Imagine being able to create amazing parts and tools right in your garage. With under $500 metal lathe automation, this dream can come true. You don’t need to spend a fortune to start your machining journey.

Have you ever wondered how a simple piece of metal can turn into something useful? Metal lathes do just that. They shape metal with precision and speed. Plus, many affordable options now come with automation features.

A fun fact: metal lathes have been around since ancient times. They have evolved, making them more accessible to hobbyists. An automated lathe under $500 can help you save time on projects. This lets you focus on creativity instead of manual work.

Are you ready to explore the world of metalworking? Let’s dive into how you can find the right metal lathe for your needs. It might just inspire you to build your next great invention!

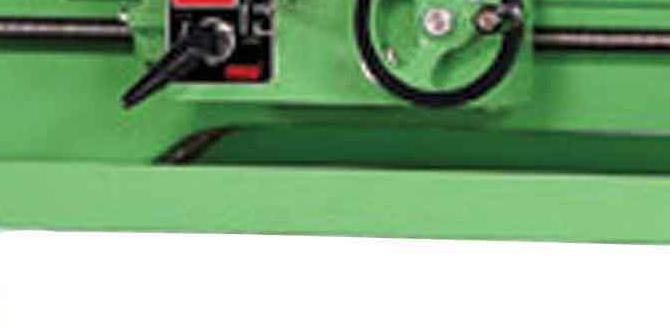

Under $500 Metal Lathe Automation: Affordable Solutions For Precision Crafting — **Introduction** When It Comes To Precision Crafting And Machining, Finding The Right Tools Can Be A Challenge—Especially On A Budget. For Hobbyists And Small-Scale Producers, An Under $500 Metal Lathe Automation Solution Can Provide The Necessary Features Without Breaking The Bank. In This Article, We Will Explore Various Options Available In The Market, Their Key Features, And How They Can Enhance Your Metalworking Projects. **Understanding Metal Lathe Automation** Metal Lathe Automation Refers To The Use Of Automated Systems That Allow For Precision Machining Of Metal Pieces Without The Need For Constant Manual Intervention. This Technology Can Be Particularly Beneficial For Those Looking To Increase Efficiency And Improve Accuracy In Their Work. **Why Choose An Under $500 Metal Lathe?** 1. **Affordability**: The Primary Advantage Of These Budget Lathes Is Their Cost-Effectiveness, Allowing Newcomers And Seasoned Machinists Alike Access To Essential Tools Without Significant Financial Investment. 2. **Ease Of Use**: Many Of The Under $500 Options Are User-Friendly, Making Them Ideal For Beginners Who Want To Learn The Basics Of Metalworking While Still Having Automation Features. 3. **Versatility**: These Lathes Often Come Equipped With Various Functions And Attachments That Enable Users To Handle Different Types Of Projects, From Small Repairs To Intricate Designs. **Key Features To Look For** 1. **Size And Weight**: Depending On Your Workspace, It’S Important To Consider The Lathe’S Size And Weight. A Compact Machine Might Be Ideal For Smaller Shops, While A More Robust Unit Might Be Required For Heavier Jobs. 2. **Power And Speed**: Check The Motor’S Horsepower And The Variable Speed Settings Available. A Lathe With Adjustable Speeds Will Allow For Better Control Over The Machining Process. 3. **Build Quality**: Look For A Sturdy Construction That Ensures Stability During Operations, Reducing Vibration For Better Precision. 4. **Control Mechanism**: For Automation, Consider Lathes With Cnc Capabilities Or Digital Readouts That Simplify The Setup And Execution Of Tasks. **Top Recommendations** 1. **Grizzly G8688 Mini Metal Lathe** With A Price Point Just Under $500, This Mini Metal Lathe Combines Quality With Affordability. It Includes Variable Speed Control And Is Ideal For Small Projects And Delicate Work. 2. **Wen 3421 3.2-Amp 8-Inch By 12-Inch Benchtop Metal Lathe** This Model Offers Solid Performance With A Durable Build, Making It A Great Choice For Workshops Where Space And Budget Are Limited. 3. **Jet Bdb-1340A 13” X 40” Metal Lathe** Though Slightly Above The $500 Range At Times, Discounts Can Make This Machine Affordable. It’S Known For Its Precision And Built-In Automation For Longer Running Projects. **Conclusion** Finding The Right Under $500 Metal Lathe Automation Can Significantly Upgrade Your Metalworking Experience. By Selecting A Machine That Fits Your Specific Needs And Budget, You Will Have The Necessary Tools To Embark On Projects With Enhanced Precision, Efficiency, And Enjoyment. Whether You Are Just Starting Or Looking To Expand Your Capabilities, These Affordable Lathes Can Serve As A Valuable Addition To Your Workshop.

