Have you ever wondered how a simple piece of metal can be shaped into something amazing? A variable speed metal lathe drive system can do just that! This machine helps turn raw metal into beautiful and precise parts for various projects.

Imagine you have a block of metal. With the right tools, you can craft it into anything, from toys to car parts. It’s like magic, but it’s all science and engineering! The key player in this process is the variable speed drive system.

This system controls the speed of the lathe. Why is speed important? Different tasks require different speeds. A slower speed is great for delicate work, while faster speeds help remove metal quickly. Knowing how to adjust this speed makes all the difference.

Fun fact: did you know that the first lathes were used thousands of years ago? They have come a long way since then! Today, the variable speed metal lathe drive system helps hobbyists and professionals create incredible designs and products.

This article will explore how this system works and why it’s so important. Let’s dive into the world of metalworking and discover the wonders of variable speed lathe technology!

Understanding The Variable Speed Metal Lathe Drive System

Variable Speed Metal Lathe Drive System

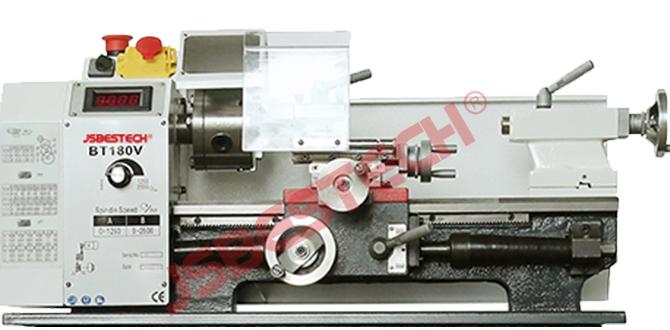

Want to craft precise metal pieces? A variable speed metal lathe drive system is key! This system allows you to adjust the speed easily, making your work smooth and efficient. Imagine working on different projects, from small parts to large pieces. This flexibility helps beginners and experts alike. Did you know that lathes have been around for thousands of years? They have evolved a lot, making metalworking more exciting today. With a variable speed system, every turn can lead to new creations!What is a Variable Speed Metal Lathe Drive System?

Definition and functionality of a variable speed metal lathe drive system.. Importance of variable speed in metalworking applications..A variable speed metal lathe drive system is like the superhero of metalworking. It lets you change speeds without a hassle. This flexibility helps you cut, shape, and finish metal pieces smoothly and accurately. Imagine trying to slice bread with a rock! That’s how important speed control is in metalwork. With the right speed, every turn brings you closer to perfection.

| Feature | Benefit |

|---|---|

| Speed Control | Helps in achieving better finish |

| Versatility | Works on different materials easily |

| Efficiency | Saves time and energy |

Advantages of Variable Speed Drive Systems

Enhanced precision and control in machining operations.. Increased versatility for various materials and applications..Using a variable speed drive system is like having a magic wand for your metal lathe! 🎩 It gives you better precision and control over your machining tasks. This means fewer mistakes, making you the superhero of your workshop. Plus, you can work on many materials with ease. Imagine switching from soft plastic to hard steel without breaking a sweat! The drive system’s flexibility allows you to tackle various projects, keeping your creativity buzzing like a busy bee.

| Advantages | Details |

|---|---|

| Precision | Improves accuracy for better results. |

| Versatility | Works with different materials and projects. |

Disadvantages and Limitations

Common issues faced with variable speed systems.. Maintenance and repair considerations..Variable speed systems come with some challenges. One common issue is wear and tear. Constant changes in speed can stress parts over time. Maintenance and repairs are crucial. Without proper care, problems may arise. Regular checks can prevent big issues. Learning how to fix basic faults is important too. Here are some concerns:

- Frequent adjustments can wear out components quickly.

- Finding replacement parts might be difficult.

- Unusual noises can signal problems needing attention.

What are the common issues faced with variable speed systems?

Common issues include worn out components and difficulties in finding replacement parts. Regular maintenance can minimize these problems.

