Have you ever seen a metal lathe in action? It’s fascinating! Imagine turning a metal piece into a shiny, perfect shape. That’s what a training metal lathe bench can help you do.

Many people don’t realize how fun it is to work with a lathe. With the right training, anyone can learn. A metal lathe makes it easy to create amazing things. Just picture making parts for your bike or toy. How cool would that be?

But why is training so important? Using a metal lathe safely requires skills. The training metal lathe bench offers a perfect setup for beginners. It teaches you all the basics without any pressure. Plus, the bench is designed to keep you safe while you learn.

If you love working with your hands, you’ll enjoy this process. Think about how proud you’ll feel showing off your first project. Let’s dive into the world of metal lathes and discover how you can start your journey today!

Comprehensive Guide To Training Metal Lathe Bench Techniques

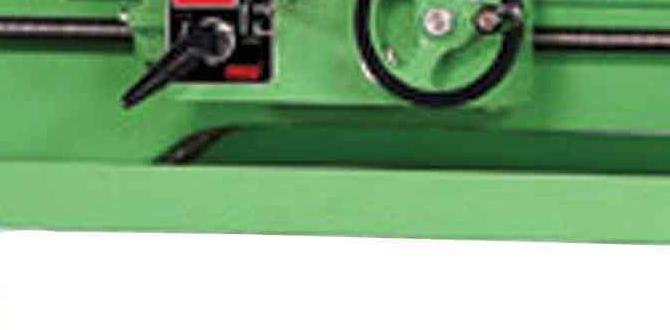

Training Metal Lathe Bench

Discover the essentials of a metal lathe bench for your training journey. A sturdy, well-organized bench makes metalworking easier and safer. Learn how to select the right materials and tools. Did you know that the balance of your lathe can affect precision? Proper setup ensures smoother operation and better results. Training on a metal lathe is not just about technique; it’s about creating your own projects. What will you create first?Understanding the Metal Lathe

Definition and purpose of a metal lathe. Different types of metal lathes and their applications.A metal lathe is a tool that cuts and shapes metal. Think of it as the magician of metalworking! It spins metal pieces while a sharp tool carves them into various shapes. There are different types of lathes, each with its own special powers. For example, engine lathes are popular for making precise pieces, while CNC lathes are like robots that do it automatically. Here’s a quick look:

| Type of Lathe | Application |

|---|---|

| Engine Lathe | General machining and shaping |

| CNC Lathe | Automated precision work |

| Turret Lathe | Production of multiple items |

So, whether you’re making a tiny bolt or a huge gear, there’s a metal lathe ready to help. Just don’t forget to wear safety goggles – metal shavings do not make good confetti!

Safety Precautions When Using a Metal Lathe

Essential safety gear and protective equipment. Common hazards and how to mitigate risks.Using a metal lathe can be fun, but safety comes first! Always wear goggles to protect your eyes from flying chips and ear protection to avoid a noisy disaster. Don’t forget gloves, but not too loose!” Why? Because we don’t want any accidental handshakes with sharp tools! Some common dangers include getting tangled in moving parts or inhaling dust. To stay safe, keep your workspace clean and your focus sharp. Remember, a safe lathe is a happy lathe!

| Safety Gear | Purpose |

|---|---|

| Goggles | Protects eyes from debris |

| Ear protection | Reduces noise pollution |

| Gloves | Prevents cuts (just don’t let them get caught!) |

Setting Up Your Metal Lathe Bench

Required space and layout for optimal workflow. Tools and accessories to keep on your bench.Before you start working, set up your metal lathe bench correctly. You need enough space to move around and work safely. A good layout helps you work faster and better. Keep important tools nearby. Some must-haves include:

- Vise: to hold your workpiece securely.

- Calipers: for measuring sizes accurately.

- Lubricants: to keep your tools running smoothly.

This setup makes a big difference. A clear space can help you create more amazing projects!

What tools should you keep on your metal lathe bench?

It’s smart to keep your best tools close by. Look for a quality cutting tool set, measuring tapes, and safety goggles. This way, everything is ready when you need it!

Step-by-Step Training Process for Beginners

Initial training steps for new operators. Practical exercises to build foundational skills.For beginners, the first steps in learning to use a metal lathe bench are vital. Start by getting familiar with the machine. Understanding its parts helps you use it confidently. Next, practice basic techniques, like speed settings and tool changes.

- Learn safety rules.

- Try simple projects, like turning a small cylinder.

- Ask for tips or watch others.

These exercises build strong skills. With practice, you’ll become a pro in no time!

What should beginners focus on during training?

Beginners should focus on safety, basic operations, and hands-on practice while using a metal lathe bench.Maintenance and Troubleshooting

Routine maintenance practices to extend lathe life. Common issues and solutions for troubleshooting.Keeping a metal lathe in good shape helps it work better and last longer. Regularly check and clean the machine. Tighten loose parts and oil moving pieces to keep everything running smoothly. It’s smart to check for common problems, like strange noises or uneven cuts. Address these quickly to prevent bigger issues.

- Clean the machine after each use.

- Check and tighten all fasteners.

- Lubricate moving parts regularly.

What are common problems with a lathe and how to fix them?

Common lathe issues include unusual noises, vibration, and poor cuts. If you hear strange sounds, check for loose parts. For vibrations, ensure the lathe is on a flat surface. Poor cuts may mean you need to adjust the cutting tool or check the workpiece.