Under $500 Metal Lathe Automation

Automation for metal lathes under $500 is an exciting option for hobbyists and small businesses. These affordable machines can help create precise metal parts easily. Imagine turning raw metal into useful shapes with just a push of a button. Some models even have user-friendly features like touchscreen controls. With a bit of practice, anyone can learn how to use them. Did you know that the right lathe can save you time and improve your projects? Discover the benefits of automation today!Understanding Metal Lathe Automation

Definition and purpose of metal lathe automation. Benefits of automating metal lathes in workshops.Metal lathe automation means using machines to help shape metal parts. It makes the work easier and faster. This is important in workshops where people make products. Automating metal lathes can lead to better overall quality. People save time and make fewer mistakes. Here are some benefits:

- Increased speed

- Less effort needed

- Better accuracy

- Lower production costs

Automating these machines is smart and helps everyone. It allows workers to focus on other tasks while machines work efficiently.

What is the main purpose of metal lathe automation?

The main purpose of metal lathe automation is to improve efficiency, accuracy, and reduce labor costs. It helps in making high-quality metal parts with less time and effort.

Key Components of Metal Lathe Automation

Essential parts for automation (CNC kits, stepper motors, etc.). Importance of control systems and software.To automate a metal lathe under $500, you need some key parts. First, consider **CNC kits**. These kits turn your manual lathe into a smart machine, saving you from cranking handles for hours. Then there are the **stepper motors**, which whisper sweet nothings to your lathe’s movements. You also need **control systems and software** to keep everything running smoothly. Think of them as the brains of your operation—like a wise old owl but much less feathery!

| Component | Purpose |

|---|---|

| CNC Kits | Convert manual lathe to automated |

| Stepper Motors | Control precise movements |

| Control Systems | Manage machine functions |

| Software | Interface for user commands |

Top Affordable Metal Lathe Automation Kits

Comparison of popular automation kits available for under $500. Pros and cons of each kit.There are great automation kits under $500 for metal lathes. Let’s look at a few popular options. Each kit has pros and cons. It’s important to pick one that fits your needs.

- Kit A: Easy to use and set up. Good for beginners. However, it has limited features.

- Kit B: Offers advanced options. It can create complex designs. But, it’s harder to learn.

- Kit C: Affordable and great for small projects. Some users find it less durable.

Choosing the right kit helps you make the most of your metal lathe.

What are the benefits of metal lathe automation kits?

Automation kits speed up your projects. They help create precise parts. This saves time and reduces mistakes, making everyone happy!

DIY vs. Pre-Built Solutions

Advantages of building your own automation system. When to choose a prebuilt solution.Building your own automation system can be fun and cost-effective. You get to pick what you need. Plus, you’ll feel like a robot wizard! It lets you tweak things just right and it often fits your budget. But, if you want quick results and less hassle, prebuilt solutions are a good choice. They save you time and usually come with support. Think of it like cooking: sometimes, it’s fun to make your meal from scratch, and other times, a frozen pizza saves the day!

| DIY Solutions | Prebuilt Solutions |

|---|---|

| Flexible and customizable | Quick setup and support |

| Skill development | Less time-consuming |

| Potentially lower costs | Reliable performance |

Setting Up Your Metal Lathe Automation

Stepbystep guide to installing automation components. Common challenges and how to overcome them.Getting your metal lathe automation ready doesn’t have to feel like rocket science. Start by gathering all your components. You’ll need sensors, motors, and a controller. Lay everything out like you’re about to build the Lego castle of your dreams. Next, connect the parts step by step, following the instructions. Remember, if wires look like spaghetti, take a breather and double-check your connections!

| Common Challenge | Solution |

|---|---|

| Wiring Confusion | Color-code your wires! |

| Software Glitches | Restart and update! |

Don’t forget to test everything before calling it a day. A little patience goes a long way! Remember, every expert was once a beginner who made a few silly mistakes. And hey, if all else fails, a good cup of coffee can solve almost anything!

