Have you ever thought about how your wood lathe works? This tool is essential for shaping wood into beautiful pieces. But what happens when the motor stops working? It can be a real headache for any woodworker. Understanding wood lathe motor replacement tips can save you time and money.

Imagine your project is nearly finished, and suddenly your lathe’s motor fails. Frustrating, right? You’re not alone. Many woodworkers face this challenge. They often wonder if they can fix it themselves or need to call for help. With the right tips, you can tackle this issue easily!

Did you know that proper care can extend your wood lathe motor’s life? Small changes can make a big difference. In this article, we will show you practical steps for replacing your wood lathe motor. Get ready to dive into a world of tools and techniques that will keep your projects on track!

Wood Lathe Motor Replacement Tips: Essential Guidance For Success

Wood Lathe Motor Replacement Tips

Replacing a wood lathe motor can seem tricky. Start by knowing the motor’s specifications. Take note of the horsepower and RPM needed for your lathe. Always disconnect power before beginning! A handy tip is to keep all screws and parts organized. Understand the wiring basics to avoid any mishaps. Did you know that a motor’s efficiency can enhance your projects? With these tips, you can enjoy smooth turning and better results in your woodworking!Understanding Your Wood Lathe Motor

Types of wood lathe motors and their functions. Importance of motor specifications for performance.Wood lathe motors come in different types. Each type has a special job. Some motors are AC motors that run on alternating current. Others are DC motors that run on direct current. Choosing the right motor matters. It affects how fast and smooth your lathe will work. Check the motor’s power and speed. These details help you pick the best one for your projects.

What are important motor specifications?

Look at these key specifications:

- Horsepower: More power means better performance.

- RPM: This shows how fast the lathe spins.

- Voltage: Make sure it matches your power supply.

Signs Your Wood Lathe Motor Needs Replacement

Common symptoms indicating motor failure. How to diagnose motor issues effectively.Several signs can show that your wood lathe motor may be failing. Listen for unusual noises like grinding or squeaking. If the motor struggles to start or stops unexpectedly, that’s a warning sign. You might also notice smoke or a burning smell. Observing these signs can help catch problems early and save your tools. Regular checks can spot issues before they worsen.

How can I diagnose motor issues?

To diagnose motor problems, follow these steps:

- Check for loose connections.

- Test the power supply.

- Listen for strange sounds.

- Inspect for visible damage.

- Look for overheating.

These simple checks help you find the root cause quickly.

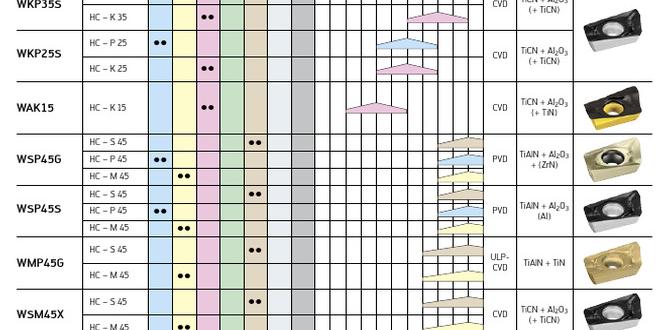

Choosing the Right Replacement Motor

Key factors to consider when selecting a new motor. Comparing different brands and models.Finding the perfect replacement motor can feel like searching for a needle in a haystack. First, power matters! Check how many watts you need. Next, think about speed. You want a motor that spins just right for your projects. Brands can be like ice cream flavors—so many to choose from! Take a look at group reviews and see if people give a thumbs-up. Some popular options are shown in the table below:

| Brand | Power (Watts) | Speed (RPM) |

|---|---|---|

| CoolWood | 1,200 | 1,800 |

| CraftyLathe | 1,500 | 2,000 |

| ProTurn | 1,000 | 1,600 |

Always pick a motor that suits your lathe. It’s like finding the right pair of shoes—too small and you’ll be uncomfortable! Happy turning!

Preparation for Motor Replacement

Essential tools and materials needed. Safety precautions to take before starting the replacement.Before changing the motor on your wood lathe, gather essential tools. You will need a wrench, screwdriver, and pliers. Also, have a clean cloth and safety glasses handy. Safety first! Always unplug the lathe before starting work. Wear gloves to protect your hands from sharp edges. Make sure your workspace is clean and well-lit to avoid accidents. Staying safe helps you focus on the task!

What safety precautions should I take?

Unplugging the machine, wearing gloves, and ensuring a clear workspace are key safety tips to follow.Essential tools to gather:

- Wrench

- Screwdriver

- Pliers

- Clean cloth

- Safety glasses

Step-by-Step Guide to Replacing Your Wood Lathe Motor

Detailed instructions for removing the old motor. Installation process for the new motor.Replacing your wood lathe motor can be simple. First, disconnect the power. Then, remove the old motor. Check the screws and nuts and unfasten them. Carefully take off the motor from its mount. Next, install the new motor. Align it in place and secure it with screws. Reconnect the wires and ensure they are tight. Finally, test the motor. Make sure everything is working correctly. This can bring new life to your wood lathe!

