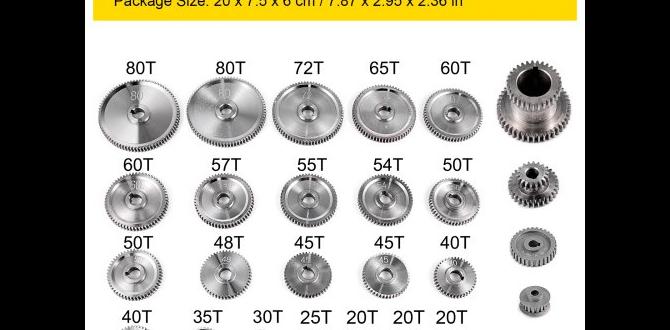

Key Features of Top Rated Metal Lathes

Essential specifications to consider (horsepower, RPM, etc.). Importance of build quality and materials used.Choosing the right metal lathe involves looking at key features. Here are some important specifications:

- Horsepower: Higher horsepower means your lathe works harder.

- RPM (Revolutions Per Minute): More RPM gives you speed and efficiency.

- Build Quality: Strong materials provide better stability and last longer.

- Precision: Good lathes offer precise cuts, which is essential for quality work.

Quality parts ensure safety and performance. A sturdy lathe can handle tough jobs. Remember, better tools make better projects!

Why is horsepower important in a metal lathe?

Horsepower impacts the lathe’s ability to cut materials smoothly and effectively.

What materials are best for lathe construction?

- Cast Iron: Great for stability.

- Steel: Durable and tough.

- Aluminum: Light, yet strong.

Top Rated Metal Lathes on the Market

Review of leading brands (e.g., Grizzly, Jet, etc.). Detailed torque specifications and performance analysis.Several brands dominate the metal lathe market. Grizzly is known for its durability and precision. Jet offers reliable models with excellent torque. Users appreciate their user-friendly designs. Here are some key features:

- Grizzly G0602: Offers torque up to 18.5 Nm, great for heavy-duty work.

- Jet JWL-1442: Provides 12 Nm of torque for smooth operation.

- Shop Fox M1015: Features 10 Nm torque, perfect for hobbyists.

These specifications highlight why they are top-rated. Performance matters, and these brands deliver results.

Why is torque important in metal lathes?

Torque helps metal lathes cut through materials smoothly. Higher torque means better performance and less chance of stalling. It ensures precise work.

Torque Testing and Performance Metrics

Methods for measuring lathe torque. Realworld performance factors to consider.Measuring lathe torque is key to understanding performance. There are simple methods to check torque. One way is using a dynamometer. This tool measures power and force accurately. Another method is using a torque wrench for hands-on measurement.

Real-world factors affect lathe performance:

- Material type

- Speed settings

- Tool condition

- Load amount

Considering these factors helps you choose the right lathe for your work. A well-chosen lathe makes jobs easier and more efficient!

How can I measure lathe torque?

To measure lathe torque, you can use a dynamometer for precise readings, or you can try a torque wrench for hands-on checks.

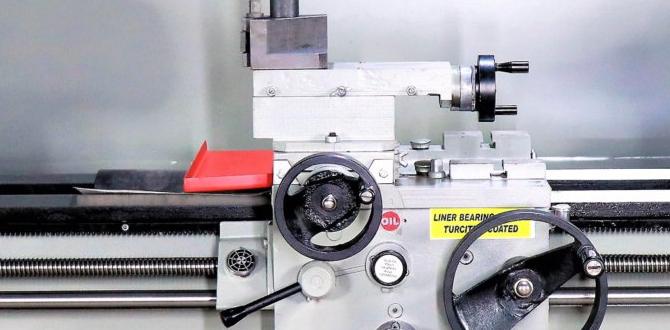

Maintenance Tips for Optimizing Lathe Torque

Routine maintenance practices to enhance torque performance. Common issues that can affect torque and how to fix them.To keep your lathe working well, follow some simple steps. Regular cleaning helps remove dust and debris. Oiling the moving parts keeps them running smoothly. Check the belt for wear often. If it’s loose or damaged, replace it right away. Here are some common issues you might face:

- Overheating: Ensure proper cooling.

- Noisy operation: Lubricate the moving parts.

- Vibration: Check for loose screws or a crooked setup.

Fixing these problems quickly can help improve torque performance. It keeps your metal lathe in shape and ready for work.

What is the importance of maintenance for lathe torque?

Good maintenance helps prevent breakdowns. A well-kept lathe runs better and lasts longer. This keeps your projects on track.

User Reviews and Experiences

Insight into customer feedback on torque performance. Analysis of user ratings compared to specifications.Customers share exciting stories about their experiences with metal lathes. Many notice excellent torque performance, which helps them work better. User ratings often match the specs provided. When people compare ratings, they feel happy about their choice. Most reviewers mention:

- Strong torque abilities.

- Reliable machines.

- Great for various projects.

The feedback shows that many are satisfied with their tools and feel they made the right decision.

What do customers say about torque?

Customers report high satisfaction with torque ratings. They find that their lathes perform well and meet their needs. This positive feedback helps others make informed choices when buying.

