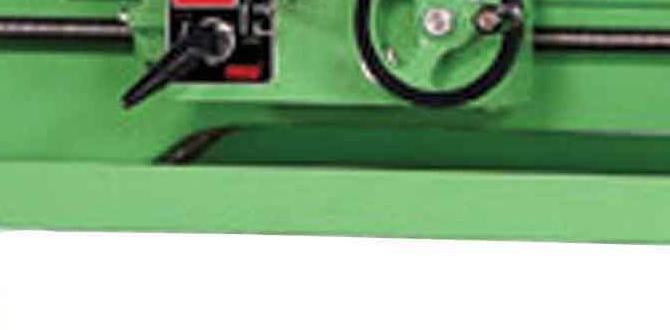

Have you ever watched a metal lathe spin? It’s like magic! A metal lathe shapes pieces of metal into perfect forms. But did you know that the speed and torque of a lathe can change everything?

Variable speed metal lathes are amazing tools. They can adjust how fast they spin and how much force they use. Think about it. If you need to cut through thick metal, you want a lot of torque. But for delicate work, you need a slower, gentle touch. Isn’t that cool?

This article will explore how variable speed affects torque. We’ll dive into why this matters in the workshop. Get ready to discover some fun facts about metal lathes that might surprise you!

Variable Speed Metal Lathe Torque: Understanding Its Importance

Variable Speed Metal Lathe Torque

Variable speed metal lathes offer flexibility by adjusting speed and torque for various tasks. This feature enhances precision and productivity in crafting metal parts. Did you know that many beginners find these lathes easier to use? With the right torque settings, you can reduce the risk of damaging materials. Imagine expertly shaping metal with ease! Learning how to adjust speed and torque opens new possibilities for both hobbyists and professionals. Don’t miss out on discovering this powerful tool.What is Torque in Metal Lathes?

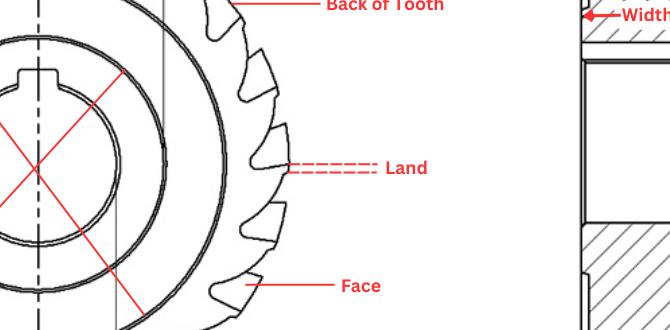

Definition of torque in the context of metal lathes. Importance of torque in machining processes.Torque in metal lathes is the turning force that helps shape materials. Imagine trying to open a tight jar lid. The strength you use to twist it is similar to torque in machining. It’s crucial because strong torque ensures smooth cuts and better results. Without enough torque, machines can struggle or even stall. Proper torque allows for quick and accurate work. This makes it a key factor in any metal shaping process.

Why is torque important in machining?

Torque plays a vital role in machining. It affects the speed and quality of cuts. High torque helps machines cut through tough materials easily. Without it, the machining process becomes slower and less efficient. This can lead to mistakes and wasted materials. Keeping the right torque boosts productivity and ensures quality work.

How Variable Speed Mechanisms Affect Torque

Explanation of variable speed drive systems. Impact of RPM changes on torque output.Variable speed drive systems add a fun twist to how machines work. They let you change the RPM, which is the number of times something spins in a minute. This change affects torque, or how powerful the spin is. Imagine trying to spin a heavy pizza! If you go too fast, the toppings fly off! So, adjusting speed can really boost torque output. Below is a table to show how different RPM levels impact torque:

| RPM | Torque Output |

|---|---|

| 100 | Low |

| 500 | Medium |

| 1000 | High |

So remember, with variable speeds, you can reach the sweet spot for your machining needs. It’s all about finding that perfect speed—much like finding the right dance tempo!

