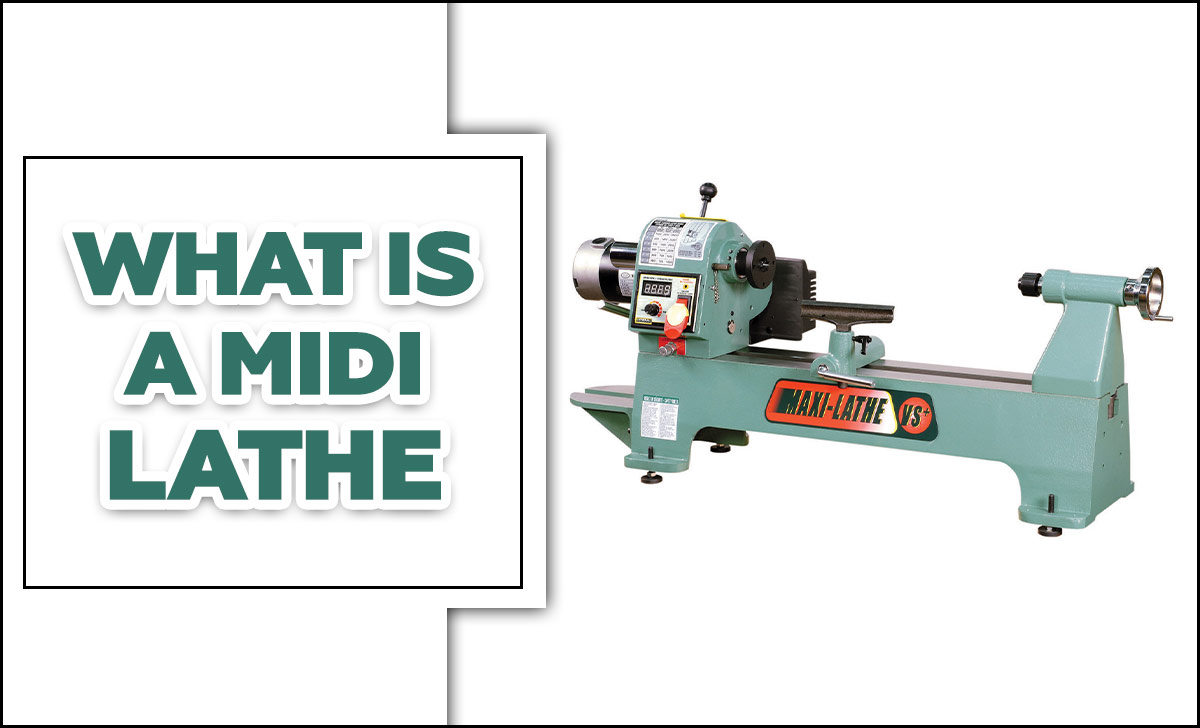

Imagine taking a plain block of wood and turning it into something amazing. With a wood lathe, this magic happens right between centers. But what does that mean? Picture spinning a top. You hold it steady with one hand, while it spins wildly with the other.

This is how a wood lathe works when turning wood between centers. The wood stays firm, yet moves quickly, letting you shape it into a spoon or a baseball bat. Isn’t that fascinating? Working with a wood lathe can feel like being an artist or a wizard.

Here’s a fun fact: Some of the oldest tools craftsmen used were lathes! People have been transforming wood for thousands of years. Now, with a simple twist between centers, you can continue this ancient tradition. Curious to learn how it works? Let’s explore.

Understanding Wood Lathe Between Centers Techniques

Wood Lathe Between Centers: A Hands-On Adventure

Ever wonder how impressive wooden bowls come to life? Imagine a wood lathe as a magic tool. It holds the wood steady “between centers,” meaning it’s gripped from two sides. This setup allows perfect spins, crafting our favorite wooden toys or bowls. Beginners find it exciting as it feels almost like sculpting clay! Ever tried using one? You’ll love creating smooth and beautiful shapes with ease!Understanding the Concept of Turning Between Centers