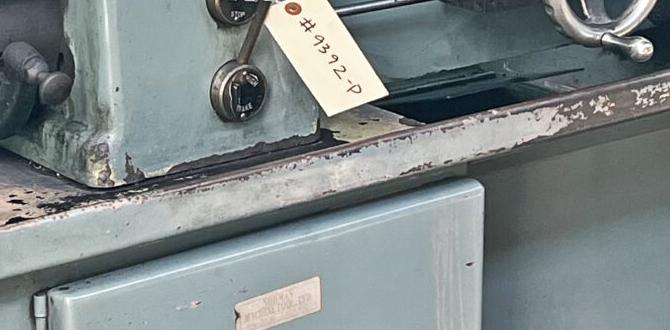

Maintenance Tips for Automated Metal Lathes

Regular maintenance practices to ensure longevity. Troubleshooting common issues with automation systems.Keeping your automated metal lathe in good shape is key to its long life. Regular check-ups stop problems before they start. Clean it often and check parts for wear. If things go wrong, here are some quick fixes:

- Check power connections.

- Inspect the software settings.

- Clean sensors to avoid hiccups.

Don’t ignore odd sounds or signs of trouble. A little care now means it will work well for years to come!

What are some common maintenance tips for metal lathes?

Clean regularly, check for wear, and keep software updated to avoid common issues!

Case Studies: Success Stories of Automated Metal Lathes

Reallife examples of workshops benefiting from cheap automation. Lessons learned from successful metal lathe automation projects.Many workshops have found great success using automated metal lathes. These tools help them produce parts quickly and accurately, saving time and money. For example, a small workshop in Ohio upgraded to an automated lathe for under $500. They reported a 50% increase in productivity and less wasted material. Here are some key points:

- Improved efficiency: Automation speeds up production.

- Cost savings: Less waste means more profit.

- Better quality: Machines create parts with high accuracy.

Learning from these success stories is important. Workshops can adopt best practices and get similar results.

What are the benefits of automated metal lathes?

Automated metal lathes improve speed, accuracy, and reduce costs. These tools help create precise parts and make the work easier for everyone.

Future Trends in Metal Lathe Automation

Emerging technologies and innovations in metal lathe automation. Predictions for the future of affordable automation solutions.Metal lathe automation is changing fast. New tools and ideas are making it easier for people to use. For example, 3D printing and smart sensors are helping machines work better. More companies are making these machines cheaper, too. Soon, you might see metal lathes that cost under $500. This will allow many small makers and hobbyists to enjoy automation.

What are the predictions for affordable automation solutions?

Experts believe that as technology grows, prices will drop. Soon, many people will own robotic tools that are friendly to their wallets. This means metal lathe automation will be for everyone, not just big companies.

Emerging technologies

- 3D Printing

- Smart Sensors

- Cloud Computing

Conclusion

In conclusion, affordable metal lathes under $500 can boost your projects with automation. They save time and improve accuracy. Always research features before buying to find the best fit for you. Whether you’re a beginner or an expert, these tools can enhance your skills. Explore reviews and guides to find the perfect machine for your needs!FAQs

Sure! Here Are Five Related Questions On The Topic Of Under $5Metal Lathe Automation:Sure! Here are five related questions about metal lathe automation under $5: 1. What is a metal lathe? A metal lathe is a machine that shapes metal. It spins metal and helps us make things like tools. 2. How does automation help with metal lathes? Automation makes machines work on their own. This helps us save time and do a better job. 3. Can I build an automated lathe for under $5? Building a fully automated lathe for under $5 is very hard. You usually need more money for materials and tools. 4. Why is automation important? Automation is important because it helps us work faster. It also makes things more accurate and safe. 5. What can I make with a metal lathe? You can make many things with a metal lathe! You can create parts for toys, models, or even small machines.

Sure! Please provide the question you would like me to answer.

