Have you ever wondered how machines create perfect metal parts? This process often involves a tool called a lathe. A variable speed metal lathe is a powerful machine that can spin metal at different speeds. But how do you design one? That’s where CAD, or computer-aided design, comes into play.

Imagine being a modern inventor. You sit at your computer, using CAD software to create blueprints for your lathe. You can experiment with different designs and speeds without ever touching a piece of metal! It’s like magic, but it’s real engineering.

Did you know that the right speed on a lathe can make all the difference? It affects how smooth the final product is. Discovering the best design can help you build amazing projects. Whether you’re a hobbyist or a professional, understanding variable speed metal lathe CAD design is the key to elevating your work.

So, are you ready to dive into the world of metalworking? Let’s explore how these fascinating tools and techniques come together to create incredible things!

Variable Speed Metal Lathe Cad Design: Enhancing Precision And Flexibility

Understanding Variable Speed Metal Lathe CAD Design

Variable speed metal lathes are essential tools for precision work. With the right CAD design, you can customize settings easily. Imagine being able to adjust speeds for different materials instantly! This flexibility increases your efficiency and improves project outcomes. CAD software allows for 3D modeling, helping you visualize your designs better. Did you know that effective planning can save time and materials? Embracing these technologies in your projects is a game-changer!Understanding Variable Speed Lathes

Explanation of variable speed lathe technology. Benefits of using variable speed over traditional lathes.A variable speed lathe allows for easy speed changes. This means you can select the perfect speed for your project. It is better than traditional lathes in many ways. For example:

- Versatility: It handles different materials easily.

- Precision: It gives more control when shaping items.

- Efficiency: You work faster and save time.

This technology is helpful for both beginners and experts. You can achieve great results with less hassle!

What is a variable speed lathe?

A variable speed lathe is a tool that lets you change the speed while working. This helps you create smoother finishes and more accurate shapes. It is perfect for various materials and projects.

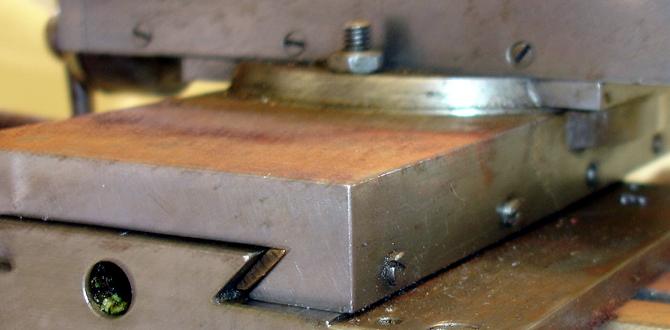

Essential Features of a Variable Speed Metal Lathe

Key components to consider for effective CAD design. Importance of speed control and adjustability.When picking a variable speed metal lathe, several key features stand out. First, speed control is crucial for precision. The ability to adjust speed makes it easier to handle different tasks. Think of it like changing gears in a bike—you wouldn’t want to ride uphill in the same gear as on a flat road! Next, look for a good range of speeds. Too few options can be like trying to find socks in a dark room! Also, reliable components mean less time fixing and more time creating.

| Feature | Importance |

|---|---|

| Speed Control | Allows for precision in design |

| Adjustability | Helps tackle various tasks |

| Quality Components | Reduces maintenance time |

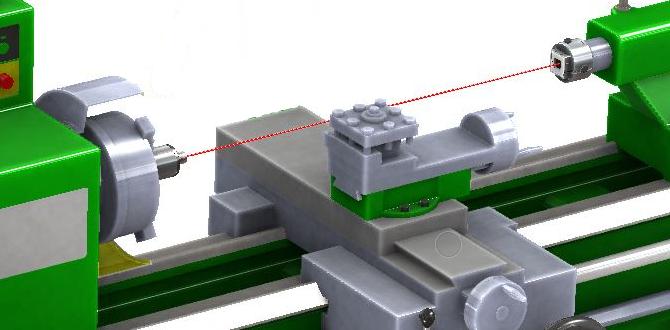

Designing the Lathe Model in CAD

Stepbystep process for creating a lathe design. Common pitfalls to avoid during the design phase.Creating a lathe model in CAD can be a fun yet tricky task. Start with a clear idea of your design. Sketch it out first—remember, this isn’t just doodling; it’s like a roadmap! Next, use CAD to create 3D shapes. Follow these steps:

| Step | Description |

|---|---|

| 1 | Draw the base for stability. |

| 2 | Add the spindle and tailstock components. |

| 3 | Include moving parts and adjust for size. |

| 4 | Check each part’s alignment. |

Watch out for common mistakes. Avoid cluttering your design; simplicity is key! Also, don’t forget to save your work often—nothing feels worse than losing hours of effort. If your lathe design makes the “beep” of doom, it’s time to review your measurements! Follow these tips, and you’ll be spinning those metal pieces like a pro!