Definition and explanation of turning between centers. Importance and benefits of using this method in woodturning.Turning between centers might sound like a circus act, but it’s a woodturning skill! It involves holding a piece of wood between two points on a lathe, letting it spin and transform into wonderful shapes. This method’s a big deal because it gives stability and balance. It also allows for creating symmetrical designs. Many woodworkers swear by this technique, stating, “It’s like giving the wood a steady hug.” Below is a simple illustration of this setup:

| Part | Function |

|---|---|

| Headstock | Power source |

| Tailstock | Support |

| Wood piece | Art in progress |

Using this approach, the wood spins evenly, making smoother and more precise products. A wood lathe between centers is like the maestro of a wooden orchestra, ensuring every part works in harmony. Plus, it’s a fun way to see your creativity come to life!

Essential Tools and Equipment for Turning Between Centers

List and description of necessary tools (e.g., wood lathe, headstock, tailstock). Differences between a drive center and a live center.Ever thought woodturning felt like magic? Meet your tools of enchantment! Your wood lathe, headstock, and tailstock are key characters in this transformation. The wood lathe spins your wood piece while the headstock holds the drive center to set it in motion. The tailstock keeps everything secure with a live center. Confused between drive and live centers? Think of the drive center as the DJ starting the party and the live center as the bodyguard ensuring the fun doesn’t stop! Here’s a quick comparison:

| Tool | Function |

|---|---|

| Drive Center | Initiates rotation |

| Live Center | Provides support |

Ready to craft that perfect wooden centerpiece? These tools ensure you’re set up for success, each step of the way! A wise old woodworker once said, “A lathe in motion is like a storyteller in action.”

Setting Up Your Wood Lathe for Center Turning

Stepbystep guide to setting up the lathe for turning between centers. Tips for ensuring alignment and stability.Ready to make your wood lathe spin magic between centers? First, ensure your lathe is on a solid surface to avoid unexpected wobbles (we don’t want runaway wood!). Secure your workpiece between the headstock and tailstock—make sure it feels snug; like a sandwich without the squish. Align the centers carefully, so they point to each other like long-lost friends. Keep checking alignment as you turn. And hey, don’t forget to lock everything in place! Need a quick checklist? Check out this table:

| Step | Description |

|---|---|

| 1 | Place the lathe on a stable surface. |

| 2 | Insert your workpiece between headstock and tailstock. |

| 3 | Align the centers. |

| 4 | Check and adjust alignment during turning. |

| 5 | Lock everything in place. |

Ensure to tighten things up; loose is never a good look for wood or pants! Following these steps keeps your wood turning session fun and safe. As one woodworker humorously said, “A wobbly lathe is no different from dancing before noon, odd and unnecessary!” Remember, a good setup is the key to a good start, so take your time and set it right. Happy turning!

Selecting the Right Wood for Turning Between Centers

Recommended types of wood and their characteristics. Factors to consider when choosing wood for this method.Selecting wood for turning between centers can be fun! Different wood types offer unique qualities.

- **Oak** is strong and durable. Perfect for beginners.

- **Maple** is smooth and easy to work with, great for detailed work.

- **Walnut** adds a dark, rich color finish.

Step-by-Step Process of Turning Between Centers

Detailed instructions from preparing the wood to the finishing touches. Common techniques and practices for optimal results.Turning wood between centers can be a fun task. First, prepare your wood by cutting it to the size you need. Make sure it’s smooth.

- Next, find the center of each end of your wood. This helps it spin well.

- Mount the wood on the wood lathe and lock it in place securely.

- Turn on the lathe and start shaping the wood with your tools. Slowly is key!

As you work, use common techniques like bevel cuts. This ensures good results. Always wear safety gear. Finally, sand your piece until it’s smooth. A neat finish makes all the difference!

How can I make my wood smooth?

To make wood smooth, use sandpaper gradually, starting from coarse to fine grit. Sand each section until you feel it’s even. Feel for any rough spots and smooth them gently. Polishing with a cloth can also add a nice touch.Safety Precautions When Turning Between Centers

Essential safety gear and procedures. Best practices to prevent accidents and injuries.Ensuring safety while using a wood lathe is crucial. Always wear essential safety gear. This includes goggles to protect your eyes and gloves to guard your hands. Ear protection is also important since lathes can be noisy. Follow these best practices:

- Check that the wood is secure before turning.