How do I disconnect my wood lathe motor safely?

Always unplug the motor first. This keeps you safe from electric shocks. Check that the machine is turned off before starting any work.

Troubleshooting Common Problems After Replacement

Issues you may encounter postinstallation. Solutions to fix common motor problems.After replacing the wood lathe motor, you might face some common problems. These can include strange noises or the motor not turning on. It’s important to check a few things first. Make sure all wires are secure and connected. If it vibrates too much, check if it’s balanced. Here are some tips to help:

- Check for loose connections.

- Look for obstructions near the motor.

- Ensure the motor is mounted correctly.

- Inspect the belts for wear.

Maintaining Your Wood Lathe Motor for Longevity

Best practices for regular maintenance. Tips to enhance motor efficiency and lifespan.Regular check-ups can make your wood lathe motor as happy as a clam! Start with a quick cleaning to stop dust from throwing a party in your motor. Change the oil as needed—think of it as giving your lathe a refreshing smoothie. Also, make sure the wiring is snug, like a warm hug. For peak performance, keep it cool and avoid overloads. Remember, a happy motor means smooth turning! Check out this handy table for quick tips:

| Maintenance Task | Frequency | Tip |

|---|---|---|

| Clean Dust | Weekly | Use a soft cloth! |

| Oil Change | Monthly | Think of it as a spa day! |

| Check Wiring | Every 3 Months | Keep it snug! |

| Temperature Check | Regularly | Keep it cool! |

Resources for Further Learning

Recommended books and online courses on wood lathe maintenance. Useful forums and communities for wood lathe enthusiasts.Want to dive deeper into wood lathe maintenance? Grab a few good books! Titles like “The Woodturner’s Bible” offer handy tips and tricks. Also, online courses, such as those on platforms like Udemy, can be game-changers. Don’t forget to explore forums like Woodturning Online. They’re full of friendly experts ready to answer your questions. Chatting there might save you from turning into a wood pile!

| Resource Type | Recommended Names |

|---|---|

| Books | “The Woodturner’s Bible”, “Woodturning for Beginners” |

| Online Courses | Udemy, Skillshare |

| Forums | Woodturning Online, Reddit Woodturning |

Conclusion

In summary, replacing a wood lathe motor can be straightforward. First, choose the right motor size for your lathe. Then, follow the manufacturer’s instructions carefully. Remember to check all connections before testing. You can find helpful videos online for extra guidance. For hands-on help, consider asking a local expert. Enjoy your woodworking journey!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Wood Lathe Motor Replacement Tips:Sure! When replacing your wood lathe motor, first turn off the power. You should disconnect the old motor carefully. Then, check the new motor to see if it fits well. Attach it securely, and connect the wires. Finally, test it out to make sure it works!

Sure! Please ask your question, and I will be happy to help you with the answer.

What Are The Key Factors To Consider When Selecting A Replacement Motor For A Wood Lathe?When we choose a new motor for a wood lathe, we need to think about a few things. First, check the motor’s power. It should match or be better than the old one. Next, look at the size. The new motor must fit where the old motor was. Finally, make sure the type of motor can work well with the wood lathe. These steps will help you pick the right motor!

How Can I Determine The Correct Horsepower Rating Needed For My Wood Lathe Motor?To find the right horsepower for your wood lathe motor, look at the size of the wood you will work with. For small projects, a motor with ½ to 1 horsepower is usually enough. For bigger projects, you might need 1 to 2 horsepower. Check your lathe’s manual; it often says what motor power is best for it.

What Tools And Safety Equipment Should I Have On Hand When Replacing A Wood Lathe Motor?When you replace a wood lathe motor, you need some tools and safety gear. First, have a screwdriver set to take off parts. You’ll also need a wrench to tighten bolts. Safety glasses protect your eyes, and gloves keep your hands safe. A mask can help if there’s dust.

Are There Specific Mounting Or Alignment Tips To Ensure The New Motor Functions Effectively With My Existing Wood Lathe?Yes, there are tips to help your new motor work well with your wood lathe. First, make sure the motor is level and secure when you mount it. Use a level tool to check it. Next, align the motor with the lathe’s drive shaft. This helps everything spin together smoothly. Finally, double-check all the screws and bolts to make sure they are tight.

How Do I Properly Wire A New Motor To My Wood Lathe’S Electrical System?First, make sure to turn off the power to your wood lathe. Next, you need to connect the wires from the new motor to the electrical system. Usually, there are three wires: one for power, one for neutral, and one for ground. You can match the colors of the wires. After connecting them, double-check everything before turning the power back on. Finally, test your lathe to make sure it works safely.