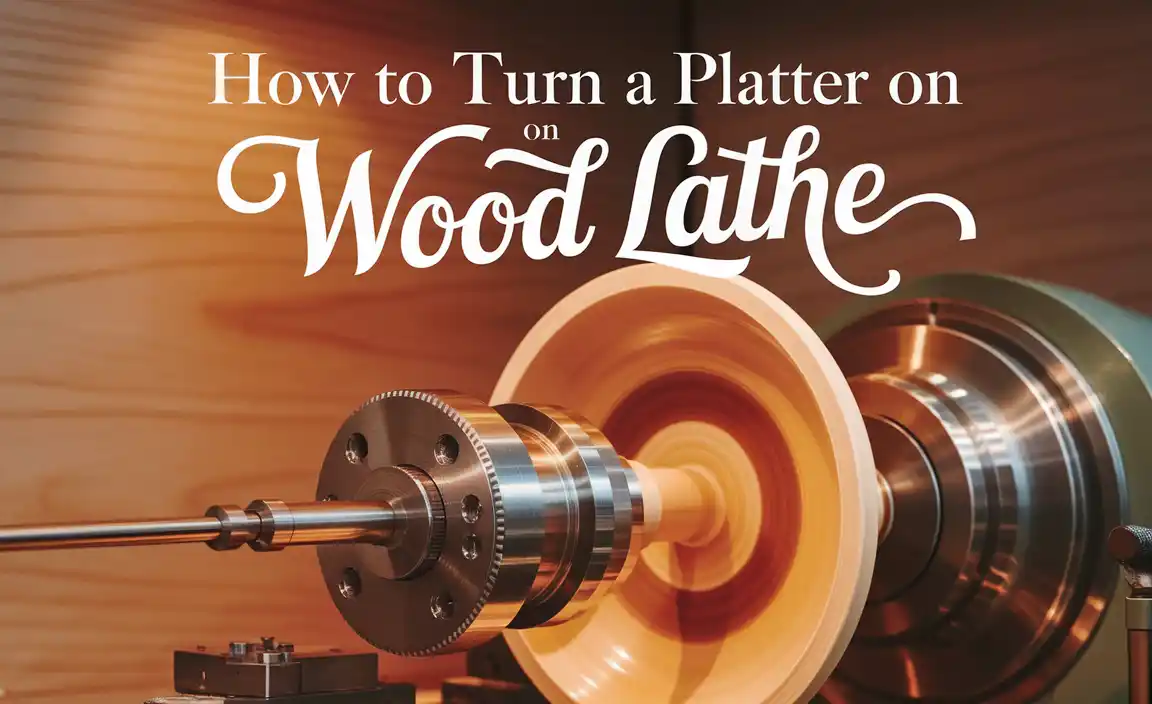

Have you ever wondered how wood becomes smooth and round? The secret lies in a tool called the wood lathe. This amazing machine spins wood into shapes. But there’s another hero in this story—the live center taper. Imagine trying to hold a spinning top without letting it fly off. A wood lathe’s live center taper does just that for wood. It keeps the wood steady so shapes can be made. Here’s a fun fact: some ancient wood lathes were powered by foot pedals. Can you picture that? Wood lathe work has been around for centuries, yet this spinning tool never gets old. Are you ready to learn more about how these tools create magic with wood?