- Stand to the side, not directly in line.

- Keep your work area clean and free from clutter.

- Focus on your task; don’t get distracted.

These steps prevent accidents. By being careful, and alert, you stay safe while working between centers.

What safety gear is essential for wood turning?

Always wear eye protection and gloves. Ear protection is needed too. Safety is key when working with a lathe.How can you prevent lathe accidents?

Keep the wood secure and stay focused. Don’t get distracted. A tidy work area helps prevent injuries.What do experts say?

Experts note that most accidents happen due to distractions or improper setup. Ensure attention to detail.

Troubleshooting Common Issues in Center Turning

Identification of typical problems encountered. Solutions and tips for overcoming these challenges.When working on a wood lathe, certain problems may pop up. Identifying these issues quickly is key. Common ones include:

- **Vibration:** The lathe might shake. Check if everything is tight.

- **Tool Dullness:** Does it cut poorly? Try sharpening your tools.

- **Wood Splintering:** Avoid by ensuring your tool angle is correct.

To tackle these, always keep your tools sharp and check that all components are secure. Adjusting your cutting speed can also help. Remember, being attentive can greatly improve your center turning experience!

Why does my wood lathe vibrate a lot?

A vibrating lathe could be due to loose parts or uneven wood. Ensure parts are tight and the wood is balanced.

How do I prevent wood from splintering?

To prevent splintering, use sharp tools and cut from thicker to thinner sections smoothly.

Maintaining Your Wood Lathe and Accessories

Routine maintenance tasks for optimal performance. How to extend the life of your tools and equipment.Keeping your wood lathe and accessories in tip-top shape is key to making great projects. Regular checks are like giving your tools a health check-up, ensuring they stay healthy and happy.

To lengthen the life of your lathe, clean it often, sharpen tools, and apply lubricant where needed. A little love goes a long way! Here’s a quick table with some simple tasks:

| Task | Frequency |

|---|---|

| Clean the lathe bed | After each use |

| Check the drive belt | Monthly |

| Sharpen tools | Every 5 projects |

| Lubricate moving parts | Every 3 months |

Remember, neglecting maintenance is like forgetting to feed a pet—you might end up with a cranky tool! So, show your lathe some love, and it’ll reward you with smooth spins and delightful creations.

Exploring Projects and Applications of Turning Between Centers

Examples of projects suitable for turning between centers. Creative ideas and inspiration for woodturning enthusiasts.Turning between centers offers a world of creative wood projects. It’s perfect for making items like spindles, bowls, and candle holders. Each project lets woodturners showcase their skills and style. Here are some exciting ideas:

- Spinning tops for kids

- Beautiful wooden bowls

- Stylish furniture legs

- Unique door handles

Woodturning can be rewarding. Each piece tells a story of creativity and craft. Let your imagination soar and explore this fascinating hobby!

What can you make with a wood lathe between centers?

You can create items like bowls, spindles, or unique art pieces. The only limit is your creativity!

Expert Tips and Tricks for Successful Center Turning

Insights from experienced woodturners. Proven tips for improving efficiency and results.Learning from skilled woodturners can help you master center turning. Here are some tools to boost your skills:

- Always measure twice and cut once to avoid mistakes.

- Keep your tools sharp for cleaner cuts.

- Practice with different woods to see what you like best.

- Adjust your speed for each type of wood to achieve the best results.

Remember, patience is key. Take your time to improve. Each piece you turn teaches you something new!

What is the best wood for turning between centers?

Softwoods like pine and hardwoods like maple are great for beginners. They are easier to work with and give good results. Plus, they help you learn quickly!

Conclusion

A wood lathe between centers helps you carve detailed, symmetrical wood pieces. It’s essential for turning, offering stability and precision. Understanding its parts and safety improves your skills. Practice using different tools, and check online resources or books to learn more. Start small, and gradually tackle bigger projects to boost your confidence and expertise.FAQs

Here Are Five Related Questions On The Topic Of Wood Lathes Between Centers:A wood lathe is a machine that helps you shape wood. You can use it to make things like bowls or furniture. When we use the lathe “between centers,” we hold the wood at both ends. This keeps the wood steady while you shape it. It’s a fun way to create cool wooden items!