Factors Influencing Torque in Metal Lathes

Material properties and their effects on torque. Tool selection and its relationship with torque requirements. Lathe design features that contribute to torque.Many factors affect torque in metal lathes. First, material properties play a big role. Softer materials need less torque. Harder materials require more force. Second, tool selection is important. A sharp tool cuts easily and uses less torque. Dull tools take more power. Lastly, lathe design features also matter. A sturdy design can handle higher torque levels. In summary, knowing these factors helps optimize performance.

How do material properties affect torque?

Softer materials need less torque, while harder ones require more. Choosing the right material is key for effective machining.

What tool selection affects torque requirements?

- Sharp tools cut better and reduce torque.

- Dull tools need more force and increase torque demands.

How do lathe design features impact torque?

Sturdy designs manage higher torque. Features like strong frames help maintain efficiency.

Calculating Torque for Variable Speed Metal Lathes

Formula for calculating torque. Examples of torque calculations for different materials and settings.Calculating torque isn’t as tricky as it sounds, promise! You can use the formula: Torque = Power / Angular Velocity. For instance, let’s say you’re working with aluminum. If your lathe uses 2 horsepower and rotates at 300 RPM, the torque is around 4.24 foot-pounds. Wow, the metal’s really feeling the love! For harder materials like steel, the torque increases, leading to a bit more work for the machine. Here’s a handy table for quick reference:

| Material | Horsepower | RPM | Torque (ft-lbs) |

|---|---|---|---|

| Aluminum | 2 | 300 | 4.24 |

| Steel | 3 | 200 | 9.00 |

| Brass | 1.5 | 400 | 3.70 |

Isn’t math fun? It’s like a puzzle for metalworkers!

Benefits of Using Variable Speed Metal Lathes

Advantages of torque flexibility in machining. Higher precision and efficiency in operations.Using a variable speed metal lathe means you get more control. With adjustable torque, you can tackle tough materials without a sweat. It’s like having a superpower in your workshop! This flexibility leads to higher precision. You can smoothly change speeds for any project, which boosts efficiency. No more struggling with the wrong settings! Plus, you’ll shine bright like a diamond in your machining skills. Who knew making metal could be this fun?

| Benefits | Description |

|---|---|

| Torque Flexibility | Control over speed for various materials |

| Higher Precision | Reduced errors and improved results |

| Increased Efficiency | Faster setup and operation time |

Common Applications of Variable Speed Metal Lathes

Industries that frequently use variable speed lathes. Specific projects that benefit from adjustable torque.From car making to boat repairs, variable speed metal lathes are real heroes in many industries. They are great for crafting unique parts that need different speeds and torques. Machinists love them for their ability to make precise cuts. This flexibility also shines in hobbies like model making. Whether you’re whipping up tiny gears or big car parts, having adjustable torque helps get the job done right. And let’s be honest: who doesn’t want a machine that can go fast and slow, like a teenager deciding what to wear?

| Industry | Applications |

|---|---|

| Automotive | Parts manufacturing |

| Aerospace | Precision components |

| Marine | Boat repairs |

| Hobbyists | Model making |

Maintenance Tips for Optimal Torque Performance

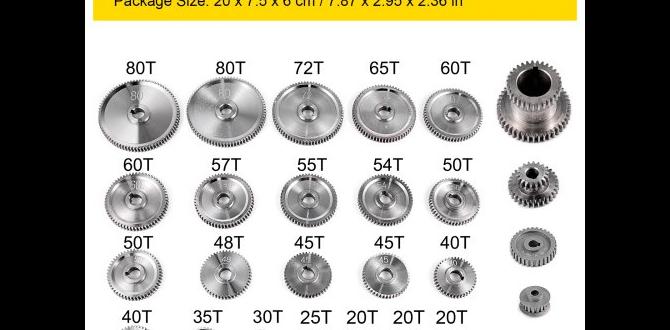

Regular checks and maintenance routines to preserve torque efficiency. Importance of lubrication and parts inspection.Keeping your metal lathe in shape is crucial for strong torque performance. Regular checks can save you from disaster, like a runaway lathe! Check the belts, gears, and all the moving parts. Make sure they’re not playing hide and seek! Lubrication is your best friend—without it, your lathe may sound like a rusty robot. A quick inspection can extend your tool’s life and keep that torque working like a charm.

