Have you ever wondered how precision and power come together in one tool? A variable speed metal lathe quill does just that! This amazing machine helps you shape metal with great accuracy. It’s like having a supercharged pencil that can craft anything you imagine.

Picture yourself in a workshop, surrounded by the hum of machines. You’re ready to create something unique. What if you had a tool that could adjust speed to fit your project? That’s the magic of the variable speed metal lathe quill. It offers flexibility and control, allowing you to cut and shape metal exactly how you want.

Did you know that the right speed can make all the difference? With a variable speed metal lathe quill, you can change the pace as you work. This feature can help you avoid mistakes and make your projects turn out perfectly. Isn’t that interesting?

Join me as we dive deeper into the world of metal lathes. You’ll discover how this fantastic tool can help you build your next masterpiece. Whether you’re a beginner or an expert, there’s always something new to learn!

Understanding Variable Speed Metal Lathe Quill Features & Benefits

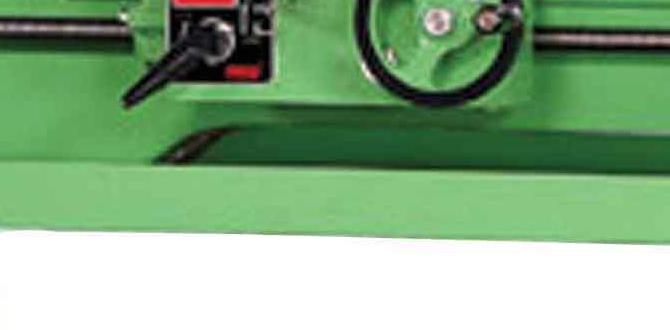

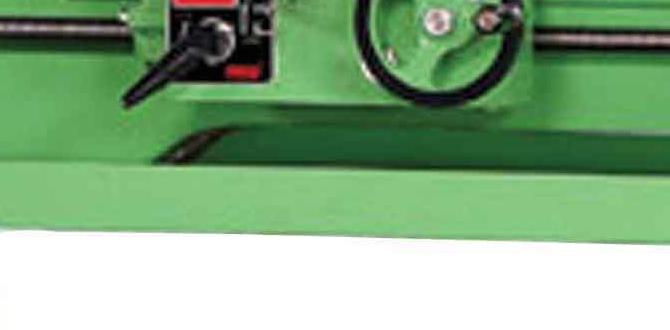

Variable Speed Metal Lathe Quill

The variable speed metal lathe quill offers flexibility in machining projects. With adjustable speed settings, it allows users to work on various materials efficiently. Imagine creating precise parts for a model car or crafting unique tools! This quill helps achieve smooth finishes and intricate designs. Did you know that controlling speed can also extend the life of your tools? Understanding how to use a variable speed quill can enhance your crafting experience tremendously.What is a Variable Speed Metal Lathe Quill?

Definition and function of a quill in metal lathes. Importance of variable speed in lathe operations.A quill in a metal lathe is like the superhero sidekick of machining! It holds the cutting tool and moves it up and down, helping to shape the metal. Now, the variable speed part is super important. It lets you control how fast or slow the quill moves. Fast speeds are great for quick cuts, while slower speeds give you more control for detailed work. The right speed can make a big difference, just like using the right amount of seasoning in your dinner!

| Quill Functions | Speed Importance |

|---|---|

| Holds Cutting Tool | Fast for Quick Cuts |

| Up and Down Motion | Slow for Detailed Work |

Benefits of Using a Variable Speed Metal Lathe Quill

Enhanced precision and quality of machining. Flexibility for a variety of materials and projects.Using a variable speed metal lathe quill offers many perks. First, it boosts precision in machining. This means you get cleaner cuts and better finishes. Who doesn’t want their work to shine? Plus, it’s flexible! You can use it for different materials like wood, aluminum, or even that strange metal from your uncle’s old toolshed. It’s like having a Swiss Army knife for your projects—handy and versatile!

