Have you ever wondered how machines work with such precision? One key to their success is understanding how to connect them. A variable speed metal lathe is a fascinating tool in many workshops. But it can be confusing when you look at the wiring.

Imagine you’re excited to start a new project, but the wires seem tangled. You might feel stuck. That’s where a variable speed metal lathe wiring diagram comes in handy. This diagram acts like a map. It shows you where each wire needs to go so your machine runs smoothly.

Did you know that the right wiring can help your lathe perform better? It can even extend the life of your machine. Knowing how to read the wiring diagram can turn any beginner into a pro. Let’s dive deeper into how this diagram works and makes your projects easier!

Understanding Variable Speed Metal Lathe Wiring Diagram

Understanding Variable Speed Metal Lathe Wiring Diagrams

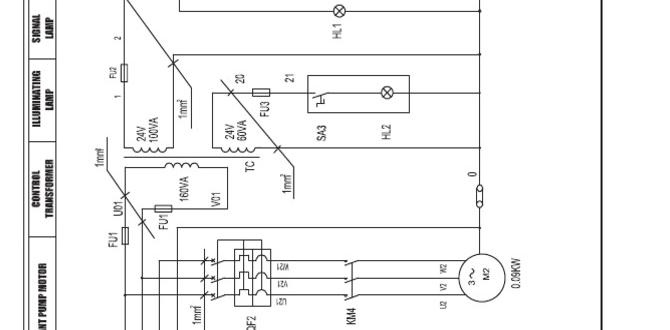

When exploring a variable speed metal lathe wiring diagram, you discover how to connect different components. These diagrams show motor connections, speed controls, and power sources. Understanding this wiring helps users operate lathes safely and effectively. Did you know that a well-wired lathe can last longer and perform better? This knowledge empowers hobbyists and professionals alike, making their metalworking projects smoother and more enjoyable!Understanding Variable Speed Metal Lathes

Explanation of variable speed lathe technology. Benefits of using variable speed in metalworking.Variable speed metal lathes are awesome tools that can change their spinning speed. This means you can work on different materials and sizes without a hitch! The main perk? You get better control over your cuts. Want to make a fine detail? Slow it down! Need to zoom through a tough job? Crank it up! Plus, they are more efficient, saving you time and effort. It’s like having a chef who can adjust the oven temperature on the fly—no burnt cookies here!

| Benefits | Description |

|---|---|

| Improved Precision | Get exact cuts every time! |

| Increased Efficiency | Finish jobs faster with less hassle! |

| Material Versatility | Work with various materials smoothly! |

Importance of Wiring Diagrams

Significance of wiring diagrams in electrical setup. How wiring diagrams can prevent common mistakes.Wiring diagrams are like maps for electrical setups. They show how everything connects. Imagine trying to find your way in the dark without a flashlight! Using a wiring diagram can keep you from making silly mistakes. For example, they help avoid mixing up wires. One wrong connection can lead to a shocking surprise! Trust me, nobody enjoys sparks flying when they just wanted to power up a machine. Plus, wiring diagrams make repairs easier and faster!

| Benefits of Wiring Diagrams |

|---|

| Clear connections |

| Prevent errors |

| Speed up repairs |

Step-by-Step Wiring Diagram Guide

Detailed breakdown of wiring components for a variable speed lathe. Visual aids and examples for better understanding.Understanding how to wire your variable speed lathe is essential for safety and proper function. Let’s break it down. First, identify the main components: the motor, control box, and power supply. Each part plays a vital role in operation. Visual aids can help clarify the setup. Here’s a simple overview:

- Motor: Powers the lathe.

- Control Box: Regulates speed settings.

- Power Supply: Provides electricity to the system.

Using wiring diagrams makes it easier to see where everything connects. Diagrams serve as a roadmap for your project!

What are the essential components of a lathe wiring diagram?

Essential components include the motor, control box, and power supply. They work together to ensure smooth operation and allow for speed adjustments. Understanding these parts helps in effective wiring.

Common Wiring Issues and Solutions

List of frequent wiring problems encountered. Troubleshooting tips for efficient repair and maintenance.Wiring problems can give anyone a headache, especially if you’re trying to make that shiny lathe work. Common issues include loose connections, broken wires, and incorrect terminals. These can turn your project into a frustrating puzzle. But don’t fret! Here are some quick fixes: always check for loose wires and ensure connections are tight. Also, double-check your wiring diagram—it’s like following a treasure map! Remember, a good wiring diagram keeps you on track like a GPS—but without the annoying voice.

| Common Issues | Troubleshooting Tips |

|---|---|

| Loose Connections | Check and tighten all screws and wires. |

| Frayed Wires | Replace damaged wires immediately. |

| Incorrect Wiring | Refer to the wiring diagram for guidance. |

Upgrades and Modifications

Options for enhancing variable speed performance. Considerations for wiring modifications.Upgrading your variable speed metal lathe can greatly improve its performance. You can enhance speed with several options. For example, consider adding a better motor or upgrading the drive system for smoother operations. Also, carefully plan any wiring changes you make. This helps to avoid issues. Think about using thicker wires for better power flow.

