Are you a hobbyist or beginner looking for a metal lathe under $1000? If so, you might need a solid wiring diagram to get started. Knowing how to wire your lathe properly can save you time and frustration. Have you ever wondered how others set up their machines?

Imagine turning raw metal into precise shapes with ease. It sounds cool, right? A good wiring diagram can help you achieve that. Even a simple mistake can lead to problems. That’s why understanding the wiring plan is key.

In this article, we will explore what you need to know. We’ll start with the basics of metal lathe wiring. Then, we’ll share tips for finding a quality lathe under $1000. By the end, you’ll feel more confident about your metalworking journey.

So, gear up and dive in! Your dream of creating beautiful metal pieces can be just a wiring diagram away.

Under $1000 Metal Lathe Wiring Diagram: Essential Guide

Understanding the Under $1000 Metal Lathe Wiring Diagram

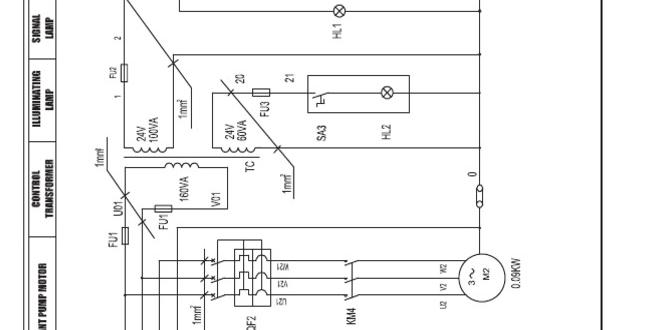

If you’re into machining, knowing how to wire a metal lathe is essential. A wiring diagram can make the task easier, especially if your budget is under $1000. You’ll learn about the components like the motor, switch, and power supply. Did you know a simple mistake could lead to a short circuit? By following the diagram, you can avoid costly errors. Proper wiring not only improves performance but also keeps you safe while working on your projects.Understanding Metal Lathe Wiring Basics

Explanation of common wiring components in metal lathes. Safety precautions when working with electrical systems.Wiring a metal lathe includes key parts. Common components are power cords, switches, relays, and fuses. Each plays an important role in making the lathe work safely. Always remember safety first! Here are some tips:

- Turn off power before starting.

- Use insulated tools.

- Wear safety glasses.

Following these steps helps avoid accidents. Understanding wiring keeps you safe while working on your lathe!

What are the common components in metal lathe wiring?

The main components in metal lathe wiring include power cords, switches, relays, and fuses. These parts help control electricity and keep the lathe safe to use.

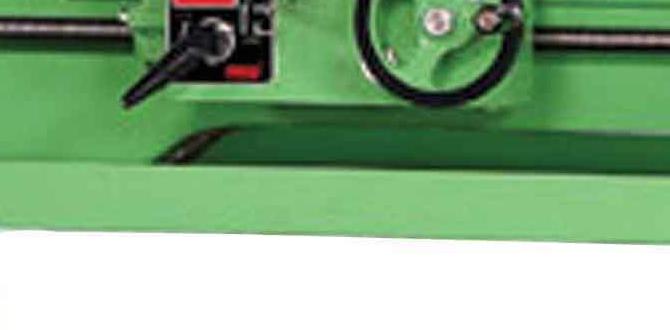

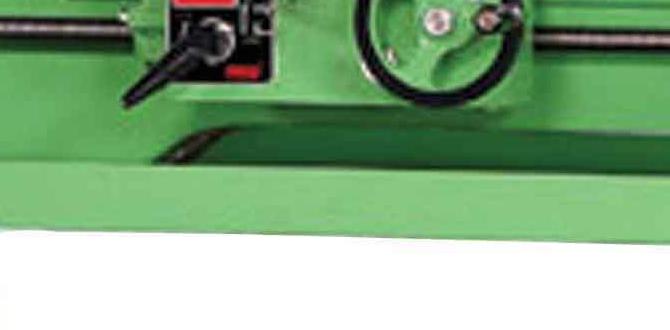

Choosing the Right Metal Lathe Under $1000

Features to consider when selecting a metal lathe. Comparison of various models available in the market.Finding a great metal lathe under $1000 is exciting but tricky. First, think about what you’ll be making. Different lathes offer various features. Some have extra stability while others perform better for precise cuts. Check for horsepower, bed length, and swing capacity. Don’t forget to compare popular models. For example, the Grizzly G8688 and Jet JWL-1015 offer unique perks. Here’s a quick comparison:

| Model | Horsepower | Bed Length | Price |

|---|---|---|---|

| Grizzly G8688 | 1 HP | 16 Inches | $799 |

| Jet JWL-1015 | 3/4 HP | 15 Inches | $599 |

Choosing wisely can save you from lathe heartbreak later. Happy turning!