Understanding Wood Lathe Live Center Taper Basics When Working With A Wood Lathe, One Crucial Component That Ensures Precision And Efficiency Is The Live Center. Specifically, The Wood Lathe Live Center Taper Plays A Significant Role In Stabilizing And Supporting Your Workpiece During Operations. In This Article, We’Ll Explore The Basics Of Live Center Taper, Its Importance, And Related Concepts To Enhance Your Woodworking Projects. What Is A Wood Lathe Live Center? A Live Center Is A Tool That Sits In The Tailstock Of A Lathe, Providing A Rotating Point To Support Longer Workpieces. This Support Is Vital In Preventing Vibrations, Ensuring That The Machining Process Is Smooth And Accurate. The Live Center Rotates With The Workpiece, Unlike A Dead Center, Which Remains Stationary. Understanding The Taper System The Taper Part Of The Live Center Is The Section That Inserts Into The Tailstock Spindle. The Taper Ensures A Tight Fit And Optimal Alignment For Stable Operations. The Most Commonly Used Tapers In Wood Lathes Are Morse Tapers, Ranging From 1 To 5, With The Number Indicating The Size Of The Taper. Choosing The Appropriate Taper Size Is Essential For Compatibility And Efficiency In Your Lathe Operations. Importance Of The Taper In Woodturning The Correct Taper Size Provides Several Benefits: 1. **Enhanced Stability**: A Proper Taper Fit Ensures That The Live Center Does Not Wobble Or Come Loose During Heavy Operations, Thus Maintaining Continuous Support. 2. **Precision**: By Aligning The Workpiece Accurately, The Taper Contributes To Achieving High Precision In Turning Operations. 3. **Vibration Reduction**: Tightly Fitted Tapers Minimize Vibrations During Turning, Crucial For Achieving Smooth Surfaces On Your Workpiece. Selecting The Right Taper For Your Lathe When Selecting A Live Center For Your Wood Lathe, Consider The Following: – **Lathe Specifications**: Check Your Lathe’S Tailstock Requirements To Ensure Compatibility With The Taper Size. – **Workpiece Size And Material**: Heavier And Larger Workpieces May Require Larger Tapers To Provide Sufficient Support And Alignment. – **Project Requirements**: Determine The Level Of Precision And Stability Needed For Your Specific Project And Choose A Taper Size Accordingly. Maintaining Your Live Center To Ensure Prolonged Efficiency And Effectiveness Of Your Live Center, Follow These Maintenance Tips: – **Regular Inspection**: Check For Any Signs Of Wear Or Damage On The Taper And Replace It If Necessary. – **Proper Installation**: Ensure The Taper Is Securely Fitted Into The Tailstock To Prevent Accidents And Ensure Optimal Performance. – **Lubrication**: Occasionally Lubricate The Bearings Of The Live Center To Promote Smooth Rotation And Reduce Wear. Understanding And Utilizing The Wood Lathe Live Center Taper Correctly Can Significantly Enhance Your Woodturning Experience, Delivering Stable, Precise, And Efficient Results. Making Informed Choices About Your Equipment Will Lead To More Successful Woodworking Projects.

Unlocking the Secrets of Wood Lathe Live Center Tapers

Imagine building a wooden toy on a wood lathe. The live center taper is a hero in your tool kit. It helps the lathe spin wood safely. Can you picture that? It reduces wobble and makes carving smooth. From woodworking wizards to beginners, understanding tapers means less trouble with spinning blocks. Some call it the best-kept secret. Now, isn’t that a neat trick up your sleeve?What is a Wood Lathe Live Center Taper?

Definition of wood lathe live center taper. Importance in woodturning projects.A wood lathe live center taper is a tool on a lathe for woodturning. It holds wood steady while it spins. This piece fits into the tailstock of the lathe. Why is it important? It keeps the wood from wobbling, making your project smooth and even. Without it, the wood can slip or shake.

- This ensures safety.

- It helps in making precise shapes.

- Your work becomes much easier with it.

Choosing the Right Live Center Taper for Your Lathe

Factors to consider when selecting a taper. Compatibility with various wood lathe models.Picking the perfect live center taper can feel like choosing a wand in a magic shop! Size and type are key factors. Think of them as puzzle pieces that must fit your lathe perfectly. A mismatched taper may make your woodworking wobble. Compatibility is a must! Not every taper gets along with every lathe. Check the model’s guidelines to find your taper’s BFF. As a caution, your wood won’t enjoy a tango where nobody leads.

| Factor | Details |

|---|---|

| Size | Ensure it matches your lathe model. |

| Type | Choose based on your woodworking needs. |

| Compatibility | Check the manufacturer’s guidelines. |

Experts say that using the wrong taper is like using a spoon to cut steak — it doesn’t work!

Installation and Maintenance of Live Center Tapers

Stepbystep installation guide. Tips for maintaining a live center taper.Setting up a live center taper is simple. Start with inspecting the taper for dirt or damage. Clean any dirt out. Insert it into the lathe’s tailstock. Give it a firm push to ensure it’s secure. To maintain it, keep checking for signs of wear. Regular oiling helps smooth movement. Tighten any loose parts often. Here’s a tip: Store it in a dry place to prevent rust. Regular care extends the tool’s life and keeps your work much smoother!

What is the purpose of a live center taper in wood lathes?