What are key maintenance considerations for variable speed lathe systems?

Check belts, lubrication, and electrical connections regularly. This helps keep the system running smoothly and extends its life.

Choosing the Right Variable Speed Drive for Your Lathe

Key factors to consider: power, speed range, and torque.. Recommendations for specific applications and user levels..Choosing the right drive for your lathe is important for success. Here are key factors to consider:

- Power: Make sure it can handle your tasks.

- Speed Range: More speed options help with different materials.

- Torque: Higher torque means better performance for tough jobs.

For beginners, a simple model works well. Experienced users may need advanced features. Think about what you will make before deciding. This choice will help you work better and enjoy your projects more.

What should I consider when buying a variable speed drive?

Pay attention to power, speed range, and torque. These features determine how well your lathe performs tasks.

Installation and Setup Guidelines

Stepbystep process for installing a variable speed drive system.. Tips for optimal setup and calibration..To install a variable speed drive system, start by gathering all tools and parts. First, turn off power to the lathe. Next, mount the drive motor securely. Then, connect the wiring according to the manual. After that, set up the control panel. Finally, double-check connections for safety.

For optimal setup and calibration, consider these tips:

- Adjust the belt tension correctly.

- Calibrate the speed settings precisely.

- Test the system at various speeds before use.

What should I do before starting the installation?

Before you start, ensure your workspace is clean and organized. It’s important to have all tools ready. Proper planning helps avoid mistakes.

Common Troubleshooting Tips

Identifying and resolving common issues.. Maintenance practices to prolong system life..Is your metal lathe drive system acting up? Don’t worry! Here are some common fixes. First, check connections. Loose wires can cause issues. Next, listen for strange sounds. This might mean parts need lubrication.

To keep your system running well, use these easy maintenance tips:

- Clean regularly to remove dust.

- Lubricate moving parts to reduce wear.

- Inspect belts for wear and replace if needed.

By following these steps, you can enjoy a longer-lasting and smoother-running machine!

What should I do if my lathe suddenly stops?

Check the power supply and any emergency stop buttons first. Then, inspect the drive system for issues or loose parts.

Comparison with Fixed Speed Lathe Systems

Pros and cons of variable speed vs. fixed speed systems.. Cost analysis and overall value proposition..Variable speed systems offer flexibility that fixed speed systems do not. This means you can adjust the speed for different tasks. Fixed speed lathes are simpler and usually cost less. However, they can limit your options. Here’s a quick comparison:

- Pros of Variable Speed: Flexible speed adjustments, better for various materials.

- Cons of Variable Speed: Generally more expensive and complex.

- Pros of Fixed Speed: Lower cost, easier to use.

- Cons of Fixed Speed: Less versatility, not ideal for all tasks.

In terms of cost, fixed speed lathes tend to save money at first but may lack value over time. Investing a bit more in a variable speed lathe can boost overall performance. It might save you money on projects, thanks to its adaptability.

Are variable speed lathes worth the cost?

Yes, the ability to switch speeds can make projects easier and save time.

What are the best uses for each type?

- Variable speed: Complex projects requiring different materials.

- Fixed speed: Basic tasks that use the same material.

Future Trends in Variable Speed Technology

Innovations and advancements in drive systems.. Predictions for the future of metal lathe technology..Exciting changes are coming for metal lathe tech! From super-smart sensors to eco-friendly power systems, the future looks bright. Expect innovations that make metal lathes faster and easier to use, helping makers create with less fuss. Predictions say more machines will have adaptive drive systems that adjust speed automatically. That means your lathe might become the next best friend in your workshop—just watch out, it might ask for a coffee break!

| Innovation | Description |

|---|---|

| Smart Sensors | Help machines adjust to changing conditions for smoother operation. |

| Eco-friendly Power | Use less energy, making your projects better for the planet. |

| Adaptive Systems | Automatically change speed based on the material being worked. |

Conclusion

In conclusion, a variable speed metal lathe drive system gives you control over machining speed. This means you can achieve better results on different materials. It also improves your project efficiency. If you’re interested in learning more, check out tutorials online or visit a local workshop. Exploring this technology can boost your skills and creativity in metalworking!FAQs

What Are The Advantages Of Using A Variable Speed Drive System In Metal Lathes Compared To Traditional Fixed-Speed Systems?Using a variable speed drive system in metal lathes is better than fixed-speed systems. You can change the speed easily. This helps you work on different materials better. It also saves energy because you only use what you need. Plus, it makes your work smoother and reduces wear on the machine.