Essential Tools and Materials for Wiring

List of tools needed for wiring a metal lathe. Information on wiring materials and their specifications.Wiring a metal lathe is a fun project that doesn’t require wizard-level skills! To get started, you’ll need a few tools. Grab a wire cutter, a screwdriver, and some pliers. Don’t forget a good multimeter to check your connections. For materials, use insulated copper wire. It keeps things safe and sound. Oh, and a dash of electrical tape is your best friend here! Here’s a simple list to help you assemble your arsenal:

| Tool/Material | Purpose |

|---|---|

| Wire Cutter | To snip wires |

| Screwdriver | To tighten connections |

| Pliers | To bend and shape wires |

| Multimeter | To test electrical flow |

| Insulated Copper Wire | For safe wiring |

| Electrical Tape | To secure and insulate |

With these tools and materials, you’re on your way to wiring like a pro—not Houdini, but pretty close!

Step-by-Step Wiring Diagram Interpretation

Breakdown of a typical wiring diagram for metal lathes under $1000. Explanation of symbols and terminology used in wiring diagrams.Understanding a wiring diagram for metal lathes can be like trying to decode a secret message. A typical diagram shows how all parts connect. Look out for symbols like resistors and capacitors; they each have their special job. Don’t worry—if you mix them up, it won’t cause an explosion! Each line tells you where to connect wires. Think of it as a treasure map, but instead of gold, you’re finding smooth ‘lathe-ing’ skills!

| Symbol | Meaning |

|---|---|

| 🔌 | Power Source |

| 🔗 | Connection |

| ⚡ | Electric Component |

Troubleshooting Wiring Issues

Common wiring problems and their solutions. Tips for diagnosing electrical issues in metal lathes.Tangled wires can make any metal lathe user feel like they’re in a fast-paced game of electric hide-and-seek. Common problems include frays, loose connections, and blown fuses. Fear not! Tightening connections or replacing fuses can often solve these pesky issues. To diagnose wiring problems, check for breaks in insulation and use a multimeter to test voltage. Remember, safety comes first—turn off power before poking around. After all, a well-functioning lathe is way better than a shocking experience!

| Common Wiring Problems | Simple Solutions |

|---|---|

| Frayed Wires | Replace or tape them up |

| Loose Connections | Tighten connectors |

| Blown Fuses | Replace with the same rating |

Upgrading Your Metal Lathe Wiring

Benefits of upgrading wiring for performance and safety. Recommended upgrades for users working with advanced operations.Upgrading the wiring of your metal lathe can bring many benefits. It improves performance, making your lathe run smoother and more efficiently. This upgrade also enhances safety by reducing fire hazards. If you do advanced operations, consider these upgrades:

- Use thicker wires for better power delivery.

- Install better circuit breakers to prevent overloads.

- Upgrade to a digital controller for precise speed settings.

These steps can help your lathe perform at its best.

What are the benefits of upgrading metal lathe wiring?

The key benefits include smoother operation and increased safety. Better wiring reduces the risk of electrical problems and helps with accurate machining.

Resources for Further Learning

Recommended books and online courses on metal lathe wiring. Links to online forums and communities for support and advice.Learning about metal lathe wiring can be exciting! Here are some helpful resources:

- Books: Look for titles like “Lathe Wiring Basics” and “Metalworking for Beginners.

- Online Courses: Websites like Udemy offer affordable courses on metal lathe wiring.

- Forums: Join communities like Reddit’s r/Metalworking for tips and support.

These resources can help you learn and connect with others. Enjoy your journey in metalworking!

What are the best online courses for metal lathe wiring?

Udemy and Skillshare provide great options for online courses. You can find beginner-friendly classes that teach wiring skills effectively.

Where can I find support for metal lathe projects?

- Reddit groups

- Facebook groups

- Dedicated metalworking forums

Conclusion

In summary, understanding the wiring diagram for a metal lathe under $1000 is essential for safe use. Knowing the components helps you set it up confidently. Carefully following the diagram can prevent mistakes. We encourage you to explore more resources for detailed guides. With practice, you’ll master metal lathe operation and create great projects. Happy lathing!FAQs

Sure! Here Are Five Questions Related To Under $10Metal Lathe Wiring Diagrams:Sure! Here are the answers to your questions about metal lathe wiring diagrams for under $10: 1. **What is a wiring diagram?** A wiring diagram shows how to connect wires in a machine. It helps us understand the setup. 2. **Why do we need one for a metal lathe?** We need a wiring diagram so we can properly connect the lathe. This keeps it safe and working well. 3. **Where can I find diagrams for under $10?** You can find them online or in stores. Look for diagrams that are labeled for your specific lathe model. 4. **Can I make my own wiring diagram?** Yes, you can! Just draw how you think the wires connect. Make sure to check it with a real diagram. 5. **What tools will I need to follow a wiring diagram?** You will need basic tools like screwdrivers and pliers. You might also need wire connectors and electrical tape.