Resources for Continued Learning

Recommended books, online courses, and workshops. Communities and forums for metal lathe enthusiasts.To keep learning about metal lathes, you can explore various resources. Here are some great options:

- Books: Look for titles like “Metal Lathe for Beginners” and “Lathe Work. These can teach you a lot.

- Online Courses: Websites like Udemy or Skillshare offer easy courses.

- Workshops: Local community centers often have hands-on workshops.

- Communities: Join forums like CNCzone or Reddit’s metalworking group for tips and discussions.

These resources can make your training easier and more fun!

What are good resources for learning about metal lathes?

Useful resources include books, online courses, and workshops. Forums like CNCzone or Reddit connect you with other enthusiasts for help and ideas.

Conclusion

In summary, training on a metal lathe bench helps you master important skills. You learn to create precise parts and improve safety. With practice, you become more confident in your abilities. Consider taking a hands-on class or finding online resources to dive deeper. Remember, the more you practice, the better you’ll get! Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Training For A Metal Lathe Bench:Sure! When you train on a metal lathe, you learn how to use the machine safely. You can make round parts from metal pieces. You will practice measuring and cutting accurately. It’s important to wear safety gear like goggles and gloves. With practice, you can create cool projects and improve your skills!

Sure! Please provide the question you want me to answer.

What Are The Essential Safety Precautions That Should Be Taken When Operating A Metal Lathe?When you use a metal lathe, always wear safety goggles to protect your eyes. Tie back long hair and avoid loose clothes to prevent getting caught in the machine. Keep your fingers away from the spinning parts. Make sure all guards are in place and never reach in while the lathe is running. Finally, always be alert and focused to stay safe.

What Basic Components And Functions Of A Metal Lathe Should Trainees Be Familiar With Before Starting Hands-On Training?Before using a metal lathe, you should know some key parts. The bed holds everything steady. The headstock spins the metal and has a motor. The tailstock helps you support the other end of the metal. The carriage moves the cutting tool to shape the metal. Understanding these parts helps you use the lathe safely and correctly.

How Do You Properly Set Up A Workpiece On The Lathe For Accurate Turning?To set up a workpiece on the lathe, first, make sure the lathe is turned off. Then, place the workpiece in the lathe’s chuck, which holds it tight. Adjust the center so it lines up with the lathe’s center. Tighten everything securely. Finally, check that the workpiece spins evenly before starting to turn.

What Common Techniques And Practices Should New Operators Learn To Produce Quality Parts On A Metal Lathe?To make good parts on a metal lathe, you should learn some key skills. First, always measure your pieces carefully. Use tools like calipers for accuracy. Second, keep the cutting tools sharp to ensure clean cuts. Third, set the right speed for the metal you are using. Finally, make sure to stay safe by wearing protective gear and following all rules.

How Can One Diagnose And Troubleshoot Common Issues That May Arise During The Operation Of A Metal Lathe?To diagnose and fix problems with a metal lathe, first, check for loud noises. Those sounds might mean parts are loose or broken. Next, look at the material you’re working on. Is it moving too much? If so, make sure it’s held tightly in place. Lastly, if your cuts aren’t smooth, the tool might be dull or need to be adjusted. Always remember to turn off the machine before you look inside!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Training For A Metal Lathe Bench:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you train on a metal lathe, you learn how to use the machine safely. You can make round parts from metal pieces. You will practice measuring and cutting accurately. It’s important to wear safety gear like goggles and gloves. With practice, you can create cool projects and improve your skills!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Safety Precautions That Should Be Taken When Operating A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe, always wear safety goggles to protect your eyes. Tie back long hair and avoid loose clothes to prevent getting caught in the machine. Keep your fingers away from the spinning parts. Make sure all guards are in place and never reach in while the lathe is running. Finally, always be alert and focused to stay safe.”}},{“@type”: “Question”,”name”: “What Basic Components And Functions Of A Metal Lathe Should Trainees Be Familiar With Before Starting Hands-On Training?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Before using a metal lathe, you should know some key parts. The bed holds everything steady. The headstock spins the metal and has a motor. The tailstock helps you support the other end of the metal. The carriage moves the cutting tool to shape the metal. Understanding these parts helps you use the lathe safely and correctly.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up A Workpiece On The Lathe For Accurate Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a workpiece on the lathe, first, make sure the lathe is turned off. Then, place the workpiece in the lathe’s chuck, which holds it tight. Adjust the center so it lines up with the lathe’s center. Tighten everything securely. Finally, check that the workpiece spins evenly before starting to turn.”}},{“@type”: “Question”,”name”: “What Common Techniques And Practices Should New Operators Learn To Produce Quality Parts On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make good parts on a metal lathe, you should learn some key skills. First, always measure your pieces carefully. Use tools like calipers for accuracy. Second, keep the cutting tools sharp to ensure clean cuts. Third, set the right speed for the metal you are using. Finally, make sure to stay safe by wearing protective gear and following all rules.”}},{“@type”: “Question”,”name”: “How Can One Diagnose And Troubleshoot Common Issues That May Arise During The Operation Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To diagnose and fix problems with a metal lathe, first, check for loud noises. Those sounds might mean parts are loose or broken. Next, look at the material you’re working on. Is it moving too much? If so, make sure it’s held tightly in place. Lastly, if your cuts aren’t smooth, the tool might be dull or need to be adjusted. Always remember to turn off the machine before you look inside!”}}]}