How Does The Control Mechanism Work In A Variable Speed Metal Lathe Drive System?A variable speed metal lathe uses a control mechanism to change how fast it spins. We can turn a dial or push buttons to set the speed we want. The machine reads this setting and adjusts its motor to match. This helps us cut metal smoothly and safely at different speeds. It makes our work easier and more precise!

What Types Of Motors Are Typically Used In Variable Speed Metal Lathe Drive Systems, And What Factors Influence Their Selection?In variable speed metal lathes, we often use DC (direct current) motors and AC (alternating current) motors. DC motors can change speed easily, which is great for different tasks. AC motors are strong and very reliable for heavy work. When picking a motor, we think about how much power we need and how fast we want it to go. We also consider how long the motor will run and how much space we have for it.

How Does The Use Of A Variable Speed Drive Impact The Machining Performance And Finish Quality In Metalworking Applications?Using a variable speed drive (VSD) helps machines run at different speeds. This means you can choose the best speed for each job. When we use the right speed, we get better cuts and smoother finishes on metal. It also helps the machines work more efficiently and last longer. So, a VSD makes the work easier and the results nicer!

What Maintenance Practices Are Essential For Ensuring Optimal Performance And Longevity Of A Variable Speed Drive System In A Metal Lathe?To keep a variable speed drive system in a metal lathe working well, you need to do some simple things. First, check the connections and wires for any wear or damage. Next, clean out dust and dirt from the machine regularly. You should also check and change the oil or grease if needed. Finally, listen for strange sounds and fix them quickly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Variable Speed Drive System In Metal Lathes Compared To Traditional Fixed-Speed Systems? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a variable speed drive system in metal lathes is better than fixed-speed systems. You can change the speed easily. This helps you work on different materials better. It also saves energy because you only use what you need. Plus, it makes your work smoother and reduces wear on the machine.”}},{“@type”: “Question”,”name”: “How Does The Control Mechanism Work In A Variable Speed Metal Lathe Drive System? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A variable speed metal lathe uses a control mechanism to change how fast it spins. We can turn a dial or push buttons to set the speed we want. The machine reads this setting and adjusts its motor to match. This helps us cut metal smoothly and safely at different speeds. It makes our work easier and more precise!”}},{“@type”: “Question”,”name”: “What Types Of Motors Are Typically Used In Variable Speed Metal Lathe Drive Systems, And What Factors Influence Their Selection? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In variable speed metal lathes, we often use DC (direct current) motors and AC (alternating current) motors. DC motors can change speed easily, which is great for different tasks. AC motors are strong and very reliable for heavy work. When picking a motor, we think about how much power we need and how fast we want it to go. We also consider how long the motor will run and how much space we have for it.”}},{“@type”: “Question”,”name”: “How Does The Use Of A Variable Speed Drive Impact The Machining Performance And Finish Quality In Metalworking Applications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a variable speed drive (VSD) helps machines run at different speeds. This means you can choose the best speed for each job. When we use the right speed, we get better cuts and smoother finishes on metal. It also helps the machines work more efficiently and last longer. So, a VSD makes the work easier and the results nicer!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Essential For Ensuring Optimal Performance And Longevity Of A Variable Speed Drive System In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a variable speed drive system in a metal lathe working well, you need to do some simple things. First, check the connections and wires for any wear or damage. Next, clean out dust and dirt from the machine regularly. You should also check and change the oil or grease if needed. Finally, listen for strange sounds and fix them quickly.”}}]}