| Benefit | Description |

|---|---|

| Precision | Cleaner cuts and improved finishes. |

| Flexibility | Works with a variety of materials and projects. |

How to Choose the Right Variable Speed Metal Lathe Quill

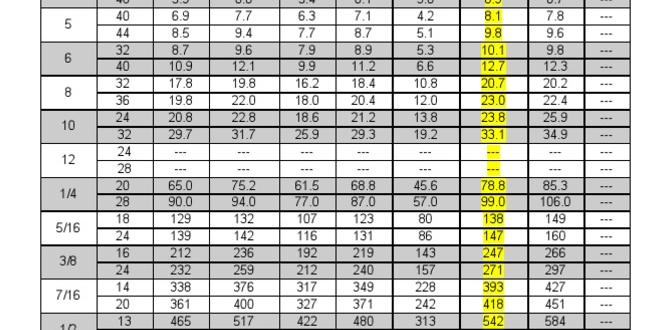

Factors to consider (size, power, and material). Recommended brands and models based on user needs.Choosing the right quill for your variable speed metal lathe can feel like dating—pick wisely! First, think about size. Make sure it fits your machine snugly; nobody likes a loose fit. Next, consider power. More power means smoother operation, like a well-oiled dance. Lastly, material matters. Go for durable options like steel to avoid premature break-ups.

Here’s a handy table of recommended brands:

| Brand | Model | Best For |

|---|---|---|

| Grizzly | G4003G | Hobbyists |

| Jet | JWL-1442 | Professionals |

| Shop Fox | W1752 | Heavy-duty |

Ask around. The best lathe quill is the one that meets your unique needs. A little research can go a long way—like wearing clean socks on a first date!

Maintenance Tips for Variable Speed Metal Lathe Quills

Regular inspections and cleaning procedures. Lubrication best practices to ensure longevity.Taking care of your metal lathe quill is key to keeping it running smooth. Regular inspections help catch any problems before they really get going. Give your quill a good wipe with a clean cloth and check for wear. A little routine cleaning can go a long way!

Next, let’s talk about lubrication. Apply the right oil to the moving parts. This ensures they don’t wear out too soon. Think of it like giving your quill a nice spa day! Lubricated parts can last up to 30% longer, so don’t skip this step. Keep that quill happy, and it will repay you with excellent performance!

| Maintenance Task | Frequency |

|---|---|

| Inspection and Cleaning | Every 20 hours of use |

| Lubrication | Every 40 hours of use |

Common Issues and Troubleshooting with Variable Speed Metal Lathe Quills

Identifying typical problems (e.g., inconsistent speed). Stepbystep troubleshooting guide.Lathe users sometimes face hiccups like inconsistent speed. It can feel like the machine is auditioning for a dance show, spinning unpredictably. To troubleshoot, start by checking the power supply. Then inspect the belt—it’s the superhero of the machine, keeping everything running smoothly. Lastly, confirm that the speed settings are correctly adjusted. Don’t forget, even lathes need a little TLC! Here’s a quick guide:

| Problem | Possible Cause | Solution |

|---|---|---|

| Inconsistent Speed | Loose belt | Check and tighten the belt |

| Unusual Noises | Worn bearings | Replace bearings |

| Machine Stalling | Overloaded spindle | Reduce the load |

Upgrading Your Variable Speed Metal Lathe Quill

Signs it’s time to upgrade. Benefits of modern quills and technology advancements.Is your quill starting to creak louder than a haunted house door? It’s time for an upgrade! Signs like inconsistent cuts or poor performance signal that your old quill is ready for retirement. Modern quills come with cool features like precise movements and advanced materials that last longer. These upgrades make your work easier and faster, leaving more time for snacks and high-fives!

| Old Quill Issues | Benefits of Modern Quills |

|---|---|

| Creaking sounds | Smoother operations |

| Inconsistent cuts | Precise adjustments |

| Frequent breakdowns | Durable materials |

Real-World Applications of Variable Speed Metal Lathe Quills

Industries that rely on metal lathes (e.g., automotive, aerospace). Case studies showcasing successful projects using variable speed quills.Many industries use metal lathes, and not just for fun projects! The automotive and aerospace sectors rely heavily on these machines. A variable speed metal lathe quill allows for precise work, making it perfect for crafting parts that keep cars and planes flying smoothly. For instance, a company once made a lightweight aircraft component with this tool, reducing weight by 30%. That’s like dropping a puppy from a balloon! Below, find a few industries that love metal lathes:

| Industry | Uses |

|---|---|

| Automotive | Parts manufacturing and repairs |

| Aerospace | Lightweight component crafting |

| Manufacturing | Creating machine parts |

Conclusion

In summary, a variable speed metal lathe quill is an important tool for shaping metal precisely. It lets you adjust speeds easily, making your work smoother. We recommend exploring different lathe models to find one that fits your needs. You can learn more by reading guides or watching tutorials online. Get started with your metalworking projects today!FAQs