- Upgrade the motor for better speed.

- Install a new drive system for smoother operations.

- Use thicker wires for power flow.

What are some easy upgrades for a variable speed metal lathe?

Some easy upgrades include improving the motor, enhancing the drive system, and using better wiring for efficiency.

Resources for Further Assistance

Recommended manuals and guides for lathe wiring. Online forums and communities for expert support.Finding help with lathe wiring can feel like looking for a needle in a haystack. Luckily, recommended manuals and guides provide clear explanations and pictures, making it easier. Websites like Instructables and YouTube have fantastic videos showing each step. For real-time help, check out online forums like Reddit or woodworking groups. You’ll find many friendly experts willing to help—sometimes with dad jokes thrown in! Don’t forget to explore this handy table for quick resources:

| Resource | Description |

|---|---|

| Instructables | Step-by-step guides with images. |

| Communities ready to answer your questions. | |

| YouTube | Videos that demystify the wiring process. |

Conclusion

In conclusion, understanding a variable speed metal lathe wiring diagram is crucial for safe and effective use. It helps you identify parts and connections. By learning about this wiring, you can troubleshoot and improve your lathe. Explore more resources or guides to enhance your skills further. Happy machining, and remember, practice makes perfect!FAQs

What Are The Essential Components Needed For Wiring A Variable Speed Metal Lathe?To wire a variable speed metal lathe, you need a few important parts. First, get a power supply to provide electricity. Then, you need a motor to help it spin. You also need a control box to adjust the speed. Finally, you will need wires to connect everything together.

How Do You Properly Connect A Variable Speed Control Unit To A Metal Lathe Motor?To connect a variable speed control unit to your metal lathe motor, first, turn off the power. Next, you need to find the motor wires. Usually, there are three wires: one for power, one for speed, and one for ground. Connect the wires from the motor to the control unit using the instructions that come with it. Finally, check your connections and turn on the power to test if it works correctly.

What Safety Precautions Should Be Taken When Wiring A Variable Speed Lathe?When wiring a variable speed lathe, you should always unplug it first. This keeps you safe from electric shocks. Next, wear safety glasses to protect your eyes from flying bits. Also, keep your tools organized so you don’t trip. Finally, double-check your connections to make sure everything is secure.

How Can You Troubleshoot Issues With The Wiring Of A Variable Speed Metal Lathe?To troubleshoot wiring issues with a variable speed metal lathe, first unplug the machine. Then, check all the wires for damage or loose connections. Look for any burnt or broken parts. If you see anything wrong, you might need to repair or replace those parts. Finally, plug the lathe back in and test it to see if it works.

What Is The Difference Between Single-Phase And Three-Phase Wiring For Variable Speed Metal Lathes?Single-phase wiring uses one electric line, while three-phase wiring uses three lines. You can think of single-phase like one water pipe for all the water. Three-phase is like three pipes, which can deliver more water quickly. This means three-phase can help machines run smoother and faster, which is good for metal lathes. So, if you need more power and speed, three-phase is better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Components Needed For Wiring A Variable Speed Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a variable speed metal lathe, you need a few important parts. First, get a power supply to provide electricity. Then, you need a motor to help it spin. You also need a control box to adjust the speed. Finally, you will need wires to connect everything together.”}},{“@type”: “Question”,”name”: “How Do You Properly Connect A Variable Speed Control Unit To A Metal Lathe Motor? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To connect a variable speed control unit to your metal lathe motor, first, turn off the power. Next, you need to find the motor wires. Usually, there are three wires: one for power, one for speed, and one for ground. Connect the wires from the motor to the control unit using the instructions that come with it. Finally, check your connections and turn on the power to test if it works correctly.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Wiring A Variable Speed Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When wiring a variable speed lathe, you should always unplug it first. This keeps you safe from electric shocks. Next, wear safety glasses to protect your eyes from flying bits. Also, keep your tools organized so you don’t trip. Finally, double-check your connections to make sure everything is secure.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Issues With The Wiring Of A Variable Speed Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot wiring issues with a variable speed metal lathe, first unplug the machine. Then, check all the wires for damage or loose connections. Look for any burnt or broken parts. If you see anything wrong, you might need to repair or replace those parts. Finally, plug the lathe back in and test it to see if it works.”}},{“@type”: “Question”,”name”: “What Is The Difference Between Single-Phase And Three-Phase Wiring For Variable Speed Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Single-phase wiring uses one electric line, while three-phase wiring uses three lines. You can think of single-phase like one water pipe for all the water. Three-phase is like three pipes, which can deliver more water quickly. This means three-phase can help machines run smoother and faster, which is good for metal lathes. So, if you need more power and speed, three-phase is better!”}}]}