Have you ever wondered how metal parts are made? It all starts with a design. Training in metal lathe CAD design helps you create these designs. With the right skills, you can turn ideas into real objects!

Imagine having a cool idea for a toy or a tool. You sketch it out, but how do you make it a reality? A metal lathe can shape metal into amazing forms. CAD, or Computer-Aided Design, makes this process easier and more precise.

Did you know that professional engineers use CAD software to design everything from cars to airplane parts? Training in metal lathe CAD design gives you a chance to join this exciting field. Whether you aim for a hobby or a career, understanding CAD is a superpower in the world of metalworking.

So, let’s dive into the world of training metal lathe CAD design. You might find a passion that sparks your creativity!

Training Metal Lathe Cad Design: Mastering Techniques And Tools — In Today’S Manufacturing Landscape, Mastering Training Metal Lathe Cad Design Is Crucial For Aspiring Machinists And Engineers. This Specialized Training Focuses On Enabling Individuals To Effectively Utilize Computer-Aided Design (Cad) Software While Operating Metal Lathes, Providing Them With The Skills Necessary To Create Precise And Intricate Components. The Importance Of Cad In Metal Lathe Design Computer-Aided Design Has Revolutionized The Way Machinists Approach Project Planning And Execution. By Integrating Cad Into Metal Lathe Training, Learners Can Visualize Their Designs In 2D And 3D Before Any Physical Machining Begins. This Not Only Reduces Material Waste But Also Allows For Quick Modifications And Enhancements To Designs. Key Components Of Training Metal Lathe Cad Design 1. **Software Familiarization**: Students Must Become Proficient In Industry-Standard Cad Software Such As Autocad, Solidworks, Or Fusion 360. Each Of These Platforms Offers Unique Tools That Facilitate Precise Design And Drafting. 2. **Understanding Lathe Operations**: A Solid Grasp Of Metal Lathe Operations Is Vital. This Includes Learning About Different Lathe Types, Tooling, And Machining Techniques. 3. **Combining Theory With Practice**: Effective Training Combines Theoretical Knowledge Of Design Principles With Hands-On Practice On Metal Lathes. This Dual Approach Helps Students Internalize Concepts, Improving Their Problem-Solving Skills. 4. **Best Practices In Design**: Incorporating Best Practices Such As Tolerance Considerations, Material Selection, And Design For Manufacturability Ensures That The Final Products Meet Quality Standards And Work Within Production Capabilities. Advancing Your Skills In Metal Lathe Cad Design To Excel In Training Metal Lathe Cad Design, Practitioners Should Seek Out Workshops, Online Courses, Or Community College Programs That Offer Specialized Curricula. Additionally, Participating In Forums And Discussions With Industry Experts Can Provide Invaluable Insights And Real-World Applications Of Cad In Machining. Conclusion Mastering Training Metal Lathe Cad Design Is A Pivotal Step In A Machining Career, Blending Creativity With Technical Skills. As Manufacturing Continues To Evolve With Technological Advancements, Those Equipped With The Knowledge And Experience In Cad Will Have A Significant Advantage In The Job Market. Engaging In Comprehensive Training Will Empower Individuals To Harness The Full Potential Of Metal Lathes And Produce High-Quality Designs Efficiently.

Training Metal Lathe CAD Design

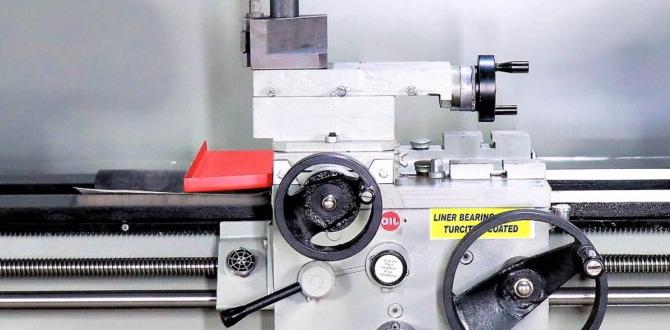

Training in metal lathe CAD design opens doors to creative projects. This skill helps you design metal parts accurately. Ever wondered how precise tools like gears and shafts are made? With CAD software, you can create detailed 3D models. Practicing on a metal lathe can boost your understanding. You learn about measurements, tool selection, and even safety practices. This training builds confidence and prepares you for exciting future projects. Embrace the challenge and discover the art of design!Fundamentals of CAD Design for Metal Lathes

Key principles of CAD software relevant to metal lathe training. Common design techniques used in metal lathe projects.Understanding CAD design for metal lathes is like learning to ride a bike. At first, it feels tricky, but soon enough, you’ll zoom around with confidence! Key principles of CAD software include precision, which means drawing accurate shapes. Common techniques involve creating profiles and using layouts that can bring ideas to life. And let’s not forget – if your design goes wrong, it might end up looking more like abstract art than a tool. Oops!