A live center taper in wood lathes supports the workpiece as it turns. It helps keep the wood stable, ensuring precision and smooth operation. The tool rotates with the wood, reducing friction.

How can I tell if my live center taper needs replacement?

Check for wear and tear or any visible damage. If there’s excessive vibration or noise during operation, it might be time to replace it. Regular checks can prevent sudden failures.

Steps for installation:

- Inspect the taper.

- Clean it before use.

- Insert and secure in the tailstock.

Remember, a well-maintained live center taper ensures efficient work. Follow these tips for easy installation and care. Your projects will turn out better, and your tools will last longer!

Benefits of Using a Tapered Live Center

Enhanced stability and accuracy in woodturning. Reduction of workpiece damage.Using a tapered live center on your wood lathe? It’s like adding training wheels for your wood. It helps keep your workpiece steady and straight, even if your hands get a bit wobbly like jelly. Enhanced stability and accuracy in woodturning mean your projects look neat, not wonky. Plus, your wood won’t end up with dents or scratches. Imagine how happy your wood will be with less damage!

| Benefits | How It Helps |

|---|---|

| Enhanced Stability | Keeps wood steady for smooth turning. |

| Improved Accuracy | Makes sure each cut is spot-on. |

| Less Damage | Your workpiece will thank you! No more scratches. |

Common Troubleshooting Tips for Live Center Tapers

Identifying and addressing common issues. Ensuring smooth operation and longevity.When using a live center taper, it’s wise to know common issues that can arise. If your lathe makes a strange noise or vibrates, it might need a clean or oiling. Sticky movement? Look out for dust or wood chips. Misalignment? This can lead to uneven work. Check often to tweak and fix. A well-tuned lathe lasts longer!

How do you align a live center taper?

Step-by-step alignment is vital.- Securely position the workpiece.

- Adjust centers until aligned.

- Check with a test cut.

- Readjust if necessary.

Why does my lathe vibrate?

A lathe vibrates due to a misaligned or loose component. Ensure all parts are tight and properly aligned.Regular checks can prevent most issues. Remember to tighten loose parts and clean them often. Using the right techniques helps avoid mishaps. As an old carpenter saying goes, “Measure twice, cut once.” Keep this in mind to ensure your lathe always works smoothly!

Innovations and Advances in Live Center Taper Technology

Recent advancements in live center designs. Future trends and potential developments.Technology in live center tapers is changing fast. These tools help when shaping wood. New designs now make them more accurate. For instance, some advanced centers cut vibrations more. This makes work smoother.

What’s next? Smart centers might tell you how much pressure is safe to use. They could connect to apps for better control. Lightweight materials might make tools easier to handle. These changes could help us make even cooler wood projects!

What are some recent innovations in live center taper?

Recent innovations include- vibration control

- smart pressure sensors

- connections to digital apps

What might future live center tapers offer?

Future centers may use light materials to feel lighter. They can become part of smart workshops with app support. This offers users tips and better precision.

These changes make woodwork fun and exciting, not as much like Grandpa’s time. As Albert Einstein once said, “The best way to predict the future is to create it.” With these tools, the future of woodwork is bright!

User Reviews and Recommendations

Analysis of customer feedback and popular models. Expert recommendations for best practices.Many users share their thoughts about wood lathe live centers. They often highlight how these tools improve their work. Feedback suggests popular models like the “Jet 719180” and “Grizzly G1090” stand out for their ease of use and durability. Customers appreciate strong support for stability and accuracy.

- Choosing the right taper size is key for best results.

- Regularly check for wear and tear on your live center.

- Lubrication helps prolong the life of the tool.

Experts recommend using appropriate speeds and feeds for your projects. This can make your job easier and safer. Following these tips leads to better woodturning experiences.

What are the best wood lathe live center models?

Many recommend options like the Jet 719180 and Grizzly G1090 for their strong performance and reliability. These models are favorites among both beginners and experts.

Conclusion

A wood lathe live center taper is essential for woodturning. It helps spin wood smoothly and safely. Understanding its function and size can improve your projects. Next, you can explore different taper sizes for your needs or watch videos to see them in action. Keep learning and practicing to become a confident woodworker!FAQs

Sure! Here Are Five Related Questions On The Topic Of Wood Lathe Live Center Taper:A wood lathe live center is a tool that helps hold your wood while you work on it. The taper is the shape at the end of the center that fits into the lathe. It usually comes in different sizes, like Morse taper 1, 2, or 3. You need the right taper size for your lathe to make sure everything fits snugly. This helps you create smooth and nice shapes in your wood projects!