Sure! Please provide me with the question you need help with, and I will gladly answer it.

What Are The Essential Components Needed For Wiring A Metal Lathe Under $1000?To wire a metal lathe, you need a few important parts. First, you need a power switch to turn it on and off safely. Next, get some electrical wire to connect everything. You will also need a motor to make the lathe move. Finally, use connectors to join the wires together. These pieces will help you set up the lathe without spending too much money.

How Do You Determine The Appropriate Power Supply For A Low-Cost Metal Lathe?To choose the right power supply for a low-cost metal lathe, you start by checking the lathe’s power needs. Look at the motor’s voltage and wattage. You want a power supply that matches these numbers. If the lathe needs 120 volts and 500 watts, get a supply with those ratings or a bit higher. Finally, ensure the power supply fits your workspace and can be safely used.

What Safety Precautions Should Be Taken When Wiring A Metal Lathe?When wiring a metal lathe, you should unplug it first to stay safe. Always check for any loose wires or damages. Use rubber gloves to protect your hands from shocks. Keep your work area clean and free of clutter. Finally, always ask for help if you’re unsure about something!

Are There Any Specific Wiring Diagrams Available For Popular Under $10Metal Lathe Models?Yes, you can find wiring diagrams for popular metal lathes under $10. These diagrams show you how to connect the wires. Check websites, forums, or the manuals that come with the lathes. You can also ask other people who use these lathes for help.

What Troubleshooting Steps Can Be Taken If A Wired Metal Lathe Does Not Operate Correctly?First, check if the lathe is plugged in and the power is on. Next, look for any loose or damaged wires. You can also see if there are any stuck parts by moving them gently. If it still doesn’t work, ask an adult for help or check the manual.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Under $10Metal Lathe Wiring Diagrams:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are the answers to your questions about metal lathe wiring diagrams for under $10: 1. **What is a wiring diagram?** A wiring diagram shows how to connect wires in a machine. It helps us understand the setup. 2. **Why do we need one for a metal lathe?** We need a wiring diagram so we can properly connect the lathe. This keeps it safe and working well. 3. **Where can I find diagrams for under $10?** You can find them online or in stores. Look for diagrams that are labeled for your specific lathe model. 4. **Can I make my own wiring diagram?** Yes, you can! Just draw how you think the wires connect. Make sure to check it with a real diagram. 5. **What tools will I need to follow a wiring diagram?** You will need basic tools like screwdrivers and pliers. You might also need wire connectors and electrical tape.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you need help with, and I will gladly answer it.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Needed For Wiring A Metal Lathe Under $1000?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a metal lathe, you need a few important parts. First, you need a power switch to turn it on and off safely. Next, get some electrical wire to connect everything. You will also need a motor to make the lathe move. Finally, use connectors to join the wires together. These pieces will help you set up the lathe without spending too much money.”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Power Supply For A Low-Cost Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right power supply for a low-cost metal lathe, you start by checking the lathe’s power needs. Look at the motor’s voltage and wattage. You want a power supply that matches these numbers. If the lathe needs 120 volts and 500 watts, get a supply with those ratings or a bit higher. Finally, ensure the power supply fits your workspace and can be safely used.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Wiring A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When wiring a metal lathe, you should unplug it first to stay safe. Always check for any loose wires or damages. Use rubber gloves to protect your hands from shocks. Keep your work area clean and free of clutter. Finally, always ask for help if you’re unsure about something!”}},{“@type”: “Question”,”name”: “Are There Any Specific Wiring Diagrams Available For Popular Under $10Metal Lathe Models?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can find wiring diagrams for popular metal lathes under $10. These diagrams show you how to connect the wires. Check websites, forums, or the manuals that come with the lathes. You can also ask other people who use these lathes for help.”}},{“@type”: “Question”,”name”: “What Troubleshooting Steps Can Be Taken If A Wired Metal Lathe Does Not Operate Correctly?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “First, check if the lathe is plugged in and the power is on. Next, look for any loose or damaged wires. You can also see if there are any stuck parts by moving them gently. If it still doesn’t work, ask an adult for help or check the manual.”}}]}