| Key Principle | Description |

|---|---|

| Precision | Accuracy in dimensions and details. |

| 3D Modeling | Building a visual representation of the design. |

| Layering | Organizing different parts in a clear way. |

Step-by-Step Process of Designing for Metal Lathes

Initial project planning and concept development. Creating technical drawings and specifications. Converting designs into CAD models.Planning your metal lathe project is like packing for a trip—super fun but needs some thought! First, think about what you want to make. Write down your ideas and draw basic sketches. Next, create technical drawings to show details like sizes and shapes. This part is like following a treasure map; clear directions lead to treasure, or in this case, your finished project! Finally, convert your drawings into CAD models. It’s like turning your doodles into 3D!

| Step | Description |

|---|---|

| 1. Planning | Decide what you want to create and sketch ideas. |

| 2. Drawings | Create technical drawings with sizes and details. |

| 3. CAD Models | Turn drawings into digital models using CAD software. |

This step-by-step process makes designing for metal lathes easier. Remember, every expert was once a beginner! 😄

Best Practices for Effective Metal Lathe Training

Strategies for mastering CAD design skills. Importance of handson practice alongside software training.Learning CAD design for metal lathes can be an exciting journey! First, dive into your software with enthusiasm—think of it like a treasure map! Explore each tool and feature while keeping a sketch pad nearby. This helps you connect theory with practice. Then, roll up your sleeves for some hands-on experience. It’s like cooking—you need to mix the ingredients to get a delicious dish! A little practice can turn you into a metal lathe wizard!

| Practice Tips | Why It Works |

|---|---|

| Take short CAD lessons | Small bites are easier to digest! |

| Work on real projects | Experience makes you a pro! |

| Ask for feedback | Others see what you might miss! |

Common Mistakes to Avoid in CAD Design for Metal Lathes

Typical errors made by beginners and how to correct them. Tips for ensuring accuracy and efficiency in designs.Beginners often face common errors in CAD design for metal lathes. These mistakes can lead to problems down the road. Here’s how to avoid them:

- Incorrect measurements: Always double-check your dimensions before finalizing a design.

- Poor file management: Organize your files with clear names and folders.

- Ignoring tolerances: Understand and apply proper tolerances for your project.

- Not using layers: Use layers to separate different parts for clarity.

To ensure accuracy and efficiency, practice regularly. Review your past designs and learn from mistakes. Also, seek feedback from experienced users. Learning from others can save you time and effort.

What are common mistakes made in CAD design?

The most common mistakes include incorrect measurements, poor organization, and not applying tolerances. Avoiding these mistakes helps create better designs.

With practice, your skills will grow. Remember to stay organized and always check your work! Happy designing!

Real-Life Applications of Metal Lathe CAD Design

Case studies showcasing successful metal lathe projects. Industryspecific examples that highlight the importance of CAD design.Many companies rely on metal lathe CAD design for amazing projects. These designs help make parts that fit perfectly and work well. For example, in the automotive industry, CAD allows engineers to design engine components precisely. In aerospace, it creates lightweight materials for planes. These case studies show how important CAD is:

- Automotive parts with tighter tolerances lead to better performance.

- Aerospace designs improve safety and reduce weight.

By using CAD in metal lathe projects, engineers create effective solutions. This not only saves time but also cuts costs. CAD designs make a big difference in many industries.

What are some successful examples of metal lathe projects using CAD?

Successful examples include automotive gears, aerospace brackets, and machinery components. These projects show the effectiveness of CAD in achieving high-quality results.

Future Trends in Metal Lathe Technologies and CAD Design

Emerging technologies influencing metal lathe design. Predictions for the future of CAD in metalworking industries.Exciting changes are ahead for metal lathe technologies and CAD design! New tools, like 3D printing and smart sensors, are shaking things up. Imagine a lathe that talks back! These gadgets will make machines smarter, helping workers do their jobs faster and with less fuss. Looking ahead, CAD will become even more user-friendly. Soon, anyone can design amazing parts with just a few clicks. Who knows? In the future, we might even see robots taking over the boring tasks. Let’s hope they can handle coffee breaks!

| Emerging Technology | Impact on Metal Lathe Design |

|---|---|

| 3D Printing | Enables rapid prototyping |

| Smart Sensors | Improves precision and monitoring |

| AI Integration | Automates complex tasks |

Conclusion

In summary, training in metal lathe CAD design is essential for creating precise parts. You gain skills in both design and machine operation. By practicing regularly, you improve your abilities. We encourage you to explore online resources or local classes. With dedication, you can master this valuable skill and open new opportunities in engineering or manufacturing.FAQs

Here Are Five Related Questions On The Topic Of Training For Metal Lathe Cad Design:Sure! Metal lathe CAD design training helps you learn how to create 3D models of metal parts. In this training, you use special software to design and plan how to shape metal. You’ll get to practice using tools and learn about different machines. This skill is important for making things like car parts or tools. It’s fun to see your designs come to life!