What Are The Advantages Of Using A Variable Speed Metal Lathe Quill Compared To A Fixed Speed Model?A variable speed metal lathe quill lets you change how fast the machine spins. This is great because you can work on different materials better. For soft materials, you can go slower, which helps you cut cleanly. For hard materials, you can speed it up to get the job done faster. This flexibility makes your work easier and can help you make better parts!

How Does The Variable Speed Mechanism In A Metal Lathe Quill Work To Control Spindle Rpm?A metal lathe is a machine that shapes metal. The quill is part of the lathe that holds the tool. The variable speed mechanism lets us change how fast the spindle turns. When you adjust a lever or turn a knob, it changes the speed. This helps you work better with different types of metal and projects.

What Are The Best Practices For Maintaining The Variable Speed System In A Metal Lathe Quill?To keep the variable speed system in your metal lathe quill working well, you should check it often. First, clean the quill from dust and oil to avoid sticky parts. Next, make sure all belts are tight and not worn out. It’s also important to lubricate moving parts with the right oil. Lastly, always follow the manufacturer’s instructions for the best care.

How Do You Troubleshoot Common Issues Related To The Variable Speed Functionality Of A Metal Lathe Quill?To troubleshoot problems with the variable speed on a metal lathe quill, first, check the power. Make sure the lathe is plugged in and turned on. Then, look at the belts and pulleys. They might be loose or broken. If the speed control doesn’t work, you can check if any wires are loose or damaged. Finally, clean any dust or dirt from the controls. Keeping everything clean helps the lathe work better!

What Types Of Materials And Applications Benefit Most From A Variable Speed Metal Lathe Quill Setup?A variable speed metal lathe quill setup is great for different materials. Soft metals like aluminum and brass are easy to work with. Hard metals like steel or titanium need careful speed adjustments to avoid damage. You can use it for making parts, tools, or even crafts. This flexibility helps you create better and more precise items.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Variable Speed Metal Lathe Quill Compared To A Fixed Speed Model? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A variable speed metal lathe quill lets you change how fast the machine spins. This is great because you can work on different materials better. For soft materials, you can go slower, which helps you cut cleanly. For hard materials, you can speed it up to get the job done faster. This flexibility makes your work easier and can help you make better parts!”}},{“@type”: “Question”,”name”: “How Does The Variable Speed Mechanism In A Metal Lathe Quill Work To Control Spindle Rpm? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe is a machine that shapes metal. The quill is part of the lathe that holds the tool. The variable speed mechanism lets us change how fast the spindle turns. When you adjust a lever or turn a knob, it changes the speed. This helps you work better with different types of metal and projects.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Maintaining The Variable Speed System In A Metal Lathe Quill? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the variable speed system in your metal lathe quill working well, you should check it often. First, clean the quill from dust and oil to avoid sticky parts. Next, make sure all belts are tight and not worn out. It’s also important to lubricate moving parts with the right oil. Lastly, always follow the manufacturer’s instructions for the best care.”}},{“@type”: “Question”,”name”: “How Do You Troubleshoot Common Issues Related To The Variable Speed Functionality Of A Metal Lathe Quill? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot problems with the variable speed on a metal lathe quill, first, check the power. Make sure the lathe is plugged in and turned on. Then, look at the belts and pulleys. They might be loose or broken. If the speed control doesn’t work, you can check if any wires are loose or damaged. Finally, clean any dust or dirt from the controls. Keeping everything clean helps the lathe work better!”}},{“@type”: “Question”,”name”: “What Types Of Materials And Applications Benefit Most From A Variable Speed Metal Lathe Quill Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A variable speed metal lathe quill setup is great for different materials. Soft metals like aluminum and brass are easy to work with. Hard metals like steel or titanium need careful speed adjustments to avoid damage. You can use it for making parts, tools, or even crafts. This flexibility helps you create better and more precise items.”}}]}