Investment Considerations for Metal Lathes

Cost vs. performance: finding the best value. Longterm benefits of choosing a toprated model.Buying a metal lathe is like picking a superhero: you want one that can do the job without breaking the bank. Cost is important, but so is performance. Don’t just chase a low price; look for a lathe that gives you bang for your buck. Investing in a top-rated model may feel steep at first, but it pays off in the long run. Think of it as buying a sturdy umbrella—better to spend a bit more than to get soaked! Below is a simple overview:

| Model | Cost | Performance Rating | Long-term Benefit |

|---|---|---|---|

| Model A | $1,000 | 4.5/5 | High durability |

| Model B | $800 | 4/5 | Good for beginners |

| Model C | $1,500 | 5/5 | Best for pros |

Looking Ahead: The Future of Metal Lathe Technology

Innovations in torque technology and materials. Predictions for upcoming features and improvements in metal lathes.New tech is buzzing in metal lathe world! Innovations in torque technology are speeding things up, making machines work smarter. Lathes will soon have fancy features like digital displays and sensors that make them easier to use and safer. Imagine a lathe with a built-in coffee maker or one that tells jokes while you work! Predictions for the future are bright, with lighter materials and stronger torque. Get ready for lathes that are not only powerful but also friendly!

| Upcoming Features | Benefits |

|---|---|

| Advanced Sensors | Increased safety |

| Lightweight Materials | Better portability |

| Smart Displays | Ease of use |

Conclusion

In conclusion, a top-rated metal lathe with strong torque offers great performance for your projects. You should look for models that balance power and precision. Remember to check reviews and ask for recommendations. With the right lathe, you can turn your ideas into reality. Explore more guides to help you pick the best one for your needs!FAQs

What Are The Key Factors That Determine The Torque Output Of A Metal Lathe?The torque output of a metal lathe depends on a few key factors. First, the motor’s power is important; stronger motors can create more torque. Next, the lathe’s speed also matters; lower speeds can give more torque. Finally, the type of material you are cutting affects torque too; harder materials usually need more torque to cut. So, you need a good motor, the right speed, and the right material for the best results!

How Does The Size And Power Of A Metal Lathe Affect Its Torque Capabilities?A metal lathe is a tool used to shape metal. Bigger lathes usually have more power. More power means they can turn things faster and handle heavier materials. When a lathe is larger and stronger, it can create more torque, which helps it cut better. So, size and power help the lathe work smoothly and effectively.

What Is The Significance Of Torque In Achieving Precision Machining With A Metal Lathe?Torque is the twisting force that helps a metal lathe turn gears and parts. When we have the right amount of torque, we can cut metal evenly and accurately. This makes our projects look nice and fit together better. If there’s too little torque, things can get wobbly and messy. So, good torque helps us make precise shapes and sizes when we work with metal.

Can You Recommend Some Top-Rated Metal Lathes Known For Their Excellent Torque Performance?Sure! Some great metal lathes with strong torque are the Grizzly G0602 and the Jet 321360. We can also look at the Laguna Tools MLAR. These lathes are known for their power and can help you make cool projects. Make sure to check customer reviews to find the best one for you!

How Does The Design Of A Metal Lathe Influence Its Torque Efficiency During Operation?The design of a metal lathe helps it work better when you shape metal. A strong base keeps the lathe steady, which gives better control. Good parts fit together smoothly, allowing the lathe to use less energy. This means it can twist and turn metal easily, making it more efficient. When a lathe is designed well, it works faster and better for you!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Factors That Determine The Torque Output Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The torque output of a metal lathe depends on a few key factors. First, the motor’s power is important; stronger motors can create more torque. Next, the lathe’s speed also matters; lower speeds can give more torque. Finally, the type of material you are cutting affects torque too; harder materials usually need more torque to cut. So, you need a good motor, the right speed, and the right material for the best results!”}},{“@type”: “Question”,”name”: “How Does The Size And Power Of A Metal Lathe Affect Its Torque Capabilities? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe is a tool used to shape metal. Bigger lathes usually have more power. More power means they can turn things faster and handle heavier materials. When a lathe is larger and stronger, it can create more torque, which helps it cut better. So, size and power help the lathe work smoothly and effectively.”}},{“@type”: “Question”,”name”: “What Is The Significance Of Torque In Achieving Precision Machining With A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Torque is the twisting force that helps a metal lathe turn gears and parts. When we have the right amount of torque, we can cut metal evenly and accurately. This makes our projects look nice and fit together better. If there’s too little torque, things can get wobbly and messy. So, good torque helps us make precise shapes and sizes when we work with metal.”}},{“@type”: “Question”,”name”: “Can You Recommend Some Top-Rated Metal Lathes Known For Their Excellent Torque Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Some great metal lathes with strong torque are the Grizzly G0602 and the Jet 321360. We can also look at the Laguna Tools MLAR. These lathes are known for their power and can help you make cool projects. Make sure to check customer reviews to find the best one for you!”}},{“@type”: “Question”,”name”: “How Does The Design Of A Metal Lathe Influence Its Torque Efficiency During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design of a metal lathe helps it work better when you shape metal. A strong base keeps the lathe steady, which gives better control. Good parts fit together smoothly, allowing the lathe to use less energy. This means it can twist and turn metal easily, making it more efficient. When a lathe is designed well, it works faster and better for you!”}}]}