Have you ever watched a machine work and wondered what makes it run so smoothly? If you’re curious about how metal lathes create perfectly shaped parts, you are in for a treat. One of the secrets lies in the metal lathe gear train.

A gear train is like a clever team of gears working together. Each gear has a special job that helps the lathe spin at the right speed. This makes it easier to cut, shape, and finish metal pieces.

Training on the metal lathe gear train is important for anyone who wants to master this skill. Imagine building your own toy or project, perfect in every detail. Understanding how these gears fit and work can help you create amazing things.

Did you know that the right gear ratio can change the way a lathe cuts? This means you can make finer cuts or remove more material, depending on your project. Learning about gear trains can open a whole new world of possibilities!

So, are you ready to dive into the world of metal lathe gear trains? Buckle up, as we explore how these mechanical wonders can help you craft your dreams!

Essential Guide To Training Metal Lathe Gear Train Techniques Training On A Metal Lathe Gear Train Is A Crucial Skill For Those Looking To Master Metalworking. Understanding How Gear Trains Operate In Conjunction With Lathes Can Greatly Enhance Precision And Efficiency In Machining Processes. In This Article, We Will Dive Into The Fundamentals Of Training On Metal Lathe Gear Trains, Discuss The Necessary Components, And Offer Insights Into Practical Applications. Understanding Gear Trains In Metal Lathes A Gear Train Is A System Of Gears That Transmits Torque And Alters Rotation Speed. In The Context Of Metal Lathes, Gear Trains Play A Pivotal Role In Adjusting Spindle Speeds And Providing The Necessary Torque Required For Different Machining Operations. Training On These Systems Involves Familiarizing Oneself With How Gears Work, Their Configurations, And Impacts On Lathe Performance. Key Components Of Metal Lathe Gear Trains 1. **Spindle Gear**: This Is The Main Gear Connected To The Motor, Controlling The Rotation Of The Spindle. 2. **Change Gears**: These Are Interchangeable Gears Used To Modify The Ratio Of The Spindle Speed, Allowing For Finer Control Over Machining Operations. 3. **Feed Gears**: They Regulate The Movement Of The Cutting Tool Across The Material Being Worked. 4. **Idler Gears**: These May Not Affect The Gear Ratio But Are Used To Make The Gear Train More Flexible, Facilitating Smooth Transitions. The Importance Of Training On Metal Lathe Gear Trains Proper Training On Gear Trains Can Prevent Common Pitfalls In Metalworking, Such As Tool Chatter, Uneven Cutting, And Equipment Wear. Understanding How To Set Up And Adjust The Gear Components According To The Requirements Of A Specific Project Can Lead To Enhanced Performance And Significantly Improved Results. Practical Applications And Techniques When Training On A Metal Lathe Gear Train, Practical Applications Can Include: – **Setting Up Gear Ratios**: Learning How Different Gear Combinations Affect Spindle Speed And Feed Rate. – **Maintenance**: Understanding The Importance Of Regular Checks On Gear Condition To Prevent Malfunctions. – **Troubleshooting**: Developing The Ability To Identify Issues In The Gear Train Configuration Or Worn Gears Can Save Time And Resources. Conclusion Mastering The Training Of Metal Lathe Gear Trains Is An Essential Part Of Becoming A Proficient Machinist. Through Understanding The Components And Their Functions, As Well As The Skills To Apply Them Effectively, You Will Enhance Your Capability To Produce High-Quality Machined Parts. With Consistent Practice And Training, Your Skills In Operating Metal Lathe Gear Trains Will Become Second Nature, Paving The Way For Successful Machining Projects.

Training Metal Lathe Gear Train

Understanding how a metal lathe gear train works is key for any budding machinist. A gear train helps control the speed and torque of the lathe. It’s like the heartbeat of your machine. Did you know that proper gear train adjustments can make even the toughest materials easier to shape? Training can help you learn these skills quickly. With practice, you’ll create precise parts that fit perfectly together. So, why not get started today?Understanding the Basics of Gear Trains

Definition and components of gear trains. Importance of gear trains in metal lathe operation.Gear trains are systems that transfer power between gears. Each gear can change the speed and torque of the machine. Components include gears, shafts, and bearings. In metal lathe operation, gear trains are very important. They help control the speed of the lathe, making it easier to cut metal accurately. Without them, the lathe would not work well.

- Gears: Change speed and torque.

- Shafts: Connect the gears together.

- Bearings: Support the rotating parts.

Why are gear trains important in metal lathe operation?