Sure! Please provide the question you’d like me to answer.

What Is The Purpose Of A Live Center In Woodturning, And How Does Its Taper Design Affect Performance?A live center helps hold the wood while you turn it on the lathe. It spins with the wood, making it smoother and easier to shape. The tapered design makes it fit snugly, so it stays in place better. This helps you create better pieces without them wobbling or coming loose.

What Are The Common Taper Sizes Used For Live Centers In Wood Lathes, And How Do You Determine Which One To Use For Your Specific Lathe?Live centers in wood lathes commonly use Morse Tapers. The most common sizes are Morse Taper #1, #2, and #3. To find out which size to use, check your lathe’s manual. You can also look for markings on the tailstock, where the live center goes. This will tell you the right size for your lathe.

How Can You Properly Maintain And Care For A Live Center To Ensure Optimal Performance And Longevity In Wood Lathe Projects?To keep your live center working well, you should clean it regularly. Use a soft cloth to wipe off any wood dust and dirt. Oil the moving parts sometimes to keep them smooth. Always check for damage before you use it, and store it safely when you’re done. Taking care of it helps it last longer!

What Are The Differences Between A Live Center And A Dead Center In Lathe Operations, And When Would You Choose One Over The Other?A live center spins with the workpiece while a dead center does not move. You can use a live center for fast jobs. It helps reduce friction and can turn quickly. A dead center is good for heavy loads but can make things slow. We choose a live center when speed matters, and a dead center for strong support.

How Do You Accurately Measure And Check The Taper Of A Live Center To Ensure A Proper Fit With The Tailstock Of Your Wood Lathe?To check the taper of your live center, you can use a special tool called a caliper. First, measure the small end of the taper and then the larger end. The sizes should fit perfectly into your lathe’s tailstock. If they don’t, your center won’t work well. Always make sure to check these sizes before you start working.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Wood Lathe Live Center Taper:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A wood lathe live center is a tool that helps hold your wood while you work on it. The taper is the shape at the end of the center that fits into the lathe. It usually comes in different sizes, like Morse taper 1, 2, or 3. You need the right taper size for your lathe to make sure everything fits snugly. This helps you create smooth and nice shapes in your wood projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of A Live Center In Woodturning, And How Does Its Taper Design Affect Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A live center helps hold the wood while you turn it on the lathe. It spins with the wood, making it smoother and easier to shape. The tapered design makes it fit snugly, so it stays in place better. This helps you create better pieces without them wobbling or coming loose.”}},{“@type”: “Question”,”name”: “What Are The Common Taper Sizes Used For Live Centers In Wood Lathes, And How Do You Determine Which One To Use For Your Specific Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Live centers in wood lathes commonly use Morse Tapers. The most common sizes are Morse Taper #1, #2, and #3. To find out which size to use, check your lathe’s manual. You can also look for markings on the tailstock, where the live center goes. This will tell you the right size for your lathe.”}},{“@type”: “Question”,”name”: “How Can You Properly Maintain And Care For A Live Center To Ensure Optimal Performance And Longevity In Wood Lathe Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your live center working well, you should clean it regularly. Use a soft cloth to wipe off any wood dust and dirt. Oil the moving parts sometimes to keep them smooth. Always check for damage before you use it, and store it safely when you’re done. Taking care of it helps it last longer!”}},{“@type”: “Question”,”name”: “What Are The Differences Between A Live Center And A Dead Center In Lathe Operations, And When Would You Choose One Over The Other?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A live center spins with the workpiece while a dead center does not move. You can use a live center for fast jobs. It helps reduce friction and can turn quickly. A dead center is good for heavy loads but can make things slow. We choose a live center when speed matters, and a dead center for strong support.”}},{“@type”: “Question”,”name”: “How Do You Accurately Measure And Check The Taper Of A Live Center To Ensure A Proper Fit With The Tailstock Of Your Wood Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check the taper of your live center, you can use a special tool called a caliper. First, measure the small end of the taper and then the larger end. The sizes should fit perfectly into your lathe’s tailstock. If they don’t, your center won’t work well. Always make sure to check these sizes before you start working.”}}]}