| Maintenance Task | Frequency |

|---|---|

| Inspect belts | Weekly |

| Lubricate moving parts | Every use |

| Check gears | Monthly |

| Clean lathe | After each project |

These steps can help maintain torque efficiency. Remember, a little care goes a long way. And hey, better safe than sorry, right?

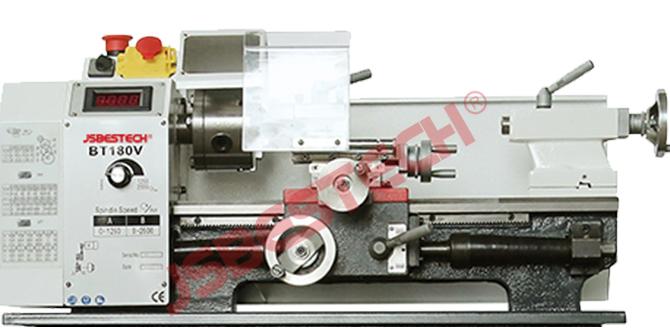

Choosing the Right Variable Speed Metal Lathe

Key specifications to consider for torque performance. Comparison of top metal lathe brands and models on the market.Selecting the perfect variable speed metal lathe is key for good torque performance. Look at specifications like power, speed range, and torque ratings. Top brands like Smithy, Grizzly, and Jet offer models that meet diverse needs. Comparing these options helps you find the best fit for your projects.

- Power: More power means better torque.

- Speed Range: Wider ranges give more control.

- Torque Ratings: Higher ratings allow for tougher materials.

What should I consider for torque performance?

Key factors include power, speed range, and torque ratings. These numbers help you know how well the lathe can handle different tasks, making your work easier and more efficient.

Troubleshooting Torque Issues in Metal Lathes

Common problems related to torque and their solutions. How to identify and fix torquerelated challenges during machining.Torque problems in metal lathes can make your project feel like a game of whack-a-mole. Luckily, most issues have clear solutions. For instance, if you sense a lack of power during cuts, your lathe settings might need adjusting. Check if the belt is tight enough; a loose belt is like wearing floppy shoes while running. Also, make sure to clean the spindle and change worn gears to keep things spinning smoothly. Here’s a handy table to help troubleshoot:

| Problem | Solution |

|---|---|

| Low torque | Adjust lathe settings and check belt tension. |

| Strange noises | Inspect components for wear and tear. |

| Inconsistent cuts | Clean the spindle and replace dull tools. |

Identifying these challenges early can save you time and a headache. Remember, keeping your lathe in shape is key to smooth machining! So, don’t let torque troubles get the best of you. Let’s keep that metal spinning like your favorite tune!

Conclusion

In conclusion, variable speed metal lathes offer flexible torque for different tasks. They help you control the cutting speed based on your material. This feature improves precision and efficiency in your projects. If you’re interested, explore more about lathes and their uses. Understanding how they work can boost your skills and make your work easier and more enjoyable!FAQs

Sure! Here Are Five Related Questions On The Topic Of Variable Speed Metal Lathe Torque:Sure! A variable speed metal lathe helps you shape metal pieces. The torque is how much power it uses to do that. Higher torque means the lathe can move faster and handle tougher jobs. You can change the speed to fit what you’re making. This means you have more control, making your work easier and better!

Sure! Please provide the question you’d like me to answer.

How Does The Torque Output Of A Variable Speed Metal Lathe Change With Different Spindle Speeds?When you change the spindle speed on a metal lathe, the torque changes too. At lower speeds, the lathe can give more torque. This helps when you need to cut hard materials. As the speed gets higher, the torque usually gets lower. So, you pick the speed based on what you’re working on!