Gear trains ensure smooth movement. They help adjust the cutting speed. This precision is key for making accurate cuts. Strong gear trains lead to better performance.

Types of Gear Trains Used in Metal Lathes

Fixed vs. variable gear trains. Comparison of helical and spur gear designs.In the world of metal lathes, gear trains come in two main styles: fixed and variable. Fixed gear trains have a set speed and work great for steady tasks. Think of them as your favorite cereal—always good, but no surprises! On the flip side, variable gear trains let you adjust speed. They’re like a buffet, letting you choose what you need.

Next, let’s compare helical and spur gears. Helical gears have angled teeth, like a slide. They make less noise and work smoothly, which is great when you don’t want to wake the neighbors! Spur gears are simpler, with teeth that are straight. They’re strong, but they can be a bit noisy. It’s the difference between a cozy library and a rock concert!

| Gear Type | Noise Level | Efficiency |

|---|---|---|

| Fixed Gear | Quiet | High |

| Variable Gear | Variable | Very High |

| Helical Gear | Low | Very Efficient |

| Spur Gear | High | Good |

Choosing the right type can make all the difference in your projects. Remember, every gear has its role! So pick wisely and get ready to spin into action.

Setting Up and Adjusting Gear Trains

Stepbystep guide for setup. Common adjustments for optimal performance.Setting up a gear train on your metal lathe can feel like assembling a tricky puzzle. Start by aligning the gears to make sure everything fits snugly. Next, adjust the tension using the tensioner. This helps to avoid sudden breaks or slips. If the train doesn’t spin smoothly, check for any misaligned parts—nobody likes a wobbly ride! For peak performance, ensure you apply a bit of oil to keep things running slick. Remember, even machines enjoy a good massage!

| Step | Action |

|---|---|

| 1 | Align the gears |

| 2 | Adjust the tension |

| 3 | Check for misalignments |

| 4 | Apply oil for smooth operation |

Common Issues with Gear Trains

Identifying wear and tear. Troubleshooting gear train problems.Gears are important parts of a machine. They can wear out over time. Identifying wear and tear helps to keep the machine running well. Look for signs of damage, like cracks or rust. This can help you spot issues early. Troubleshooting gear train problems needs careful attention. Listen for strange noises and watch for jerky movements. Check oil levels regularly to avoid trouble. Your machine will thank you!

What Should You Look For in Gear Train Issues?

Look for worn or damaged gears, strange noises, and irregular movements. These signs help spotlight problems and save you from bigger issues later.

Signs of Gear Train Problems

- Cracks or chips on the gears

- Excessive noise during operation

- Unusual shaking or vibrations

- Low lubrication levels

Best Practices for Maintenance

Regular inspections and maintenance schedules. Lubrication and cleaning techniques.Keeping your metal lathe in top shape is like giving it a spa day! Regular inspections help catch any sneaky problems before they turn into big headaches. Create a maintenance schedule that’s easy to follow, so you won’t forget. Lubrication is key; think of it as giving your lathe a nice oily massage. Don’t forget to clean it often. Dust and debris are like uninvited guests that should be shown the door. Here’s a neat table to help you remember:

| Maintenance Task | Frequency |

|---|---|

| Inspect belts and gears | Monthly |

| Lubricate moving parts | Weekly |

| Clean the machine | After each use |

With these best practices, your lathe will run smoother than a cat on a sled! Remember, a little upkeep goes a long way.

Advanced Techniques for Gear Train Optimization

Modifications for increased efficiency. Use of CNC technology in modern gear trains.To improve gear train performance, several smart changes can be made. First, modifying the gear shapes can help them fit together better. This makes movements smoother. Second, using CNC technology ensures each piece is made very accurately. This precision reduces errors and wear. Together, these methods boost the efficiency of gear trains, making machines work better and last longer.

How can modifying gears make a difference?

Modifying gears can lead to smoother operation and less energy loss. Better-fitting gears mean less friction. This change can increase the machine’s lifespan.

Key modifications include:

- Changing gear shapes for better fit

- Using stronger materials to reduce wear

- Implementing tighter tolerances for accuracy

What role does CNC technology play?

CNC technology allows for precise cutting and shaping of gears. This means parts fit together perfectly, which improves overall machine performance.

Safety Considerations When Working with Gear Trains

Personal protective equipment (PPE) recommendations. Safety protocols for operation and maintenance.Working with gear trains can be fun but also dangerous. To stay safe, always wear personal protective equipment (PPE). This includes:

- Safety goggles – Protect your eyes from flying debris.

- Ear protection – Keep your hearing safe from loud machines.

