Mastering Your Wood Lathe: Effortless Wood Lathe Chuck Removal

Possessing a wood lathe opens up a universe of creative possibilities, allowing you to transform raw timber into exquisite bowls, spindles, and decorative pieces. However, at some point in your turning journey, you’ll encounter the need to swap out your chuck – the crucial device securing your workpiece to the lathe. This seemingly simple task can sometimes become a point of frustration, marked by stubborn grips and a general feeling of being stuck. Fortunately, the right equipment can transform this potential hurdle into a remarkably smooth and efficient process. Understanding and utilizing a dedicated wood lathe chuck removal tool is the key to unlocking effortless chuck changes, ensuring you spend less time wrestling with machinery and more time bringing your artistic visions to life.

The design and function of a wood lathe chuck removal tool are surprisingly straightforward, yet their impact on efficiency is profound. These specialized tools are engineered to provide the optimal leverage and grip needed to overcome the often tight and sometimes slightly seized connection between the chuck and the lathe spindle. Imagine trying to unscrew a tightly fitted lid without proper grip – it’s an exercise in futility and potentially damaging to both the lid and your hands. The same principle applies to chucks. Without a properly designed tool, you risk damaging the chuck’s jaws, the spindle threads, or even injuring yourself through slips and excessive force.

Why You Need a Dedicated Wood Lathe Chuck Removal Tool

The primary reason for investing in a wood lathe chuck removal tool boils down to leverage and precision. Lathe chucks are designed to hold workpieces securely under significant rotational forces. This means their mating with the lathe spindle needs to be exceptionally firm. Standard wrenches or even pliers are often inadequate for this task. They might lack the necessary reach, the correct form to engage the chuck’s mounting points, or the robust construction to handle the torque required.

Furthermore, the threads on both the chuck and the spindle are precision components. Applying brute force with inappropriate tools can easily strip these threads, leading to costly repairs or even the replacement of entire components. A dedicated chuck removal tool is designed with the specific geometry of common chuck mounting systems in mind. This ensures that force is applied precisely where it’s needed, minimizing the risk of damage and maximizing the effectiveness of your efforts. The handle is typically long enough to provide ample leverage, and the engagement points are shaped to fit snugly into the chuck’s mounting holes or surfaces, preventing slippage and ensuring a secure fit.

Understanding Different Types of Wood Lathe Chuck Removal Tools

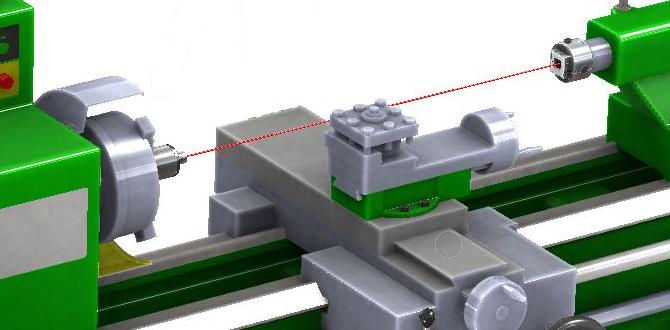

While the core purpose remains the same, there’s a variety of wood lathe chuck removal tool designs available on the market, catering to different chuck types and user preferences. Some are simple, robust levers specifically designed for certain brands or models of chucks, featuring pins or hooks that engage with the chuck’s body. Others are more universal, employing adjustable clamping mechanisms or specialized jaws that can adapt to various chuck designs.

For chucks that mount via a scroll mechanism and locking pin, specialized tools often feature a pin that aligns with the chuck’s locking hole and a handle to rotate the chuck body. This applies direct force to the chuck’s body, effectively unscrewing it from the spindle. For larger or heavier chucks, you might find tools with longer handles or even those that allow for the use of a pipe extension for increased leverage. The materials used in the construction of these tools are also important; durable steel alloys are standard, ensuring they can withstand the forces involved without bending or breaking.

The Simple Steps to Effortless Chuck Changes

Using a wood lathe chuck removal tool simplifies the process significantly. The exact steps may vary slightly depending on the specific tool and chuck you are using, but the general principle is consistent.

1. Safety First: Before you begin, always ensure the lathe is powered off and the chuck has been released from any workpiece. It’s also a good practice to wear safety glasses.

2. Engage the Tool: Identify the appropriate points on your chuck for the removal tool to engage. This could be specific holes on the chuck body or a designated slot. Securely attach the wood lathe chuck removal tool to the chuck.

3. Apply Steady Pressure: With the tool firmly in place, apply smooth, continuous rotational pressure in the counter-clockwise direction (for standard threads). Avoid jerky movements. You might hear a “pop” as the threads break free – this is normal.

4. Unscrew and Remove: Once the chuck begins to loosen, continue unscrewing it by hand or with the assistance of the tool until it comes free from the spindle. Be prepared to support the weight of the chuck as it detaches.

5. Inspect and Store: Briefly inspect the threads on both the chuck and the spindle for any signs of damage. Clean and store your wood lathe chuck removal tool in an accessible location for its next use.

Beyond Just Removal: Maintenance and Best Practices

The investment in a quality wood lathe chuck removal tool extends beyond just facilitating easy changes. By using the correct tool, you are actively contributing to the longevity and optimal performance of your wood turning equipment. Regular inspection of your chuck’s threads and the lathe spindle threads is advisable. A small amount of appropriate lubricant applied sparingly to the spindle threads can further ease future removals.

Additionally, understanding the different mounting systems of your chucks is essential. Some chucks might have specific instructions or limitations regarding removal tools. Always refer to the manufacturer’s guidelines for both your chuck and your lathe. Choosing the right wood lathe chuck removal tool is not about having a fancy gadget; it’s about investing in a practical solution that enhances safety, efficiency, and the overall enjoyment of your woodworking endeavors at the lathe. It’s an indispensable item for any serious woodturner, transforming a potentially frustrating task into a seamless part of the creative workflow.