Integrating Variable Speed Mechanisms in Design

Different types of variable speed mechanisms. How to effectively incorporate them into a CAD model.Variable speed mechanisms let machines run at different speeds. This flexibility is important for tasks that need precision. There are different types, such as:

- Mechanical Variators

- Electronic Speed Controllers

- Gearbox Adjustments

To add these features in a CAD model, you can:

- Use sketches to plan out the mechanism.

- Simulate movements to test speed changes.

- Adjust dimensions accurately for each part.

This allows you to create a precise and effective design for your project.

How to integrate variable speed mechanisms in a CAD design?

Focus on sketches and simulations to explore different designs. This helps you see how the parts work together with speed adjustments.

Testing and Simulation of CAD Designs

Importance of simulation in validating lathe designs. Tools and methods for testing variable speed lathe functionality.Testing and simulating CAD designs is key for variable speed lathes. These tests help ensure that the designs work as planned. Simulation validates designs by revealing any weaknesses. Engineers can use specific tools for testing, such as:

- Computer software for 3D simulations

- Physical prototypes for hands-on checks

- Performance metrics to measure speed and accuracy

This process saves time and money by catching errors early. Remember, a small problem can lead to big issues later. Testing is like a safety net for your design.

Why is simulation important for CAD designs?

Simulation helps confirm that designs perform correctly and meet safety standards. It allows engineers to see potential problems before actual production.

What tools help test a variable speed lathe’s functionality?

Essential tools include simulation software, gauges for measurements, and physical test models. Each tool plays a part in ensuring the lathe works smoothly.

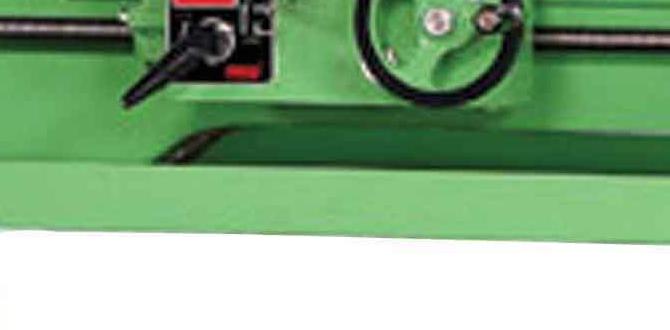

Practical Applications of Variable Speed Metal Lathes

Industries that utilize variable speed metal lathes. Realworld examples of CAD designed variable speed lathes in action.Many industries rely on variable speed metal lathes for their work. They are champs in making precise parts for everything from cars to aircrafts. For instance, a car manufacturer uses a variable speed lathe to shape engine parts. It ensures each piece fits perfectly, like a puzzle! Check out this table for more cool examples:

| Industry | Use of Variable Speed Metal Lathes |

|---|---|

| Automotive | Creating engine components |

| Aerospace | Machining precision parts |

| Manufacturing | Producing custom tools |

In the world of CAD designed lathes, flexibility is key. They allow users to change speeds easily, making them perfect for different tasks. One minute, you’re crafting a small part, and the next, you’re turning a hefty metal chunk—just like magic! These machines save time and help make top-quality products everywhere.

Maintenance and Optimization of Designed Lathes

Best practices for maintaining variable speed lathes. Tips for optimizing performance based on CAD design adjustments.Keeping your variable speed lathe in top shape is key for great performance. Regular maintenance is important. Clean the machine after each use. Lubricate moving parts regularly to avoid rust. Make sure to check the belt tension often. Here are some tips to optimize your lathe based on CAD design:

- Adjust feed rates for better results.

- Change settings based on the material used.

- Regularly update your CAD design for efficiency.

These practices help your lathe work well and last longer. Remember, a well-maintained machine is a happy machine!

What are some tips for maintaining a lathe?

Regular cleaning, lubrication, and checking belt tension are essential tips for maintaining a lathe. You can avoid many problems by following these steps.

Conclusion

In conclusion, a variable speed metal lathe with CAD design is powerful for crafting precise metal parts. It allows you to adjust speeds easily, improving your work quality. We encourage you to explore tutorials on CAD software and practice using lathes. This hands-on experience will boost your skills and confidence. Happy designing and machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Variable Speed Metal Lathe Cad Design:Sure! Variable speed metal lathes help you shape metal into different forms. When designing one using CAD (which means Computer-Aided Design), you can easily make changes. You can see how the lathe will work before you build it. This helps make sure everything fits together nicely. It’s a fun way to create cool metal projects!