- Gloves – Shield your hands but ensure they fit well to avoid snagging.

- Steel-toed boots – Protect your feet from heavy items.

Follow these safety protocols:

- Always power off machines before maintenance.

- Keep hands clear of moving parts.

- Use tools correctly to prevent accidents.

Remember, safety first makes work better!

What should I wear for safety while using gear trains?

Wear safety goggles, ear protection, gloves, and steel-toed boots for the best protection.

Resources and Further Reading

Recommended books and guides on metal lathe gear trains. Online courses and workshops for advanced training.Dive into the world of metal lathe gear trains! For those eager to learn more, there are excellent resources available. Books like “Lathe Work: A Complete Handbook” offer solid foundational knowledge. Online platforms like Coursera or Udemy host workshops too. These courses can help you turn from a rookie into a gear-train guru faster than your lathe can spin! Below is a handy table with some recommended reads and courses:

| Resource Type | Name | Link |

|---|---|---|

| Book | Lathe Work: A Complete Handbook | Find it here |

| Online Course | Advanced Metal Lathe Techniques | Enroll now! |

| Workshop | Mastering Gear Train Design | Sign up! |

These resources will sharpen your skills and keep you entertained. Remember, every expert was once a beginner who knew how to turn on their lathe!

Conclusion

In conclusion, understanding the training metal lathe gear train is essential for smooth machine operation. You learned how gear trains transmit power effectively. By mastering these concepts, you can improve your skills. Consider experimenting with your lathe or reading more about gear design. Keep practicing, and soon you’ll become more confident in using lathe machines!FAQs

Sure! Here Are Five Questions Related To Training On Metal Lathe Gear Trains:Sure! A metal lathe is a tool that helps us cut and shape metal. Gear trains are parts that help the lathe spin faster or slower. When you train on it, you learn how to set up the gears. This makes your work easier and better. We have to be careful and practice to get good at it!

Sure! Just ask your question and I’ll give you a short answer.

What Is The Purpose Of A Gear Train In A Metal Lathe, And How Does It Affect Machining Operations?A gear train in a metal lathe helps us change how fast the machine spins. It connects the motor to the spinning part, called the spindle. When we adjust the gears, we can make the lathe spin slower or faster. This change makes it easier to cut different materials and shapes. So, the gear train helps us work better and make better parts!

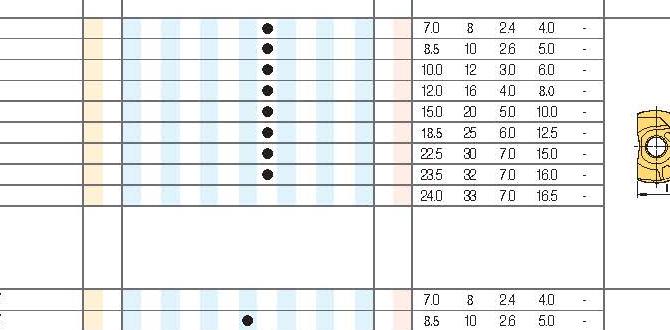

How Do You Determine The Correct Gear Ratios To Achieve Desired Spindle Speeds On A Metal Lathe?To find the right gear ratios for spindle speeds on a metal lathe, you start with the speed you want. Next, check the lathe’s manual for its gear settings. You need to match the gear teeth with the speed you want. Then, you can try different combinations of gears to see what works best. It’s like a puzzle where you connect the right pieces!

What Are The Common Types Of Gear Trains Used In Metal Lathes, And What Are Their Respective Advantages And Disadvantages?Metal lathes often use three common types of gear trains: spur gears, bevel gears, and worm gears. Spur gears are easy to make and very strong. They can be noisy, though. Bevel gears can change the direction of movement but might wear out faster. Worm gears help with heavy loads but are slower than other types. Each gear has its own benefits and downsides!

How Do You Properly Maintain And Troubleshoot Gear Trains In Metal Lathes To Ensure Reliable Operation?To keep gear trains in metal lathes working well, you should first keep them clean. Regularly check for dirt and oil them to help gears move smoothly. If you hear strange noises or see any damage, stop and look closely. Make sure all screws and parts are tight. If something is broken, replace it to keep everything running safely.

In What Ways Can The Configuration Of A Gear Train Impact The Torque And Feed Rate During Metal Lathe Operations?The gear train helps to control how much power and speed the lathe uses. If you use gears with a big difference in size, you get more torque. This means you can turn harder materials. However, a slower speed means a slower feed rate, which is how quickly you work. Choosing the right gear setup can help you balance power and speed for the best results.