Sure! Please provide the question you’d like me to answer.

What Are The Key Benefits Of Turning Wood Between Centers As Opposed To Using A Faceplate Or Chuck?Turning wood between centers means you use two points to hold the wood. This helps the wood stay steady as you shape it. You can make longer pieces without a faceplate or chuck getting in the way. It also lets you see all the sides easily. Finally, it’s great for making items like spindle shapes!

How Do You Properly Set Up And Align A Wood Lathe When Turning Between Centers?To set up a wood lathe for turning between centers, first, make sure the lathe is on a stable surface. Next, attach the live center to the headstock and the dead center to the tailstock. Both centers should point straight at each other. Then, you can place your wood piece between them and tighten it well. Now you’re ready to start turning!

What Types Of Wood And Sizes Of Stock Are Most Suitable For Turning Between Centers On A Lathe?For turning between centers on a lathe, softwoods like pine and hardwoods like maple work well. You can use pieces that are about 1 to 3 inches thick. Length should be at least 12 inches, but longer is usually better. Make sure the wood is straight and has no big knots. This helps you create smooth shapes.

What Safety Precautions Should Be Taken When Operating A Wood Lathe With Workpieces Mounted Between Centers?When using a wood lathe, always wear safety goggles to protect your eyes. Keep your fingers away from the moving parts. Make sure your workpiece is tightly secured before starting. Check for loose clothing or long hair that could get caught in the lathe. Lastly, never rush; take your time and work carefully.

How Can You Achieve Accurate And Smooth Finishes When Turning Wood Between Centers?To get a nice finish when turning wood, you should start with good quality wood. Make sure the wood is tight between the centers so it doesn’t move. You can use sharp tools to cut and shape the wood smoothly. Lastly, sand the wood well after you shape it. This will make it feel soft and look shiny!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Wood Lathes Between Centers:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A wood lathe is a machine that helps you shape wood. You can use it to make things like bowls or furniture. When we use the lathe “between centers,” we hold the wood at both ends. This keeps the wood steady while you shape it. It’s a fun way to create cool wooden items!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Benefits Of Turning Wood Between Centers As Opposed To Using A Faceplate Or Chuck?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Turning wood between centers means you use two points to hold the wood. This helps the wood stay steady as you shape it. You can make longer pieces without a faceplate or chuck getting in the way. It also lets you see all the sides easily. Finally, it’s great for making items like spindle shapes!”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Align A Wood Lathe When Turning Between Centers?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a wood lathe for turning between centers, first, make sure the lathe is on a stable surface. Next, attach the live center to the headstock and the dead center to the tailstock. Both centers should point straight at each other. Then, you can place your wood piece between them and tighten it well. Now you’re ready to start turning!”}},{“@type”: “Question”,”name”: “What Types Of Wood And Sizes Of Stock Are Most Suitable For Turning Between Centers On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For turning between centers on a lathe, softwoods like pine and hardwoods like maple work well. You can use pieces that are about 1 to 3 inches thick. Length should be at least 12 inches, but longer is usually better. Make sure the wood is straight and has no big knots. This helps you create smooth shapes.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Wood Lathe With Workpieces Mounted Between Centers?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a wood lathe, always wear safety goggles to protect your eyes. Keep your fingers away from the moving parts. Make sure your workpiece is tightly secured before starting. Check for loose clothing or long hair that could get caught in the lathe. Lastly, never rush; take your time and work carefully.”}},{“@type”: “Question”,”name”: “How Can You Achieve Accurate And Smooth Finishes When Turning Wood Between Centers?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get a nice finish when turning wood, you should start with good quality wood. Make sure the wood is tight between the centers so it doesn’t move. You can use sharp tools to cut and shape the wood smoothly. Lastly, sand the wood well after you shape it. This will make it feel soft and look shiny!”}}]}