Imagine turning a block of wood into a beautiful bowl. Sounds fun, right? A wood lathe coring system can make this happen! But, what is it, and why is it useful? Think of a coring system like a magical tool for woodworkers. It saves time and wood by carving out perfect shapes. Have you ever wondered how bowl makers get those smooth curves? This guide opens the door to that magic. Did you know that using a coring system reduces waste? It’s true! Woodworkers love it because it means less mess and more creativity. Ready to discover the secrets of the wood lathe coring system? Let’s dive into this world and get started.

Comprehensive Wood Lathe Coring System Guide

Discover the Wood Lathe Coring System Guide

Imagine turning a block of wood into a masterpiece. A wood lathe coring system can help. It’s like magic for woodworkers. With this guide, you learn how to shape wood with precision. Avoid waste and save time. Your wooden bowls will wow everyone. Did you know? A good coring system can give you multiple bowls from one piece of wood. Start crafting your dreams today!Understanding Wood Lathe Coring Systems

Definition and purpose of a wood lathe coring system. Benefits of using a coring system in woodworking.A wood lathe coring system helps to shape and hollow wood pieces. It cuts out material from the center, making it lighter and more useful. This tool saves time and effort while creating bowls and other shapes. The main purpose is to maximize the use of wood. Using a coring system has several benefits:

- Less Waste: You use more of the wood, reducing waste.

- Efficient Production: It speeds up the process of making items.

- Creative Designs: It allows for unique shapes and styles.

Overall, a coring system is great for anyone who loves woodworking!

What are the benefits of using a wood lathe coring system?

The key benefits of a wood lathe coring system include:

- Time-Saving: It makes hollowing wood faster.

- Material Efficiency: It reduces waste and maximizes wood use.

- Versatile Designs: You can create various shapes and items.

Choosing the Right Coring System for Your Needs

Factors to consider: size, material, and budget. Matching the coring system to your lathe specifications.Picking the right coring system can feel like trying to find the right socks – you want a good fit! First, think about the size of your projects. Larger items need bigger tools. Next, consider the material. Wood varieties can be tricky, and some systems work better with certain ones. Lastly, your budget matters. You want a solid system without emptying your wallet! Also, ensure the coring system matches your lathe’s specs. It’s like dating; you need a good match to get the best results!

| Factor | Details |

|---|---|

| Size | Choose based on your project needs. |

| Material | Match the coring system to wood type. |

| Budget | Stay within your limits but aim for quality! |

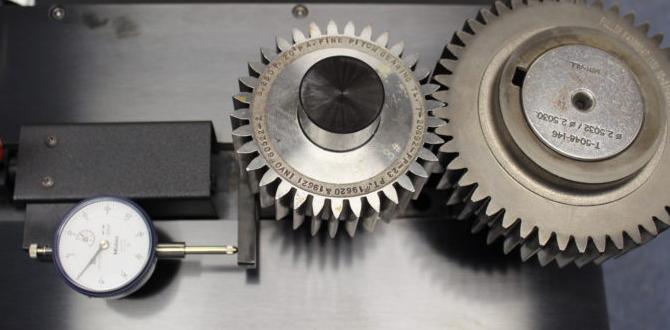

Essential Tools and Accessories for Coring

Necessary tools for setting up the coring system. Recommended accessories to enhance performance.To set up a coring system, you need some important tools. First, a high-quality wood lathe is key. You’ll also need coring tools, like a coring knife or a hollowing tool. These help shape your wood perfectly. Don’t forget safety gear! Safety glasses and gloves keep your hands and eyes safe, especially when wood shavings fly around like confetti at a party.

| Essential Tools | Recommended Accessories |

|---|---|

| Wood Lathe | Safety Glasses |

| Coring Knife | Gloves |

| Hollowing Tool | Extra Sharp Blades |

Using these tools and accessories not only improves your coring experience but also makes your projects look great. Remember, the better your setup, the more fun you’ll have! So, grab your gear and let’s get coring!

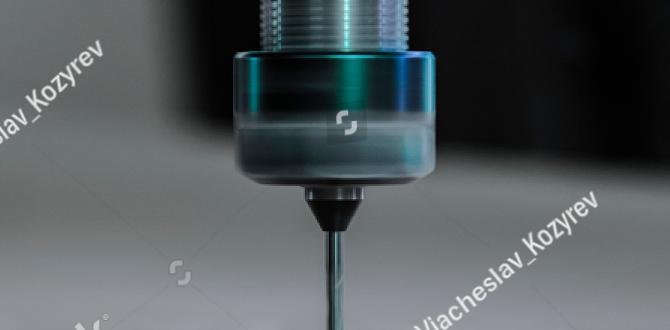

Step-by-Step Guide to Setting Up a Coring System

Preparing your workspace and materials. Installing and aligning the coring system on the lathe.First, clean your workspace. Clear off any dust bunnies and make room for your materials. You need space to breathe and work! Gather all your tools and wood. You don’t want to be chasing after that screwdriver later, trust me!

Next, let’s install the coring system on your lathe. Align it carefully. Think of it like trying to park a car – you want it to fit perfectly. Use the right screws and check your alignment twice. Once everything looks good, tighten those bolts. Remember, a wobbly setup can lead to wonky results!

| Step | What to Do |

|---|---|

| 1 | Clean your workspace |

| 2 | Gather materials |

| 3 | Install coring system |

| 4 | Align everything |

| 5 | Tighten bolts |

And voilà! You’re ready to start making some amazing pieces. Now, go make some shavings! Who knows? You might even impress your friends with your new skills!