Sure! Please provide the question you would like me to answer.

What Are The Key Design Considerations For Integrating A Variable Speed Mechanism In A Metal Lathe Cad Model?When you design a variable speed mechanism for a metal lathe, you should think about a few important things. First, make sure it fits well with the lathe’s parts. You also need to consider how fast you want the lathe to spin. The motor should be strong enough to handle different speeds without breaking. Finally, ensure that it’s easy for users to control the speed while they work.

How Can Cad Software Be Utilized To Simulate The Mechanical Components Of A Variable Speed Lathe For Optimal Performance?You can use CAD software to create a 3D model of a variable speed lathe. This means you can see how different parts fit together. You can also change speeds in the software to see how it affects the machine. This helps us find the best settings for smooth operation. By testing it in the program first, we can make sure it works well before building it.

What Types Of Variable Speed Drive Systems Are Most Commonly Used In Metal Lathe Designs, And How Can They Be Represented In Cad?Metal lathes often use belt drives and electronic drives to control speed. Belt drives are simple and easy to fix. Electronic drives can change speed smoothly and quickly. In Computer-Aided Design (CAD), we can show these systems using simple shapes and lines to represent the parts. We can add notes to explain how they work.

How Do You Optimize The Design Of The Lathe Bed And Spindle To Accommodate The Variable Speed Features While Ensuring Stability And Precision?To make the lathe bed and spindle work well with different speeds, we can use strong materials. This helps keep everything steady when it moves fast. We also design the shape to avoid vibrations, which keeps our work accurate. Finally, we test different setups to find what works best for both speed and stability.

What Are The Challenges Of Including Automation Features In A Variable Speed Metal Lathe Design, And How Can These Be Addressed Using Cad Tools?Including automation features in a variable speed metal lathe can be tricky. We might face problems like complex designs or parts not fitting together. Using CAD (Computer-Aided Design) tools can help us see how each piece should look and fit. These tools let us test ideas and fix issues easily before we build anything. This way, we can make a better lathe that works well with automation!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Variable Speed Metal Lathe Cad Design:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Variable speed metal lathes help you shape metal into different forms. When designing one using CAD (which means Computer-Aided Design), you can easily make changes. You can see how the lathe will work before you build it. This helps make sure everything fits together nicely. It’s a fun way to create cool metal projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Design Considerations For Integrating A Variable Speed Mechanism In A Metal Lathe Cad Model?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you design a variable speed mechanism for a metal lathe, you should think about a few important things. First, make sure it fits well with the lathe’s parts. You also need to consider how fast you want the lathe to spin. The motor should be strong enough to handle different speeds without breaking. Finally, ensure that it’s easy for users to control the speed while they work.”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Utilized To Simulate The Mechanical Components Of A Variable Speed Lathe For Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use CAD software to create a 3D model of a variable speed lathe. This means you can see how different parts fit together. You can also change speeds in the software to see how it affects the machine. This helps us find the best settings for smooth operation. By testing it in the program first, we can make sure it works well before building it.”}},{“@type”: “Question”,”name”: “What Types Of Variable Speed Drive Systems Are Most Commonly Used In Metal Lathe Designs, And How Can They Be Represented In Cad?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes often use belt drives and electronic drives to control speed. Belt drives are simple and easy to fix. Electronic drives can change speed smoothly and quickly. In Computer-Aided Design (CAD), we can show these systems using simple shapes and lines to represent the parts. We can add notes to explain how they work.”}},{“@type”: “Question”,”name”: “How Do You Optimize The Design Of The Lathe Bed And Spindle To Accommodate The Variable Speed Features While Ensuring Stability And Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make the lathe bed and spindle work well with different speeds, we can use strong materials. This helps keep everything steady when it moves fast. We also design the shape to avoid vibrations, which keeps our work accurate. Finally, we test different setups to find what works best for both speed and stability.”}},{“@type”: “Question”,”name”: “What Are The Challenges Of Including Automation Features In A Variable Speed Metal Lathe Design, And How Can These Be Addressed Using Cad Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Including automation features in a variable speed metal lathe can be tricky. We might face problems like complex designs or parts not fitting together. Using CAD (Computer-Aided Design) tools can help us see how each piece should look and fit. These tools let us test ideas and fix issues easily before we build anything. This way, we can make a better lathe that works well with automation!”}}]}