What Are The Most Affordable Metal Lathe Automation Kits Available For Under $500?If you’re looking for affordable metal lathe automation kits under $500, there are a few options. The SainSmart CNC Kit is popular and easy to use. Another good choice is the Genmitsu CNC Kit, which is also good for beginners. You can find them online at places like Amazon or eBay. Remember to check the reviews to see what others think!

How Can I Retrofit An Existing Manual Metal Lathe For Automated Operation Without Exceeding A $5Budget?To automate a manual metal lathe on a $5 budget, first look for old toys or gadgets. You can take their motors or gears to create small movements. You can use a simple switch to turn them on and off. Lastly, test everything carefully to make sure it works. Remember, safety first!

What Are The Key Features To Look For In Low-Cost Automation Solutions For Metal Lathes?When looking for cheap automation solutions for metal lathes, you should check for a few important features. First, see if it’s easy to use. You want something that doesn’t need a lot of training. Next, look for good safety features to keep everyone safe. Lastly, make sure it works well with your current tools and machines. This way, you can save money and improve your work!

Are There Any Diy Projects Or Plans For Building A Simple Automated System For A Metal Lathe Within The $5Price Range?You can find some simple DIY projects to automate a metal lathe. However, building one for only $5 is very hard. Most parts needed for automation cost more than that. You might be able to use old toys or scrap parts, but it will take time and creativity. Look online for ideas that match your budget!

What Safety Considerations Should Be Taken Into Account When Automating A Metal Lathe At A Budget Level?When automating a metal lathe, we should think about safety first. Always wear safety goggles to protect your eyes. Keep loose clothes and hair away from moving parts. You should also have emergency stop buttons in easy reach. Finally, make sure to read the instructions before you start working.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Under $5Metal Lathe Automation:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five related questions about metal lathe automation under $5: 1. What is a metal lathe? A metal lathe is a machine that shapes metal. It spins metal and helps us make things like tools. 2. How does automation help with metal lathes? Automation makes machines work on their own. This helps us save time and do a better job. 3. Can I build an automated lathe for under $5? Building a fully automated lathe for under $5 is very hard. You usually need more money for materials and tools. 4. Why is automation important? Automation is important because it helps us work faster. It also makes things more accurate and safe. 5. What can I make with a metal lathe? You can make many things with a metal lathe! You can create parts for toys, models, or even small machines.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Most Affordable Metal Lathe Automation Kits Available For Under $500?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you’re looking for affordable metal lathe automation kits under $500, there are a few options. The SainSmart CNC Kit is popular and easy to use. Another good choice is the Genmitsu CNC Kit, which is also good for beginners. You can find them online at places like Amazon or eBay. Remember to check the reviews to see what others think!”}},{“@type”: “Question”,”name”: “How Can I Retrofit An Existing Manual Metal Lathe For Automated Operation Without Exceeding A $5Budget?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To automate a manual metal lathe on a $5 budget, first look for old toys or gadgets. You can take their motors or gears to create small movements. You can use a simple switch to turn them on and off. Lastly, test everything carefully to make sure it works. Remember, safety first!”}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For In Low-Cost Automation Solutions For Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When looking for cheap automation solutions for metal lathes, you should check for a few important features. First, see if it’s easy to use. You want something that doesn’t need a lot of training. Next, look for good safety features to keep everyone safe. Lastly, make sure it works well with your current tools and machines. This way, you can save money and improve your work!”}},{“@type”: “Question”,”name”: “Are There Any Diy Projects Or Plans For Building A Simple Automated System For A Metal Lathe Within The $5Price Range?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can find some simple DIY projects to automate a metal lathe. However, building one for only $5 is very hard. Most parts needed for automation cost more than that. You might be able to use old toys or scrap parts, but it will take time and creativity. Look online for ideas that match your budget!”}},{“@type”: “Question”,”name”: “What Safety Considerations Should Be Taken Into Account When Automating A Metal Lathe At A Budget Level?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When automating a metal lathe, we should think about safety first. Always wear safety goggles to protect your eyes. Keep loose clothes and hair away from moving parts. You should also have emergency stop buttons in easy reach. Finally, make sure to read the instructions before you start working.”}}]}