Techniques for Effective Wood Coring

Key strategies for efficient wood removal. Best practices to ensure safety and precision.Coring wood can be fun, like digging for treasure! Start with sharp tools; they make things easier. Use steady pressure and always check your angles. Safety is key; wear goggles unless you want a splinter in your eye! Remember, a well-lit workspace prevents accidents. Know your wood type; hardwoods need tougher techniques. Always follow the best practices to keep it safe—your fingers will thank you later!

| Technique | Best Practice |

|---|---|

| Use sharp tools | Check angles often |

| Maintain steady pressure | Keep workspace clear |

| Understand wood type | Wear safety gear |

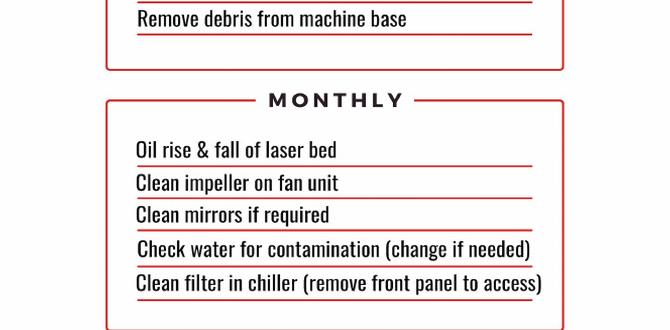

Maintaining and Troubleshooting Your Coring System

Regular maintenance tips for optimal performance. Common issues and solutions.To keep your coring system running like a well-oiled machine, regular maintenance is key. Check the sharpness of your blades often. Dull blades can cause problems, and no one likes a dull day! Also, clean all parts to prevent debris build-up. Did you know that most issues can be avoided with these simple checks? Here’s a quick look at common problems and fixes:

| Common Issue | Solution |

|---|---|

| Dull blades | Sharpen or replace blades |

| Vibration during use | Tighten loose parts |

| Wood snagging | Adjust speed settings |

By following these tips, you’ll keep your coring system happy and healthy. Remember, a little care goes a long way, so check in regularly. Your wood deserves it!

Advanced Tips and Tricks for Experienced Users

Techniques to maximize coring system potential. How to achieve different core shapes and sizes.Using a wood lathe coring system can be a fun adventure if you know some cool tips. For example, try experimenting with different speeds. Faster speeds can help achieve neat shapes, while slower speeds work wonders for finer details. Happy shaping! You can also use various cutting tools to create unique core sizes. Just remember: a dull tool is like a tired squirrel—less effective! Need shapes? Use templates to guide your creativity.

| Core Shape | Recommended Tool | Speed Setting |

|---|---|---|

| Round | Spindle gouge | High |

| Square | Square chisel | Medium |

| Custom | Router bit | Variable |

Understanding these techniques helps you make the most of your coring system. Dive into the fun, and soon you’ll be the master of core shapes!

FAQs About Wood Lathe Coring Systems

Answers to common questions and concerns. Expert advice for beginners and seasoned woodworkers.Got questions about wood lathe coring systems? You’re not alone! Many woodworkers wonder about the best practices. For beginners, remember to always start with safety gear. “Measure twice, cut once!” is your new best friend. Seasoned pros also ask about which coring tools work best. The answer? It varies! Everyone has their favorite. With the right system, you can turn a simple log into beautiful bowls. Here’s a little cheat sheet:

| Question | Answer |

|---|---|

| What is a wood lathe coring system? | A tool that removes cores from logs, creating thinner blanks for shaping. |

| Is it hard to learn? | Not at all! A little practice and you’ll be a pro. |

| Can I use it for small projects? | Absolutely! It’s perfect for bowls and smaller items. |

Conclusion

The wood lathe coring system guide helps you make the most of your lathe. It teaches you to core wood efficiently and safely. We’ve covered tool selection, setup, and techniques. Practice these skills to become a better woodturner. Keep exploring and learning to master your craft. Check out more guides and videos for extra tips!FAQs

What Are The Key Components Of A Wood Lathe Coring System, And How Do They Function Together?A wood lathe coring system has a few important parts: the lathe, the coring tool, and the support arm. The lathe spins the wood. The coring tool cuts out shapes from the wood. The support arm helps hold everything steady while you work. Together, they help you make cool bowls or other shapes quickly and easily!

How Do You Choose The Right Coring System For Your Specific Wood Lathe Model?To choose the right coring system, first check your wood lathe’s model and its specifications. You need to make sure the coring system fits well with your lathe. Look for systems that have good reviews and match your lathe’s size. It’s also a good idea to ask other woodworkers for advice. Finally, think about what projects you want to do with your lathe.

What Safety Precautions Should Be Taken When Using A Wood Lathe Coring System?When using a wood lathe coring system, you should always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothes so nothing gets caught. Stay focused and keep your hands away from moving parts. Make sure the area is clean and free of clutter to avoid accidents. Lastly, always follow the instructions for the machine to stay safe.

What Types Of Wood Are Most Suitable For Coring, And How Do Different Species Affect The Coring Process?Softwoods like pine and cedar are great for coring. They are easy to cut and shape. Hardwoods, like oak and maple, are tougher, making them harder to core. Different woods can change how quickly we can do our work. Softer woods save time, while harder ones need more care.

How Can You Maintain And Troubleshoot A Wood Lathe Coring System To Ensure Optimal Performance?To keep your wood lathe coring system running well, check it often. Clean the blades to remove any wood chips. Make sure everything is tight so nothing moves around. If something seems broken, look for loose pieces or wear. If you still have problems, ask someone with experience for help.