Sure! Just ask your question, and I’ll be happy to help you with a short answer.

What Are The Essential Cad Software Programs Commonly Used For Metal Lathe Design, And What Features Should One Look For In These Programs?Some common CAD software programs for metal lathe design are AutoCAD, SolidWorks, and Fusion 360. You should look for features like easy drawing tools, 3D modeling, and good measurements. It’s also important for the software to help you create parts and check how they fit together. Make sure it’s user-friendly so you can learn quickly.

How Can One Effectively Learn The Principles Of Metal Lathe Operation To Inform Better Cad Design Practices?To learn metal lathe operation, you can start by taking a class or watching videos. Practicing with a real lathe helps you see how it works. You should also ask questions if something is unclear. This knowledge can improve your designs in Computer-Aided Design (CAD). When you understand how real pieces are made, you can create better ideas on the computer.

What Are Some Best Practices For Creating Accurate Models Of Lathe Components In Cad Software?To create accurate models of lathe parts in CAD software, you should start with clear sketches. Use real measurements from the actual parts. Check your work often to catch mistakes. Keep your design neat so it’s easy to understand. Finally, ask for feedback from someone experienced to improve your model.

How Does Understanding Material Properties And Machining Techniques Enhance The Effectiveness Of Cad Designs For Metal Lathe Projects?Knowing about materials and machining techniques helps you create better CAD designs for metal lathe projects. When you understand what materials are strong or weak, you can choose the right one for your project. You also learn how to shape and cut those materials effectively. This makes your designs stronger and easier to build. Overall, it helps you make things that work well and look great!

What Resources, Such As Online Courses, Tutorials, Or Textbooks, Are Recommended For Beginners Looking To Improve Their Cad Design Skills Specifically For Metal Lathe Applications?To learn CAD design for metal lathes, we can use several helpful resources. Websites like YouTube have many easy-to-follow video tutorials. Courses on sites like Udemy offer structured lessons for beginners. Books like “CAD for Beginners” can teach you the basics step by step. These resources will help you get better at designing for metal lathes.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Training For Metal Lathe Cad Design:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Metal lathe CAD design training helps you learn how to create 3D models of metal parts. In this training, you use special software to design and plan how to shape metal. You’ll get to practice using tools and learn about different machines. This skill is important for making things like car parts or tools. It’s fun to see your designs come to life!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Cad Software Programs Commonly Used For Metal Lathe Design, And What Features Should One Look For In These Programs?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some common CAD software programs for metal lathe design are AutoCAD, SolidWorks, and Fusion 360. You should look for features like easy drawing tools, 3D modeling, and good measurements. It’s also important for the software to help you create parts and check how they fit together. Make sure it’s user-friendly so you can learn quickly.”}},{“@type”: “Question”,”name”: “How Can One Effectively Learn The Principles Of Metal Lathe Operation To Inform Better Cad Design Practices?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To learn metal lathe operation, you can start by taking a class or watching videos. Practicing with a real lathe helps you see how it works. You should also ask questions if something is unclear. This knowledge can improve your designs in Computer-Aided Design (CAD). When you understand how real pieces are made, you can create better ideas on the computer.”}},{“@type”: “Question”,”name”: “What Are Some Best Practices For Creating Accurate Models Of Lathe Components In Cad Software?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To create accurate models of lathe parts in CAD software, you should start with clear sketches. Use real measurements from the actual parts. Check your work often to catch mistakes. Keep your design neat so it’s easy to understand. Finally, ask for feedback from someone experienced to improve your model.”}},{“@type”: “Question”,”name”: “How Does Understanding Material Properties And Machining Techniques Enhance The Effectiveness Of Cad Designs For Metal Lathe Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Knowing about materials and machining techniques helps you create better CAD designs for metal lathe projects. When you understand what materials are strong or weak, you can choose the right one for your project. You also learn how to shape and cut those materials effectively. This makes your designs stronger and easier to build. Overall, it helps you make things that work well and look great!”}},{“@type”: “Question”,”name”: “What Resources, Such As Online Courses, Tutorials, Or Textbooks, Are Recommended For Beginners Looking To Improve Their Cad Design Skills Specifically For Metal Lathe Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To learn CAD design for metal lathes, we can use several helpful resources. Websites like YouTube have many easy-to-follow video tutorials. Courses on sites like Udemy offer structured lessons for beginners. Books like CAD for Beginners can teach you the basics step by step. These resources will help you get better at designing for metal lathes.”}}]}