What Are The Advantages Of Having Adjustable Torque Settings In A Variable Speed Metal Lathe For Different Materials?Adjustable torque settings help you control how hard the lathe works. This is important when you use different materials like wood or metal. If the torque is too high, you might break something. If it’s too low, you can’t cut properly. So, having the right setting helps you work better and safer!

How Can One Determine The Optimal Speed And Torque Settings For Machining Specific Metal Alloys On A Variable Speed Lathe?To find the best speed and torque (turning force) for cutting metal alloys, you can start by checking the material’s guidelines. These guidelines tell you the ideal speed for different metals. You can also test by starting at a low speed and adjusting up or down as you go. Always listen to the machine; if it sounds strange, you might need to change settings. Finally, keep notes on what works best for each metal you use.

What Role Do Variable Speed Drives Play In Maintaining Consistent Torque Levels During High-Speed Machining Operations On A Lathe?Variable speed drives help keep the power steady when a lathe works fast. They adjust how fast the machine spins based on what we need. This means the machine can keep strong pushing power, called torque, even when moving quickly. So, we get a smoother job and better cuts without slowing down. It’s like having a car that can change gears easily to keep going strong!

How Does The Design Of The Variable Speed Mechanism In A Lathe Impact The Overall Torque And Performance Of The Machine?The design of the variable speed mechanism in a lathe helps control how fast the machine spins. When the speed changes, the torque, which means the turning power, can also change. If we have more torque, the lathe can cut things better, especially tough materials. So, a good design makes the lathe stronger and easier to use. Overall, it helps us work faster and more efficiently.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Variable Speed Metal Lathe Torque:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A variable speed metal lathe helps you shape metal pieces. The torque is how much power it uses to do that. Higher torque means the lathe can move faster and handle tougher jobs. You can change the speed to fit what you’re making. This means you have more control, making your work easier and better!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “How Does The Torque Output Of A Variable Speed Metal Lathe Change With Different Spindle Speeds?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you change the spindle speed on a metal lathe, the torque changes too. At lower speeds, the lathe can give more torque. This helps when you need to cut hard materials. As the speed gets higher, the torque usually gets lower. So, you pick the speed based on what you’re working on!”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Having Adjustable Torque Settings In A Variable Speed Metal Lathe For Different Materials?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Adjustable torque settings help you control how hard the lathe works. This is important when you use different materials like wood or metal. If the torque is too high, you might break something. If it’s too low, you can’t cut properly. So, having the right setting helps you work better and safer!”}},{“@type”: “Question”,”name”: “How Can One Determine The Optimal Speed And Torque Settings For Machining Specific Metal Alloys On A Variable Speed Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the best speed and torque (turning force) for cutting metal alloys, you can start by checking the material’s guidelines. These guidelines tell you the ideal speed for different metals. You can also test by starting at a low speed and adjusting up or down as you go. Always listen to the machine; if it sounds strange, you might need to change settings. Finally, keep notes on what works best for each metal you use.”}},{“@type”: “Question”,”name”: “What Role Do Variable Speed Drives Play In Maintaining Consistent Torque Levels During High-Speed Machining Operations On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Variable speed drives help keep the power steady when a lathe works fast. They adjust how fast the machine spins based on what we need. This means the machine can keep strong pushing power, called torque, even when moving quickly. So, we get a smoother job and better cuts without slowing down. It’s like having a car that can change gears easily to keep going strong!”}},{“@type”: “Question”,”name”: “How Does The Design Of The Variable Speed Mechanism In A Lathe Impact The Overall Torque And Performance Of The Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design of the variable speed mechanism in a lathe helps control how fast the machine spins. When the speed changes, the torque, which means the turning power, can also change. If we have more torque, the lathe can cut things better, especially tough materials. So, a good design makes the lathe stronger and easier to use. Overall, it helps us work faster and more efficiently.”}}]}